spark plugs Hyundai Matrix 2006 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2006, Model line: Matrix, Model: Hyundai Matrix 2006Pages: 490, PDF Size: 11.58 MB

Page 427 of 490

5VEHICLE MAINTENANCE REQUIREMENTS

8

6ZF060H1-A

o Air Cleaner Filter

A Genuine Hyundai air cleaner filter is

recommended when filter is replaced.

6ZF060J1-A

o Spark Plugs

Make sure to install new spark plugs

of the correct heat range.

6ZF070B1-A

o Cooling System

Check the cooling system part, such

as radiator, coolant reservoir, hoses and connections for leakage and dam- age. Replace any damaged parts.

6ZF060E1-A

o Timing Belt Replace timimg belt and inspect all associated parts related for damage and deformation. Replace any dam- aged parts immediately. 6ZF060G1-A

o Vapour Hose and Fuel Filler Cap The vapour hose and fuel filler cap should be inspected at those intervals specified in the maintenance sched-ule. Make sure that a new vapour hose or fuel filler cap is correctly replaced.

6ZF060F1-A

o Vacuum, Crankcase

Ventilation Hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical dam-age. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessiveswelling indicate deterioration. Partic- ular attention should be paid to exam- ining those hose surfaces nearest tohigh heat sources, such as the ex- haust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact withany heat source, sharp edges or mov- ing component which might cause heatdamage or mechanical wear. Inspect all hose connections, such as clamps and couplings, to make sure they aresecure, and that no leaks are present. Hoses should be replaced immedi- ately if there is any evidence of dete-rioration or damage. F060N02E-AAT

o Valve Clearance

Inspect excessive valve noise and/or

engine vibration and adjust if neces-sary. A qualified technician should perform the operation.

Page 430 of 490

Engine Compartment .................................................... 6-2

Daily Operating Checks ............................................... 6-5

Engine Oil ..................................................................... 6-5

Engine Oil and Filter Replacement .............................. 6-9 Engine Coolant Checking and Replacing................... 6-12

Spark Plugs ................................ ................................. 6-14

Air Cleaner Element Replacement .............................. 6-16

Checking the Transaxle Oil (Manual) ......................... 6-19

Checking the Transaxle Fluid (Automatic) .................6-20

Brake System Checking ............................................. 6-22

Checking the Clutch Fluid ........................................... 6-24

Air Conditioning System Maintenance ........................ 6-25

Changing the Pollen Filter (In Front of Blower Unit) ... 6-26

Checking Drive Belts .................................................. 6-28

Checking and Replacing Fuses ..................................6-29

Battery Mai ntenance ................................................... 6-30

Eclectric Cooling Fans ................................................ 6-31

Power Steering Fluid Level ......................................... 6-32

Headlight Aiming Adjustment ...................................... 6-34

Replacing Light Bulbs ................................................. 6-36

Bulb Wattage ............................................................... 6-38

Fuse Panel D escription ............................................... 6-39

OWNER MAINTENANCE

6

6

Page 444 of 490

6

OWNER MAINTENANCE

15

HGK256

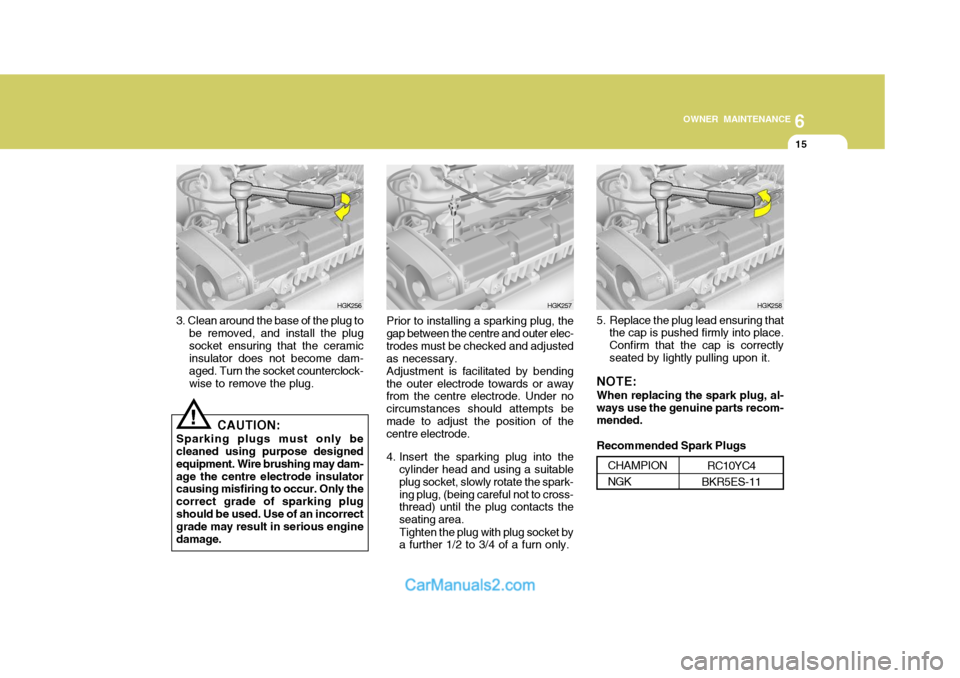

3. Clean around the base of the plug to be removed, and install the plug socket ensuring that the ceramic insulator does not become dam- aged. Turn the socket counterclock-wise to remove the plug.

CAUTION:

Sparking plugs must only be cleaned using purpose designed equipment. Wire brushing may dam-age the centre electrode insulator causing misfiring to occur. Only the correct grade of sparking plugshould be used. Use of an incorrect grade may result in serious engine damage.

! Prior to installing a sparking plug, the

gap between the centre and outer elec- trodes must be checked and adjustedas necessary.

Adjustment is facilitated by bending

the outer electrode towards or away from the centre electrode. Under no circumstances should attempts bemade to adjust the position of the centre electrode.

4. Insert the sparking plug into the cylinder head and using a suitable plug socket, slowly rotate the spark-ing plug, (being careful not to cross- thread) until the plug contacts the seating area. Tighten the plug with plug socket by a further 1/2 to 3/4 of a furn only.

HGK257

5. Replace the plug lead ensuring thatthe cap is pushed firmly into place. Confirm that the cap is correctlyseated by lightly pulling upon it.

NOTE: When replacing the spark plug, al- ways use the genuine parts recom- mended. Recommended Spark PlugsHGK258

CHAMPION NGK RC10YC4

BKR5ES-11