ABS Hyundai Matrix 2007 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2007, Model line: Matrix, Model: Hyundai Matrix 2007Pages: 490, PDF Size: 12.81 MB

Page 375 of 490

2

Before Starting the Engine ........................................... 2-3

Key Positions ................................................................ 2-4Starting......................................................................... 2-5

Manual Transaxle ......................................................... 2-8Automatic Transaxle .................................................... 2-10

Anti-Lock Brake System (ABS) ................................... 2-14

Brake Traction Control System (BTCS) ...................... 2-14

Electronic Stability Program (ESP) ..............................2-16

Driving for Economy .................................................... 2-18

Smooth Cornering ........................................................ 2-19

Winter Motoring ............................................................ 2-19

Trailer and Caravan Towing .......... ..............................2-21

DRIVING YOUR HYUNDAI

2

fcuk-2.p65

12/27/2006, 10:14 AM

1

Page 388 of 490

2 DRIVING YOUR HYUNDAI

14ANTI-LOCK BRAKE SYSTEM (ABS)

SC140B2-E (Not all models) The Anti-Lock Brake System (ABS) is designed to prevent wheel lock-up dur-ing sudden braking or on hazardous road surfaces. The ABS control module monitors the wheel speed and controlsthe pressure applied to each brake. Thus, in emergency situations or on slick roads, ABS will increase vehiclecontrol during braking. NOTE: A click sound may be heard in the engine compartment when the ve- hicle begins to move after the engine is started. These conditions are nor-mal and indicate that the anti-lock brake system (Electronic Stability Program) is functioning properly. During ABS (ESP) operation, a slight pulsation may be felt in the brake pedalwhen the brakes are applied. Also, a noise may be heard in the engine com- partment whilst braking. These condi-tions are normal and indicate that the anti-lock brake system is functioning properly. WARNING:

ABS (ESP) will not prevent accidents due to improper or dangerous driv-ing maneuvers. Even though vehicle control is improved during emer- gency braking, always maintain a safe distance between you and ob- jects ahead. Vehicle speeds should always be reduced during extreme road conditions. The braking distance for cars equipped with an anti-lock braking system may be longer than for those without it, in the following road con- ditions.

o Driving on rough, gravel or snow- covered roads.

o Driving with tyre chains installed.

o Driving on roads where the road surface is pitted or has differentsurface height.

These roads should be driven at reduced speeds. The safety features of an ABS (ESP) equipped vehicle should not be tested by high speed driving or cornering. This could en- danger the safety of yourself or oth- ers.

!

BRAKE TRACTION CON- TROL SYSTEM (BTCS)

C300A01O-EAT (Not all models) On slippery road surfaces, the traction control system (TCS) limits the drive wheels from spinning excessively, thushelping the car to accelerate. It alsoprovides sufficient driving force andsteering performance as the car turns at accelerated speeds. SLIP Control Limits the drive wheels from spinning excessively during starting or whilstmaking accelerated turns on slipperyroads to avoid losing the driving force of the front wheels. Driving hints TCS does not actively apply brakes. Be sure to decelerate the car sufficiently

before entering curves.

fcuk-2.p65 12/27/2006, 10:14 AM

14

Page 416 of 490

4

CORROSION PREVENTION AND APPEARANCE CARE

3

4

APPEARANCE CARE

3VALETING

SE040A2-E Regular cleaning of the exterior paintwork serves two important func- tions. Firstly, the removal of abrasive dirt and contaminants will maintain thelustre of the paintwork and will prevent discolouration and dulling due to pro- longed contact.Secondly, the presence of damage through impact or abrasion will be ap- parent allowing early rectification to bemade thus preventing corrosion from becoming established and spreading beneath the paint film. To avoid "waterspotting" the vehicle should not be washed in direct sunlight particularly in the case of vehicles having dark bodycolours. The heat from the sun rays is absorbed by the paint film increasing the surface temperature. This actioncauses water used for washing to evaporate quickly leaving behind the deposits from the water and the sham-poo used. Use only a shampoo intended for the purpose and ensure that the body workis thoroughly wet to soften the dirt film prior to attempting to remove this. After removing the dirt film with a soft sponge, the body work should be thor-oughly rinsed and then dried with a good quality chamois leather to prevent streak- ing or spotting of the paint work.Household detergents, solvents and abra- sive cleaning materials should not be used in order to avoid damaging the paint film.Plastic wheel covers should be cleaned using a sponge and water. Cast alloy wheels should be cleaned using a mildsoap or neutral detergent. Abrasive compounds must not be used since in the event of these damaging the lac-

quer coating, oxidization of the aluminium wheel will occur, spoiling the appearance. The use of a toothbrush will facilitatecleaning between the wheel "spokes".

CAUTION:

!

o Water washing in the engine com- partment including high pressure water washing may cause the fail- ure of electrical circuits located in the engine compartment.

o Never allow water or other liquids to come in contact with electrical/electronic components inside thevehicle as this may damage them.

OJB037800

fcuk-4.p65 12/27/2006, 10:15 AM

3

Page 466 of 490

6 OWNER MAINTENANCE

38FUSE PANEL DESCRIPTION

G200C03FC-EAT Engine Compartment (Petrol Engine)

G200C03FC

NOTE: Not all fuse panel descriptions in this manual may be applicable to your vehicle. It is accurate at the time of printing. When you inspect the fuse box on your vehicle, refer to the fuse box label.

PROTECTED COMPONENTS Generator (A/CON, RR HTD, STOP, D/LOCK, HAZARD) Fuse Generator, Engine control relay, ECM Radiator fan relay Start relay, Ignition switch Blower relay Power window relay Condenser fan relay #1 ABS control module, ABS bleeding connector, ESP ABS control module, ABS bleeding connector, ESP Fuel pump relay Injector, lgnition coil MAP sensor, Oxygen sensor, CP sensor, Knock sensor, Throttle position sensor Audio, Room lamp, Overhead console lamp, lnstrument cluster DRL control module Horn relay A/C relay Front fog lamp relay ECM, TCM Tail lamp relay Left rear combi lamp, Left position lamp, Left License lamp Right rear combi lamp, Right position lamp, Right License lamp Left head lamp Right head lamp, (H/LP IND) Fuse

FUSE RATING

120A40A30A 20A 40A 40A 30A 20A 40A 40A 10A 15A 10A 10A 15A 10A 10A 15A 10A 20A 10A 10A 15A 15A

DESCRIPTION

ALT

B+

ECURAD IGN

BLR

P/WINCOND ABSABS

F/PUMP

INJ

SNSR

ROOM LP DRL

HORN

A/CON

FR FOG ECU

LP

TAIL LH

TAIL RH H/LP LH

H/LP RH

fcuk-6.p65 12/27/2006, 10:16 AM

38

Page 468 of 490

6 OWNER MAINTENANCE

40

ALTB+

ECU RAD IGN

BLR

P/WIN

COND

ABSABS

F/PUMP ECUECU

SNSR

ROOM LP DRL

HORN

A/CON

FR FOG

ECULP

TAIL LH

TAIL RH H/LP LH

H/LP RH

PTC HTR 1 GLOW

PTC HTR 2 FFHS

PTC HTR 3 PROTECTED COMPONENTS

Generator(A/CON, RR HTD, STOP, D/LOCK, HAZARD) Fuse, DeicerGenerator, Engine control relay, ECMRadiator fan relayStart relay, Ignition switchBlower relay Power window relay Condenser fan relay #1ABS control module, ABS bleeding connector, ESPABS control module, ABS bleeding connector, ESPFuel pump relayECM No.5 (Batt+) ECM No.4 (Batt+), Stop lamp switch, PTC heater relay #1 Glow plug relay, Assistor heater relay 1/2, Stop lamp switch,TDC sensor, EGR act, Throttle plate act, VGT vacuumAudio, Room lamp, Overhead console lamp, lnstrument cluster, ETACM, Luggage lampDRL control moduleHorn relayA/C relay Front fog lamp relay ECM, TCMTail lamp relayLeft rear combi lamp, Left position lamp, Left License lampRight rear combi lamp, Right position lamp, Right License lampLeft head lamp Right head lamp, (H/LP IND) Fuse PTC heater relay #1GLOW relayPTC heater relay #2FFHS relayPTC heater relay #3

FUSE RATING

140A40A 30A 30A40A40A30A30A 40A 40A10A30A10A 15A 10A 15A 10A10A15A10A20A 10A 10A15A15A40A80A 40A 30A40A

FUSE

FUSIBLE DESCRIPTION

fcuk-6.p65

12/27/2006, 10:16 AM

40

Page 469 of 490

6

OWNER MAINTENANCE

41

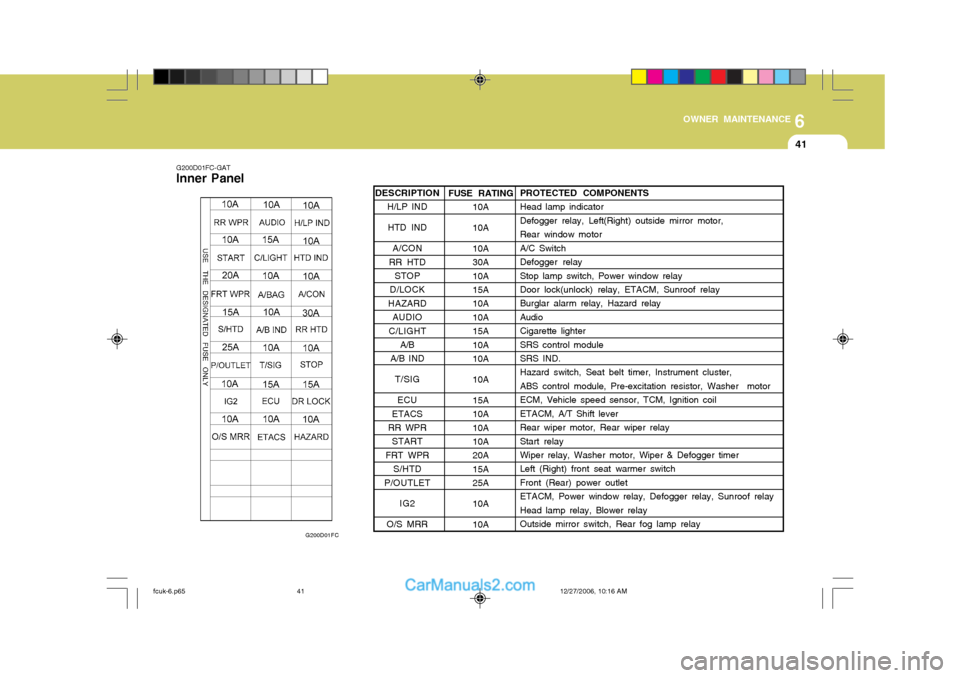

G200D01FC-GAT

Inner Panel

G200D01FCDESCRIPTION

H/LP IND

HTD IND

A/CON

RR HTD STOP

D/LOCK

HAZARD AUDIO

C/LIGHT A/B

A/B IND

T/SIG

ECU

ETACS

RR WPR

START

FRT WPR S/HTD

P/OUTLET

IG2

O/S MRR

PROTECTED COMPONENTS Head lamp indicator Defogger relay, Left(Right) outside mirror motor,Rear window motorA/C SwitchDefogger relayStop lamp switch, Power window relay Door lock(unlock) relay, ETACM, Sunroof relay Burglar alarm relay, Hazard relayAudioCigarette lighterSRS control moduleSRS IND. Hazard switch, Seat belt timer, Instrument cluster, ABS control module, Pre-excitation resistor, Washer motorECM, Vehicle speed sensor, TCM, Ignition coilETACM, A/T Shift leverRear wiper motor, Rear wiper relayStart relay Wiper relay, Washer motor, Wiper & Defogger timer Left (Right) front seat warmer switchFront (Rear) power outletETACM, Power window relay, Defogger relay, Sunroof relayHead lamp relay, Blower relayOutside mirror switch, Rear fog lamp relay

FUSE RATING

10A 10A 10A 30A10A15A 10A 10A15A10A10A 10A 15A 10A10A 10A 20A15A25A 10A 10A

fcuk-6.p65 12/27/2006, 10:16 AM

41

Page 471 of 490

7EMISSION CONTROL SYSTEMS

2EMISSION CONTROL SYSTEMS

SH010A1-E

(Not all models)

Depending upon the market for which

the vehicle is destined, the emission control system will comprise one or more of the following emission control devices.

(1) Crankcase emission control sys-

tem

(2) Evaporative emission control sys- tem

(3) Exhaust emission control system

In order that the proper functioning of

the emission control systems may be ensured, it is recommended that the vehicle is inspected and maintained by an Hyundai authorised repairer inaccordance with the maintenance schedule in this manual. SH010B1-E

1. Crankcase Emission Control

System

The positive crankcase ventilation

system is employed to prevent air pollution caused by blow-by gasesbeing emitted from the crankcase by introducing fresh air to the crankcase through the air cleaner where this mixeswith blow-by gases and then passes through the PCV valve into the intake manifold from where it subsequentlyenters the combustion chamber and is burned.

SH010C1-E

2. Evaporative Emission Control

System

The Evaporative Emission Control Sys-

tem is designed to prevent fuel vapours from escaping into the atmosphere through the fuel tank ventilation sys- tem. Whilst the engine is not running, fuel

vapours generated inside the fuel tankare absorbed and stored in a charcoal canister. When the engine is started, the vapours

stored in the canister are drawn intothe induction system through the purge control solenoid valve and are subse-quently burned. The purge control solenoid valve is

controlled by the ECU; when the en- gine coolant temperature is low or the engine is idling, the purge control valveis closed and fuel vapours remain stored in the canister. Under normal running conditions when the engine iswarm, the valve opens and the vapours are drawn into the inlet tract and sub- sequently burned in the combustionchamber.

SH010D1-E

3. Exhaust Emission Con Trol

System

The exhaust emission control system

is a highly effective system whichcontrols exhaust emission whilst main-taining good vehicle performance.

fcuk-7.p65 12/27/2006, 10:17 AM

2

Page 485 of 490

10INDEX

2

A ACCESSORY TRAY ................................................. 1-67

AIR CONDITIONING SWITCH.................................. 1-82

AIR CONDITIONING SYSTEM MAINTENANCE ....... 6-24

AIR CLEANER ELEMENT REPLACEMENT .............6-14

ANTENNA ................................................................. 1-95

ANTI-LOCK BRAKE SYSTEM (ABS) .......................2-14

ANTI-THEFT ALARM SYSTEM .................................. 1-8

ASHTRAY ................................................................. 1-61

AUTO FUEL CUT SWITCH ....................................... 1-75

AUTOMATIC TRANSAXLE .......................................2-10

AUTOMATIC TRANSAXLE FLUID ........................... 6-19

B BATTERY MAINTENANCE .......................................6-30

BEFORE STARTING THE ENGINE ............................ 2-3

BLEEDING THE FUEL SYSTEM .............................. 6-32

BONNET RELEASE .................................................. 1-70

BRAKE PEDAL FREEPLAY .....................................6-27

BRAKE TRACTION CONTROL SYSTEM (BTCS) .... 2-14

BRAKE SYSTEM CHECKING.................................. 6-22

C

CARE OF SEAT BELTS .... .......................................1-20

CARGO AREA COVER ............................................. 1-74

CATALYTIC CONVERTOR OPERATING PRECAUTIONS ............................................................................. 7-3

CENTRE VENTILATOR ............................................. 1-76

CENTRAL DOOR LOCKS ......... .................................. 1-7

CHANGING A FLAT TYRE ......................................... 3-7

CHECKING THE CLUTCH FLU ID .............................6-23CHILD-PROOF REAR DOOR LOCK

........................... 1-7

CHILD RESTRAINT SYSTEM ................................... 1-24

CIGAR LIGHTER ....................................................... 1-60

CLUTCH PEDAL FREEPLAY ....................................6-26

COMBINATION IGNITION SWITCH ANDSTEERING LOCK ....................................................... 2-3

COOLANT TEMPERATURE GAUGE ........................1-49

DDAILY OPERATING CHECKS .................................... 6-5

DIGITAL CLOCK ....................................................... 1-59

DOOR LOCKS ............................................................. 1-5

DOOR WINDOWS ..................................................... 1-11

DRINK HOLDER ........................................................ 1-61

DRIVE BELTS ........................................................... 6-27

DRIVING FOR ECONOMY ....... .................................2-18

E EFFECTIVE BRAKING ............................................. 2-17

ELECTRIC COOLING FANS ..................................... 6-31

ELECTRONIC STABILITY PROGRAM (ESP) ...........2-16

EMERGENCY TOWING ............................................ 3-14

EMISSION CONTROL SYSTEM ................................. 7-2

ENGINE COMPARTMENT ....... ................................... 6-2

ENGINE COOLANT CHECKING AND REPLACING . 6-12

ENGINE OIL AND FILTER REPLACEMENT .............. 6-8

ENGINE OIL CONSUMPTION .................................... 6-8

ENGINE OIL REPLENISHMENT ................................. 6-7

ENGINE OIL ................................................................ 6-5 EXTERIOR REAR VIEW MIRROR ........................... 1-67

fcuk-10.p65 12/27/2006, 10:14 AM

2