fuel filter Hyundai Matrix 2007 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2007, Model line: Matrix, Model: Hyundai Matrix 2007Pages: 490, PDF Size: 12.81 MB

Page 425 of 490

5

VEHICLE MAINTENANCE REQUIREMENTS

7EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

!

6ZF060M1-A

o Engine Oil and Filter

The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the car is being driven in severe conditions,more frequent oil and filter changes are required. 6ZF060B1-A

o Drive Belts

Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil contamination and replace if neces- sary. Drive belts should be checkedperiodically for proper tension and ad- justed as necessary. 6ZF060C1-A

o Fuel Filter A clogged filter can limit the speed at which the vehicle may be driven, dam- age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently.After installing a new filter, run theengine for several minutes, and checkfor leaks at the connections.

WARNING (Diesel only):

Never work on injection system with engine running or within 30 sec- onds after shutting off engine. Highpressure pump, rail, injectors and high pressure pipes are subject to high pressure even after the enginestopped. The fuel jet produced by fuel leaks may cause serious injury, if it contacts the body. People usingpacemakers should ensure that they keep a distance of 30cm from the ECU or wiring harness within theengine room whilst engine is run- ning, since the high currents in the Common Rail system produce con-siderable magnetic fields.

6ZF060D2-A

o Fuel lines, Fuel Hoses and

Connections

Check the fuel lines, fuel hoses and connections for leakage and damage. Replace any damaged or leaking parts immediately.

fcuk-5.p65 12/27/2006, 10:15 AM

7

Page 426 of 490

5VEHICLE MAINTENANCE REQUIREMENTS

8

6ZF060H1-A

o Air Cleaner Filter

A Genuine Hyundai air cleaner filter is

recommended when filter is replaced.

6ZF060J1-A

o Spark Plugs

Make sure to install new spark plugs

of the correct heat range.

6ZF070B1-A

o Cooling System

Check the cooling system part, such

as radiator, coolant reservoir, hoses and connections for leakage and dam- age. Replace any damaged parts.

6ZF060E1-A

o Timing Belt Replace timimg belt and inspect all associated parts related for damage and deformation. Replace any dam- aged parts immediately. 6ZF060G1-A

o Vapour Hose and Fuel Filler Cap The vapour hose and fuel filler cap should be inspected at those intervals specified in the maintenance sched-ule. Make sure that a new vapour hose or fuel filler cap is correctly replaced.

6ZF060F1-A

o Vacuum, Crankcase

Ventilation Hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical dam-age. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessiveswelling indicate deterioration. Partic- ular attention should be paid to exam- ining those hose surfaces nearest tohigh heat sources, such as the ex- haust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact withany heat source, sharp edges or mov- ing component which might cause heatdamage or mechanical wear. Inspect all hose connections, such as clamps and couplings, to make sure they aresecure, and that no leaks are present. Hoses should be replaced immedi- ately if there is any evidence of dete-rioration or damage. F060N02E-AAT

o Valve Clearance

Inspect excessive valve noise and/or

engine vibration and adjust if neces-sary. A qualified technician should perform the operation.

fcuk-5.p65 12/27/2006, 10:15 AM

8

Page 430 of 490

6 OWNER MAINTENANCE

2

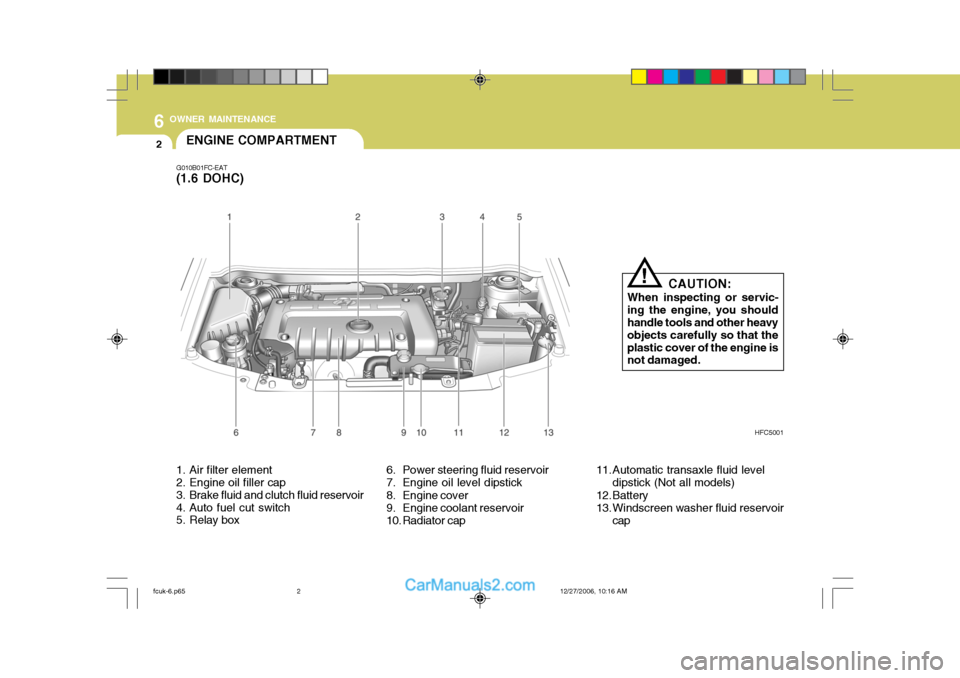

1. Air filter element

2. Engine oil filler cap

3. Brake fluid and clutch fluid reservoir

4. Auto fuel cut switch

5. Relay box 6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Engine cover

9. Engine coolant reservoir

10. Radiator cap11. Automatic transaxle fluid level

dipstick (Not all models)

12. Battery

13. Windscreen washer fluid reservoir cap HFC5001

G010B01FC-EAT (1.6 DOHC)

CAUTION:

When inspecting or servic-

ing the engine, you should handle tools and other heavy objects carefully so that theplastic cover of the engine is not damaged.

!

ENGINE COMPARTMENT

fcuk-6.p65

12/27/2006, 10:16 AM

2

Page 431 of 490

6

OWNER MAINTENANCE

3

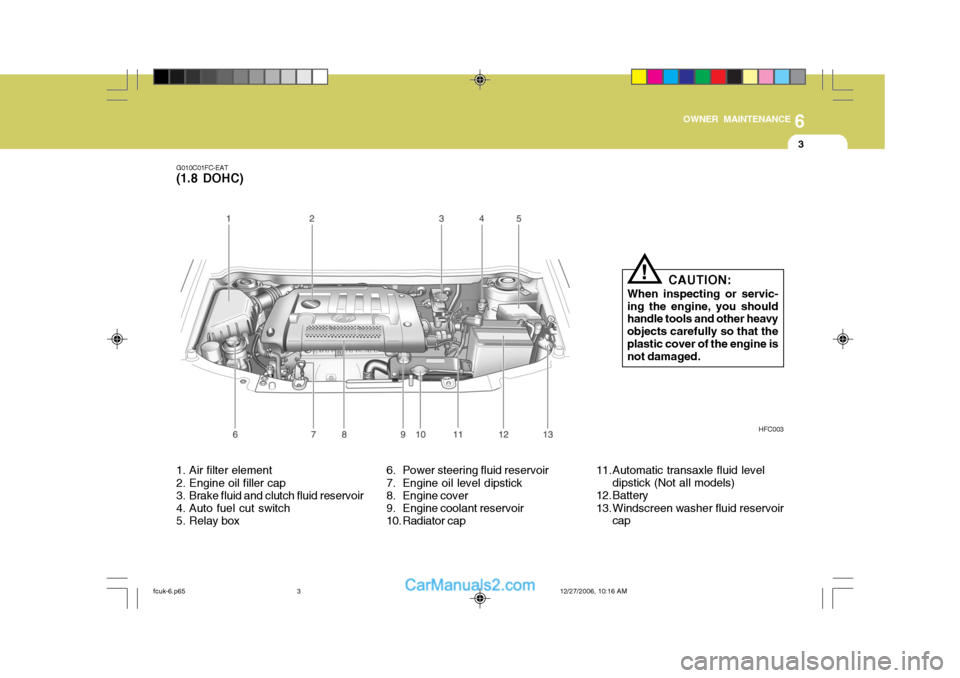

G010C01FC-EAT

(1.8 DOHC)

HFC003

1. Air filter element

2. Engine oil filler cap

3. Brake fluid and clutch fluid reservoir

4. Auto fuel cut switch

5. Relay box 6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Engine cover

9. Engine coolant reservoir

10. Radiator cap11. Automatic transaxle fluid level

dipstick (Not all models)

12. Battery

13. Windscreen washer fluid reservoir cap CAUTION:

When inspecting or servic- ing the engine, you should handle tools and other heavy objects carefully so that the plastic cover of the engine is not damaged.

!

fcuk-6.p65 12/27/2006, 10:16 AM

3

Page 432 of 490

6 OWNER MAINTENANCE

4

1. Air filter element

2. Engine oil filler cap

3. Brake fluid and clutch fluid reservoir

4. Fuel filter 5. Relay box

6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Engine coolant reservoir G010E02FC

G010E02FC-EAT

Diesel (1.5 CRDi)

CAUTION:

When inspecting or servic-

ing the engine, you should handle tools and other heavyobjects carefully so that the plastic cover of the engine is not damaged.

!

9. Radiator cap

10. Battery

11. Windscreen washer fluid reservoir

cap

fcuk-6.p65 12/27/2006, 10:16 AM

4

Page 460 of 490

6 OWNER MAINTENANCE

32

2. Pump the hand pump until there are

no more bubbles in the fuel coming out of the air pipe. When doing this, place a cloth around the air pipe to prevent the escaping fuel from spew-ing about.

3. Replace the air cap when there are no more bubbles in the fuel.

4. Continue pumping until the hand pump becomes stiff.

5. Finally, check to be sure that there

is no leakage of fuel. If in doubt, consult your nearest Hyundai authorised repairer. G350B01FC

Air pipeG350B01FC-EAT

(Diesel engine)

The fuel system should be bled to

remove air as described in the illustra- tion if the fuel supply is exhaustedduring travel, when the fuel filter is replaced, or if the vehicle is not used for a long time.

1. Remove the air cap with pushing

the button.

G350A01FC

BLEEDING THE FUEL SYSTEM

SG230B1-E POWER STEERING HOSES Power steering hoses should be checked for damage, deterioration and leakage at each service.

fcuk-6.p65 12/27/2006, 10:16 AM

32

Page 461 of 490

6

OWNER MAINTENANCE

33

!WARNING:

o Do not smoke or have any other open flame near the vehicle whilst bleeding the fuel system.

o Be sure to carefully wipe away

any water drained out in thismanner, because the fuel mixed in the water might be ignited and result in a fire.

G300A02FC

G300A02B-EAT

(Diesel engine)

If the fuel filter warning lamp illumi- nates during driving, it indicates thatwater has accumulated in the fuel filter. If this occurs, remove the water as described. REMOVAL OF WATER FROM THE FUEL FILTER1. Loosen the drain plug at the bottom

of the fuel filter.

2. Tighten the drain plug when water no longer comes out.

3. Check to be sure that the warning lamp illuminates when the ignition key is turned to "ON", and that it goes off when the engine is started. If in doubt, consult your nearest Hyundai authorised repairer.

NOTE: It is recommended that water accu-

mulated in the fuel filter should be removed by an authorised Hyundaiauthorised repairer. G300B02FC

fcuk-6.p65

12/27/2006, 10:16 AM

33

Page 462 of 490

6 OWNER MAINTENANCE

34

G290A01FC

5. Open the bonnet.

6. Draw the vertical line (through the centre of each headlight beam pat- tern) and the horizontal line (through the centre of each headlight beampattern) on the aiming screen.And then, draw the horizontal paral-lel line at 1.18 in. (30 mm) under the horizontal line.

7. Adjust each cut-off line of the low beam to the parallel line with a phillipsscrewdriver - VERTICAL AIMING

8. Adjust each cut-off line of the low beam to each vertical line with a phillips screwdriver - HORIZONTALAIMING.

Horizontal Aiming

Vertical Aiming

HEADLIGHT AIMING ADJUSTMENT

G290A01FC-EAT Before performing aiming adjustment,

make sure of the following.

1. Keep all tyres inflated to the correct

pressure.

2. Place the vehicle on level ground and press the front bumper & rear bumper down several times. Place the vehicle at a distance of 118 in. (3,000 mm) from the test wall.

3. See that the vehicle is unloaded (except for full levels of coolant,engine oil and fuel, and spare tyre,jack, and tools).

4. Clean the head lights lens and turn on the headlight (Low beam).

!WARNING:

o Do not smoke or have any other open flame near the vehicle whilst bleeding the fuel system.

o Be sure to carefully wipe away any water drained out in thismanner, because the fuel mixed in the water might be ignited and result in a fire.

Extracting air in the fuel filter If you drove until you have no fuel left

or if you replaced the fuel filter, be sureto extract air in the fuel system as it makes you difficult to start the engine.

1) Remove the air extract nozzle cap

on the fuel filter.

2) Pump up and down until the fuel flows out of the plug opening.

NOTE: Use cloths when you extract air so

that the fuel is not sprayed around. Clean the fuel around the fuel filteror the injection pump before start- ing the engine to prevent fire. Fi- nally, check each part if the fuel isleaking.

fcuk-6.p65 12/27/2006, 10:16 AM

34

Page 485 of 490

10INDEX

2

A ACCESSORY TRAY ................................................. 1-67

AIR CONDITIONING SWITCH.................................. 1-82

AIR CONDITIONING SYSTEM MAINTENANCE ....... 6-24

AIR CLEANER ELEMENT REPLACEMENT .............6-14

ANTENNA ................................................................. 1-95

ANTI-LOCK BRAKE SYSTEM (ABS) .......................2-14

ANTI-THEFT ALARM SYSTEM .................................. 1-8

ASHTRAY ................................................................. 1-61

AUTO FUEL CUT SWITCH ....................................... 1-75

AUTOMATIC TRANSAXLE .......................................2-10

AUTOMATIC TRANSAXLE FLUID ........................... 6-19

B BATTERY MAINTENANCE .......................................6-30

BEFORE STARTING THE ENGINE ............................ 2-3

BLEEDING THE FUEL SYSTEM .............................. 6-32

BONNET RELEASE .................................................. 1-70

BRAKE PEDAL FREEPLAY .....................................6-27

BRAKE TRACTION CONTROL SYSTEM (BTCS) .... 2-14

BRAKE SYSTEM CHECKING.................................. 6-22

C

CARE OF SEAT BELTS .... .......................................1-20

CARGO AREA COVER ............................................. 1-74

CATALYTIC CONVERTOR OPERATING PRECAUTIONS ............................................................................. 7-3

CENTRE VENTILATOR ............................................. 1-76

CENTRAL DOOR LOCKS ......... .................................. 1-7

CHANGING A FLAT TYRE ......................................... 3-7

CHECKING THE CLUTCH FLU ID .............................6-23CHILD-PROOF REAR DOOR LOCK

........................... 1-7

CHILD RESTRAINT SYSTEM ................................... 1-24

CIGAR LIGHTER ....................................................... 1-60

CLUTCH PEDAL FREEPLAY ....................................6-26

COMBINATION IGNITION SWITCH ANDSTEERING LOCK ....................................................... 2-3

COOLANT TEMPERATURE GAUGE ........................1-49

DDAILY OPERATING CHECKS .................................... 6-5

DIGITAL CLOCK ....................................................... 1-59

DOOR LOCKS ............................................................. 1-5

DOOR WINDOWS ..................................................... 1-11

DRINK HOLDER ........................................................ 1-61

DRIVE BELTS ........................................................... 6-27

DRIVING FOR ECONOMY ....... .................................2-18

E EFFECTIVE BRAKING ............................................. 2-17

ELECTRIC COOLING FANS ..................................... 6-31

ELECTRONIC STABILITY PROGRAM (ESP) ...........2-16

EMERGENCY TOWING ............................................ 3-14

EMISSION CONTROL SYSTEM ................................. 7-2

ENGINE COMPARTMENT ....... ................................... 6-2

ENGINE COOLANT CHECKING AND REPLACING . 6-12

ENGINE OIL AND FILTER REPLACEMENT .............. 6-8

ENGINE OIL CONSUMPTION .................................... 6-8

ENGINE OIL REPLENISHMENT ................................. 6-7

ENGINE OIL ................................................................ 6-5 EXTERIOR REAR VIEW MIRROR ........................... 1-67

fcuk-10.p65 12/27/2006, 10:14 AM

2

Page 487 of 490

10INDEX

4

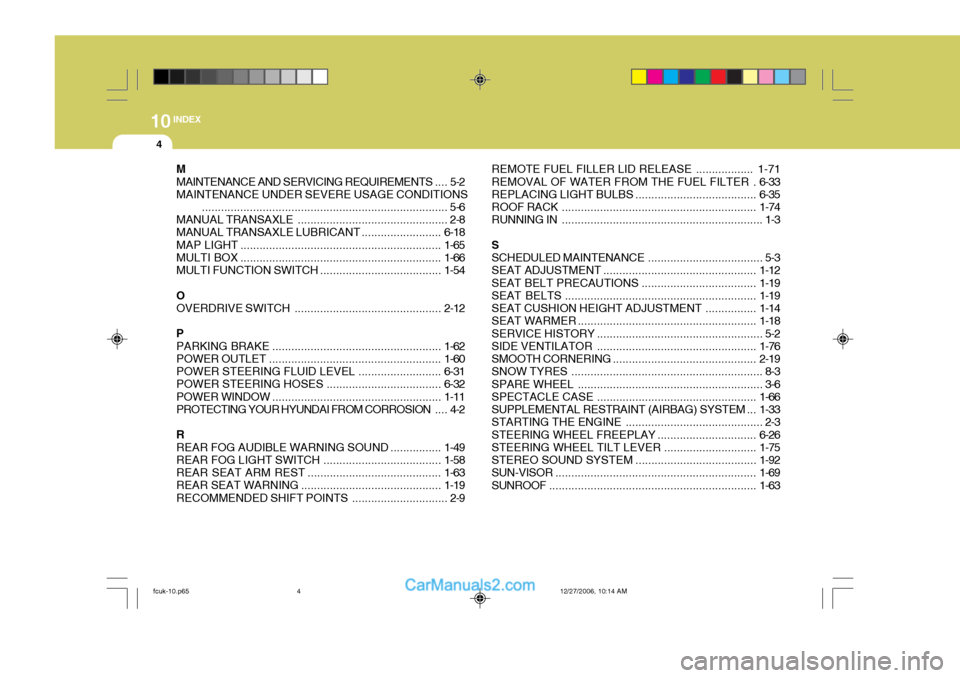

M MAINTENANCE AND SERVICING REQUIREMENTS .... 5-2

MAINTENANCE UNDER SEVERE USAGE CONDITIONS ............................................................................. 5-6

MANUAL TRANSAXLE ............................................... 2-8

MANUAL TRANSAXLE LUBRICANT .........................6-18

MAP LIGHT ............................................................... 1-65

MULTI BOX ............................................................... 1-66

MULTI FUNCTION SWITCH ......................................1-54

O

OVERDRIVE SWITCH .............................................. 2-12

P PARKING BRAKE ..................................................... 1-62

POWER OUTLET ...................................................... 1-60

POWER STEERING FLUI D LEVEL .......................... 6-31

POWER STEERING HOSES .................................... 6-32

POWER WINDOW ..................................................... 1-11

PROTECTING YOUR HYUNDAI FROM CORROSION .... 4-2

RREAR FOG AUDIBLE WARNING SOUND ................ 1-49

REAR FOG LIGHT SWITCH ..................................... 1-58

REAR SEAT ARM REST .......................................... 1-63

REAR SEAT WARNING ............................................ 1-19

RECOMMENDED SHIFT POINTS .............................. 2-9REMOTE FUEL FILLER LID

RELEASE .................. 1-71

REMOVAL OF WATER FROM THE FUEL FILTER . 6-33

REPLACING LIGHT BULBS ...................................... 6-35

ROOF RACK ............................................................. 1-74

RUNNING IN ............................................................... 1-3

SSCHEDULED MAINTENANCE .................................... 5-3

SEAT ADJUSTMENT ................................................ 1-12

SEAT BELT PRECAUTIONS ....................................1-19

SEAT BELTS ............................................................ 1-19

SEAT CUSHION HEIGHT ADJUSTMENT ................1-14

SEAT WARMER ........................................................ 1-18

SERVICE HISTORY .................................................... 5-2

SIDE VENTILATOR .................................................. 1-76

SMOOTH CORNERING ............................................. 2-19

SNOW TYRES ............................................................ 8-3

SPARE WHEEL .......................................................... 3-6

SPECTACLE CASE .................................................. 1-66

SUPPLEMENTAL RESTRAINT (AIRBAG) SYSTEM ... 1-33

STARTING THE ENGINE ........................................... 2-3

STEERING WHEEL FREEPLAY ...............................6-26

STEERING WHEEL TILT LEVER ............................. 1-75

STEREO SOUND SYSTEM ...................................... 1-92

SUN-VISOR ............................................................... 1-69

SUNROOF ................................................................. 1-63

fcuk-10.p65 12/27/2006, 10:14 AM

4