oil Hyundai Sonata

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: , Model line: , Model:Pages: 340, PDF Size: 18.45 MB

Page 306 of 340

763

Maintenance

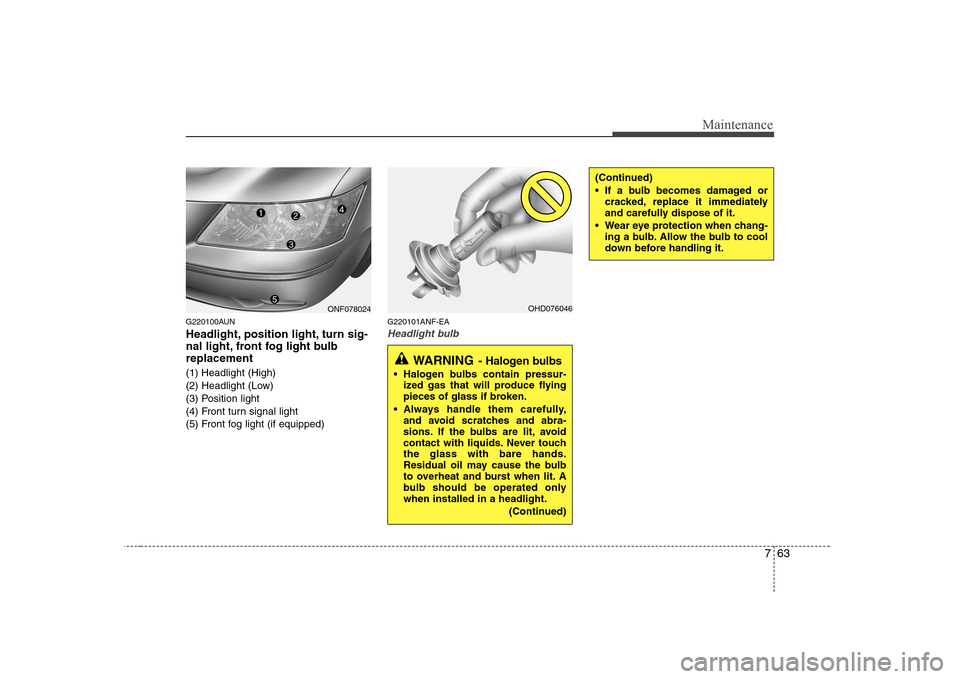

G220100AUN

Headlight, position light, turn sig-

nal light, front fog light bulbreplacement

(1) Headlight (High)

(2) Headlight (Low)

(3) Position light

(4) Front turn signal light

(5) Front fog light (if equipped)G220101ANF-EA

Headlight bulb

OHD076046

WARNING

- Halogen bulbs

Halogen bulbs contain pressur-

ized gas that will produce flying

pieces of glass if broken.

Always handle them carefully, and avoid scratches and abra-

sions. If the bulbs are lit, avoid

contact with liquids. Never touchthe glass with bare hands.

Residual oil may cause the bulb

to overheat and burst when lit. A

bulb should be operated onlywhen installed in a headlight.

(Continued)

(Continued)

If a bulb becomes damaged orcracked, replace it immediately

and carefully dispose of it.

Wear eye protection when chang- ing a bulb. Allow the bulb to cool

down before handling it.

ONF078024

Page 311 of 340

Maintenance

68

7

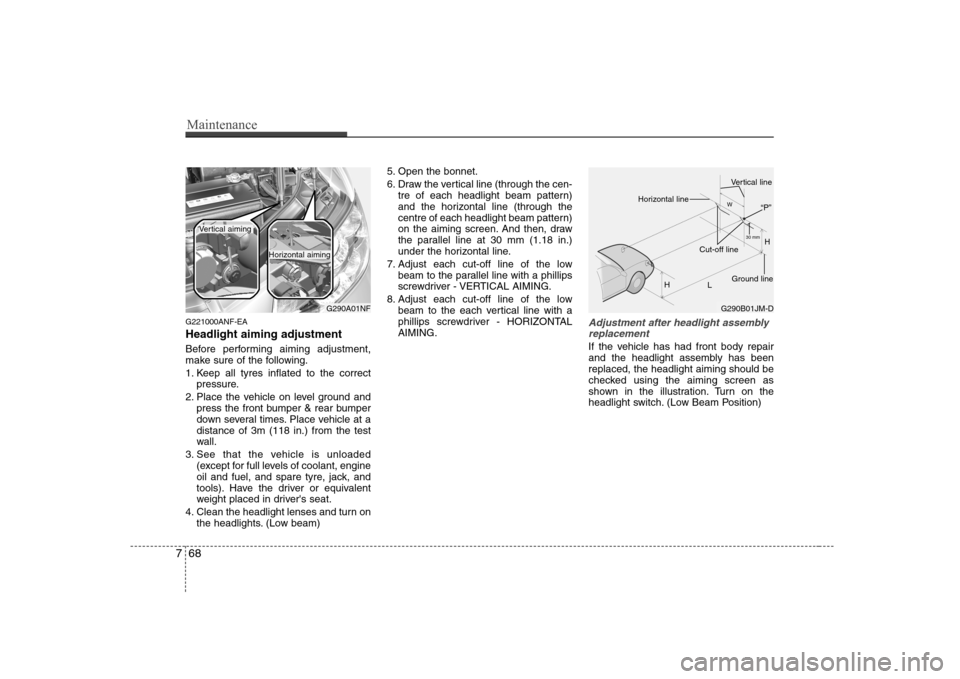

G221000ANF-EA Headlight aiming adjustment

Before performing aiming adjustment,

make sure of the following.

1. Keep all tyres inflated to the correct

pressure.

2. Place the vehicle on level ground and press the front bumper & rear bumper

down several times. Place vehicle at adistance of 3m (118 in.) from the test

wall.

3. See that the vehicle is unloaded (except for full levels of coolant, engine

oil and fuel, and spare tyre, jack, and

tools). Have the driver or equivalent

weight placed in driver's seat.

4. Clean the headlight lenses and turn on the headlights. (Low beam) 5. Open the bonnet.

6. Draw the vertical line (through the cen-

tre of each headlight beam pattern)

and the horizontal line (through the

centre of each headlight beam pattern)

on the aiming screen. And then, draw

the parallel line at 30 mm (1.18 in.)

under the horizontal line.

7. Adjust each cut-off line of the low beam to the parallel line with a phillips

screwdriver - VERTICAL AIMING.

8. Adjust each cut-off line of the low beam to the each vertical line with a

phillips screwdriver - HORIZONTALAIMING.Adjustment after headlight assembly

replacement

If the vehicle has had front body repair

and the headlight assembly has beenreplaced, the headlight aiming should be

checked using the aiming screen as

shown in the illustration. Turn on the

headlight switch. (Low Beam Position)

G290A01NF

Vertical aiming

Horizontal aiming

G290B01JM-D H

H L30 mm

W

Horizontal line

Vertical line

“P”

Ground line

Cut-off line

Page 314 of 340

771

Maintenance

Waxing

Wax the vehicle when water will no longer bead on the paint.

Always wash and dry the vehicle before

waxing. Use a good quality liquid or

paste wax, and follow the manufacturer’s

instructions. Wax all metal trim to protect

it and to maintain its luster.

Removing oil, tar, and similar materials

with a spot remover will usually strip the

wax from the finish. Be sure to re-wax

these areas even if the rest of the vehicle

does not yet need waxing.G230103AUN

Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly rust

and may develop into a major repair

expense.

✽✽

NOTICE

If your vehicle is damaged and requires

any metal repair or replacement, be sure

the body shop applies anti-corrosion

materials to the parts repaired or

replaced.

B230104AUN

Bright-metal maintenance

To remove road tar and insects, use a tar remover, not a scraper or other

sharp object.

To protect the surfaces of bright-metal parts from corrosion, apply a coating of

wax or chrome preservative and rub to

a high luster.

During winter weather or in coastal areas, cover the bright metal parts with

a heavier coating of wax or preserva-

tive. If necessary, coat the parts with

non-corrosive petroleum jelly or other

protective compound.

CAUTION

Wiping dust or dirt off the body

with a dry cloth will scratch thefinish.

Do not use steel wool, abrasive cleaners, or strong detergentscontaining high alkaline or caus- tic agents on chrome-plated oranodized aluminium parts. This

may result in damage to the pro- tective coating and cause discol-oration or paint deterioration.

Page 318 of 340

775

Maintenance

Interior care

G230201AUN

Interior general precautions

Prevent caustic solutions such as per- fume and cosmetic oil from contacting

the dashboard because they may cause

damage or discoloration. If they do con-tact the dashboard, wipe them off imme-

diately. See the instructions that follow for

the proper way to clean vinyl.G230202AUN-EA

Cleaning the upholstery and interior

trim

Vinyl

Remove dust and loose dirt from vinyl

with a whisk broom or vacuum cleaner.

Clean vinyl surfaces with a vinyl cleaner. Fabric

Remove dust and loose dirt from fabric

with a whisk broom or vacuum cleaner.Clean with a mild soap solution recom-

mended for upholstery or carpets.

Remove fresh spots immediately with a

fabric spot cleaner. If fresh spots do not

receive immediate attention, the fabriccan be stained and its colour can be

affected. Also, its fire-resistant properties

can be reduced if the material is not

properly maintained. G230203AUN

Cleaning the lap/shoulder belt web-

bing

Clean the belt webbing with any mild

soap solution recommended for cleaning

upholstery or carpet. Follow the instruc-

tions provided with the soap. Do not

bleach or re-dye the webbing because

this may weaken it.

G230204AUN

Cleaning the interior window glass

If the interior glass surfaces of the vehi-

cle become fogged (that is, covered with

an oily, greasy or waxy film), they should

be cleaned with glass cleaner. Follow the

directions on the glass cleaner container.CAUTION

Never allow water or other liquidsto come in contact with electrical/electronic components

inside the vehicle as this may dam-age them.

CAUTION

Using anything but recommendedcleaners and procedures may affect

the fabric’s appearance and fire-resistant properties.

CAUTION

Do not scrape or scratch the inside of the rear window. This may resultin damage to the rear window defroster grid.

Page 328 of 340

Specifications

4

9

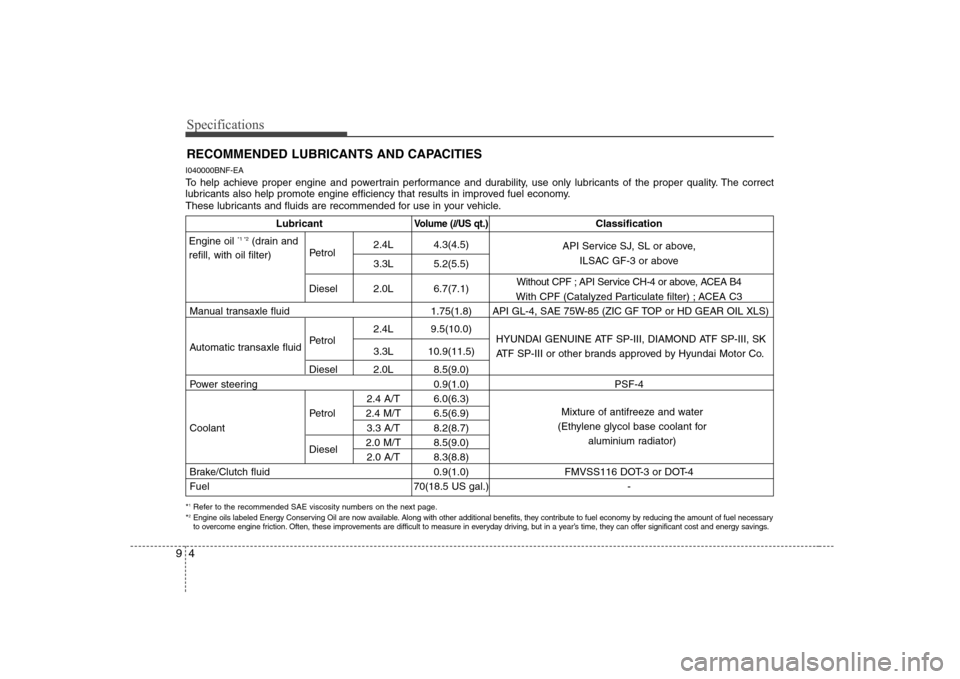

RECOMMENDED LUBRICANTS AND CAPACITIES

I040000BNF-EA

To help achieve proper engine and powertrain performance and durability, use only lubricants of the proper quality. The correct

lubricants also help promote engine efficiency that results in improved fuel economy.

These lubricants and fluids are recommended for use in your vehicle.

LubricantVolume ( l/US qt.)Classification

API Service SJ, SL or above,

Petrol 2.4L 4.3(4.5)

ILSAC GF-3 or above

3.3L 5.2(5.5)

Diesel 2.0L 6.7(7.1)

Without CPF ; API Service CH-4 or above, ACEA B4

With CPF (Catalyzed Particulate filter) ; ACEA C3

Manual transaxle fluid 1.75(1.8) API GL-4, SAE 75W-85 (ZIC GF TOP or HD GEAR OIL XLS)

Automatic transaxle fluid Petrol2.4L 9.5(10.0)

3.3L 10.9(11.5)

Diesel 2.0L 8.5(9.0)

Power steering 0.9(1.0) PSF-4

2.4 A/T 6.0(6.3)

Petrol 2.4 M/T 6.5(6.9)

Coolant 3.3 A/T 8.2(8.7)

Diesel2.0 M/T 8.5(9.0)

2.0 A/T 8.3(8.8)

Brake/Clutch fluid 0.9(1.0) FMVSS116 DOT-3 or DOT-4 Fuel 70(18.5 US gal.) -

Engine oil *1 *2

(drain and

refill, with oil filter)

HYUNDAI GENUINE ATF SP-III, DIAMOND ATF SP-III, SK

ATF SP-III or other brands approved by Hyundai Motor Co.

Mixture of antifreeze and water

(Ethylene glycol base coolant for aluminium radiator)

* 1

Refer to the recommended SAE viscosity numbers on the next page.

* 2

Engine oils labeled Energy Conserving Oil are now available. Along with other additional benefits, they contribute to fuel econo

my by reducing the amount of fuel necessary

to overcome engine friction. Often, these improvements are difficult to measure in everyday driving, but in a year’s time, they can offer significant cost and energy savings.

Page 329 of 340

95

Specifications

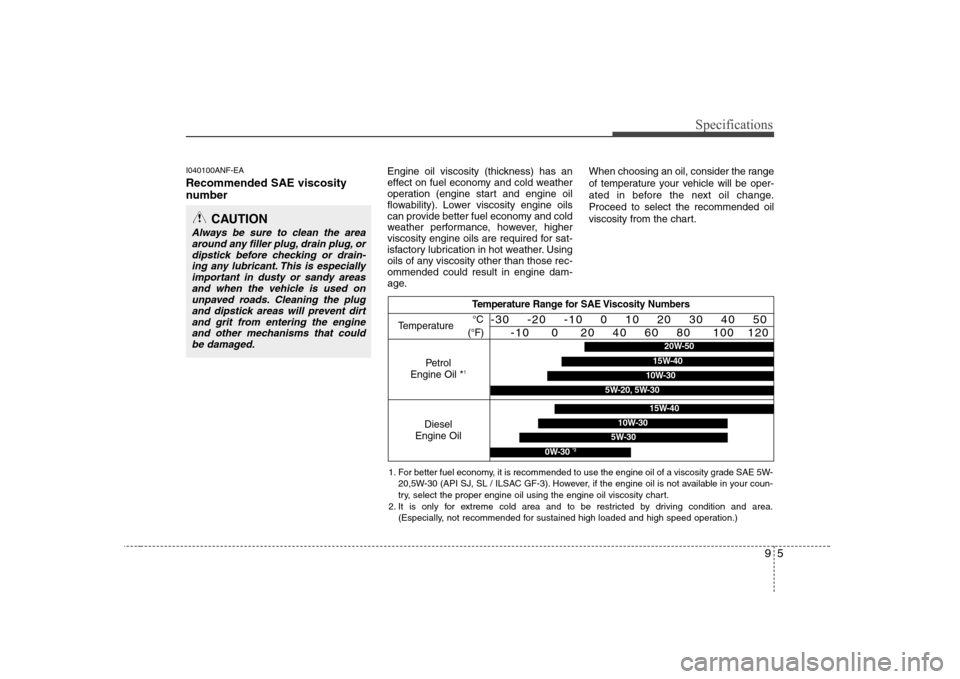

I040100ANF-EA Recommended SAE viscosity

number Engine oil viscosity (thickness) has an

effect on fuel economy and cold weather

operation (engine start and engine oil

flowability). Lower viscosity engine oils

can provide better fuel economy and cold

weather performance, however, higher

viscosity engine oils are required for sat-

isfactory lubrication in hot weather. Using

oils of any viscosity other than those rec-ommended could result in engine dam-

age.When choosing an oil, consider the range

of temperature your vehicle will be oper-

ated in before the next oil change.Proceed to select the recommended oil

viscosity from the chart.

CAUTION

Always be sure to clean the area

around any filler plug, drain plug, ordipstick before checking or drain-

ing any lubricant. This is especiallyimportant in dusty or sandy areas and when the vehicle is used onunpaved roads. Cleaning the plug

and dipstick areas will prevent dirtand grit from entering the engineand other mechanisms that could

be damaged.

Temperature Range for SAE Viscosity Numbers

Temperature

Petrol

Engine Oil *

1

°C

(°F)-30 -20 -10 0 10 20 30 40 50 -10 0 20 40 60 80 100 120

Diesel

Engine Oil

5W-30

15W-40

10W-30

0W-30 *2

1. For better fuel economy, it is recommended to use the engine oil of a viscosity grade SAE 5W-

20,5W-30 (API SJ, SL / ILSAC GF-3). However, if the engine oil is not available in your coun-

try, select the proper engine oil using the engine oil viscosity chart.

2. It is only for extreme cold area and to be restricted by driving condition and area. (Especially, not recommended for sustained high loaded and high speed operation.)

20W-50

10W-30

15W-40

5W-20, 5W-30

Page 338 of 340

Index

2

I

Air cleaner ··································································· 7-34

Airbag-supplemental restraint system ························· 3-29

Appearance care ·························································· 7-70

Audio system ······························································· 4-87

Automatic climate control system ······························· 4-70

Automatic transaxle ····················································· 5-11

Automatic transaxle fluid ············································ 7-30

Battery ········································································· 7-40

Before driving ································································ 5-3

Bonnet ·········································································· 4-18

Boot ············································································· 4-12

Brake and clutch fluid ················································· 7-28

Brake system ······························································· 5-17

Bulb wattage ·································································· 9-2

Child restraint system ·················································· 3-23

Climate control air filter ·············································· 7-36

Cruise control system ·················································· 5-28 Defroster ······································································ 4-59

Dimensions ···································································· 9-2

Door locks ····································································· 4-8

Economical operation ·················································· 5-32

Emergency starting ························································ 6-4

Emission control system ·············································· 7-76

Engine compartment ······················································ 7-2

Engine coolant ····························································· 7-25

Engine number ······························································· 8-3

Engine oil ····································································· 7-24

Explanation of scheduled maintenance items ············· 7-21

Fuel filler lid ································································ 4-20

Fuel filter ····································································· 7-33

Fuel requirements ·························································· 1-2

Fuses ············································································ 7-53

A

B

C

D

E

F