service Hyundai Sonata

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: , Model line: , Model:Pages: 363, PDF Size: 30.3 MB

Page 282 of 363

Maintenance

6

7

SCHEDULED MAINTENANCE SERVICE

At least once a year:

Clean body and door drain holes.

Lubricate door hinges and checks, and

bonnet hinges.

Lubricate door and bonnet locks and latches.

Lubricate door rubber weatherstrips.

Check the air conditioning system.

Check the power steering fluid level.

Inspect and lubricate automatic transaxle linkage and controls.

Clean battery and terminals.

Check the brake (and clutch) fluid level. Follow Normal Maintenance Schedule if

the vehicle is usually operated where

none of the following conditions apply. If

any of the following conditions apply, fol-

low Maintenance Under Severe Usage

Conditions.

Repeated short distance driving.

Driving in dusty conditions or sandy

areas.

Extensive use of brakes.

Driving in areas where salt or other corrosive materials are being used.

Driving on rough or muddy roads.

Driving in mountainous areas.

Extended periods of idling or low speed operation.

Driving for a prolonged period in cold temperatures and/or extremely humid

climates.

More than 50% driving in heavy city traffic during hot weather above 32°C(90°F).

If your vehicle is operated under the

above conditions, you should inspect, replace or refill more frequently than thefollowing Normal Maintenance Schedule.

After 96 months or 120,000 km (80,000miles) continue to follow the prescribedmaintenance intervals.

Page 286 of 363

Maintenance

10

7

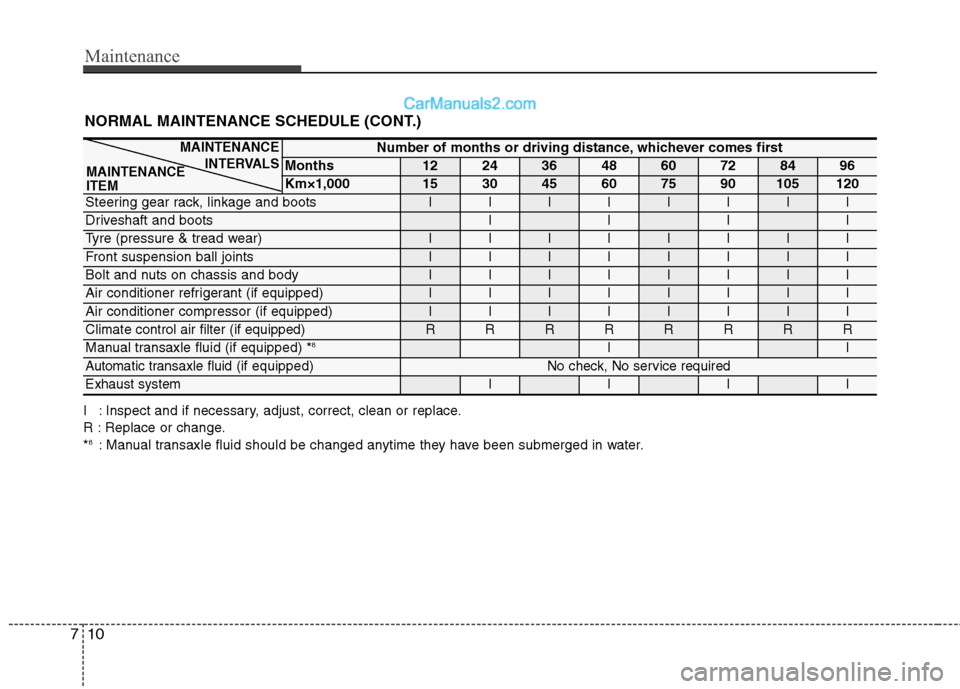

NORMAL MAINTENANCE SCHEDULE (CONT.)

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.* 8

: Manual transaxle fluid should be changed anytime they have been submerged in water.

Number of months or driving distance, whichever comes first

Months1224364860728496

Km×1,000153045607590105120

Steering gear rack, linkage and bootsIIIIIIII

Driveshaft and bootsIIII

Tyre (pressure & tread wear) IIIIIIII

Front suspension ball jointsIIIIIIII

Bolt and nuts on chassis and bodyIIIIIIII

Air conditioner refrigerant (if equipped)IIIIIIII

Air conditioner compressor (if equipped)IIIIIIII

Climate control air filter (if equipped)RRRRRRRR

Manual transaxle fluid (if equipped) * 8II

Automatic transaxle fluid(if equipped) No check, No service required

Exhaust systemIIII

MAINTENANCE

INTERVALS

MAINTENANCE ITEM

Page 287 of 363

711

Maintenance

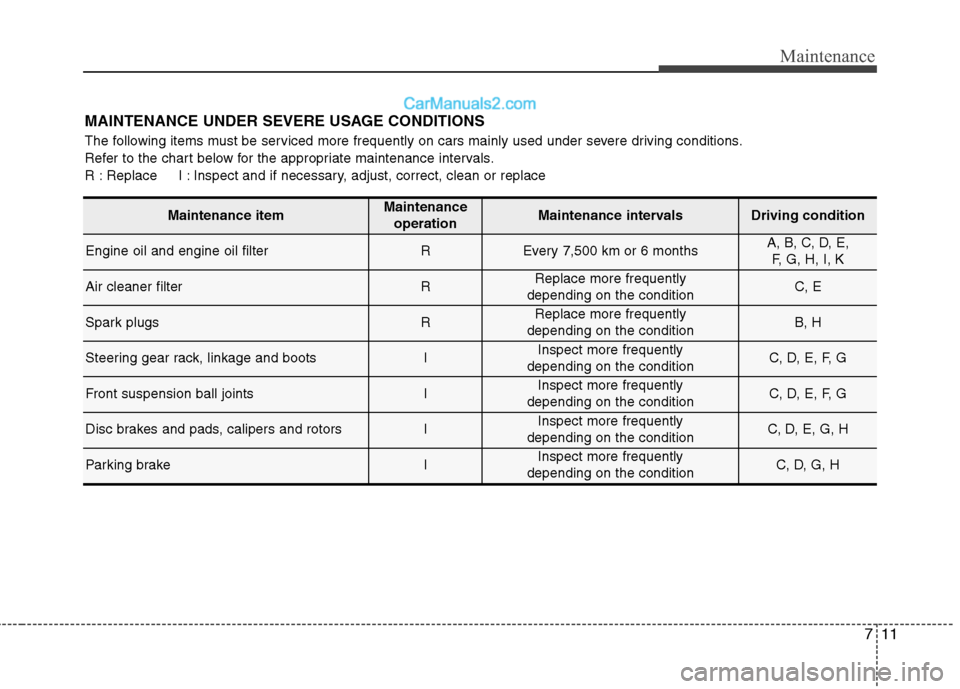

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars mainly used under severe driving conditions.

Refer to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and if necessary, adjust, correct, clean or replace

Maintenance itemMaintenance operationMaintenance intervalsDriving condition

Engine oil and engine oil filterREvery 7,500 km or 6 months A, B, C, D, E, F, G, H, I, K

Air cleaner filterRReplace more frequently

depending on the conditionC, E

Spark plugs RReplace more frequently

depending on the conditionB, H

Steering gear rack, linkage and bootsIInspect more frequently

depending on the conditionC, D, E, F, G

Front suspension ball jointsIInspect more frequently

depending on the conditionC, D, E, F, G

Disc brakes and pads, calipers and rotorsIInspect more frequently

depending on the conditionC, D, E, G, H

Parking brakeIInspect more frequently

depending on the conditionC, D, G, H

Page 307 of 363

731

Maintenance

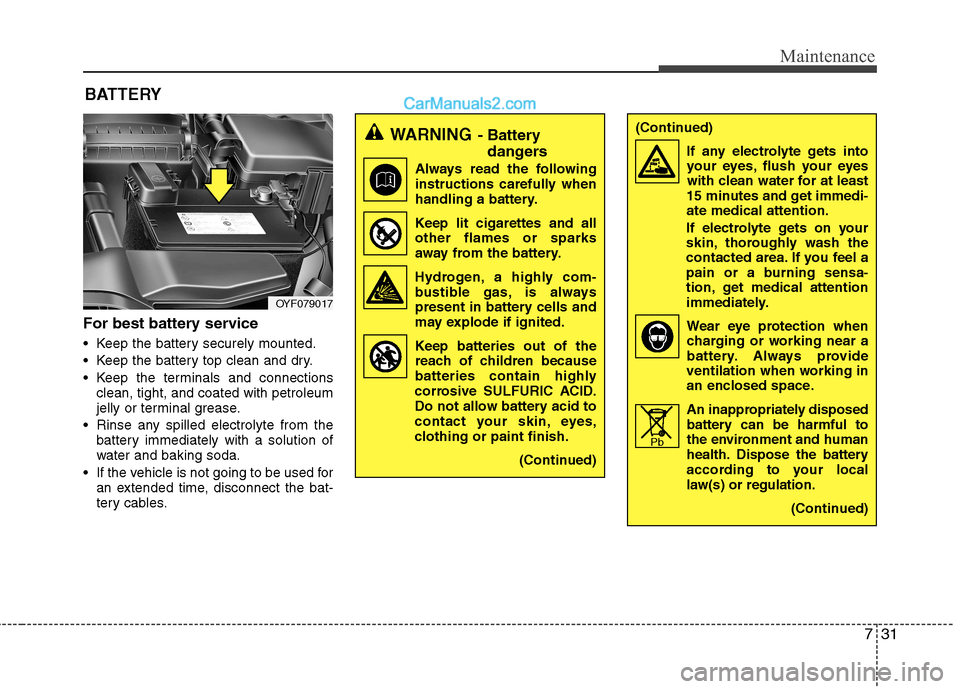

For best battery service

Keep the battery securely mounted.

Keep the battery top clean and dry.

Keep the terminals and connectionsclean, tight, and coated with petroleum

jelly or terminal grease.

Rinse any spilled electrolyte from the battery immediately with a solution of

water and baking soda.

If the vehicle is not going to be used for an extended time, disconnect the bat-

tery cables.

BATTERY

OYF079017

WARNING

- Battery

dangers

Always read the following

instructions carefully when

handling a battery.

Keep lit cigarettes and all other flames or sparks

away from the battery.

Hydrogen, a highly com- bustible gas, is always

present in battery cells and

may explode if ignited.

Keep batteries out of the reach of children because

batteries contain highly

corrosive SULFURIC ACID.

Do not allow battery acid to

contact your skin, eyes,

clothing or paint finish.

(Continued)(Continued)If any electrolyte gets intoyour eyes, flush your eyes

with clean water for at least

15 minutes and get immedi-ate medical attention.

If electrolyte gets on your

skin, thoroughly wash the

contacted area. If you feel a

pain or a burning sensa-

tion, get medical attention

immediately.

Wear eye protection whencharging or working near a

battery. Always provide

ventilation when working in

an enclosed space.

An inappropriately disposed

battery can be harmful to

the environment and human

health. Dispose the battery

according to your local

law(s) or regulation.

(Continued)

Pb

Page 317 of 363

741

Maintenance

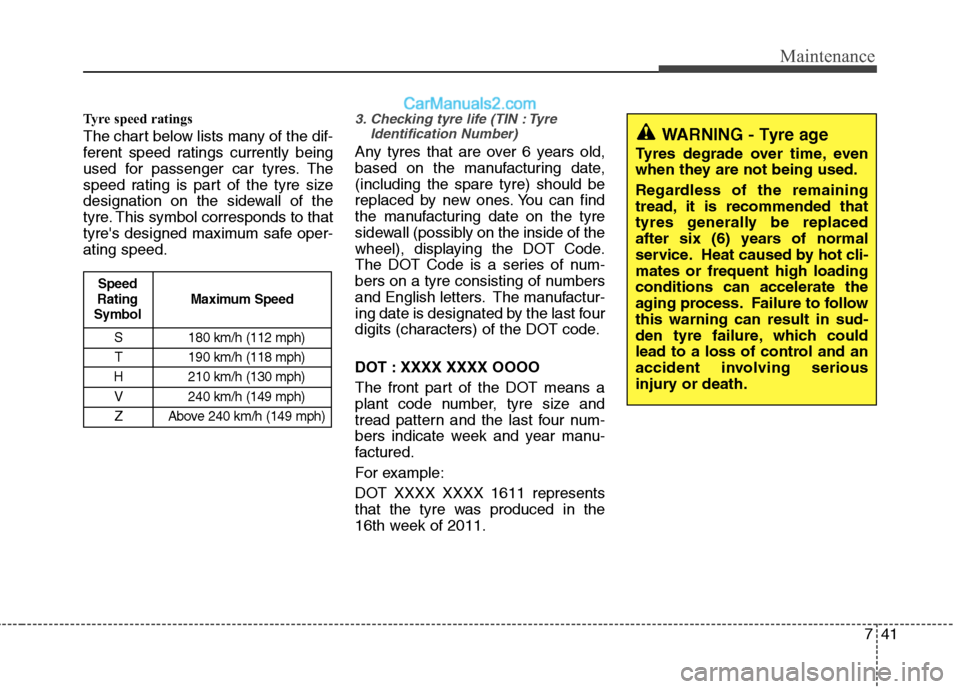

Tyre speed ratings

The chart below lists many of the dif-

ferent speed ratings currently being

used for passenger car tyres. The

speed rating is part of the tyre size

designation on the sidewall of the

tyre. This symbol corresponds to that

tyre's designed maximum safe oper-ating speed.3. Checking tyre life (TIN : TyreIdentification Number)

Any tyres that are over 6 years old,

based on the manufacturing date,(including the spare tyre) should be

replaced by new ones. You can find

the manufacturing date on the tyre

sidewall (possibly on the inside of the

wheel), displaying the DOT Code.

The DOT Code is a series of num-

bers on a tyre consisting of numbers

and English letters. The manufactur-

ing date is designated by the last four

digits (characters) of the DOT code.

DOT : XXXX XXXX OOOO

The front part of the DOT means a

plant code number, tyre size and

tread pattern and the last four num-

bers indicate week and year manu-

factured.

For example:

DOT XXXX XXXX 1611 represents

that the tyre was produced in the

16th week of 2011.

S 180 km/h (112 mph)

T 190 km/h (118 mph)

H 210 km/h (130 mph) V 240 km/h (149 mph)

Z Above 240 km/h (149 mph)

Maximum Speed

Speed

Rating

Symbol

WARNING - Tyre age

Tyres degrade over time, even

when they are not being used.

Regardless of the remaining

tread, it is recommended that

tyres generally be replaced

after six (6) years of normal

service. Heat caused by hot cli-mates or frequent high loadingconditions can accelerate the

aging process. Failure to followthis warning can result in sud-

den tyre failure, which could

lead to a loss of control and an

accident involving serious

injury or death.

Page 318 of 363

Maintenance

42

7

4. Tyre ply composition and material

The number of layers or plies of rub-

ber-coated fabric in the tyre. Tyre

manufacturers also must indicate the

materials in the tyre, which include

steel, nylon, polyester, and others.

The letter "R" means radial ply con-

struction; the letter "D" means diago-

nal or bias ply construction; and theletter "B" means belted-bias ply con-

struction.

5. Maximum permissible inflation

pressure

This number is the greatest amount of air pressure that should be put in

the tyre. Do not exceed the maximum

permissible inflation pressure. Refer

to the Tyre and Loading Information

label for recommended inflation

pressure.

6. Maximum load rating

This number indicates the maximum

load in kilograms and pounds that

can be carried by the tyre. When

replacing the tyres on the vehicle,

always use a tyre that has the same

load rating as the factory installed

tyre.

7. Uniform tyre quality grading

Quality grades can be found where

applicable on the tyre sidewall

between tread shoulder and maxi-

mum section width.

For example:

TREADWEAR 200

TRACTION AA

TEMPERATURE A Tread wear

The tread wear grade is a compara-

tive rating based on the wear rate ofthe tyre when tested under controlled

conditions on a specified govern-

ment test course. For example, a tyre

graded 150 would wear one-and-a-

half times (1½) as well on the gov-

ernment course as a tyre graded100.

The relative performance of tyres depends upon the actual conditions

of their use, however, and may

depart significantly from the norm

due to variations in driving habits,

service practices and differences in

road characteristics and climate.

These grades are molded on the

side-walls of passenger vehicle

tyres. The tyres available as standard

or optional equipment on your vehi-

cle may vary with respect to grade.

Page 335 of 363

759

Maintenance

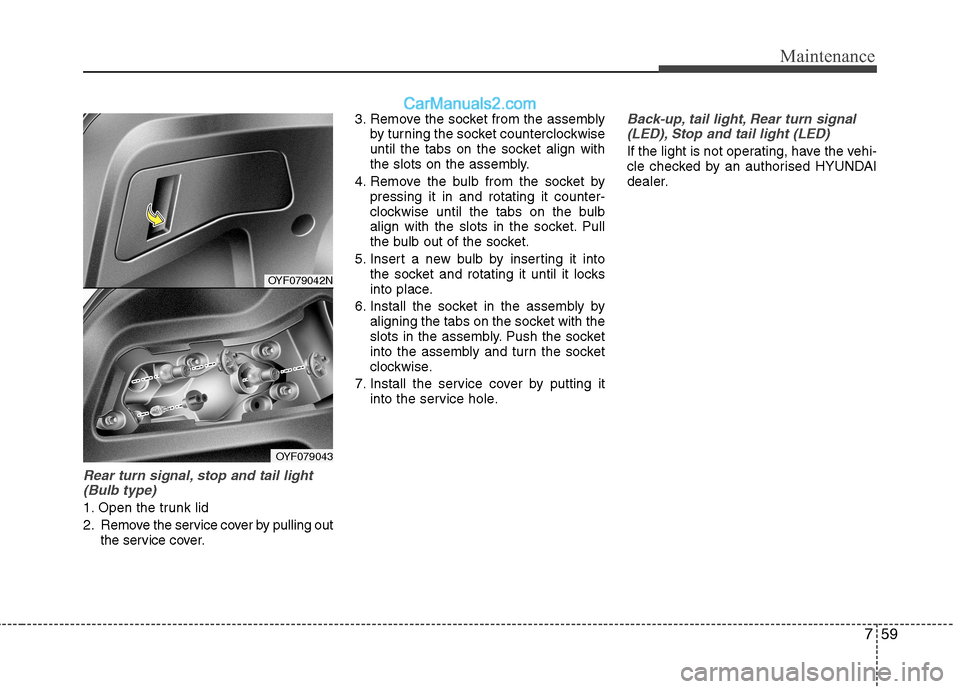

Rear turn signal, stop and tail light(Bulb type)

1. Open the trunk lid

2. Remove the service cover by pulling out the service cover. 3. Remove the socket from the assembly

by turning the socket counterclockwise

until the tabs on the socket align with

the slots on the assembly.

4. Remove the bulb from the socket by pressing it in and rotating it counter-

clockwise until the tabs on the bulb

align with the slots in the socket. Pull

the bulb out of the socket.

5. Insert a new bulb by inserting it into the socket and rotating it until it locks

into place.

6. Install the socket in the assembly by aligning the tabs on the socket with the

slots in the assembly. Push the socket

into the assembly and turn the socket

clockwise.

7. Install the service cover by putting it into the service hole.

Back-up, tail light, Rear turn signal

(LED), Stop and tail light (LED)

If the light is not operating, have the vehi-

cle checked by an authorised HYUNDAI

dealer.

OYF079042N

OYF079043

Page 344 of 363

Maintenance

68

7

EMISSION CONTROL SYSTEM (IF EQUIPPED)

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty infor-

mation contained in the Service Passport

in your vehicle.

Your vehicle is equipped with an emis-

sion control system to meet all Australian

Design Rules (ADR) requirements. There are three emission control sys-

tems, as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system(3) Exhaust emission control system In order to assure the proper function of

the emission control systems, it is rec-

ommended that you have your car

inspected and maintained by an autho-

rised HYUNDAI dealer in accordancewith the maintenance schedule in this

manual. Caution for the Inspection and

Maintenance Test (With Electronic

Stability Program (ESP) or Electronic

Stability Control (ESC) system)

To prevent the vehicle from misfiring

during dynamometer testing, turn

the Electronic Stability Program

(ESP) or Electronic Stability Control

(ESC) system off by pressing the

ESP (or ESC) switch.

After dynamometer testing is com- pleted, turn the ESP (or ESC) sys-

tem back on by pressing the ESP (or

ESC) switch again. 1. Crankcase emission control

system

The positive crankcase ventilation sys-

tem is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valveinto the induction system.

2. Evaporative emission control system

The Evaporative Emission Control

System is designed to prevent fuel

vapours from escaping into the atmos-

phere.

Page 350 of 363

Specifications & Consumer information

4

8

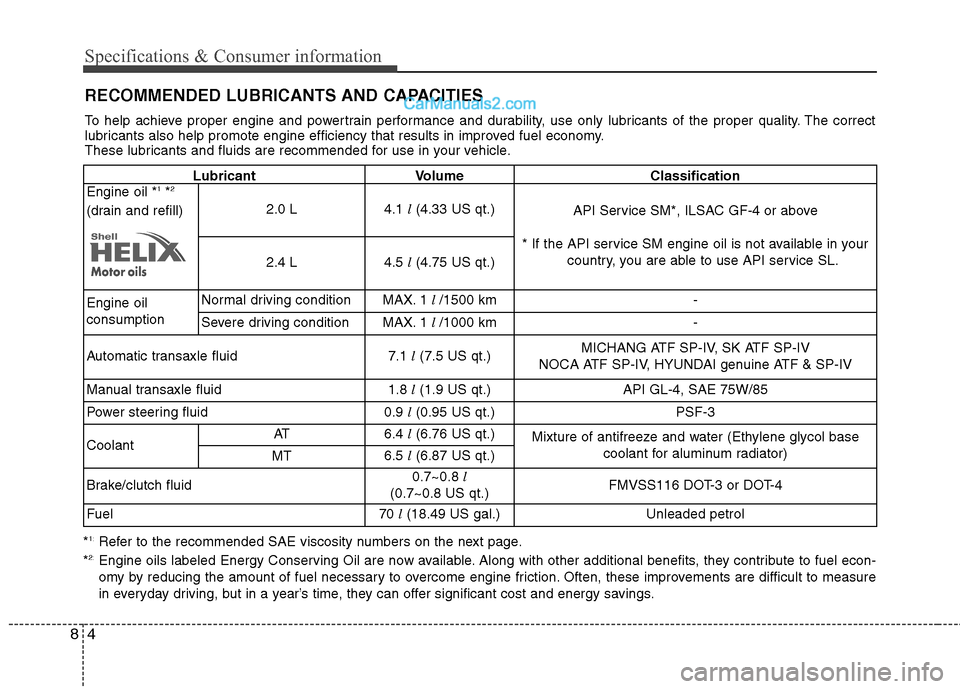

RECOMMENDED LUBRICANTS AND CAPACITIES

* 1:

Refer to the recommended SAE viscosity numbers on the next page.

* 2:

Engine oils labeled Energy Conserving Oil are now available. Along with other additional benefits, they contribute to fuel econ-

omy by reducing the amount of fuel necessary to overcome engine friction. Often, these improvements are difficult to measure

in everyday driving, but in a year’s time, they can offer significant cost and energy savings.

To help achieve proper engine and powertrain performance and durability, use only lubricants of the proper quality. The correct

lubricants also help promote engine efficiency that results in improved fuel economy.

These lubricants and fluids are recommended for use in your vehicle.

Lubricant Volume Classification

Engine oil * 1

*2

(drain and refill)

2.0 L 4.1

l(4.33 US qt.)

API Service SM*, ILSAC GF-4 or above

* If the API service SM engine oil is not available in your country, you are able to use API service SL.

2.4 L4.5 l(4.75 US qt.)

Engine oil consumptionNormal driving conditionMAX. 1 l /1500 km-

Severe driving conditionMAX. 1 l /1000 km-

Automatic transaxle fluid 7.1

l(7.5 US qt.) MICHANG ATF SP-IV, SK ATF SP-IV

NOCA ATF SP-IV, HYUNDAI genuine ATF & SP-IV

Manual transaxle fluid 1.8

l(1.9 US qt.)

API GL-4, SAE 75W/85

Power steering fluid 0.9

l(0.95 US qt.)

PSF-3

Coolant

AT 6.4

l(6.76 US qt.)

Mixture of antifreeze and water (Ethylene glycol base

coolant for aluminum radiator)

MT6.5 l(6.87 US qt.)

Brake/clutch fluid 0.7~0.8

l

(0.7~0.8 US qt.) FMVSS116 DOT-3 or DOT-4

Fuel 70

l(18.49 US gal.)

Unleaded petrol

Page 359 of 363

Index

6

I

Sunvisor ..................................................................4-103

Interior light ....................................................................4-77

Interior overview ..............................................................2-2

Interlock system ..............................................................5-20

Jack and tools....................................................................6-8

Jump starting ....................................................................6-5

Key positions ....................................................................5-5

Keys ..................................................................................4-3 Label Air bag warning label................................................3-56

Tyre sidewall labeling ..............................................7-40

Tyre specification and pressure label ..........................8-7

Vehicle certification label............................................8-6

Light bulbs ......................................................................7-55

Lighting ..........................................................................4-69 Battery saver function ..............................................4-69

Headlight escort function ..........................................4-69

Headlight welcome function ....................................4-69

Lubricants and capacities ..................................................8-4 Lumbar support ........................................................3-5, 3-7 Maintenance

Explanation of scheduled maintenance items ..........7-13

Maintenance services ..................................................7-3

Maintenance under severe usage conditions ............7-11

Normal maintenance schedule ....................................7-7

Owner maintenance ....................................................7-4

Scheduled maintenance service ..................................7-6

Tyre maintenance ......................................................7-39

Maintenance services ........................................................7-3

Manual climate control system ......................................4-81 Air conditioning ........................................................4-86

Climate control air filter............................................4-88

Heating and air conditioning ....................................4-82

Manual heating and air conditioning ..............................4-82

Manual transaxle ............................................................5-12

Memory fuse ..................................................................7-46

Mirrors ............................................................................4-39 Day/night rearview mirror ........................................4-39

Electric chromic mirror (ECM) ................................4-39

Inside rearview mirror ..............................................4-39

Outside rearview mirror ............................................4-40

Moonroof, see panorama sunroof ..................................4-31

Multi box ......................................................................4-101

Multi fuse ........................................................................7-47

M

K

L

J