spark plugs replace Hyundai Matrix 2006 Owner's Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2006, Model line: Matrix, Model: Hyundai Matrix 2006Pages: 490, PDF Size: 11.58 MB

Page 169 of 490

2

DRIVING YOUR HYUNDAI

21

C160H01A-AAT Use Approved Anti-Freeze in Window Washer System To keep the water in the window washer system from freezing, add an approvedanti-freeze solution in accordance with instructions on the container. Window washer anti-freeze is available fromHyundai dealers and most auto parts outlets. Do not use engine coolant or other types of anti-freeze as thesemay damage the finish.

C160G02A-GAT To Keep Locks from Freezing To keep the locks from freezing, squirt an approved de-icer fluid or glycerineinto the key opening. If a lock is cov- ered with ice, squirt it with an approved de-icing fluid to remove the ice. If thelock is frozen internally, you may be able to thaw it out by using a heated key. Handle the heated key with careto avoid injury. NOTE: The proper temperature for using the immobilizer key is from -40°C (-40°F) to 80°C(176°F). If you heat the immobilizer key over 80°C toopen the frozen lock, it may cause damage to the transponder in its head.

C160D01A-AAT Check Battery and Cables Winter puts additional burdens on the battery system. Visually inspect thebattery and cables as described in Section 6. The level of charge in your battery can be checked by your Hyundaidealer or a service station.

C160F01A-AAT Check Spark Plugs and Ignition System Inspect your spark plugs as described in Section 6 and replace them if neces-sary. Also check all ignition wiring and components to be sure they are not cracked, worn or damaged in any way.

C160E01A-AAT Change to "Winter Weight" Oil if Necessary In some climates it is recommended that a lower viscosity "winter weight" oil be used during cold weather. See Section 9 for recommendations. If youaren't sure what weight oil you should use, consult your Hyundai dealer.

C160I01A-AAT Don't Let Your Parking Brake Freeze Under some conditions your parking brake can freeze in the engaged posi- tion. This is most likely to happenwhen there is an accumulation of snow or ice around or near the rear brakes or if the brakes are wet. If there is a riskthe parking brake may freeze, apply it only temporarily while you put the gear selector lever in "P" (automatic) or infirst or reverse gear (manual transaxle) and block the rear wheels so the car cannot roll. Then release the parkingbrake.

Page 199 of 490

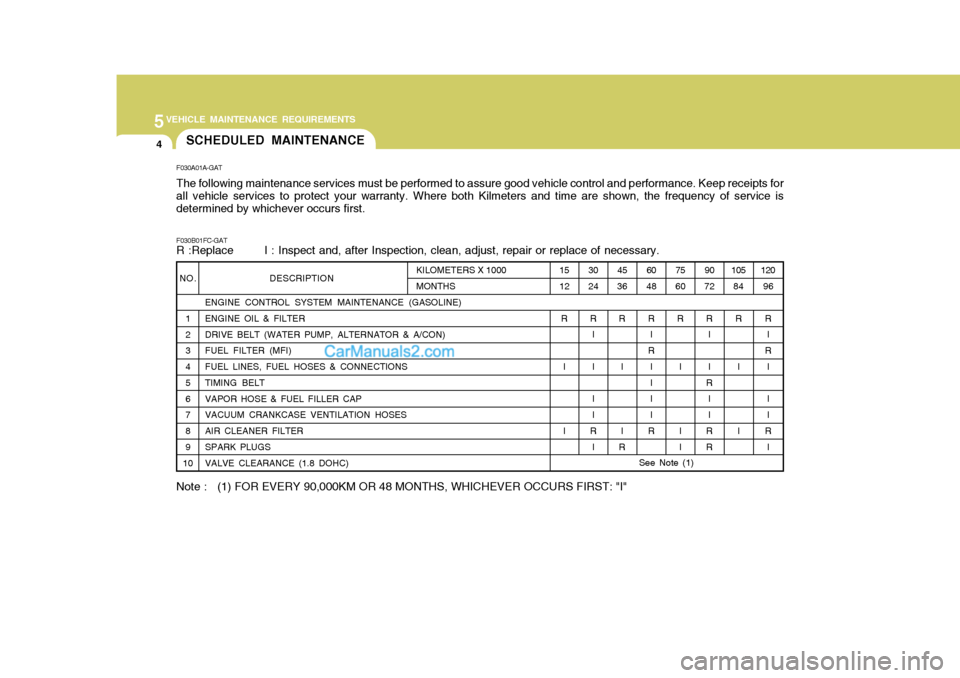

5VEHICLE MAINTENANCE REQUIREMENTS

4

NO.

1 23 4 5 6 7 8 9

10 DESCRIPTION

ENGINE CONTROL SYSTEM MAINTENANCE (GASOLINE) ENGINE OIL & FILTER DRIVE BELT (WATER PUMP, ALTERNATOR & A/CON)FUEL FILTER (MFI) FUEL LINES, FUEL HOSES & CONNECTIONS TIMING BELT VAPOR HOSE & FUEL FILLER CAP VACUUM CRANKCASE VENTILATION HOSES AIR CLEANER FILTER SPARK PLUGS VALVE CLEARANCE (1.8 DOHC)

F030A01A-GAT The following maintenance services must be performed to assure good vehicle control and performance. Keep receipts for all vehicle services to protect your warranty. Where both Kilmeters and time are shown, the frequency of service is determined by whichever occurs first. F030B01FC-GAT R :Replace I : Inspect and, after Inspection, clean, adjust, repair or replace of necessary.105

84

R

I I 120

96

R I

R I I I

R

I

90

72

R I I

R I I

RR

75

60

R

I I I

60

48

R I

R II I I

R

45

36

R

I I

R

30

24

R I II I

R

I

15

12

R

I I

KILOMETERS X 1000 MONTHS

See Note (1)

Note : (1) FOR EVERY 90,000KM OR 48 MONTHS, WHICHEVER OCCURS FIRST: "I" SCHEDULED MAINTENANCE

Page 202 of 490

5

VEHICLE MAINTENANCE REQUIREMENTS

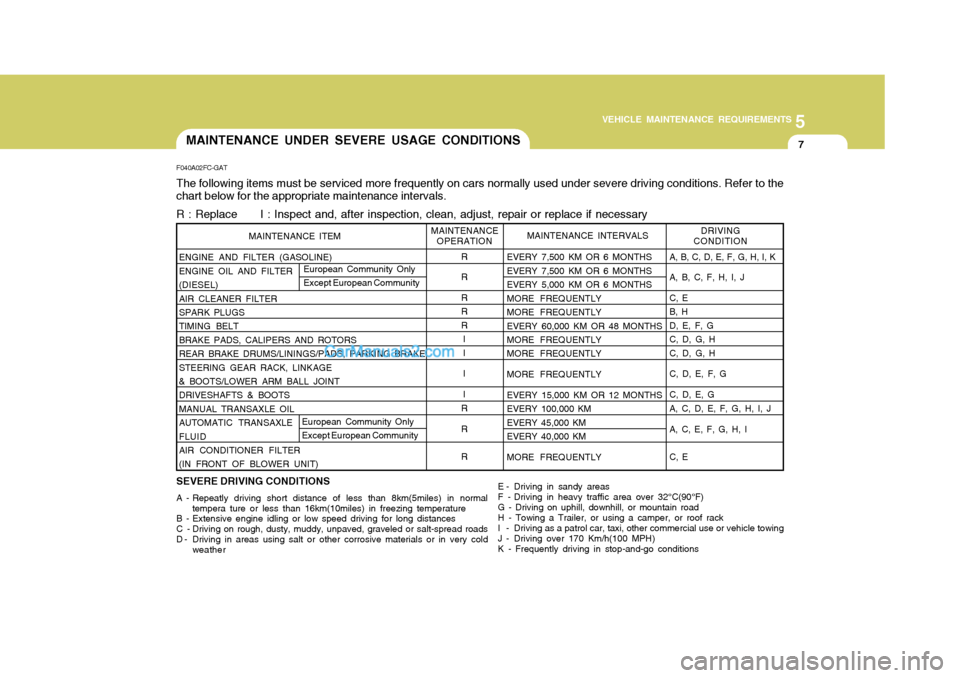

7

ENGINE AND FILTER (GASOLINE)

ENGINE OIL AND FILTER

(DIESEL)AIR CLEANER FILTER SPARK PLUGS TIMING BELTBRAKE PADS, CALIPERS AND ROTORSREAR BRAKE DRUMS/LININGS/PADS, PARKING BRAKESTEERING GEAR RACK, LINKAGE & BOOTS/LOWER ARM BALL JOINT DRIVESHAFTS & BOOTSMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLEFLUIDAIR CONDITIONER FILTER (IN FRONT OF BLOWER UNIT) A, B, C, D, E, F, G, H, I, K A, B, C, F, H, I, J C, E B, H D, E, F, GC, D, G, HC, D, G, H C, D, E, F, G C, D, E, G A, C, D, E, F, G, H, I, J A, C, E, F, G, H, I C, E

R R R RR

II I I

RR R DRIVING

CONDITION

EVERY 7,500 KM OR 6 MONTHS EVERY 7,500 KM OR 6 MONTHSEVERY 5,000 KM OR 6 MONTHSMORE FREQUENTLYMORE FREQUENTLYEVERY 60,000 KM OR 48 MONTHS MORE FREQUENTLY MORE FREQUENTLY MORE FREQUENTLY EVERY 15,000 KM OR 12 MONTHS EVERY 100,000 KMEVERY 45,000 KMEVERY 40,000 KM MORE FREQUENTLY MAINTENANCE INTERVALS

European Community Only Except European Community

F040A02FC-GAT The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the appropriate maintenance intervals. R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

SEVERE DRIVING CONDITIONS

A - Repeatly driving short distance of less than 8km(5miles) in normal

tempera ture or less than 16km(10miles) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt-spread roads

D - Driving in areas using salt or other corrosive materials or in very cold weather

MAINTENANCEOPERATION

MAINTENANCE ITEM

E - Driving in sandy areas

F - Driving in heavy traffic area over 32°C(90°F) G - Driving on uphill, downhill, or mountain road H - Towing a Trailer, or using a camper, or roof rack

I - Driving as a patrol car, taxi, other commercial use or vehicle towing

J - Driving over 170 Km/h(100 MPH)K - Frequently driving in stop-and-go conditions

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

European Community Only Except European Community

Page 204 of 490

5

VEHICLE MAINTENANCE REQUIREMENTS

9

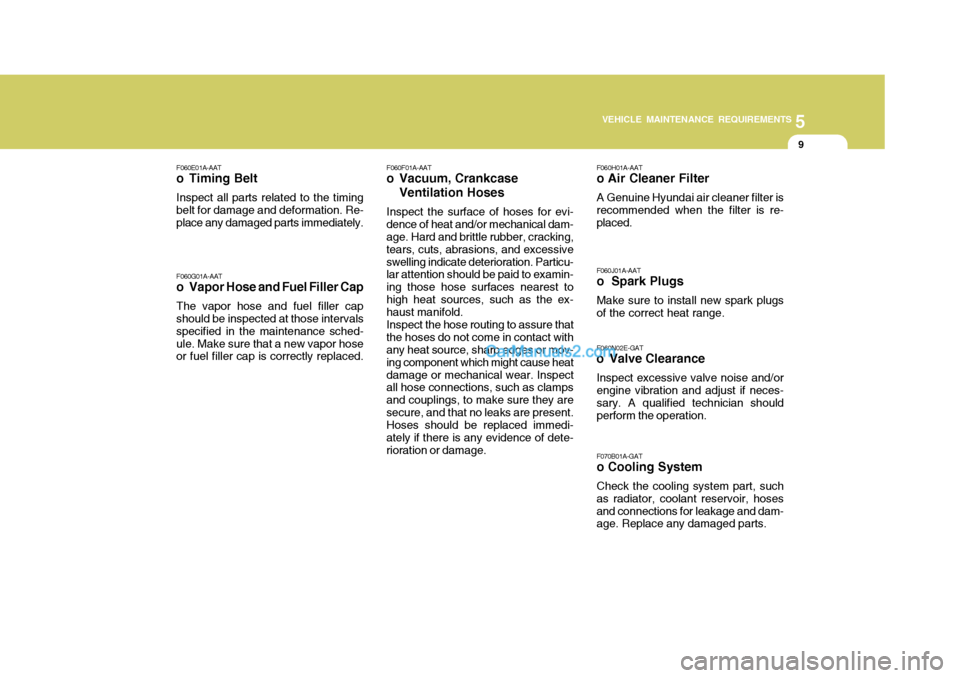

F060H01A-AAT o Air Cleaner Filter A Genuine Hyundai air cleaner filter is recommended when the filter is re- placed. F060J01A-AAT o Spark Plugs Make sure to install new spark plugs of the correct heat range. F070B01A-GAT o Cooling System Check the cooling system part, such as radiator, coolant reservoir, hosesand connections for leakage and dam- age. Replace any damaged parts.

F060E01A-AAT

o Timing Belt

Inspect all parts related to the timing belt for damage and deformation. Re- place any damaged parts immediately. F060G01A-AAT

o Vapor Hose and Fuel Filler Cap

The vapor hose and fuel filler cap should be inspected at those intervals specified in the maintenance sched-ule. Make sure that a new vapor hose or fuel filler cap is correctly replaced. F060F01A-AAT

o Vacuum, Crankcase

Ventilation Hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical dam-age. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessiveswelling indicate deterioration. Particu- lar attention should be paid to examin- ing those hose surfaces nearest tohigh heat sources, such as the ex- haust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact withany heat source, sharp edges or mov- ing component which might cause heatdamage or mechanical wear. Inspect all hose connections, such as clamps and couplings, to make sure they aresecure, and that no leaks are present. Hoses should be replaced immedi- ately if there is any evidence of dete-rioration or damage. F060N02E-GAT

o Valve Clearance

Inspect excessive valve noise and/or engine vibration and adjust if neces- sary. A qualified technician shouldperform the operation.

Page 268 of 490

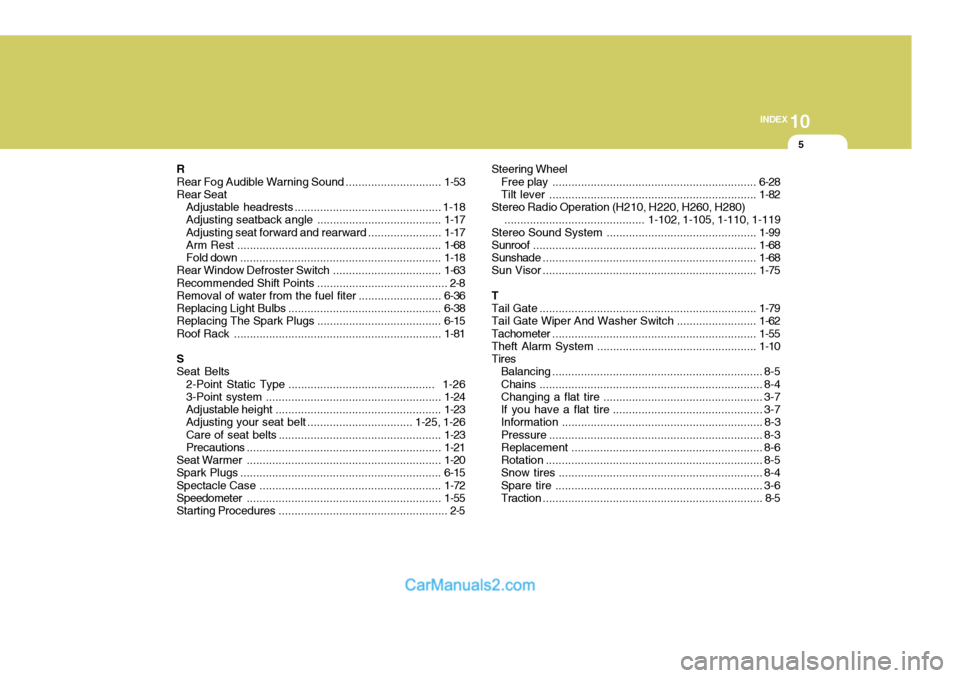

10

INDEX

5

R Rear Fog Audible Warning Sound ..............................1-53

Rear Seat

Adjustable headrests . ............................................. 1-18

Adjusting seatback angle ....................................... 1-17

Adjusting seat forward and rearward .......................1-17

Arm Rest ................................................................ 1-68

Fold down ............................................................... 1-18

Rear Window Defroster Switch .................................. 1-63

Recommended Shift Points ......................................... 2-8 Removal of water from the fuel fiter .......................... 6-36

Replacing Light Bulbs ................................................ 6-38

Replacing The Spark Plugs ....................................... 6-15

Roof Rack ................................................................. 1-81

SSeat Belts 2-Point Static Type .............................................. 1-263-Point system ....................................................... 1-24

Adjustabl e height .................................................... 1-23

Adjusting your seat belt ................................. 1-25, 1-26

Care of seat belts ................................................... 1-23

Precautions ............................................................. 1-21

Seat Warmer ............................................................. 1-20

Spark Plugs ............................................................... 6-15

Spectacle Ca se ......................................................... 1-72

Speedometer ............................................................. 1-55

Starting Pr ocedures..................................................... 2-5 Steering Wheel

Free play ................................................................ 6-28

Tilt lever ................................................................. 1-82

Stereo Radio Operation (H210, H220, H260, H280) ............................................ 1-102, 1-105, 1-110, 1-119

Stereo Sound System ............................................... 1-99

Sunroof ...................................................................... 1-68

Sunshade ................................................................... 1-68

Sun Visor ................................................................... 1-75

T Tail Gate .................................................................... 1-79

Tail Gate Wiper And Washer Switch ......................... 1-62

Tachometer ................................................................ 1-55

Theft Alarm System .................................................. 1-10

Tires Balancing .................................................................. 8-5

Chains ...................................................................... 8-4

Changing a flat tire .................................................. 3-7

If you have a flat tire ............................................... 3-7

Information ............................................................... 8-3

Pressure ................................................................... 8-3

Replacement ............................................................ 8-6

Rotation .................................................................... 8-5

Snow tires ................................................................ 8-4

Spare tire ................................................................. 3-6

Traction ..................................................................... 8-5

Page 422 of 490

5

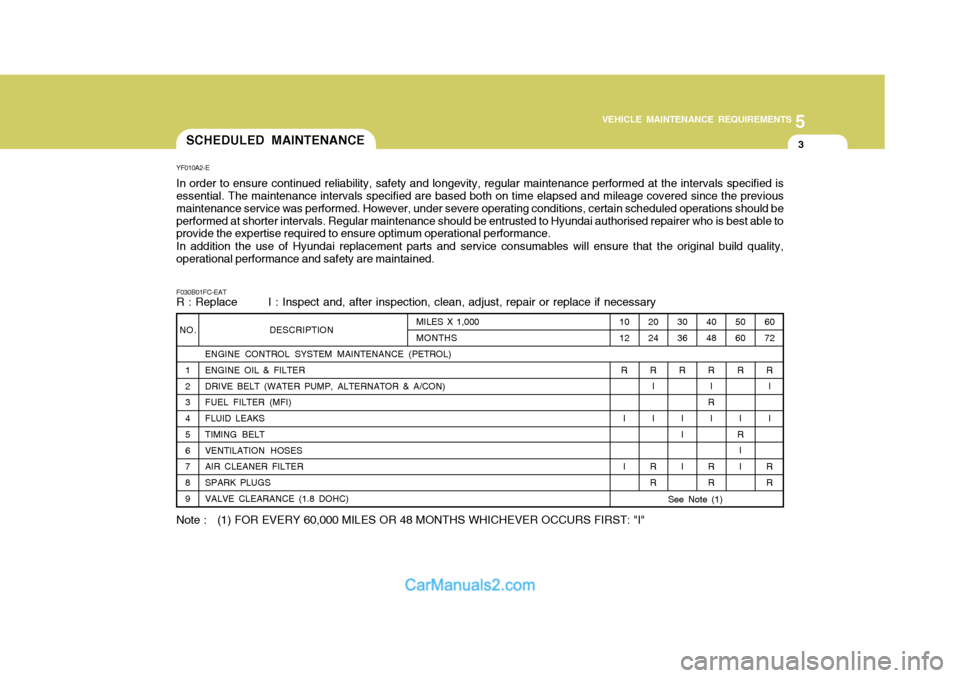

VEHICLE MAINTENANCE REQUIREMENTS

3

NO.

1 2 3 4 5 6 7 8 9 DESCRIPTION

ENGINE CONTROL SYSTEM MAINTENANCE (PETROL)ENGINE OIL & FILTER DRIVE BELT (WATER PUMP, ALTERNATOR & A/CON) FUEL FILTER (MFI) FLUID LEAKS TIMING BELT VENTILATION HOSES AIR CLEANER FILTER SPARK PLUGS VALVE CLEARANCE (1.8 DOHC)

YF010A2-E In order to ensure continued reliability, safety and longevity, regular maintenance performed at the intervals specified is essential. The maintenance intervals specified are based both on time elapsed and mileage covered since the previous maintenance service was performed. However, under severe operating conditions, certain scheduled operations should be

performed at shorter intervals. Regular maintenance should be entrusted to Hyundai authorised repairer who is best able to provide the expertise required to ensure optimum operational performance. In addition the use of Hyundai replacement parts and service consumables will ensure that the original build quality, operational performance and safety are maintained. F030B01FC-EAT R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary60 72

R I I

R R

50 60

R

I

R II

4048

R I

R I

R R

30 36

R

II I

20 24

R I I

R R

10 12

R

I I

MILES X 1,000 MONTHS

See Note (1)

Note : (1) FOR EVERY 60,000 MILES OR 48 MONTHS WHICHEVER OCCURS FIRST: "I" SCHEDULED MAINTENANCE

Page 425 of 490

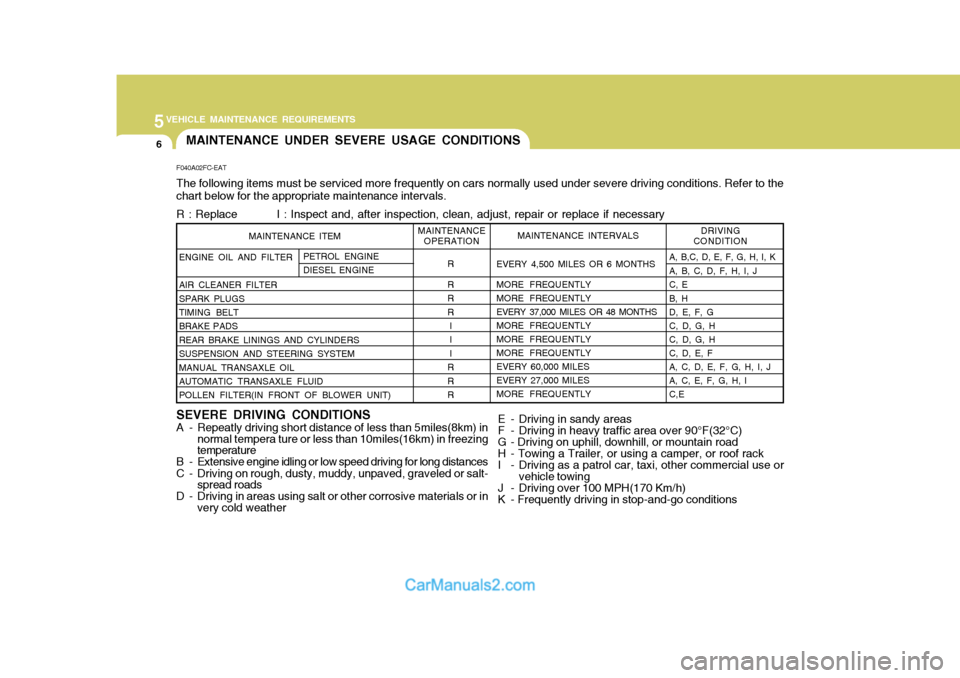

5VEHICLE MAINTENANCE REQUIREMENTS

6

ENGINE OIL AND FILTER AIR CLEANER FILTER SPARK PLUGS TIMING BELT BRAKE PADSREAR BRAKE LININGS AND CYLINDERSSUSPENSION AND STEERING SYSTEMMANUAL TRANSAXLE OIL AUTOMATIC TRANSAXLE FLUID POLLEN FILTER(IN FRONT OF BLOWER UNIT) A, B,C, D, E, F, G, H, I, KA, B, C, D, F, H, I, JC, EB, HD, E, F, G C, D, G, HC, D, G, HC, D, E, FA, C, D, E, F, G, H, I, JA, C, E, F, G, H, IC,E

R R RR

I I I

RRR DRIVING

CONDITION

EVERY 4,500 MILES OR 6 MONTHS MORE FREQUENTLY MORE FREQUENTLY

EVERY 37,000 MILES OR 48 MONTHSMORE FREQUENTLYMORE FREQUENTLYMORE FREQUENTLYEVERY 60,000 MILESEVERY 27,000 MILESMORE FREQUENTLY MAINTENANCE INTERVALS

F040A02FC-EAT The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

SEVERE DRIVING CONDITIONS

A - Repeatly driving short distance of less than 5miles(8km) in

normal tempera ture or less than 10miles(16km) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt- spread roads

D - Driving in areas using salt or other corrosive materials or in very cold weather

MAINTENANCEOPERATION

MAINTENANCE ITEM

E - Driving in sandy areas

F - Driving in heavy traffic area over 90°F(32°C)

G - Driving on uphill, downhill, or mountain road

H - Towing a Trailer, or using a camper, or roof rack

I - Driving as a patrol car, taxi, other commercial use orvehicle towing

J - Driving over 100 MPH(170 Km/h)

K - Frequently driving in stop-and-go conditions

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

PETROL ENGINE DIESEL ENGINE

Page 427 of 490

5VEHICLE MAINTENANCE REQUIREMENTS

8

6ZF060H1-A

o Air Cleaner Filter

A Genuine Hyundai air cleaner filter is

recommended when filter is replaced.

6ZF060J1-A

o Spark Plugs

Make sure to install new spark plugs

of the correct heat range.

6ZF070B1-A

o Cooling System

Check the cooling system part, such

as radiator, coolant reservoir, hoses and connections for leakage and dam- age. Replace any damaged parts.

6ZF060E1-A

o Timing Belt Replace timimg belt and inspect all associated parts related for damage and deformation. Replace any dam- aged parts immediately. 6ZF060G1-A

o Vapour Hose and Fuel Filler Cap The vapour hose and fuel filler cap should be inspected at those intervals specified in the maintenance sched-ule. Make sure that a new vapour hose or fuel filler cap is correctly replaced.

6ZF060F1-A

o Vacuum, Crankcase

Ventilation Hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical dam-age. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessiveswelling indicate deterioration. Partic- ular attention should be paid to exam- ining those hose surfaces nearest tohigh heat sources, such as the ex- haust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact withany heat source, sharp edges or mov- ing component which might cause heatdamage or mechanical wear. Inspect all hose connections, such as clamps and couplings, to make sure they aresecure, and that no leaks are present. Hoses should be replaced immedi- ately if there is any evidence of dete-rioration or damage. F060N02E-AAT

o Valve Clearance

Inspect excessive valve noise and/or

engine vibration and adjust if neces-sary. A qualified technician should perform the operation.

Page 430 of 490

Engine Compartment .................................................... 6-2

Daily Operating Checks ............................................... 6-5

Engine Oil ..................................................................... 6-5

Engine Oil and Filter Replacement .............................. 6-9 Engine Coolant Checking and Replacing................... 6-12

Spark Plugs ................................ ................................. 6-14

Air Cleaner Element Replacement .............................. 6-16

Checking the Transaxle Oil (Manual) ......................... 6-19

Checking the Transaxle Fluid (Automatic) .................6-20

Brake System Checking ............................................. 6-22

Checking the Clutch Fluid ........................................... 6-24

Air Conditioning System Maintenance ........................ 6-25

Changing the Pollen Filter (In Front of Blower Unit) ... 6-26

Checking Drive Belts .................................................. 6-28

Checking and Replacing Fuses ..................................6-29

Battery Mai ntenance ................................................... 6-30

Eclectric Cooling Fans ................................................ 6-31

Power Steering Fluid Level ......................................... 6-32

Headlight Aiming Adjustment ...................................... 6-34

Replacing Light Bulbs ................................................. 6-36

Bulb Wattage ............................................................... 6-38

Fuse Panel D escription ............................................... 6-39

OWNER MAINTENANCE

6

6

Page 444 of 490

6

OWNER MAINTENANCE

15

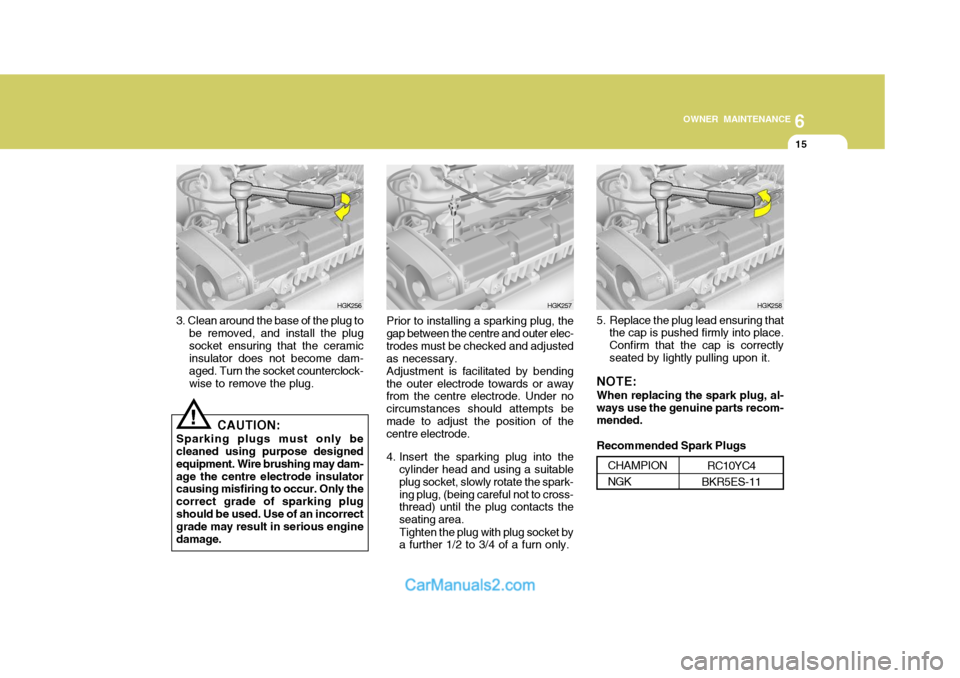

HGK256

3. Clean around the base of the plug to be removed, and install the plug socket ensuring that the ceramic insulator does not become dam- aged. Turn the socket counterclock-wise to remove the plug.

CAUTION:

Sparking plugs must only be cleaned using purpose designed equipment. Wire brushing may dam-age the centre electrode insulator causing misfiring to occur. Only the correct grade of sparking plugshould be used. Use of an incorrect grade may result in serious engine damage.

! Prior to installing a sparking plug, the

gap between the centre and outer elec- trodes must be checked and adjustedas necessary.

Adjustment is facilitated by bending

the outer electrode towards or away from the centre electrode. Under no circumstances should attempts bemade to adjust the position of the centre electrode.

4. Insert the sparking plug into the cylinder head and using a suitable plug socket, slowly rotate the spark-ing plug, (being careful not to cross- thread) until the plug contacts the seating area. Tighten the plug with plug socket by a further 1/2 to 3/4 of a furn only.

HGK257

5. Replace the plug lead ensuring thatthe cap is pushed firmly into place. Confirm that the cap is correctlyseated by lightly pulling upon it.

NOTE: When replacing the spark plug, al- ways use the genuine parts recom- mended. Recommended Spark PlugsHGK258

CHAMPION NGK RC10YC4

BKR5ES-11