light Hyundai Matrix 2006 Owner's Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2006, Model line: Matrix, Model: Hyundai Matrix 2006Pages: 490, PDF Size: 11.58 MB

Page 434 of 490

6

OWNER MAINTENANCE

5DAILY OPERATING CHECKS

SG020B1-E The following items should be checked on a daily basis or whenever the ve- hicle is refuelled, whichever occurssooner.

o Engine oil level.

o Engine coolant level.

o Power steering fluid level.

o Brake fluid level.

o Windscreen washer fluid level.

o Battery condition.

o Tyre condition and pressures.

o Operation and cleanliness of all light- ing equipment.

o Windscreen wiper and washer op- eration.

o Horn operation.

o Warning light operation.

o Adjustment and cleanliness of mir- rors.

o Seat and seat belt adjustment and

operation.

o Fluid leakage.

The vehicle must not be driven if the daily operating checks indicate that any item of equipment related to thesafety or roadworthiness of the vehicle is not functioning correctly. G030A01FC-EAT The correct engine oil level is of para-

mount importance. An excessively high or low oil level may result inirreparable damage being sustained by the engine. The engine oil level must be checked on a daily basis, wheneverthe vehicle is refuelled or before start- ing a long trip, whichever occurs sooner.

In addition, it is imperative that only an

approved grade and specification of oilis used to avoid the possibility of serious engine damage and prematurewear. The use of "budget price" oil is a false economy that must be avoided if the maximum reliability and usefullife is to be obtained from the vehicle. G030B02O-EAT Recommended Oil Petrol engine

ENGINE OIL

The engine oil quality should meet the following classification. API SJ, SL or ABOVE ILSAC GF-3 or ABOVE The oil viscosity should be selected according to the operating environ- ment of the engine by means of thetable shown above. The engine oil recommendations are complete in themselves and the use of additives isneither required nor recommended. The use of engine oil additives may result in invalidation of the vehicle warranty.

G030B01JM

Page 444 of 490

6

OWNER MAINTENANCE

15

HGK256

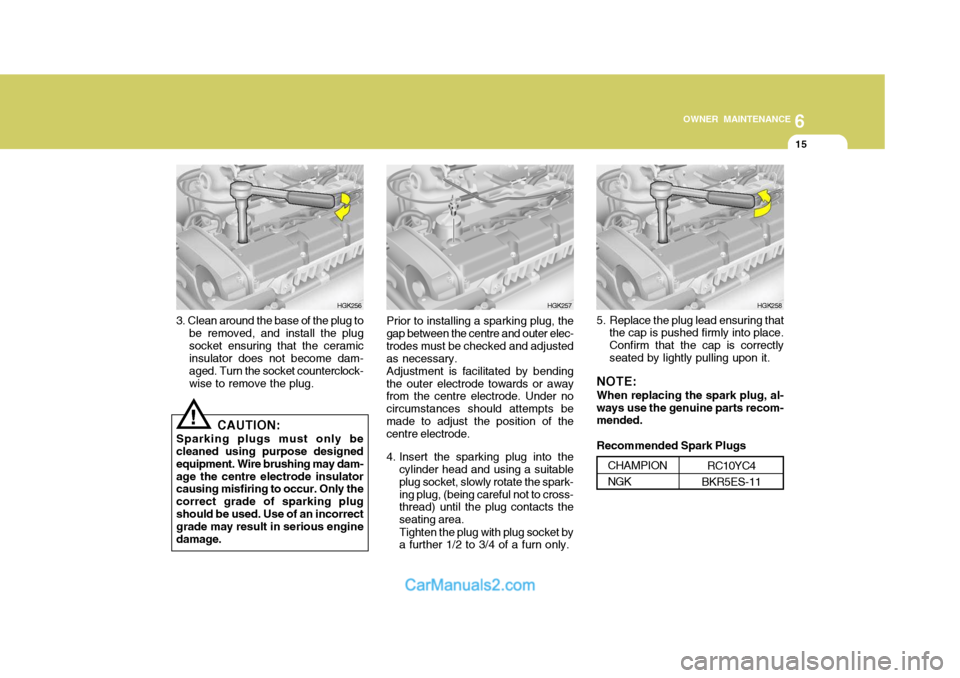

3. Clean around the base of the plug to be removed, and install the plug socket ensuring that the ceramic insulator does not become dam- aged. Turn the socket counterclock-wise to remove the plug.

CAUTION:

Sparking plugs must only be cleaned using purpose designed equipment. Wire brushing may dam-age the centre electrode insulator causing misfiring to occur. Only the correct grade of sparking plugshould be used. Use of an incorrect grade may result in serious engine damage.

! Prior to installing a sparking plug, the

gap between the centre and outer elec- trodes must be checked and adjustedas necessary.

Adjustment is facilitated by bending

the outer electrode towards or away from the centre electrode. Under no circumstances should attempts bemade to adjust the position of the centre electrode.

4. Insert the sparking plug into the cylinder head and using a suitable plug socket, slowly rotate the spark-ing plug, (being careful not to cross- thread) until the plug contacts the seating area. Tighten the plug with plug socket by a further 1/2 to 3/4 of a furn only.

HGK257

5. Replace the plug lead ensuring thatthe cap is pushed firmly into place. Confirm that the cap is correctlyseated by lightly pulling upon it.

NOTE: When replacing the spark plug, al- ways use the genuine parts recom- mended. Recommended Spark PlugsHGK258

CHAMPION NGK RC10YC4

BKR5ES-11

Page 446 of 490

6

OWNER MAINTENANCE

17

!

CAUTION:

o Do not operate the wipers on dry glass since rapid wear and dam- age to the windscreen glass mayresult.

o Keep the blade rubber out of con- tact with petroleum products suchas engine oil, petrol, etc.

G080B01HR-EAT

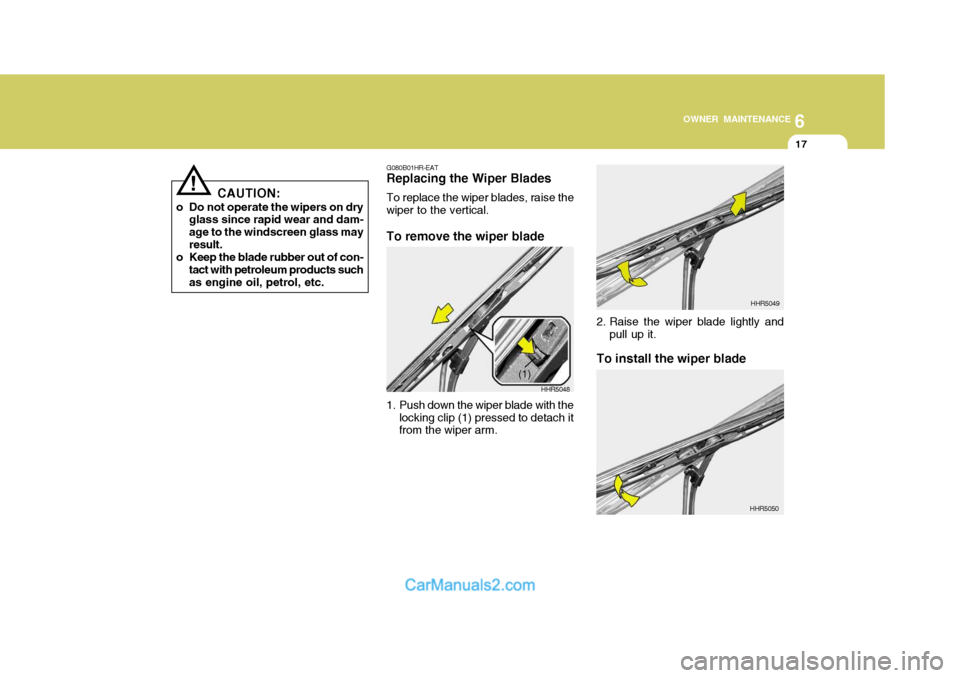

Replacing the Wiper Blades

To replace the wiper blades, raise the

wiper to the vertical. To remove the wiper blade

1. Push down the wiper blade with the locking clip (1) pressed to detach it from the wiper arm. HHR5048

(1)2. Raise the wiper blade lightly and

pull up it. HHR5049

HHR5050

To install the wiper blade

Page 452 of 490

6

OWNER MAINTENANCE

23

!

SG120D1-E

Brake Fluid Level

HFC5005

Petrol engine

G120D02FC

Diesel engine WARNING:

Brake fluid is hygroscopic and should never be stored in an un- sealed container. The presence ofwater in the braking system will cause vapour locks and increase the possibility of brake fade alongwith promoting corrosion within the braking system. The brake fluid must be changed at the specifiedtime or mileage interval to ensure continued safe operation of the sys- tem. Brake fluid will cause rapidand serious damage to paintwork. If accidental spillage occurs, the af- fected area must be rinsed withwater immediately. Do not allow brake fluid to come into contact with the eyes or to be ingested andensure that fluid is safely stored away form the reach of children.

The fluid level in the brake fluid reser-voir should be checked periodically. The level should be between the "MIN" and "MAX" marks on the side of thereservoir. If the level is at or below the "MIN" mark, fluid should be added having carefully cleaned the area sur-rounding the reservoir cap to ensure that dirt is not allowed to enter the system. It should be noted that thebrake fluid level will decrease slightly as the friction linings of the pads and shoes become worn and that this is anormal condition.

Page 458 of 490

6

OWNER MAINTENANCE

29

!

CHECKING AND REPLACING FUSES

SG200A1-E

Fusible Links

The fusible link prevents damage to the wiring harness in the event of anelectrical system malfunction. Failure of a fusiblelink is indicative of a seri- ous overload condition having occurredand therefore the electrical system should be checked by a Hyundai authorised repairer before a replace-ment link is fitted. G200B01E-EAT Individual Circuit Fuses The fuse box containing the individual circuit fuses will be found in the back- side of multi box located in the rightside of driver. The multi box is re- moved by pulling lightly and then re- leasing the lid. A fuse rating grid will befound on the reverse side of the cover. In the event of fuse failure, the fuse should be replaced with one of equiva-lent rating. A fuse removal tool is provided within the fuse box to facili- tate replacement.

WARNING:

Under no circumstances should a

fusible link be replaced with any-thing other than a new link of thesame rating. The use of higher rated links or other means of connecting the circuit will create a potential firehazard.

Good

Bad

G200A01FC

HFC4010

Page 460 of 490

6

OWNER MAINTENANCE

31

!!

SG220A1-E

o If battery electrolyte is spilled onto

skin or into eyes, the effected area must be flushed with copious amounts of water and medical as- sistance sought.

o If battery electrolyte is ingested, copious amounts of water or milkfollowed by an ant-acid (raw egg ormilk of magnesia) must be drunk. Vomiting should not be induced and medical assistance must be sought.

o Batteries must only be charged in

well ventilated areas from whichnaked lights or sources of sparks are excluded.

o Ensure that children, pets or other unauthorised persons are kept awayfrom batteries.

o Do not allow anything to bridge the positive (+) and negative (-) termi- nals of the battery.

o Never invert the battery.

The battery fitted during production isof the "Maintenance Free" type. ELECTRIC COOLING FANS

WARNING:

The cooling fan is controlled byengine coolant temperature and maysometimes operate even when the engine is not running. Use extreme caution when working near theblades of the cooling fan so that you are not injured by a rotating fan blade. As the engine coolant tem-perature decreases, the fan will au- tomatically shut off. This is a nor- mal condition. The engine cooling fan should operate before the temperature gauge reaches the upper portion of the scale and thecondenser fan should operate when- ever the air conditioning is in use.

WARNING:

The cooling fan is controlled by

engine coolant temperature and may sometimes operate even when theengine is not running. Do not touch the radiator fan until it is completely stopped.

As the coolant temperature de-

creases the fan will automaticallyshut off. This is a normal condition.

Page 463 of 490

6 OWNER MAINTENANCE

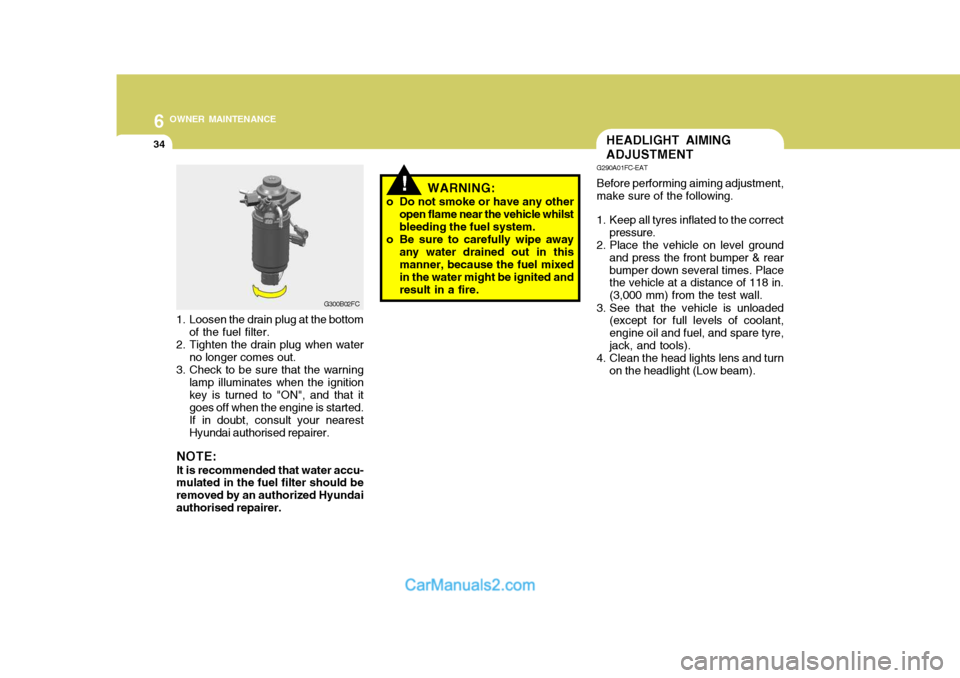

34HEADLIGHT AIMING ADJUSTMENT

G290A01FC-EAT Before performing aiming adjustment, make sure of the following.

1. Keep all tyres inflated to the correct pressure.

2. Place the vehicle on level ground and press the front bumper & rear bumper down several times. Place the vehicle at a distance of 118 in. (3,000 mm) from the test wall.

3. See that the vehicle is unloaded (except for full levels of coolant,engine oil and fuel, and spare tyre,jack, and tools).

4. Clean the head lights lens and turn on the headlight (Low beam).

!WARNING:

o Do not smoke or have any other open flame near the vehicle whilst bleeding the fuel system.

o Be sure to carefully wipe away any water drained out in thismanner, because the fuel mixed in the water might be ignited and result in a fire.

1. Loosen the drain plug at the bottomof the fuel filter.

2. Tighten the drain plug when water no longer comes out.

3. Check to be sure that the warning lamp illuminates when the ignition key is turned to "ON", and that it goes off when the engine is started. If in doubt, consult your nearest Hyundai authorised repairer.

NOTE: It is recommended that water accu-

mulated in the fuel filter should be removed by an authorized Hyundaiauthorised repairer. G300B02FC

Page 464 of 490

6

OWNER MAINTENANCE

35

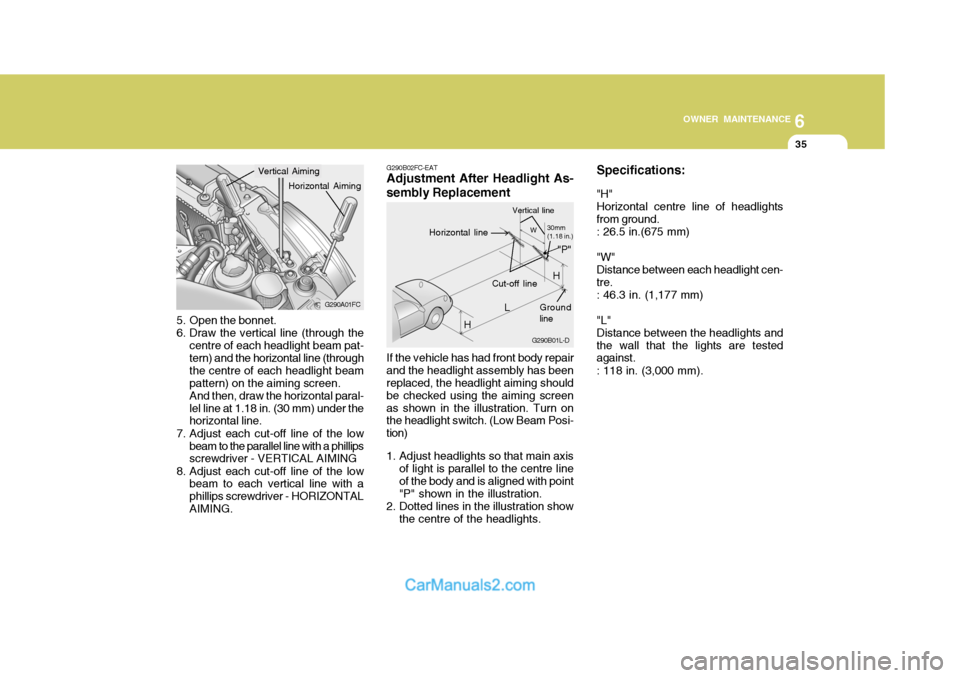

G290A01FC

5. Open the bonnet.

6. Draw the vertical line (through the centre of each headlight beam pat- tern) and the horizontal line (through the centre of each headlight beampattern) on the aiming screen.And then, draw the horizontal paral-lel line at 1.18 in. (30 mm) under the horizontal line.

7. Adjust each cut-off line of the low beam to the parallel line with a phillipsscrewdriver - VERTICAL AIMING

8. Adjust each cut-off line of the low beam to each vertical line with a phillips screwdriver - HORIZONTALAIMING.

Horizontal Aiming

Vertical Aiming

Specifications: "H" Horizontal centre line of headlights from ground. : 26.5 in.(675 mm) "W" Distance between each headlight cen-tre. : 46.3 in. (1,177 mm) "L" Distance between the headlights andthe wall that the lights are tested against. : 118 in. (3,000 mm).

G290B02FC-EAT

Adjustment After Headlight As- sembly Replacement

If the vehicle has had front body repair

and the headlight assembly has been replaced, the headlight aiming should be checked using the aiming screenas shown in the illustration. Turn on the headlight switch. (Low Beam Posi- tion)

1. Adjust headlights so that main axis of light is parallel to the centre line of the body and is aligned with point "P" shown in the illustration.

2. Dotted lines in the illustration show the centre of the headlights. G290B01L-D

L

W

H

H Cut-off line

"P"

30mm (1.18 in.)

Vertical lineHorizontal line

Ground line

Page 465 of 490

6 OWNER MAINTENANCE

36REPLACING LIGHT BULBS

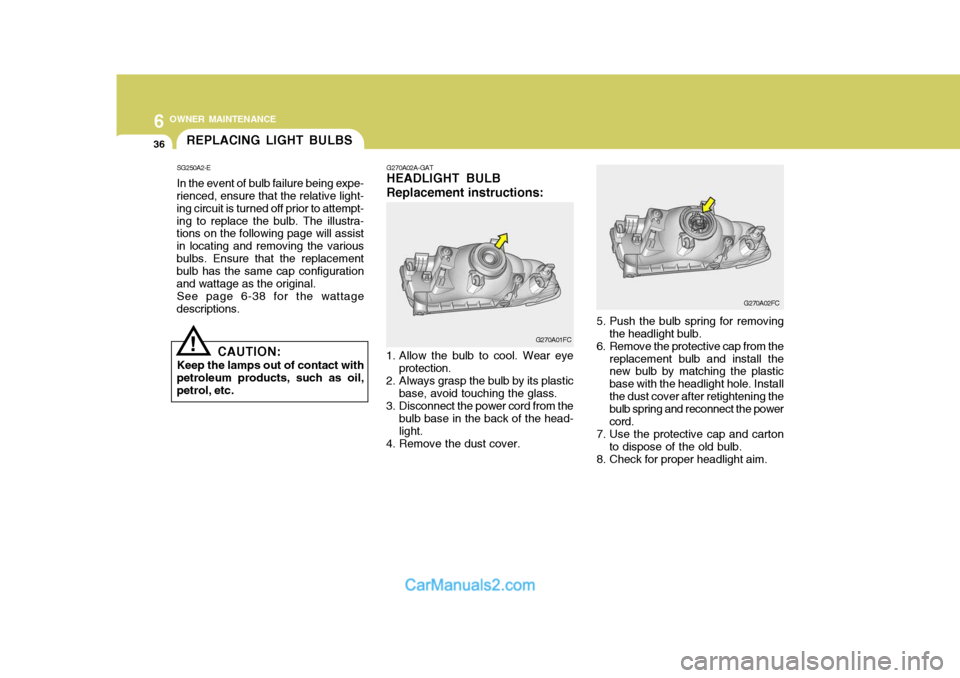

SG250A2-E In the event of bulb failure being expe-

rienced, ensure that the relative light- ing circuit is turned off prior to attempt-ing to replace the bulb. The illustra- tions on the following page will assist in locating and removing the variousbulbs. Ensure that the replacement bulb has the same cap configuration and wattage as the original.

See page 6-38 for the wattage

descriptions.

! CAUTION:

Keep the lamps out of contact with petroleum products, such as oil, petrol, etc.

G270A02A-GAT

HEADLIGHT BULB Replacement instructions:

1. Allow the bulb to cool. Wear eye protection.

2. Always grasp the bulb by its plastic

base, avoid touching the glass.

3. Disconnect the power cord from the bulb base in the back of the head- light.

4. Remove the dust cover. G270A01FC

5. Push the bulb spring for removing

the headlight bulb.

6. Remove the protective cap from the replacement bulb and install the new bulb by matching the plastic base with the headlight hole. Installthe dust cover after retightening the bulb spring and reconnect the power cord.

7. Use the protective cap and carton

to dispose of the old bulb.

8. Check for proper headlight aim. G270A02FC

Page 466 of 490

6

OWNER MAINTENANCE

37

!WARNING

The halogen bulb contains gas un-

der pressure and if impacted could shatter, resulting in flying fragments. Always wear eye protection whenservicing the bulb. Protect the bulb against abrasions or scratches and against liquids when lighted. Turnon the bulb only when installed in a headlight. Replace the headlight if damaged or cracked. Keep the bulbout of the reach of children and dispose of the used bulb with care.