service Hyundai Santa Fe 2017 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2017, Model line: Santa Fe, Model: Hyundai Santa Fe 2017Pages: 569, PDF Size: 16.88 MB

Page 453 of 569

75

Maintenance

Owner maintenance precau-

tions

Improper or incomplete service may

result in problems. This section gives

instructions only for the maintenance

items that are easy to perform.

As explained earlier in this section,

several procedures can be done only

by an authorized HYUNDAI dealer

with special tools.

✽ ✽NOTICE

Improper owner maintenance dur-

ing the warranty period may affect

warranty coverage. For details, read

the separate Owner’s Handbook &

Warranty Information booklet pro-

vided with the vehicle. If you're

unsure about any servicing or main-

tenance procedure, have it done by

an authorized HYUNDAI dealer.

WARNING- Maintenance

work

Performing maintenance work on a vehicle can be danger-

ous. You can be seriously

injured while performing some

maintenance procedures. If

you lack sufficient knowledge

and experience or the proper

tools and equipment to do the

work, have it done by an

authorized HYUNDAI dealer.

Working under the hood with the engine running is danger-

ous. It becomes even more

dangerous when you wear

jewelry or loose clothing.

These can become entangled

in moving parts and result in

injury. Therefore, if you must

run the engine while working

under the hood, make certain

that you remove all jewelry

(especially rings, bracelets,

watches, and necklaces) and

all neckties, scarves, and sim-

ilar loose clothing before get-

ting near the engine or cooling

fans.

Page 456 of 569

Maintenance

87

SCHEDULED MAINTENANCE SERVICE

Follow Normal Maintenance

Schedule if the vehicle is usually

operated where none of the following

conditions apply. If any of the follow-

ing conditions apply, follow

Maintenance Under Severe Usage

Conditions.

Repeated short distance driving.

Driving in dusty conditions orsandy areas.

Extensive use of brakes.

Driving in areas where salt or other corrosive materials are being used.

Driving on rough or muddy roads.

Driving in mountainous areas.

Extended periods of idling or low speed operation.

Driving for a prolonged period in cold temperatures and/or extreme-

ly humid climates.

More than 50% driving in heavy city traffic during hot weather

above 90°F (32°C).If your vehicle is operated under theabove conditions, you shouldinspect, replace or refill more fre-quently than the following NormalMaintenance Schedule. After 120months or 150,000 miles (240,000km) continue to follow the prescribedmaintenance intervals.

Page 457 of 569

79

Maintenance

NORMAL MAINTENANCE SCHEDULE

The following maintenance services must be performed to ensure good emission control and performance.

Keep receipts for all vehicle emission services to protect your warranty. Where both mileage and time are shown, the

frequency of service is determined by whichever occurs first.

*

1: If TOP TIER Detergent Gasoline is not available, onebottle of additive is recommended. Additives are avail-

able from your authorized HYUNDAI dealer along with

information on how to use them. Do not mix other

additives.

*

2: Fuel filter & Fuel tank air filter are considered to be maintenance free but periodic inspection is recom-

mended for this maintenance schedule depends on

fuel quality. If there are some important safety matters

like fuel flow restriction, surging, loss of power, hard

starting problem etc, replace the fuel filter immediate-

ly regardless of maintenance schedule and consult an

authorized HYUNDAI dealer for details. *

3: Transfer case oil and rear axle oil should be changed

anytime they have been submerged in water.

*

4: Inspect for excessive tappet noise and/or engine vibration and adjust if necessary.

*

5: The drive belt should be replaced when cracks occur or tension is reduced excessively.

Page 471 of 569

723

Maintenance

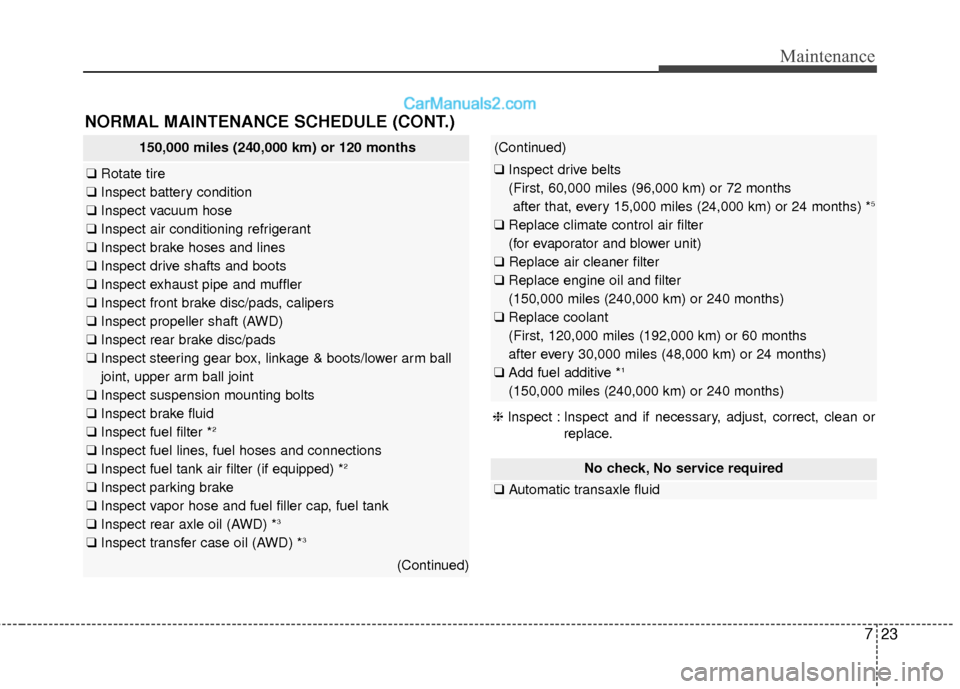

NORMAL MAINTENANCE SCHEDULE (CONT.)

No check, No service required

❑Automatic transaxle fluid

150,000 miles (240,000 km) or 120 months

❑Rotate tire

❑ Inspect battery condition

❑ Inspect vacuum hose

❑ Inspect air conditioning refrigerant

❑ Inspect brake hoses and lines

❑ Inspect drive shafts and boots

❑ Inspect exhaust pipe and muffler

❑ Inspect front brake disc/pads, calipers

❑ Inspect propeller shaft (AWD)

❑ Inspect rear brake disc/pads

❑ Inspect steering gear box, linkage & boots/lower arm ball

joint, upper arm ball joint

❑ Inspect suspension mounting bolts

❑ Inspect brake fluid

❑ Inspect fuel filter *

2

❑Inspect fuel lines, fuel hoses and connections

❑ Inspect fuel tank air filter (if equipped) *2

❑Inspect parking brake

❑ Inspect vapor hose and fuel filler cap, fuel tank

❑ Inspect rear axle oil (AWD) *

3

❑Inspect transfer case oil (AWD) *3

(Continued)

(Continued)

❑Inspect drive belts

(First, 60,000 miles (96,000 km) or 72 months

after that, every 15,000 miles (24,000 km) or 24 months) *

5

❑ Replace climate control air filter

(for evaporator and blower unit)

❑ Replace air cleaner filter

❑ Replace engine oil and filter

(150,000 miles (240,000 km) or 240 months)

❑ Replace coolant

(First, 120,000 miles (192,000 km) or 60 months

after every 30,000 miles (48,000 km) or 24 months)

❑ Add fuel additive *

1

(150,000 miles (240,000 km) or 240 months)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 472 of 569

Maintenance

24

7

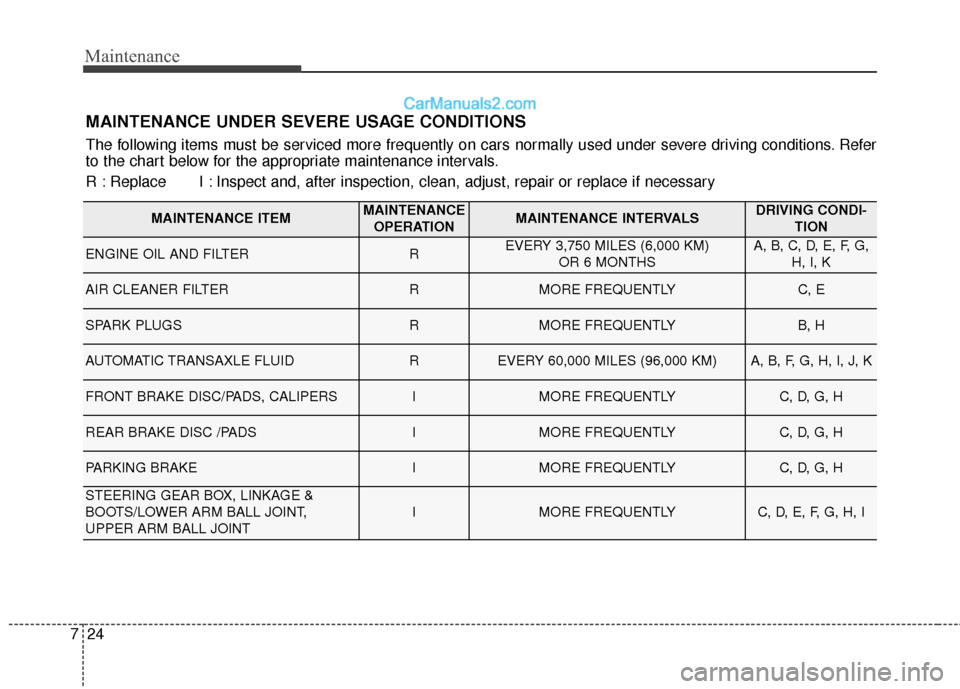

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer

to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if neces\

sary

MAINTENANCE ITEMMAINTENANCE

OPERATIONMAINTENANCE INTERVALSDRIVING CONDI- TION

ENGINE OIL AND FILTER REVERY 3,750 MILES (6,000 KM) OR 6 MONTHSA, B, C, D, E, F, G,H, I, K

AIR CLEANER FILTERRMORE FREQUENTLYC, E

SPARK PLUGSRMORE FREQUENTLYB, H

AUTOMATIC TRANSAXLE FLUIDREVERY 60,000 MILES (96,000 KM) A, B, F, G, H, I, J, K

FRONT BRAKE DISC/PADS, CALIPERSIMORE FREQUENTLYC, D, G, H

REAR BRAKE DISC /PADSIMORE FREQUENTLYC, D, G, H

PARKING BRAKEIMORE FREQUENTLYC, D, G, H

STEERING GEAR BOX, LINKAGE &

BOOTS/LOWER ARM BALL JOINT,

UPPER ARM BALL JOINT

IMORE FREQUENTLYC, D, E, F, G, H, I

Page 493 of 569

745

Maintenance

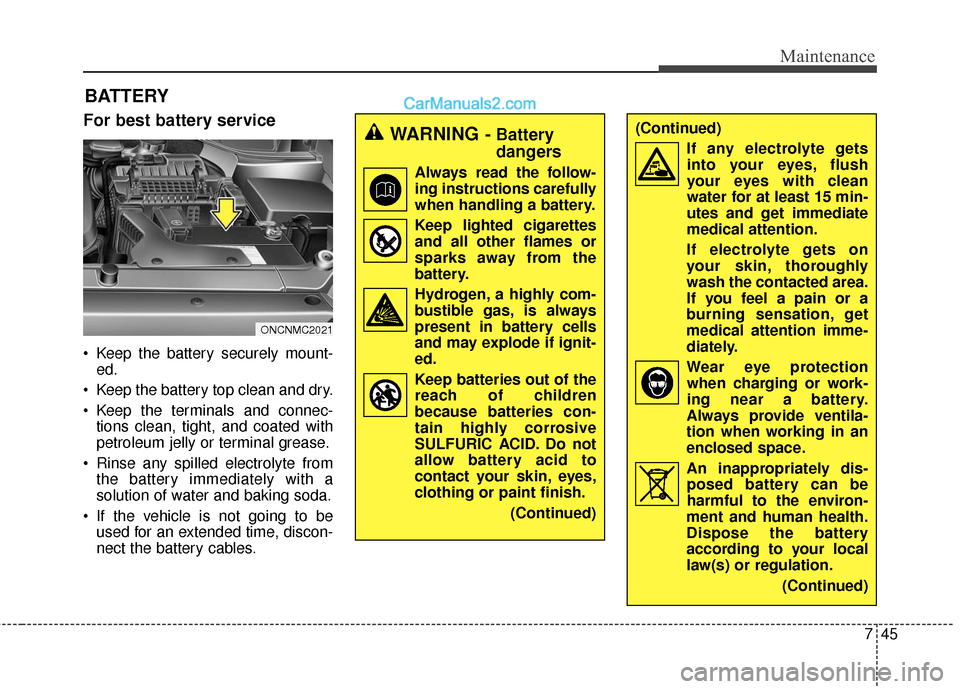

BATTERY

For best battery service

Keep the battery securely mount-ed.

Keep the battery top clean and dry.

Keep the terminals and connec- tions clean, tight, and coated with

petroleum jelly or terminal grease.

Rinse any spilled electrolyte from the battery immediately with a

solution of water and baking soda.

If the vehicle is not going to be used for an extended time, discon-

nect the battery cables.

WARNING- Battery dangers

Always read the follow-

ing instructions carefully

when handling a battery.

Keep lighted cigarettes and all other flames or

sparks away from the

battery.

Hydrogen, a highly com- bustible gas, is always

present in battery cells

and may explode if ignit-

ed.

Keep batteries out of the reach of children

because batteries con-

tain highly corrosive

SULFURIC ACID. Do not

allow battery acid to

contact your skin, eyes,

clothing or paint finish.

(Continued)

(Continued)If any electrolyte getsinto your eyes, flush

your eyes with clean

water for at least 15 min-

utes and get immediate

medical attention.

If electrolyte gets on your skin, thoroughly

wash the contacted area.

If you feel a pain or a

burning sensation, get

medical attention imme-

diately.

Wear eye protection when charging or work-

ing near a battery.

Always provide ventila-

tion when working in an

enclosed space.

An inappropriately dis- posed battery can be

harmful to the environ-

ment and human health.

Dispose the battery

according to your local

law(s) or regulation.

(Continued)

ONCNMC2021

Page 504 of 569

Maintenance

56

7

4. Tire ply composition and mate-

rial

The number of layers or plies of rub-

ber-coated fabric in the tire. Tire

manufacturers also must indicate the

materials in the tire, which include

steel, nylon, polyester, and others.

The letter "R" means radial ply con-

struction; the letter "D" means diago-

nal or bias ply construction; and the

letter "B" means belted-bias ply con-

struction.

5. Maximum permissible inflationpressure

This number is the greatest amount

of air pressure that should be put in

the tire. Do not exceed the maximum

permissible inflation pressure. Refer

to the Tire and Loading Information

label for recommended inflation

pressure.

6. Maximum load rating

This number indicates the maximum

load in kilograms and pounds that can

be carried by the tire. When replacing

the tires on the vehicle, always use a

tire that has the same load rating as

the factory installed tire.

7. Uniform tire quality grading

Quality grades can be found where

applicable on the tire sidewall

between tread shoulder and maxi-

mum section width.

For example:

TREADWEAR 200

TRACTION AA

TEMPERATURE A

WARNING - Tire age

Tires degrade over time, even

when they are not being used.

Regardless of the remaining

tread, it is recommended that

tires generally be replaced after

six (6) years of normal service.

Heat caused by not climates or

frequent high loading conditions

can accelerate the aging

process. Failure to follow this

Warning can result in sudden

tire failure, which could lead to a

loss of control and an accident

involving serious injury or death.

Page 505 of 569

757

Maintenance

Tread wear

The tread wear grade is a compara-

tive rating based on the wear rate of

the tire when tested under controlled

conditions on a specified govern-

ment test course. For example, a tire

graded 150 would wear one-and-a-

half times (1½) as well on the gov-

ernment course as a tire graded 100.

The relative performance of tires

depends upon the actual conditions

of their use, however, and may

depart significantly from the norm

because of variations in driving

habits, service practices and differ-

ences in road characteristics and cli-

mate.

These grades are molded on the

side-walls of passenger vehicle tires.

The tires available as standard or

optional equipment on your vehicle

may vary with respect to grade.Traction - AA, A, B & C

The traction grades, from highest to

lowest, are AA, A, B and C. Those

grades represent the tires ability to

stop on wet pavement as measured

under controlled conditions on speci-

fied government test surfaces of

asphalt and concrete. A tire marked C

may have poor traction performance.

Temperature -A, B & C

The temperature grades are A (the

highest), B and C representing the

tire’s resistance to the generation of

heat and its ability to dissipate heat

when tested under controlled condi-

tions on a specified indoor laboratory

test wheel.

Sustained high temperature can

cause the material of the tire to

degenerate and reduce tire life, and

excessive temperature can lead to

sudden tire failure. The Grade C cor-

responds to a level of performance

which all passenger car tires must

meet under the Federal Motor

Vehicle Safety Standard NO. 109.

Grades B and A represent higher

levels of performance on the labora-

tory test wheel than the minimum

required by the law.

WARNING

The traction grade assigned to

this tire is based on straight-

ahead braking traction tests,

and does not include accelera-

tion, cornering, hydroplaning,

or peak traction characteristics.

Page 529 of 569

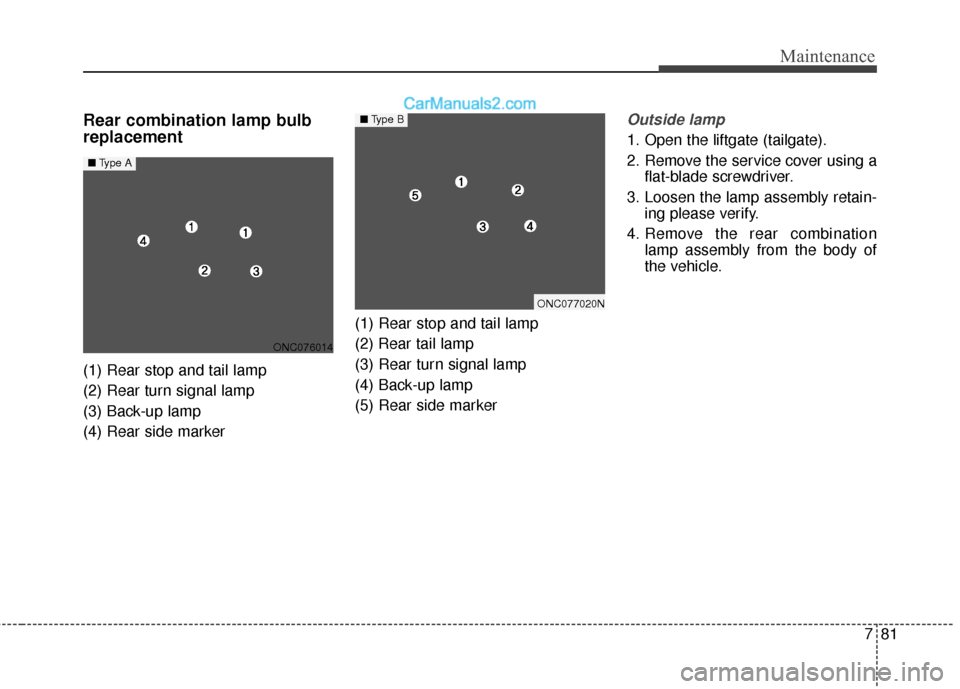

781

Maintenance

Rear combination lamp bulb

replacement

(1) Rear stop and tail lamp

(2) Rear turn signal lamp

(3) Back-up lamp

(4) Rear side marker(1) Rear stop and tail lamp

(2) Rear tail lamp

(3) Rear turn signal lamp

(4) Back-up lamp

(5) Rear side marker

Outside lamp

1. Open the liftgate (tailgate).

2. Remove the service cover using a

flat-blade screwdriver.

3. Loosen the lamp assembly retain- ing please verify.

4. Remove the rear combination lamp assembly from the body of

the vehicle.

ONC076014

ONC077020N

■Type B

■Type A

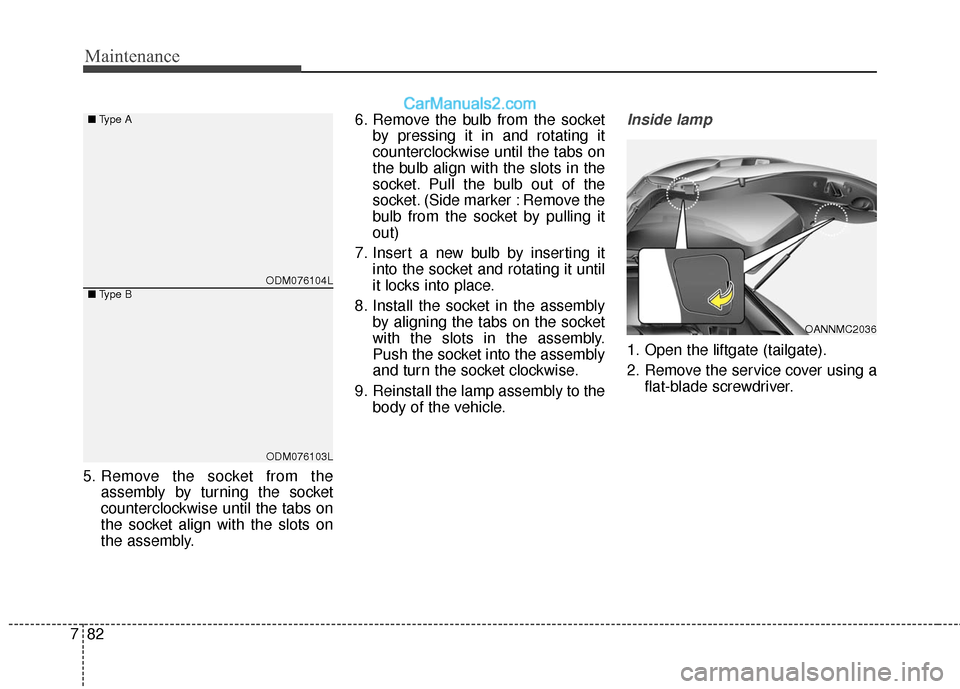

Page 530 of 569

Maintenance

82

7

5. Remove the socket from the

assembly by turning the socket

counterclockwise until the tabs on

the socket align with the slots on

the assembly. 6. Remove the bulb from the socket

by pressing it in and rotating it

counterclockwise until the tabs on

the bulb align with the slots in the

socket. Pull the bulb out of the

socket. (Side marker : Remove the

bulb from the socket by pulling it

out)

7. Insert a new bulb by inserting it into the socket and rotating it until

it locks into place.

8. Install the socket in the assembly by aligning the tabs on the socket

with the slots in the assembly.

Push the socket into the assembly

and turn the socket clockwise.

9. Reinstall the lamp assembly to the body of the vehicle.

Inside lamp

1. Open the liftgate (tailgate).

2. Remove the service cover using aflat-blade screwdriver.

OANNMC2036

ODM076104L

ODM076103L

■

Type A

■ Type B