fuel Hyundai Santa Fe 2011 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2011, Model line: Santa Fe, Model: Hyundai Santa Fe 2011Pages: 408, PDF Size: 8.63 MB

Page 330 of 408

711

Maintenance

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

G050100AUN

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the car is being

driven in severe conditions, more fre-

quent oil and filter changes are required.

G050200AUN

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil satu-

ration and replace if necessary. Drive

belts should be checked periodically for

proper tension and adjusted as neces-

sary.

G050300AFD

Fuel filter (cartridge)

A clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. Fuel filters should be

installed by an authorized HYUNDAI

dealer.

G050400AFD

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and con-

nections for leakage and damage. Have

an authorized HYUNDAI dealer replace

any damaged or leaking parts immedi-

ately.

G050600AUN

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

that a new vapor hose or fuel filler cap is

correctly replaced.

Page 351 of 408

Maintenance

32

7

TIRES AND WHEELS

G200100AUN

Tire care

For proper maintenance, safety, and

maximum fuel economy, you must

always maintain recommended tire

inflation pressures and stay within

the load limits and weight distribution

recommended for your vehicle.

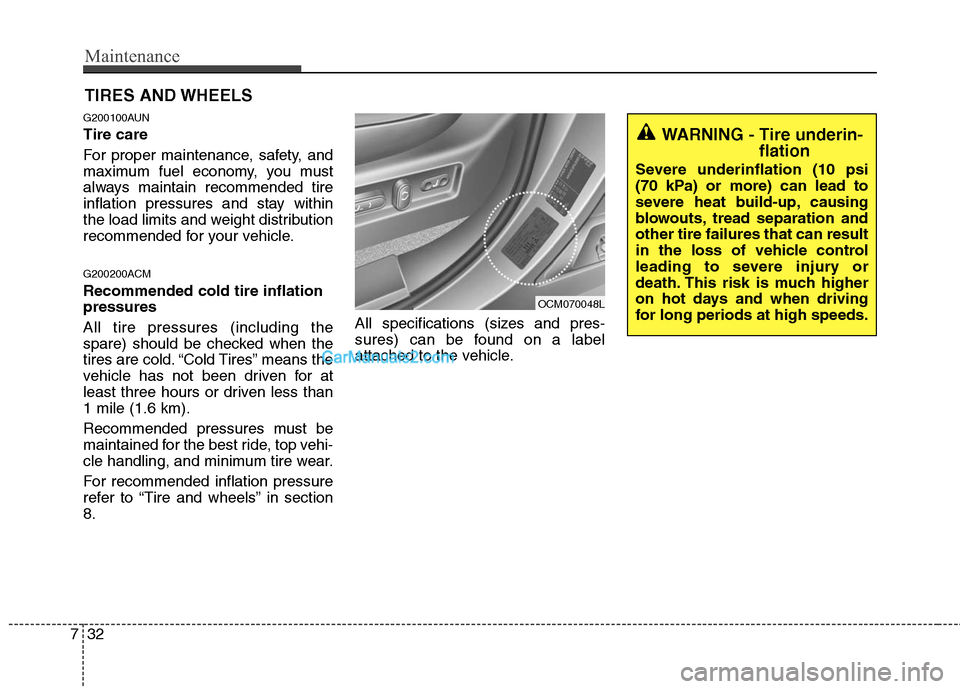

G200200ACM

Recommended cold tire inflation

pressures

All tire pressures (including the

spare) should be checked when the

tires are cold. “Cold Tires” means the

vehicle has not been driven for at

least three hours or driven less than

1 mile (1.6 km).

Recommended pressures must be

maintained for the best ride, top vehi-

cle handling, and minimum tire wear.

For recommended inflation pressure

refer to “Tire and wheels” in section

8. All specifications (sizes and pres-

sures) can be found on a label

attached to the vehicle.

WARNING - Tire underin-

flation

Severe underinflation (10 psi

(70 kPa) or more) can lead to

severe heat build-up, causing

blowouts, tread separation and

other tire failures that can result

in the loss of vehicle control

leading to severe injury or

death. This risk is much higher

on hot days and when driving

for long periods at high speeds.

OCM070048L

Page 352 of 408

733

Maintenance

WARNING - Tire inflation

Overinflation or underinflation

can reduce tire life, adversely

affect vehicle handling, and

lead to sudden tire failure. This

could result in loss of vehicle

control and potential injury.

CAUTION - Tire pressure

Always observe the following: Check tire pressure when the tires are cold. (After vehiclehas b een parked for at least

three hours or hasn't been driv- en more than 1 mile (1.6 km)since startup.)

Check the pressure of your spare tire each time you checkthe pressure of other tires.

Never overload your vehicle. Be careful not to overload avehicle luggage rack if yourvehicle is equipped with one.

Worn, old tires can cause acci- dents. If your tread is badlyworn, or if your tires havebeen damaged, replace them.

CAUTION

Underinflation also results in excessive wear, poor handlingand reduced fuel economy.Wheel deformation also ispossible. Keep your tire pres-sures at the proper levels. If atire frequently needs refilling,have it checked by an author-ized HYUNDAI dealer.

Overinflation produces a harsh ride, excessive wear atthe center of the tire tread, anda greater possibility of dam-age from road hazards.

CAUTION

Warm tires normally exceed recommended cold tire pres-sures by 4 to 6 psi (28 to 41kPa). Do not release air fromwarm tires to adjust the pres-sure or the tires will be under-inflated.

Be sure to reinstall the tire inflation valve caps. Withoutthe valve cap, dirt or moisturecould get into the valve coreand cause air leakage. If avalve cap is missing, install anew one as soon as possible.

Page 361 of 408

Maintenance

42

7

Cold Tire Pressure : The amount of

air pressure in a tire, measured in

pounds per square inch (psi) or kilo-

pascals (kPa) before a tire has built

up heat from driving.

Curb Weight : This means the weight

of a motor vehicle with standard and

optional equipment including the

maximum capacity of fuel, oil and

coolant, but without passengers and

cargo.

DOT Markings : A code molded into

the sidewall of a tire signifying that

the tire is in compliance with the U.S.

Department of Transportation motor

vehicle safety standards. The DOT

code includes the Tire Identification

Number (TIN), an alphanumeric des-

ignator which can also identify the

tire manufacturer, production plant,

brand and date of production.

GVWR : Gross Vehicle Weight Rating

GAWR FRT : Gross Axle Weight

Rating for the Front Axle.

GAWR RR : Gross Axle Weight

Rating for the Rear axle. Intended Outboard Sidewall

: The

side of an asymmetrical tire, that

must always face outward when

mounted on a vehicle.

Kilopascal (kPa) : The metric unit for

air pressure.

Load Index : An assigned number

ranging from 1 to 279 that corre-

sponds to the load carrying capacity

of a tire.

Maximum Inflation Pressure : The

maximum air pressure to which a

cold tire may be inflated. The maxi-

mum air pressure is molded onto the

sidewall.

Maximum Load Rating : The load

rating for a tire at the maximum per-

missible inflation pressure for that

tire.

Maximum Loaded Vehicle Weight :

The sum of curb weight; accessory

weight; vehicle capacity weight; and

production options weight.

Normal Occupant Weight :The

number of occupants a vehicle is

designed to seat multiplied by 150

pounds (68 kg). Occupant Distribution

: Designated

seating positions.

Outward Facing Sidewall: The side

of a asymmetrical tire that has a par-

ticular side that faces outward when

mounted on a vehicle. The outward

facing sidewall bears white lettering

or bears manufacturer, brand, and/or

model name molding that is higher or

deeper than the same moldings on

the inner facing sidewall.

Passenger (P-Metric) Tire : A tire

used on passenger cars and some

light duty trucks and multipurpose

vehicles.

Recommended Inflation Pressure :

Vehicle manufacturer's recommend-

ed tire inflation pressure and shown

on the tire placard.

Radial Ply Tire : A pneumatic tire in

which the ply cords that extend to the

beads are laid at 90 degrees to the

centerline of the tread.

Rim : A metal support for a tire and

upon which the tire beads are seat-

ed.

Sidewall : The portion of a tire

between the tread and the bead.

Page 372 of 408

753

Maintenance

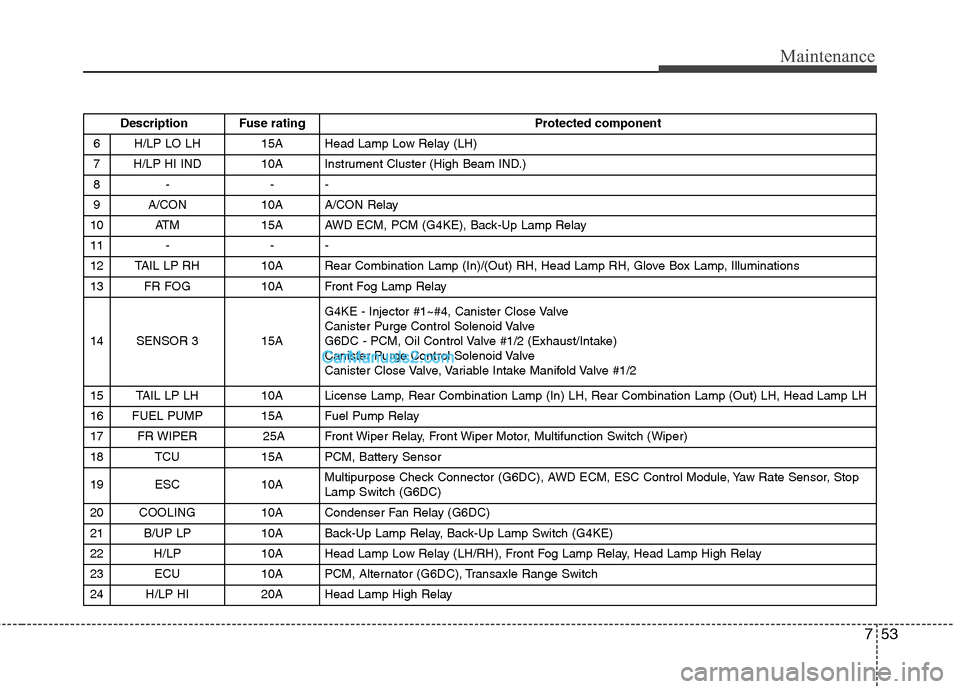

Description Fuse rating Protected component

6 H/LP LO LH 15A Head Lamp Low Relay (LH)

7 H/LP HI IND 10A Instrument Cluster (High Beam IND.)

8- --

9 A/CON 10A A/CON Relay

10 ATM 15A AWD ECM, PCM (G4KE), Back-Up Lamp Relay

11 - - -

12 TAIL LP RH 10A Rear Combination Lamp (In)/(Out) RH, Head Lamp RH, Glove Box Lamp, Illuminations

13 FR FOG 10A Front Fog Lamp Relay

14 SENSOR 3 15A G4KE - Injector #1~#4, Canister Close Valve

Canister Purge Control Solenoid Valve

G6DC - PCM, Oil Control Valve #1/2 (Exhaust/Intake)

Canister Purge Control Solenoid Valve

Canister Close Valve, Variable Intake Manifold Valve #1/2

15 TAIL LP LH 10A License Lamp, Rear Combination Lamp (In) LH, Rear Combination Lamp (Out) LH, Hea\

d Lamp LH

16 FUEL PUMP 15A Fuel Pump Relay

17 FR WIPER 25A Front Wiper Relay, Front Wiper Motor, Multifunction Switch (Wiper)

18 TCU 15A PCM, Battery Sensor

19 ESC 10A Multipurpose Check Connector (G6DC), AWD ECM, ESC Control Module, Yaw Rate Sensor, Stop

Lamp Switch (G6DC)

20 COOLING 10A Condenser Fan Relay (G6DC)

21 B/UP LP 10A Back-Up Lamp Relay, Back-Up Lamp Switch (G4KE)

22 H/LP 10A Head Lamp Low Relay (LH/RH), Front Fog Lamp Relay, Head Lamp High Relay

23 ECU 10A PCM, Alternator (G6DC), Transaxle Range Switch

24 H/LP HI 20A Head Lamp High Relay

Page 373 of 408

Maintenance

54

7

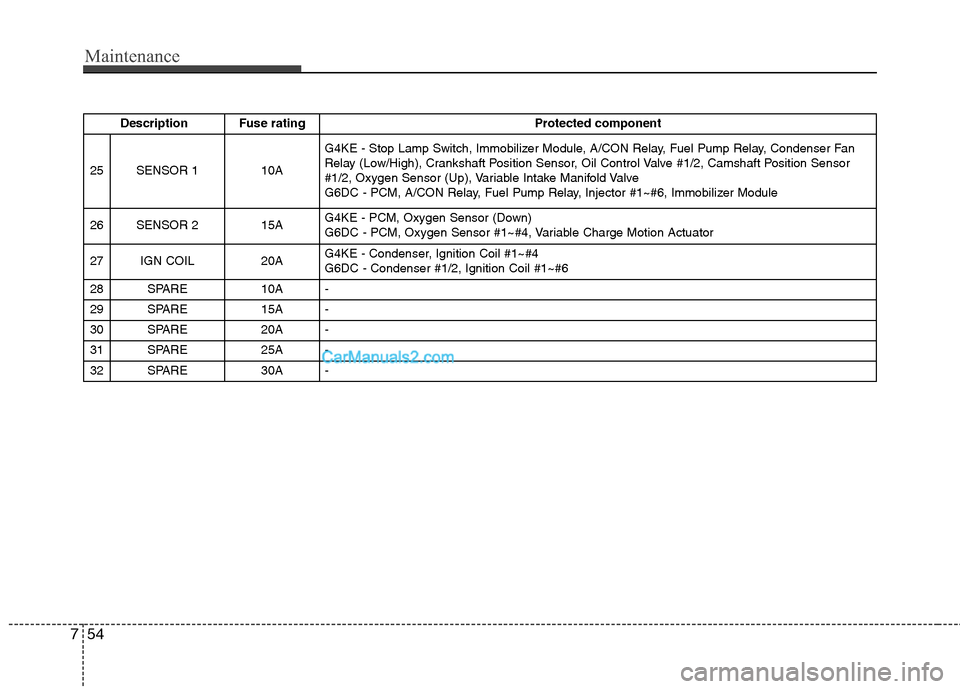

Description Fuse rating Protected component

25 SENSOR 1 10A G4KE - Stop Lamp Switch, Immobilizer Module, A/CON Relay, Fuel Pump Relay, Condenser Fan

Relay (Low/High), Crankshaft Position Sensor, Oil Control Valve #1/2, Camshaft Position Sensor

#1/2, Oxygen Sensor (Up), Variable Intake Manifold Valve

G6DC - PCM, A/CON Relay, Fuel Pump Relay, Injector #1~#6, Immobilizer Module

26 SENSOR 2 15A G4KE - PCM, Oxygen Sensor (Down)

G6DC - PCM, Oxygen Sensor #1~#4, Variable Charge Motion Actuator

27 IGN COIL 20A G4KE - Condenser, Ignition Coil #1~#4

G6DC - Condenser #1/2, Ignition Coil #1~#6

28 SPARE 10A -

29 SPARE 15A -

30 SPARE 20A -

31 SPARE 25A -

32 SPARE 30A -

Page 384 of 408

765

Maintenance

B230104AUN

Bright-metal maintenance

To remove road tar and insects, use atar remover, not a scraper or other

sharp object.

To protect the surfaces of bright-metal parts from corrosion, apply a coating of

wax or chrome preservative and rub to

a high luster.

During winter weather or in coastal areas, cover the bright metal parts with

a heavier coating of wax or preserva-

tive. If necessary, coat the parts with

non-corrosive petroleum jelly or other

protective compound.

G230105AUN

Underbody maintenance

Corrosive materials used for ice and

snow removal and dust control may col-

lect on the underbody. If these materials

are not removed, accelerated rusting can

occur on underbody parts such as the

fuel lines, frame, floor pan and exhaust

system, even though they have been

treated with rust protection.

Thoroughly flush the vehicle underbody

and wheel openings with lukewarm or

cold water once a month, after off-road

driving and at the end of each winter. Pay

special attention to these areas because

it is difficult to see all the mud and dirt. It

will do more harm than good to wet down

the road grime without removing it. The

lower edges of doors, rocker panels, and

frame members have drain holes that

should not be allowed to clog with dirt;

trapped water in these areas can cause

rusting.

WARNING

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.

Page 388 of 408

769

Maintenance

EMISSION CONTROL SYSTEM

G270000AFD

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty infor-

mation contained in the Owner’s

Handbook & Warranty Information book-

let in your vehicle.

Your vehicle is equipped with an emis-

sion control system to meet all emission

regulations.

There are three emission control sys-

tems which are as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system

(3) Exhaust emission control system

In order to assure the proper function of

the emission control systems, it is rec-

ommended that you have your car

inspected and maintained by an author-

ized HYUNDAI dealer in accordance with

the maintenance schedule in this manu-

al.Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

To prevent the vehicle from misfir-

ing during dynamometer testing,

turn the Electronic Stability Control

(ESC) system off by pressing the

ESC switch.

After dynamometer testing is com- pleted, turn the ESC system back on

by pressing the ESC switch again.

G270100AUN

1. Crankcase emission control system

The positive crankcase ventilation sys-

tem is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valve

into the induction system.

2. Evaporative emission control(including ORVR: Onboard

Refueling Vapor Recovery)

system

The Evaporative Emission Control

System is designed to prevent fuel vapors

from escaping into the atmosphere.

(The ORVR system is designed to allow

the vapors from the fuel tank to be

loaded into a canister while refueling at

the gas station, preventing the escape of

fuel vapors into the atmosphere.)

G270201AUN

Canister

Fuel vapors generated inside the fuel

tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in the

canister are drawn into the surge tank

through the purge control solenoid valve.

G270202AUN

Purge Control Solenoid Valve (PCSV)

The purge control solenoid valve is con-

trolled by the Engine Control Module

(ECM); when the engine coolant temper-

ature is low during idling, the PCSV clos-

es so that evaporated fuel is not taken

into the engine. After the engine warms-

up during ordinary driving, the PCSV

opens to introduce evaporated fuel to the

engine.

Page 390 of 408

771

Maintenance

G270303BFD

Operating precautions for catalyticconverters (if equipped)

Your vehicle is equipped with a catalytic

converter emission control device.

Therefore, the following precautions

must be observed:

Use only UNLEADED FUEL for gaso- line engine.

Do not operate the vehicle when there are signs of engine malfunction, such

as misfire or a noticeable loss of per-

formance.

Do not misuse or abuse the engine. Examples of misuse are coasting with

the ignition off and descending steep

grades in gear with the ignition off. Do not operate the engine at high idle

speed for extended periods (5 minutes

or more).

Do not modify or tamper with any part of the engine or emission control sys-

tem. All inspections and adjustments

must be made by an authorized

HYUNDAI dealer.

Avoid driving with a very low fuel level. If you run out of gasoline, it could

cause the engine to misfire and result

in excessive loading of the catalytic

converter.

Failure to observe these precautions

could result in damage to the catalytic

converter and to your vehicle.

Additionally, such actions could void your

warranties.

WARNING- Fire

A hot exhaust system can ignite

flammable items under your vehi-

cle. Do not park, idle, or drive the

vehicle over or near flammable

objects, such as dry grass, paper,

leaves, etc.

Page 395 of 408

Specifications, Consumer information, Reporting safety defects

4

8

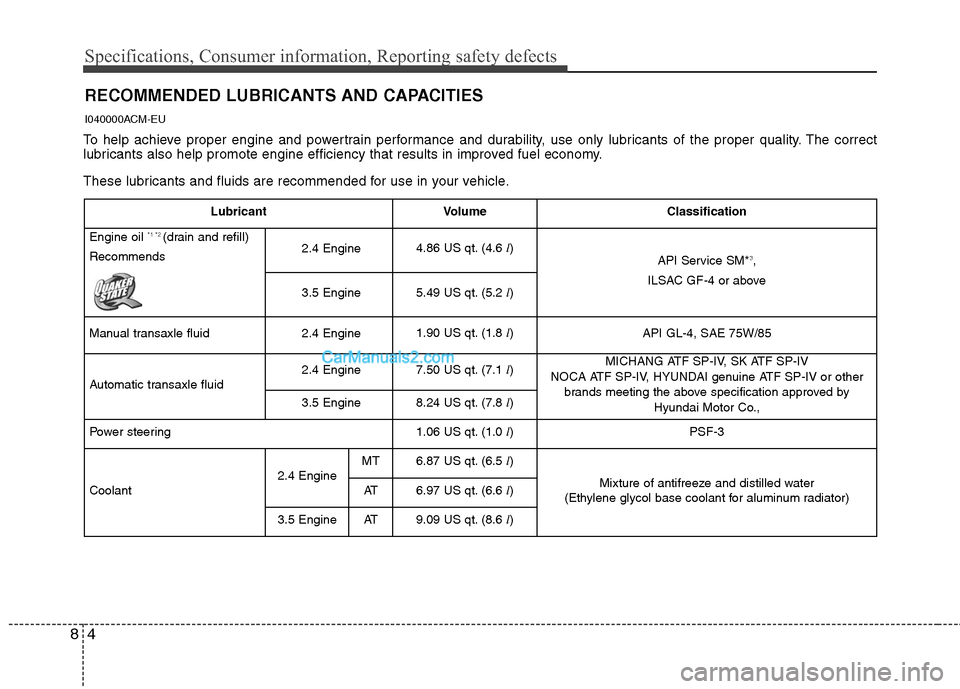

RECOMMENDED LUBRICANTS AND CAPACITIES

To help achieve proper engine and powertrain performance and durability, use only lubricants of the proper quality. The correct

lubricants also help promote engine efficiency that results in improved fuel economy.

These lubricants and fluids are recommended for use in your vehicle.

I040000ACM-EU

LubricantVolumeClassification

Engine oil *1 *2 (drain and refill)

Recommends2.4 Engine4.86 US qt. (4.6 l)API Service SM*3,

ILSAC GF-4 or above

3.5 Engine5.49 US qt. (5.2 l)

Manual transaxle fluid2.4 Engine1.90 US qt. (1.8 l)API GL-4, SAE 75W/85

Automatic transaxle fluid2.4 Engine7.50 US qt. (7.1 l)MICHANG ATF SP-IV, SK ATF SP-IV

NOCA ATF SP-IV, HYUNDAI genuine ATF SP-IV or other brands meeting the above specification approved by Hyundai Motor Co.,

3.5 Engine8.24 US qt. (7.8 l)

Power steering1.06 US qt. (1.0 l)PSF-3

Coolant 2.4 EngineMT6.87 US qt. (6.5 l)

Mixture of antifreeze and distilled water

(Ethylene glycol base coolant for aluminum radiator)AT6.97 US qt. (6.6 l)

3.5 EngineAT9.09 US qt. (8.6 l)