oil filter Hyundai Matrix 2007 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2007, Model line: Matrix, Model: Hyundai Matrix 2007Pages: 490, PDF Size: 12.81 MB

Page 421 of 490

5

VEHICLE MAINTENANCE REQUIREMENTS

3

NO.

1 2 3 4 5 6 7 8 9 DESCRIPTION

ENGINE CONTROL SYSTEM MAINTENANCE (PETROL)ENGINE OIL & FILTER DRIVE BELT (WATER PUMP, ALTERNATOR & A/CON) FUEL FILTER (MFI) FLUID LEAKS TIMING BELT VENTILATION HOSES AIR CLEANER FILTER SPARK PLUGS VALVE CLEARANCE (1.8 DOHC)

YF010A2-E In order to ensure continued reliability, safety and longevity, regular maintenance performed at the intervals specified is essential. The maintenance intervals specified are based both on time elapsed and mileage covered since the previous maintenance service was performed. However, under severe operating conditions, certain scheduled operations should be

performed at shorter intervals. Regular maintenance should be entrusted to Hyundai authorised repairer who is best able to provide the expertise required to ensure optimum operational performance. In addition the use of Hyundai replacement parts and service consumables will ensure that the original build quality, operational performance and safety are maintained. F030B03FC-EAT R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary60 72

R I I

R R

50 60

R

I

R II

4048

R I

R I I

R

30 36

R

II

R

2024

R I I I

R

10 12

R

I I

MILES X 1,000 MONTHS

See Note (1)

Note : (1) INSPECT AND ADJUST EVERY 60,000 MILE OR 48 MONTHS. SCHEDULED MAINTENANCE

fcuk-5.p65

12/27/2006, 10:15 AM

3

Page 422 of 490

5VEHICLE MAINTENANCE REQUIREMENTS

4

NO.1 2 345678 ENGINE CONTROL SYSTEM MAINTENANCE (DIESEL)

ENGINE OIL & FILTER (API Class : CH-4 or ABOVE) See Note(1)

(ACEA Class : B-4 or ABOVE)

AIR CLEANER FILTER FUEL FILTER CARTRIDGE TIMING BELTDRIVE BELT (FOR P/STR'G PUMP, ALTERNATOR & A/CON)VACUUM PUMP & VACUUM HOSEVACUUM PUMP OIL HOSE FUEL LINES, FUEL HOSE & CONNECTIONS

F030D02FC-EAT

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary.

70 84

R I

R II I

60 72

R R R R I I I

50 60

R I I I I

40 48

R I

R

III I

30 36

R R

I I I

20 24

R I

R

III I

10 12

R I I I I

MILES X 1,000 MONTHSDESCRIPTION

Note : (1) ON A DAILY BASIS, WHENEVER THE VEHICLE IS REFUELLED OR BEFORE STARTING A LONG TRIP :"I"

fcuk-5.p65 12/27/2006, 10:15 AM

4

Page 423 of 490

5

VEHICLE MAINTENANCE REQUIREMENTS

5

F030C02FC-EAT R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

DESCRIPTION

GENERAL MAINTENANCE COOLING SYSTEMCOOLANTENGINE COOLANT SPECIFIC GRAVITYMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDBRAKE PIPES, HOSES, AND CONNECTIONSBRAKE FLUIDCLUTCH FLUIDREAR BRAKE LININGS AND CYLINDERSBRAKE PADSSUSPENSION AND STEERING SYSTEMFRONT SUSPENSION BALL JOINTSPOLLEN FILTER (IN FRONT OF BLOWER UNIT)REAR WHEEL BEARINGSTYRE CONDITION AND PRESSURE (incl. Spare)LUBRICATE LOCKS AND HINGESCHECK ALL ELECTRICAL SYSTEMSROAD TESTCHECK ALL SYSTEMS WITH HI-SCAN

NO.

123456789

10111213141516171819

60 72

I I I

R I

RR IIII

R IIIIII

5060

I I IIIII I II

R IIIIII

4048

I I II

RR IIII

R IIIIII

3036

I I IIIII I II

R IIIIII

2024

I I III

RR IIII

R IIIIII

1012

I I IIIII I II

R IIIIII

MILES X 1,000 MONTHS

See Note (1)

Note :(1) FOR THE FIRST TIME, REPLACE THE COOLANT AT 60,000 MILES OR 60 MONTHS. AFTER THAT, REPLACE IT EVERY 30,000 MILES OR 24 MONTHS.

fcuk-5.p65 12/27/2006, 10:15 AM

5

Page 424 of 490

5VEHICLE MAINTENANCE REQUIREMENTS

6

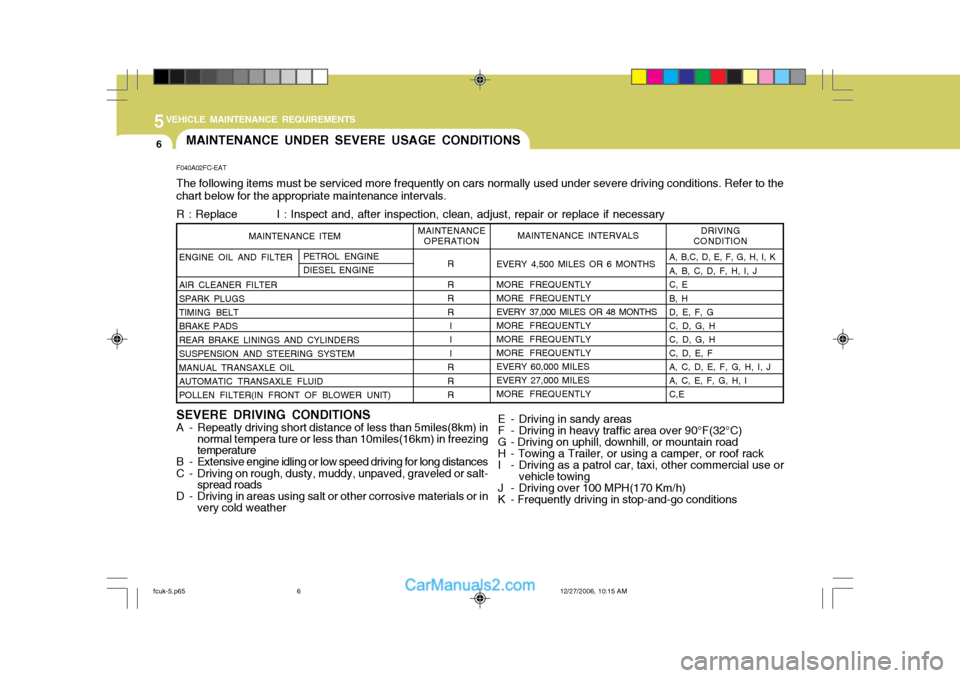

ENGINE OIL AND FILTER AIR CLEANER FILTER SPARK PLUGS TIMING BELT BRAKE PADSREAR BRAKE LININGS AND CYLINDERSSUSPENSION AND STEERING SYSTEMMANUAL TRANSAXLE OIL AUTOMATIC TRANSAXLE FLUID POLLEN FILTER(IN FRONT OF BLOWER UNIT) A, B,C, D, E, F, G, H, I, KA, B, C, D, F, H, I, JC, EB, HD, E, F, G C, D, G, HC, D, G, HC, D, E, FA, C, D, E, F, G, H, I, JA, C, E, F, G, H, IC,E

R R RR

I I I

RRR DRIVING

CONDITION

EVERY 4,500 MILES OR 6 MONTHS MORE FREQUENTLY MORE FREQUENTLY

EVERY 37,000 MILES OR 48 MONTHSMORE FREQUENTLYMORE FREQUENTLYMORE FREQUENTLYEVERY 60,000 MILESEVERY 27,000 MILESMORE FREQUENTLY MAINTENANCE INTERVALS

F040A02FC-EAT The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

SEVERE DRIVING CONDITIONS

A - Repeatly driving short distance of less than 5miles(8km) in

normal tempera ture or less than 10miles(16km) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt- spread roads

D - Driving in areas using salt or other corrosive materials or in very cold weather

MAINTENANCEOPERATION

MAINTENANCE ITEM

E - Driving in sandy areas

F - Driving in heavy traffic area over 90°F(32°C)

G - Driving on uphill, downhill, or mountain road

H - Towing a Trailer, or using a camper, or roof rack

I - Driving as a patrol car, taxi, other commercial use orvehicle towing

J - Driving over 100 MPH(170 Km/h)

K - Frequently driving in stop-and-go conditions

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

PETROL ENGINE DIESEL ENGINE

fcuk-5.p65

12/27/2006, 10:15 AM

6

Page 425 of 490

5

VEHICLE MAINTENANCE REQUIREMENTS

7EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

!

6ZF060M1-A

o Engine Oil and Filter

The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the car is being driven in severe conditions,more frequent oil and filter changes are required. 6ZF060B1-A

o Drive Belts

Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil contamination and replace if neces- sary. Drive belts should be checkedperiodically for proper tension and ad- justed as necessary. 6ZF060C1-A

o Fuel Filter A clogged filter can limit the speed at which the vehicle may be driven, dam- age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently.After installing a new filter, run theengine for several minutes, and checkfor leaks at the connections.

WARNING (Diesel only):

Never work on injection system with engine running or within 30 sec- onds after shutting off engine. Highpressure pump, rail, injectors and high pressure pipes are subject to high pressure even after the enginestopped. The fuel jet produced by fuel leaks may cause serious injury, if it contacts the body. People usingpacemakers should ensure that they keep a distance of 30cm from the ECU or wiring harness within theengine room whilst engine is run- ning, since the high currents in the Common Rail system produce con-siderable magnetic fields.

6ZF060D2-A

o Fuel lines, Fuel Hoses and

Connections

Check the fuel lines, fuel hoses and connections for leakage and damage. Replace any damaged or leaking parts immediately.

fcuk-5.p65 12/27/2006, 10:15 AM

7

Page 429 of 490

Engine Compartment .................................................... 6-2

Daily Operating Checks ............................................... 6-5

Engine Oil ..................................................................... 6-5

Engine Oil and Filter Replacement .............................. 6-9 Engine Coolant Checking and Replacing................... 6-12

Air Cleaner Element Replacement .............................. 6-14

Checking the Transaxle Oil (Manual) ......................... 6-18

Checking the Transaxle Fluid (Automatic) .................6-19

Brake System Checking ............................................. 6-22

Checking the Clutch Fluid ........................................... 6-23

Air Conditioning System Maintenance ........................ 6-24

Changing the Pollen Filter (In Front of Blower Unit) ... 6-25

Checking Drive Belts .................................................. 6-27

Checking and Replacing Fuses ..................................6-28

Battery Mai ntenance ................................................... 6-30

Eclectric Cooling Fans ................................................ 6-31

Power Steering Fluid Level ......................................... 6-31

Headlight Aiming Adjustment ...................................... 6-34

Replacing Light Bulbs ................................................. 6-36

Bulb Wattage ............................................................... 6-37

Fuse Panel D escription ............................................... 6-38

OWNER MAINTENANCE

6

6

fcuk-6.p65

12/27/2006, 10:16 AM

1

Page 430 of 490

6 OWNER MAINTENANCE

2

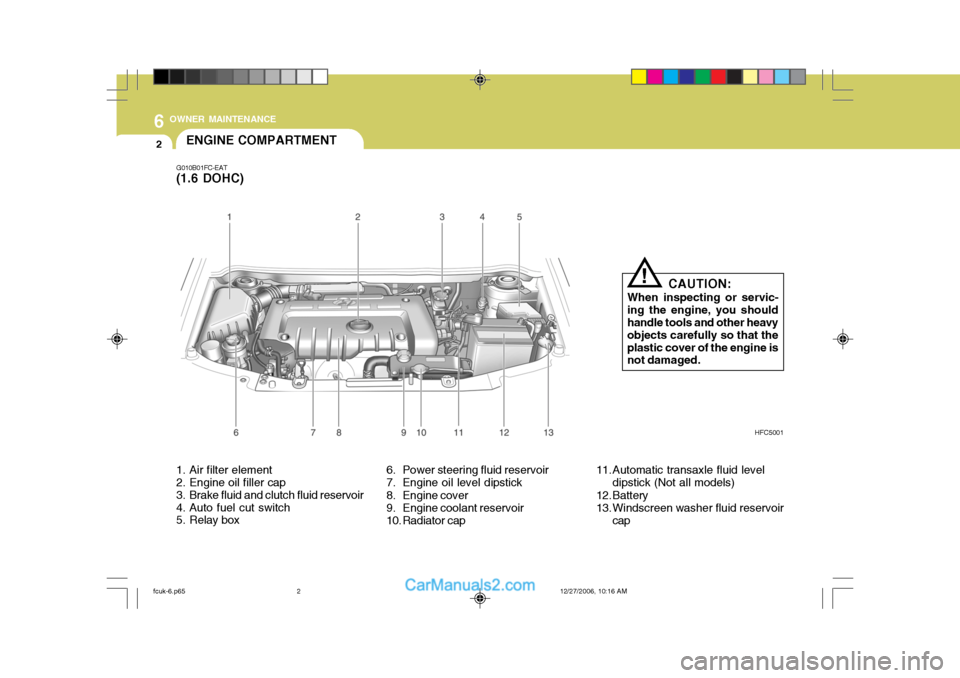

1. Air filter element

2. Engine oil filler cap

3. Brake fluid and clutch fluid reservoir

4. Auto fuel cut switch

5. Relay box 6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Engine cover

9. Engine coolant reservoir

10. Radiator cap11. Automatic transaxle fluid level

dipstick (Not all models)

12. Battery

13. Windscreen washer fluid reservoir cap HFC5001

G010B01FC-EAT (1.6 DOHC)

CAUTION:

When inspecting or servic-

ing the engine, you should handle tools and other heavy objects carefully so that theplastic cover of the engine is not damaged.

!

ENGINE COMPARTMENT

fcuk-6.p65

12/27/2006, 10:16 AM

2

Page 431 of 490

6

OWNER MAINTENANCE

3

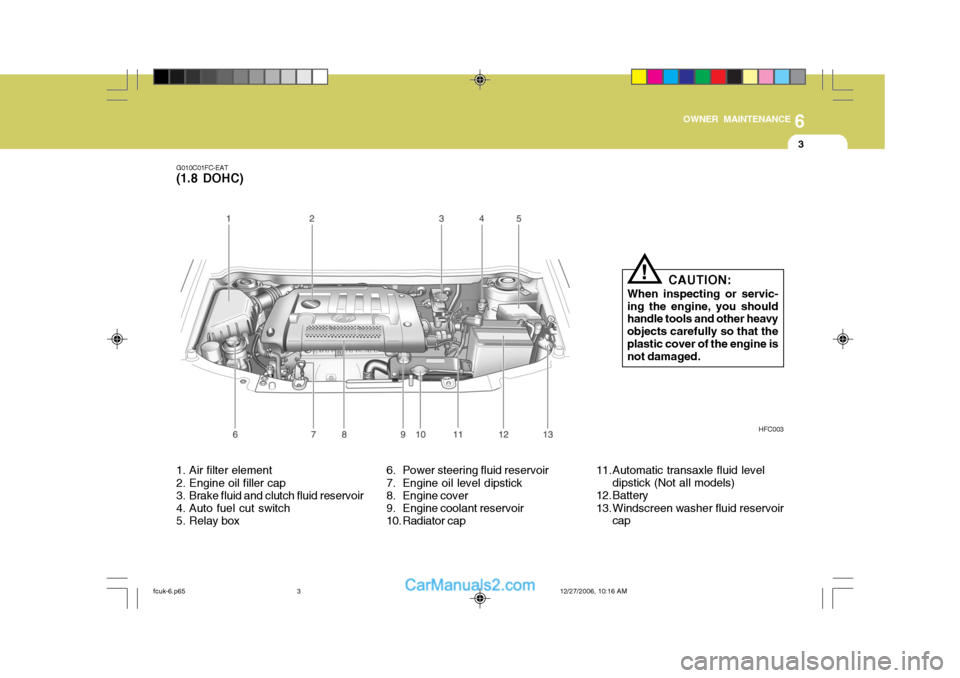

G010C01FC-EAT

(1.8 DOHC)

HFC003

1. Air filter element

2. Engine oil filler cap

3. Brake fluid and clutch fluid reservoir

4. Auto fuel cut switch

5. Relay box 6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Engine cover

9. Engine coolant reservoir

10. Radiator cap11. Automatic transaxle fluid level

dipstick (Not all models)

12. Battery

13. Windscreen washer fluid reservoir cap CAUTION:

When inspecting or servic- ing the engine, you should handle tools and other heavy objects carefully so that the plastic cover of the engine is not damaged.

!

fcuk-6.p65 12/27/2006, 10:16 AM

3

Page 432 of 490

6 OWNER MAINTENANCE

4

1. Air filter element

2. Engine oil filler cap

3. Brake fluid and clutch fluid reservoir

4. Fuel filter 5. Relay box

6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Engine coolant reservoir G010E02FC

G010E02FC-EAT

Diesel (1.5 CRDi)

CAUTION:

When inspecting or servic-

ing the engine, you should handle tools and other heavyobjects carefully so that the plastic cover of the engine is not damaged.

!

9. Radiator cap

10. Battery

11. Windscreen washer fluid reservoir

cap

fcuk-6.p65 12/27/2006, 10:16 AM

4

Page 437 of 490

6

OWNER MAINTENANCE

9ENGINE OIL AND FILTER REPLACEMENT

SSA6040A

1.6 DOHC

Oil filler cap

Drain plug

Oil filler

G040A03E

Oil filler cap

Drain plug

Oil filler

1.8 DOHC

SG040A2-E

Petrol engine The engine oil and filter must be changed at the time or mileage inter-val specified in the maintenance sched- ule. If the vehicle is operated under severe or adverse conditions, the oiland filter must be replaced more fre- quently. To replace the oil and filter, proceed as follows:

1. Ensure that the engine is at normal operating temperature and park the vehicle on level ground with the parking brake securely applied andthe engine turned off.

2. Open the bonnet and remove the oil filler cap.

3. Prepare a suitable receptacle to collect the displaced oil and re-move the drain plug from the sump.

CAUTION:

The oil being drained from the en-gine will be hot. Care should beexercised to prevent scalding. 4. When the oil has drained from the

sump, replace the drain plug usinga new gasket ensuring that the plug is not over tightened.

5. Remove the oil filter by rotating counterclockwise, using a propri-etary oil filter removal tool if neces- sary. Note that the oil filter willcontain approximately 0.5 litres of oil and this should be collected in a suitable receptacle.

6. Install a new oil filter having smeared

the sealing ring with clean oil androtating clockwise until the filter contacts the mounting and then a further one half turn. Do not over-tighten Tightening torque: 2.3 ~ 2.5 kgf.m

7. Remove the engine oil level dip- stick.

8. Pour the specified quantity of the

recommended oil into the engine and replace the filler cap. Start the engine and ensure that no oil leaksexist. Turn off the engine and after a couple minutes, recheck the oil level.

!

fcuk-6.p65 12/27/2006, 10:16 AM

9