engine coolant Hyundai Matrix 2004 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2004, Model line: Matrix, Model: Hyundai Matrix 2004Pages: 317, PDF Size: 5.12 MB

Page 158 of 317

DO-IT-YOURSELF MAINTENANCE

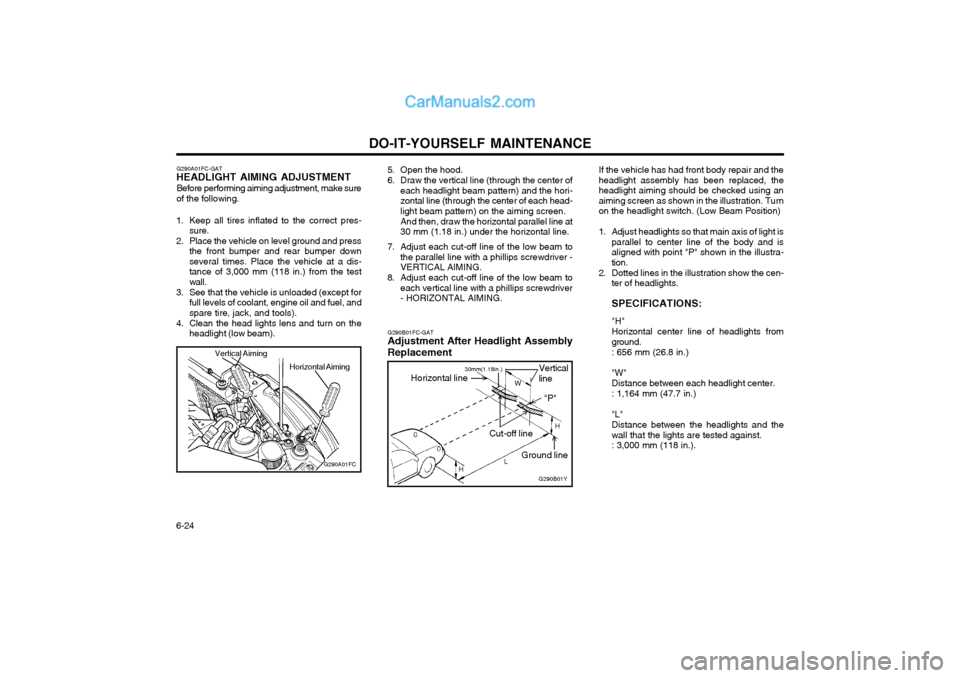

6-24 If the vehicle has had front body repair and the headlight assembly has been replaced, theheadlight aiming should be checked using anaiming screen as shown in the illustration. Turnon the headlight switch. (Low Beam Position)

1. Adjust headlights so that main axis of light is

parallel to center line of the body and is aligned with point "P" shown in the illustra-tion.

2. Dotted lines in the illustration show the cen- ter of headlights. SPECIFICATIONS: "H" Horizontal center line of headlights from ground. : 656 mm (26.8 in.) "W" Distance between each headlight center.: 1,164 mm (47.7 in.) "L" Distance between the headlights and the wall that the lights are tested against.: 3,000 mm (118 in.).

5. Open the hood.

6. Draw the vertical line (through the center of

each headlight beam pattern) and the hori- zontal line (through the center of each head-light beam pattern) on the aiming screen. And then, draw the horizontal parallel line at 30 mm (1.18 in.) under the horizontal line.

7. Adjust each cut-off line of the low beam to the parallel line with a phillips screwdriver -VERTICAL AIMING.

8. Adjust each cut-off line of the low beam to each vertical line with a phillips screwdriver- HORIZONTAL AIMING.

G290B01FC-GAT

Adjustment After Headlight Assembly Replacement

G290B01Y

Vertical line

Cut-off line Ground line

Horizontal line

LW

H

H "P"30mm(1.18in.)

G290A01FC-GAT

HEADLIGHT AIMING ADJUSTMENT

Before performing aiming adjustment, make sure of the following.

1. Keep all tires inflated to the correct pres- sure.

2. Place the vehicle on level ground and press the front bumper and rear bumper downseveral times. Place the vehicle at a dis-tance of 3,000 mm (118 in.) from the testwall.

3. See that the vehicle is unloaded (except for full levels of coolant, engine oil and fuel, andspare tire, jack, and tools).

4. Clean the head lights lens and turn on the headlight (low beam).

G290A01FC

Horizontal Aiming

Vertical Aiming

Page 163 of 317

EMISSION CONTROL SYSTEMS 7-1

7. EMISSION CON-TROL SYSTEMS

H010A01A-GAT

EMISSION CONTROL SYSTEMS (If Installed)

Your Hyundai is equipped with an emission

control system to meet all requirements of the Emission prohibition rules of your province. There are three emission control systems which

are as follows.

(1) Crankcase emission control system (2) Evaporative emission control system(3) Exhaust emission control system In order to assure the proper function of the

emission control systems, it is recommended that you have your car inspected and main-tained by an authorized Hyundai dealer in ac-cordance with the maintenance schedule in thismanual. H010D01A-AAT

3. Exhaust Emission Control System

The Exhaust Emission Control System is a

highly effective system which controls exhaustemissions while maintaining good vehicle per-formance.

H010C01E-GAT

2. Evaporative Emission Control

System

The Evaporative Emission Control System is

designed to prevent fuel vapors from escapinginto the atmosphere. Canister

While the engine is inoperative, fuel vapors

generated inside the fuel tank are absorbed and stored in the canister. When the engine isrunning, the fuel vapors absorbed in the canis-ter are drawn into the induction system through

the purge control solenoid valve.

Purge Control Solenoid Valve (PCSV) The purge control solenoid valve is controlled

by the Engine Control Module (ECM); when theengine coolant temperature is low during idling,the PCSV closes so that evaporated fuel is nottaken into the engine. After the engine warms-up during ordinary driving, the PCSV opens soas to introduce evaporated fuel to the engine. H010B01A-AAT

1. Crankcase Emission Control

System

The Positive Crankcase Ventilation System is

employed to prevent air pollution caused byblow-by gases being emitted from the crank-case. This system supplies fresh filtered air tothe crankcase through the air intake hose.Inside the crankcase, the fresh air mixes withblow-by gases, then passes through the PCVvalve into the induction system.

The catalytic converter is part of the exhaust

emission control system. Its purpose is to re-move certain engine emission products fromthe engine's exhaust. It looks something like amuffler and is located underneath the car in the

exhaust system.

H020A01A-GAT

CATALYTIC CONVERTER (If Installed); For a gasoline engine

Catalytic Converter HFC5013

7

Page 170 of 317

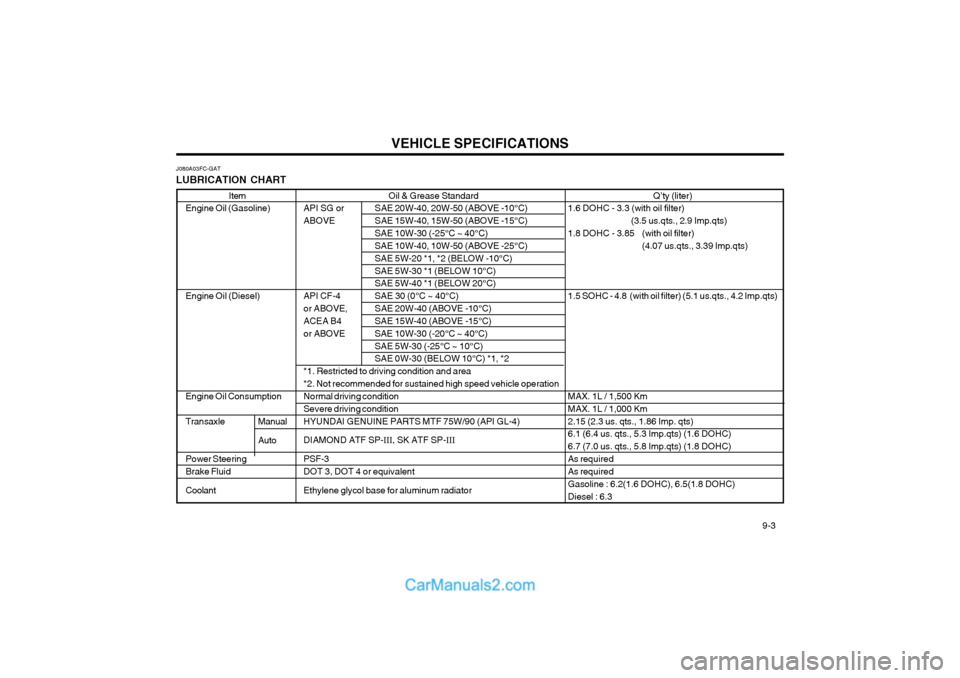

VEHICLE SPECIFICATIONS 9-3

Oil & Grease Standard

API SG or SAE 20W-40, 20W-50 (ABOVE -10°C)

ABOVE SAE 15W-40, 15W-50 (ABOVE -15°C)

SAE 10W-30 (-25°C ~ 40°C) SAE 10W-40, 10W-50 (ABOVE -25°C) SAE 5W-20 *1, *2 (BELOW -10°C)SAE 5W-30 *1 (BELOW 10°C) SAE 5W-40 *1 (BELOW 20°C)

API CF-4 SAE 30 (0°C ~ 40°C)

or ABOVE, SAE 20W-40 (ABOVE -10°C)

ACEA B4 SAE 15W-40 (ABOVE -15°C)

or ABOVE SAE 10W-30 (-20°C ~ 40°C) SAE 5W-30 (-25°C ~ 10°C) SAE 0W-30 (BELOW 10°C) *1, *2

*1. Restricted to driving condition and area *2. Not recommended for sustained high speed vehicle operation Normal driving condition Severe driving conditionHYUNDAI GENUINE PARTS MTF 75W/90 (API GL-4) DIAMOND ATF SP- III, SK ATF SP- III

PSF-3 DOT 3, DOT 4 or equivalent Ethylene glycol base for aluminum radiator

Item

Engine Oil (Gasoline) Engine Oil (Diesel)

Engine Oil Consumption Transaxle

Power Steering Brake Fluid Coolant

J080A03FC-GAT

LUBRICATION CHART

Q’ty (liter)

1.6 DOHC - 3.3 (with oil filter)

(3.5 us.qts., 2.9 Imp.qts)

1.8 DOHC - 3.85 (with oil filter) (4.07 us.qts., 3.39 Imp.qts)

1.5 SOHC - 4.8 (with oil filter) (5.1 us.qts., 4.2 Imp.qts) MAX. 1L / 1,500 Km MAX. 1L / 1,000 Km2.15 (2.3 us. qts., 1.86 Imp. qts) 6.1 (6.4 us. qts., 5.3 Imp.qts) (1.6 DOHC) 6.7 (7.0 us. qts., 5.8 Imp.qts) (1.8 DOHC)As required As required Gasoline : 6.2(1.6 DOHC), 6.5(1.8 DOHC)Diesel : 6.3

Manual Auto

Page 172 of 317

INDEX

10-2 Driving

Economical dr iving ........................................................................ 2-10

Smooth cornering .......................................................................... 2-10

Winter driving ................................................................................ 2-10

E Emissions Control Systems ................................................................ 7-1

Engine Before starting the engine ............................................................... 2-2Compartment .......................................................................... 6-1 ~ 6-3

Coolant ................................................................................. 6-8 ~ 6-10

Coolant temperature gauge ........................................................... 1-36

If the engine overheats ................................................................... 3-2

Number ............................................................................................ 8-1

Oil ........................................................................................... 6-4 ~ 6-5Starting ............................................................................................ 2-3

Engine Exhaust Can Be Dangerous ................................................... 2-1

FFold-up Tray ...................................................................................... 1-50

Front Fog Light Sw itch ...................................................................... 1-42

Front Seats Adjustable front seats ..................................................................... 1-9

Lumbar support control ................................................................. 1-10

Seat cushion height adjustment .................................................... 1-10

Fuel Capacity .......................................................................................... 9-1

Gauge ............................................................................................ 1-36

Recommendations ........................................................................... 1-1

Fuel Filler Lid

Remote release ............................................................................. 1-52

Fuse Panel Description .......................................................... 6-26 ~ 6-28

Fuses ...................................................................................... 6-19 ~6-20 GGeneral Checks

.................................................................................. 6-4

Glove box .......................................................................................... 1-47

H Hazard Warning System ................................................................... 1-41

Headlight Aiming Adjustment ........................................................... 6-24

Headlight Bulb ................................................................................... 6-23

Headlight Leveling Device System ........................................ 1-44 ~ 1-45

Heating and Ventilation

Air flow control .............................................................................. 1-58

Air intake control ........................................................................... 1-57

Bi-level heating .............................................................................. 1-59

Fan speed control ......................................................................... 1-57

Heating controls ............................................................................ 1-59

Temperature control ...................................................................... 1-59

High-mounted Rear Stoplight ............................................................ 1-50

Hood Release ................................................................................... 1-51

Horn .................................................................................................. 1-55

IIgnition Switch ..................................................................................... 2-2

Immobilizer System ............................................................................. 1-3

Instrument Cluster and Indicator ............................................ 1-31 ~ 1-35

Instruments and Controls .................................................................. 1-30

Interior Light Interior light ................................................................................... 1-47

Map light ........................................................................................ 1-46

Intermittent Wiper .............................................................................. 1-41

JJump Starting ...................................................................................... 3-1

Page 215 of 317

1- 33

CONTROLS AND EQUIPMENT

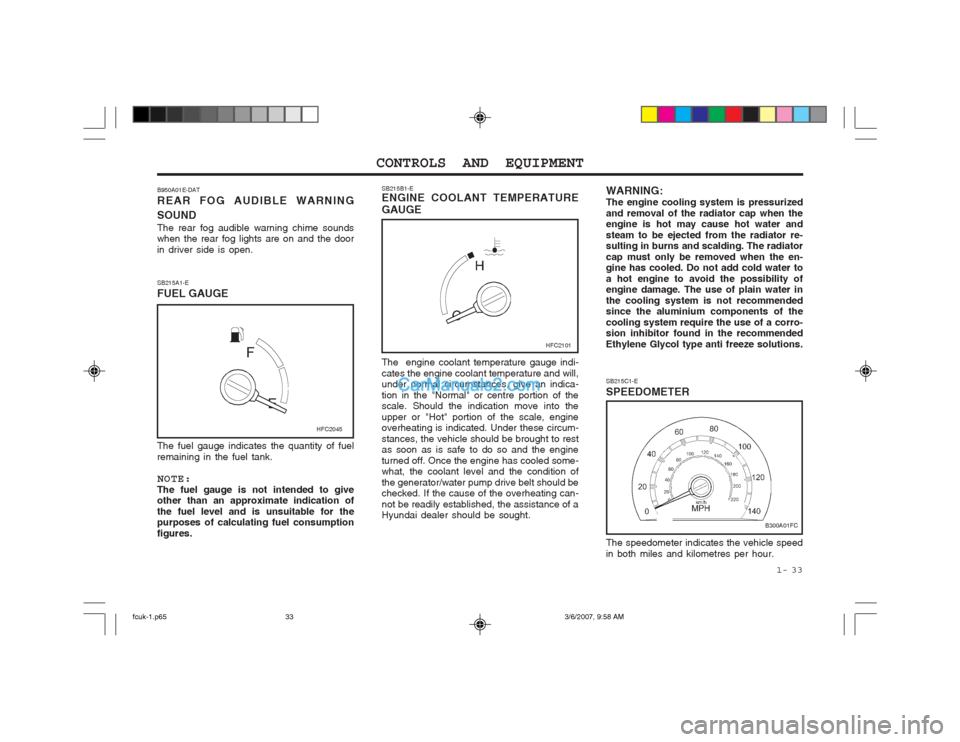

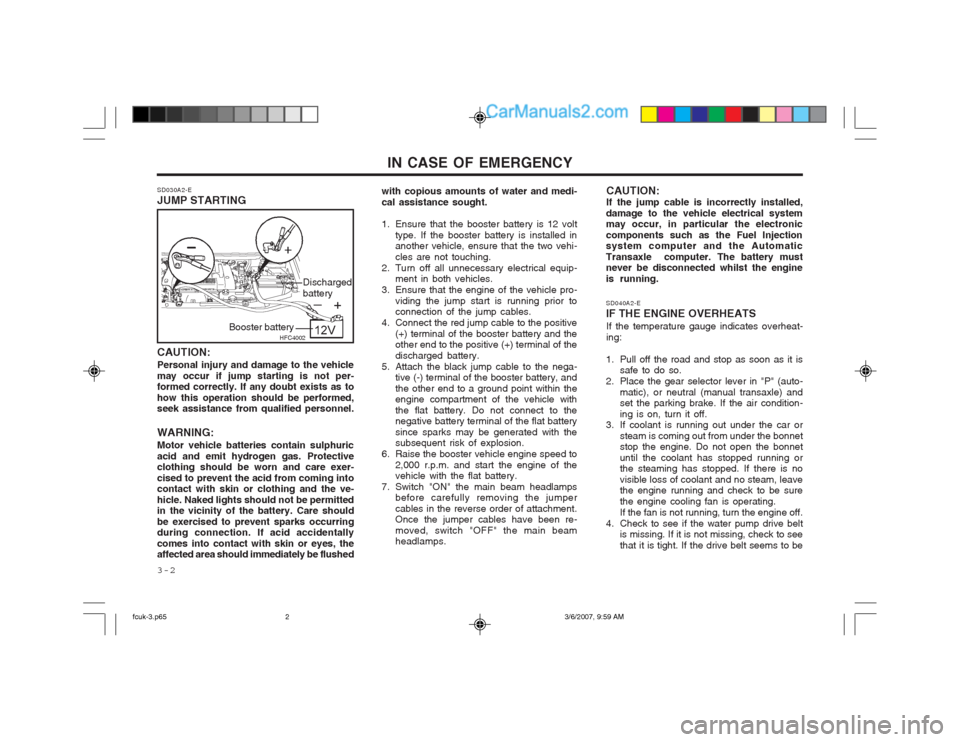

The fuel gauge indicates the quantity of fuel remaining in the fuel tank. NOTE: The fuel gauge is not intended to give other than an approximate indication of the fuel level and is unsuitable for the purposes of calculating fuel consumption figures. SB215B1-E ENGINE COOLANT TEMPERATURE GAUGE The engine coolant temperature gauge indi- cates the engine coolant temperature and will, under normal circumstances, give an indica- tion in the "Normal" or centre portion of the scale. Should the indication move into the upper or "Hot" portion of the scale, engine overheating is indicated. Under these circum- stances, the vehicle should be brought to rest as soon as is safe to do so and the engine turned off. Once the engine has cooled some- what, the coolant level and the condition of the generator/water pump drive belt should be checked. If the cause of the overheating can- not be readily established, the assistance of a Hyundai dealer should be sought.

SB215A1-E FUEL GAUGE

B950A01E-DATREAR FOG AUDIBLE WARNING SOUND The rear fog audible warning chime sounds when the rear fog lights are on and the door in driver side is open.

HFC2101

HFC2045

WARNING: The engine cooling system is pressurizedand removal of the radiator cap when the engine is hot may cause hot water and steam to be ejected from the radiator re- sulting in burns and scalding. The radiator cap must only be removed when the en- gine has cooled. Do not add cold water to a hot engine to avoid the possibility of engine damage. The use of plain water in the cooling system is not recommended since the aluminium components of the cooling system require the use of a corro- sion inhibitor found in the recommended Ethylene Glycol type anti freeze solutions.

B300A01FC

SB215C1-E SPEEDOMETER The speedometer indicates the vehicle speed in both miles and kilometres per hour.

fcuk-1.p65

3/6/2007, 9:58 AM

33

Page 256 of 317

DRIVING YOUR HYUNDAI

2- 12 NOTE: Never allow undiluted screen washer fluidadditive to spill upon the paintwork or use engine coolant anti-freeze since damage to the paintwork may result.

o When driving in extreme conditions, the

windscreen wiper blades may fail to clear the screen properly due to the formation of ice upon the blade edge. It will therefore be necessary to periodically remove such ice to restore their efficiency.

o If the power operated door mirrors become frozen, attempts to adjust these may dam-age the mechanism.

o The formation of snow or ice built up inside the wheel arches may interfere with theroad wheels or steering mechanism. In such instances, unusual noises or an in- crease in steering effort may result. There- fore, ensure that the wheel arches are checked periodically and any accumulated snow or ice removed.

o It is advisable to carry emergency equip- ment including, torch, shovel, tow rope,blankets etc., if a journey is to be under- taken into areas of severe road conditions.

ZC170D1-E Door LocksShould the door lock mechanism become frozen, a proprietary lock de-icer should be used. Alternatively, warming the door key may thaw the door lock. However, the key should be handled carefully to avoid burning the fingers. Never attempt to thaw a frozen door lock using hot water, since the water will eventu- ally freeze and compound the problem. NOTE: The proper temperature for using the immobiliser key is from -40°F to 176°F (- 40°C to 80°C). If you heat the immobiliser key over 176°F (80°C) to open the frozen lock, it may cause damage to the tran- sponder in its head.

SC170E1-E Windscreen Washers and Wipers The windscreen washer bottle should be filled with a solution of water and a proprietary winter screen wash additive. The windscreen wipers should not be used if the blades are frozen to the windscreen or if they are cov- ered with snow, before this is removed.

ZC170B1-E Electrical SystemWinter conditions impose severe demands upon vehicle electrical systems, particularly the charging circuit. The battery condition and performance along with the alternator perfor- mance and drive belt condition should be checked prior to the onset of winter. ZC170C1-E Anti-freeze/Corrosion inhibitorThe cooling system must always contain an Ethylene-Glycol based anti-freeze solution. The system is filled during manufacture with solution of the correct strength which should be checked before the onset of winter and adjusted or changed as required. NOTE: The anti-freeze solution contains a corro- sion inhibitor to prevent degradation of the aluminum castings contained within the engine. Therefore, never, drain the system and refill with water only. In addition, anti-freeze solution must ALWAYS be used in vehicles fitted with air conditioning, to prevent the heater matrix from freezing and subsequently bursting with the refrigeration system in use.

fcuk-2.p65

3/6/2007, 9:59 AM

12

Page 261 of 317

IN CASE OF EMERGENCY

3-2

CAUTION: Personal injury and damage to the vehicle may occur if jump starting is not per- formed correctly. If any doubt exists as to how this operation should be performed, seek assistance from qualified personnel. WARNING: Motor vehicle batteries contain sulphuric acid and emit hydrogen gas. Protective clothing should be worn and care exer- cised to prevent the acid from coming into contact with skin or clothing and the ve- hicle. Naked lights should not be permitted in the vicinity of the battery. Care should be exercised to prevent sparks occurring during connection. If acid accidentally comes into contact with skin or eyes, the affected area should immediately be flushed CAUTION: If the jump cable is incorrectly installed,

damage to the vehicle electrical system may occur, in particular the electronic components such as the Fuel Injection system computer and the Automatic

Transaxle computer. The battery must never be disconnected whilst the engine is running. SD040A2-E IF THE ENGINE OVERHEATS

If the temperature gauge indicates overheat- ing:

1. Pull off the road and stop as soon as it is safe to do so.

2. Place the gear selector lever in "P" (auto- matic), or neutral (manual transaxle) and set the parking brake. If the air condition- ing is on, turn it off.

3. If coolant is running out under the car or

steam is coming out from under the bonnet stop the engine. Do not open the bonnet until the coolant has stopped running or the steaming has stopped. If there is no visible loss of coolant and no steam, leave the engine running and check to be sure the engine cooling fan is operating.If the fan is not running, turn the engine off.

4. Check to see if the water pump drive belt is missing. If it is not missing, check to seethat it is tight. If the drive belt seems to be

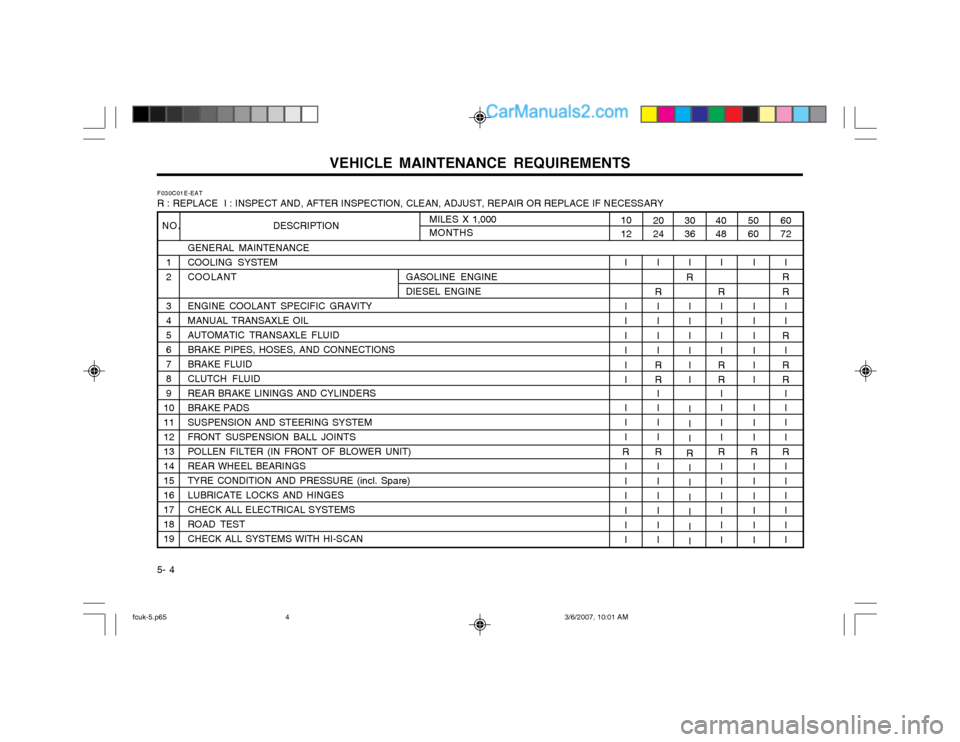

SD030A2-E JUMP STARTING

with copious amounts of water and medi- cal assistance sought.

1. Ensure that the booster battery is 12 volt

type. If the booster battery is installed in another vehicle, ensure that the two vehi- cles are not touching.

2. Turn off all unnecessary electrical equip- ment in both vehicles.

3. Ensure that the engine of the vehicle pro- viding the jump start is running prior to connection of the jump cables.

4. Connect the red jump cable to the positive (+) terminal of the booster battery and theother end to the positive (+) terminal of the discharged battery.

5. Attach the black jump cable to the nega- tive (-) terminal of the booster battery, andthe other end to a ground point within the engine compartment of the vehicle with the flat battery. Do not connect to the negative battery terminal of the flat battery since sparks may be generated with the subsequent risk of explosion.

6. Raise the booster vehicle engine speed to 2,000 r.p.m. and start the engine of thevehicle with the flat battery.

7. Switch "ON" the main beam headlamps before carefully removing the jumper cables in the reverse order of attachment. Once the jumper cables have been re- moved, switch "OFF" the main beam headlamps.

HFC4002

Booster battery Discharged battery

fcuk-3.p65

3/6/2007, 9:59 AM

2

Page 262 of 317

3-3

IN CASE OF EMERGENCY

satisfactory, check for coolant leaking from the radiator, hoses or under the car. (If the air conditioning had been in use, it is normal for cold water to be draining from it).

WARNING: While the engine is running, keep hands and clothing away from moving parts such as the fan and drive belts to prevent injury. WARNING (Diesel only): Never work on injection system with en-gine running or within 30 seconds after shutting off engine. High pressure pump, rail, injectors and high pressure pipes are subject to high pressure even after the engine stopped. The fuel jet produced by fuel leaks may cause serious injury, if it touch the body. People using pacemak- ers should not move than 30cm closer to the ECU or wiring harness within the engine room while engine is running, since the high currents in the Common Rail system produce considerable mag- netic fields.

5. If the water pump drive belt is broken or coolant is leaking out, stop the engine immediately and call the nearest Hyundai dealer for assistance. WARNING:Do not remove the radiator cap when theengine is hot since steam and boiling water may be ejected from the radiator resulting in burns or scalding.

6. If the cause of the overheating cannot be found, wait until the engine temperature has returned to normal. Then, if coolant has been lost, carefully remove the radia- tor cap and add water to bring the fluid level in the reservoir up to the base of the radiator fill opening. Fill the coolant expan- sion tank to the halfway mark.

7. Proceed with caution until it is established that the engine is operating normally. If theengine overheats repeatedly, the advice of a Hyundai dealer should be sought.

CAUTION: Serious loss of coolant indicates there isa leak in the cooling system and this should be checked as soon as possible by a Hyundai dealer. D040A01FC-EAT

TEMPORARY SPARE TYRE The following instructions for the temporary

spare tyre should be observed:

1. Check inflation pressure as soon as pos-

sible after installing the spare tyre, and adjust to the specified pressure. The tyre pressure should be periodically checked and maintained at the specified pressure while the tyre is stored.

2. The spare tyre should only be used tem- porarily and should be returned to the luggage compartment as soon as the origi- nal tyre can be repaired or replaced.

3. Continuous use at speeds of over 80 km/h

(50 mph) is not recommended.

4. As the temporary spare tyre is specifically designed for your car, it should not beused on any other vehicle.

5. The temporary spare tyre should not be used on any other wheels, nor shouldstandard tyre, snow tyre, wheel covers or trim rings be used with the temporary spare wheel. If such use is attempted, damage to these items or other car com- ponents may occur.

6. The temporary spare tyre pressure should be checked once a month while the tyre isstored.

Spare Tyre Pressure

Type Size

Inflation Pressure T115/70R(D)15

420 kPa (60 psi)

fcuk-3.p65

3/6/2007, 9:59 AM

3

Page 274 of 317

VEHICLE MAINTENANCE REQUIREMENTS

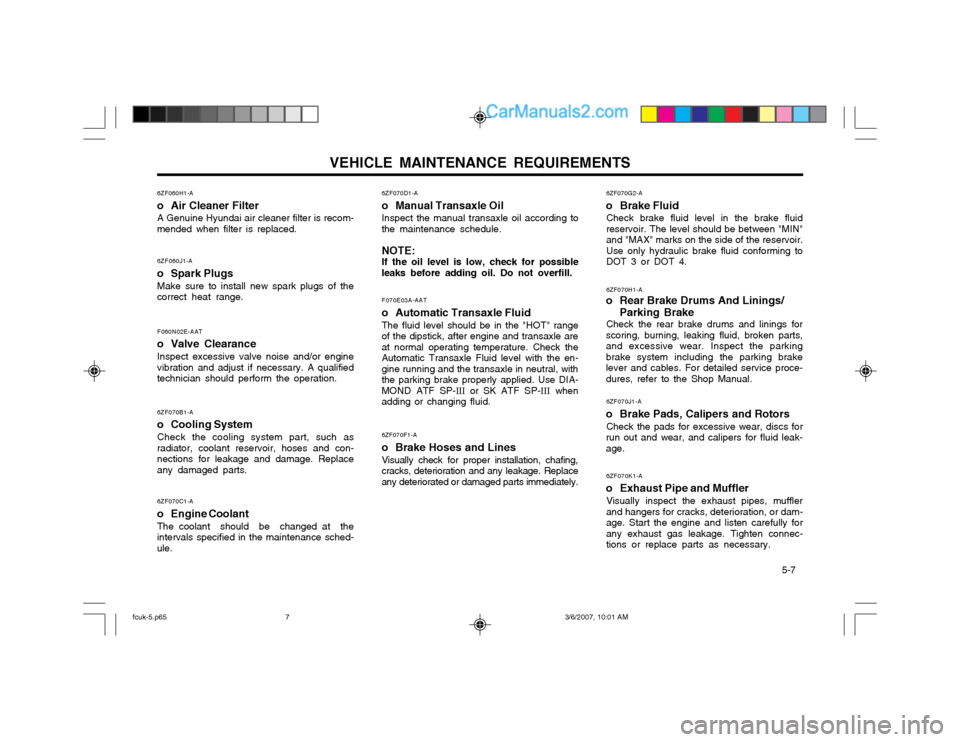

5- 4 F030C01E-EAT

R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

GENERAL MAINTENANCE COOLING SYSTEMCOOLANT GASOLINE ENGINEDIESEL ENGINE

ENGINE COOLANT SPECIFIC GRAVITYMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDBRAKE PIPES, HOSES, AND CONNECTIONSBRAKE FLUIDCLUTCH FLUIDREAR BRAKE LININGS AND CYLINDERSBRAKE PADSSUSPENSION AND STEERING SYSTEMFRONT SUSPENSION BALL JOINTSPOLLEN FILTER (IN FRONT OF BLOWER UNIT)REAR WHEEL BEARINGSTYRE CONDITION AND PRESSURE (incl. Spare)LUBRICATE LOCKS AND HINGESCHECK ALL ELECTRICAL SYSTEMSROAD TESTCHECK ALL SYSTEMS WITH HI-SCAN

60 72

50 60

4048

I

R R

I I

R I

R R I I II

R

IIIII I

I I IIII I I I I

R I III I I

I

R IIII

R R I I I I

R I III I I

30 36

2024

I

R

I IIII I I II

R IIIIII

I

R IIII

R R I I I I

R I III I I

10 12

I I IIII I I I I

R I III I I

MILES X 1,000 MONTHS

NO. DESCRIPTION

1 2 3 456789

10111213141516171819

fcuk-5.p65 3/6/2007, 10:01 AM

4

Page 277 of 317

VEHICLE MAINTENANCE REQUIREMENTS 5-7

6ZF070D1-A

o Manual Transaxle Oil Inspect the manual transaxle oil according to

the maintenance schedule. NOTE: If the oil level is low, check for possible

leaks before adding oil. Do not overfill.

6ZF070H1-A

o Rear Brake Drums And Linings/ Parking Brake

Check the rear brake drums and linings for

scoring, burning, leaking fluid, broken parts, and excessive wear. Inspect the parkingbrake system including the parking brakelever and cables. For detailed service proce-dures, refer to the Shop Manual.

6ZF070J1-A

o Brake Pads, Calipers and Rotors Check the pads for excessive wear, discs for

run out and wear, and calipers for fluid leak-age.

6ZF070K1-A

o Exhaust Pipe and Muffler Visually inspect the exhaust pipes, mufflerand hangers for cracks, deterioration, or dam-age. Start the engine and listen carefully forany exhaust gas leakage. Tighten connec-tions or replace parts as necessary.

F070E03A-AAT

o Automatic Transaxle Fluid The fluid level should be in the "HOT" range

of the dipstick, after engine and transaxle areat normal operating temperature. Check theAutomatic Transaxle Fluid level with the en-gine running and the transaxle in neutral, withthe parking brake properly applied. Use DIA-MOND ATF SP- III or SK ATF SP- III when

adding or changing fluid. 6ZF070F1-A

o Brake Hoses and Lines Visually check for proper installation, chafing, cracks, deterioration and any leakage. Replaceany deteriorated or damaged parts immediately.

6ZF060H1-A

o Air Cleaner Filter A Genuine Hyundai air cleaner filter is recom-

mended when filter is replaced.

6ZF060J1-A

o Spark Plugs Make sure to install new spark plugs of the

correct heat range.

6ZF070B1-A

o Cooling System Check the cooling system part, such asradiator, coolant reservoir, hoses and con-nections for leakage and damage. Replaceany damaged parts. 6ZF070G2-A

o Brake Fluid Check brake fluid level in the brake fluidreservoir. The level should be between "MIN"and "MAX" marks on the side of the reservoir.Use only hydraulic brake fluid conforming toDOT 3 or DOT 4.

6ZF070C1-A

o Engine Coolant The coolant should be changed at theintervals specified in the maintenance sched-ule.

F060N02E-AAT

o Valve Clearance Inspect excessive valve noise and/or enginevibration and adjust if necessary. A qualifiedtechnician should perform the operation.

fcuk-5.p65 3/6/2007, 10:01 AM

7