AV off Hyundai Sonata 2019 Owner's Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2019, Model line: Sonata, Model: Hyundai Sonata 2019Pages: 522, PDF Size: 15.66 MB

Page 379 of 522

6-8

What to do in an emergency6. If you cannot find the cause of theoverheating, wait until the engine

temperature has returned to nor-

mal. Then, if coolant has been

lost, carefully add coolant to the

reservoir to bring the fluid level in

the reservoir up to the halfway

mark.

7. Proceed with caution, keeping alert for further signs of overheat-

ing. If overheating happens again,

call an authorized HYUNDAI deal-

er for assistance.

Serious loss of coolant indi-

cates a leak in the cooling sys-

tem and should be checked as

soon as possible by an author-

ized HYUNDAI dealer.

CAUTION

NEVER remove the

radiator cap or the

drain plug while the

engine and radiator

are hot. Hot coolant

and steam may blow out under

pressure, causing serious

injury.

Turn the engine off and wait

until the engine cools down.

Use extreme care when remov-

ing the radiator cap. Wrap a

thick towel around it, and turn it

counterclockwise slowly to the

first stop. Step back while the

pressure is released from the

cooling system. When you are

sure all the pressure has been

released, press down on the

cap, using a thick towel, and

continue turning counterclock-

wise to remove it.

WARNING

Page 384 of 522

6-13

What to do in an emergency

6

The TPMS Malfunction Indicator

may illuminate after blinking for

one minute if the vehicle is near

electric power supply cables or

radio transmitters such as police

stations, government and public

offices, broadcasting stations,

military installations, airports,

transmitting towers, etc.

Additionally, the TPMS Malfunction

Indicator may illuminate if snow

chains are used or electronic

devices such as computers, charg-

ers, remote starters, navigation,

etc. This may interfere with normal

operation of the TPMS.

Changing a Tire with TPMS

If you have a flat tire, the Low Tire

Pressure and Position telltales will

come on. Have the flat tire repaired

by an authorized HYUNDAI dealer

as soon as possible or replace the

flat tire with the spare tire.

The spare tire (if equipped) does not

come with a tire pressure monitoring

sensor. When the low pressure tire or

the flat tire is replaced with the spare

tire, the Low Tire Pressure Telltale

will remain on. Also, the TPMS

Malfunction Indicator will illuminate

after blinking for one minute if the

vehicle is driven at speed above 15.5

mph (25 km/h) for approximately 20

minutes.Once the original tire equipped with

a tire pressure monitoring sensor is

reinflated to the recommended pres-

sure and reinstalled on the vehicle,

the Low Tire Pressure Telltale and

TPMS Malfunction Indicator will go

off within a few minutes of driving.

If the indicators do not extinguish

after a few minutes, please visit an

authorized HYUNDAI dealer.

Each wheel is equipped with a tire

pressure sensor mounted inside the

tire behind the valve stem (except for

the spare tire). You must use TPMS

specific wheels. It is recommended

that you always have your tires serv-

iced by an authorized HYUNDAI

dealer.

You may not be able to identify a tire

with low pressure by simply looking

at it. Always use a good quality tire

pressure gauge to measure. Please

note that a tire that is hot (from being

driven) will have a higher pressure

measurement than a tire that is cold.

NOTICE

Never use a puncture-repairing

agent not approved by

HYUNDAI dealer to repair and/

or inflate a low pressure tire.

Tire sealant not approved by

HYUNDAI dealer may damage

the tire pressure sensor.

CAUTION

Page 385 of 522

6-14

What to do in an emergency

A cold tire means the vehicle has

been sitting for 3 hours and driven for

less than 1 mile (1.6 km) in that 3

hour period.

Allow the tire to cool before measur-

ing the inflation pressure. Always be

sure the tire is cold before inflating to

the recommended pressure.

Information

This device complies with Part 15 of

the FCC rules.

Operation is subject to the following

three conditions:

1. This device may not cause harmful interference, and

2. This device must accept any inter- ference received, including interfer-

ence that may cause undesired

operation.

3. Changes or modifications not expressly approved by the party

responsible for compliance could

void the user's authority to operate

the equipment.

i

The TPMS cannot alert you to

severe and sudden tire dam-

age caused by external fac-

tors such as nails or road

debris.

If you feel any vehicle instabil-

ity, immediately take your foot

off the accelerator, apply the

brakes gradually with light

force, and slowly move to a

safe position off the road.

WARNING

Tampering with, modifying, or

disabling the Tire Pressure

Monitoring System (TPMS)

components may interfere with

the system's ability to warn the

driver of low tire pressure con-

ditions and/or TPMS malfunc-

tions. Tampering with, modify-

ing, or disabling the Tire

Pressure Monitoring System

(TPMS) components may void

the warranty for that portion of

the vehicle.

WARNING

Page 387 of 522

6-16

What to do in an emergency

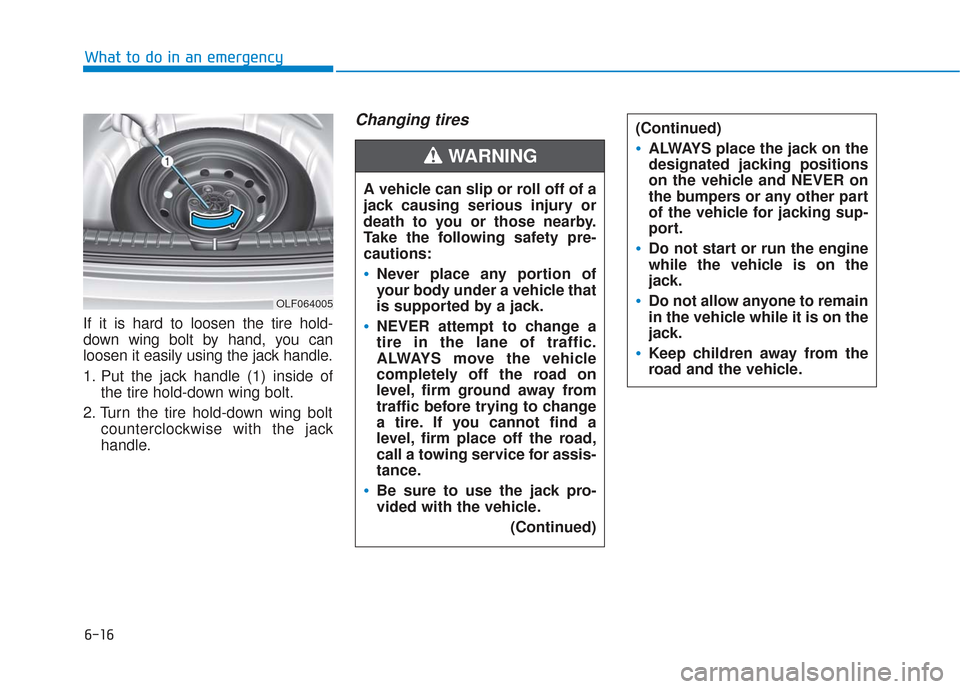

If it is hard to loosen the tire hold-

down wing bolt by hand, you can

loosen it easily using the jack handle.

1. Put the jack handle (1) inside of the tire hold-down wing bolt.

2. Turn the tire hold-down wing bolt counterclockwise with the jack

handle.

Changing tires

A vehicle can slip or roll off of a

jack causing serious injury or

death to you or those nearby.

Take the following safety pre-

cautions:

Never place any portion of

your body under a vehicle that

is supported by a jack.

NEVER attempt to change a

tire in the lane of traffic.

ALWAYS move the vehicle

completely off the road on

level, firm ground away from

traffic before trying to change

a tire. If you cannot find a

level, firm place off the road,

call a towing service for assis-

tance.

Be sure to use the jack pro-

vided with the vehicle.

(Continued)

(Continued)

ALWAYS place the jack on the

designated jacking positions

on the vehicle and NEVER on

the bumpers or any other part

of the vehicle for jacking sup-

port.

Do not start or run the engine

while the vehicle is on the

jack.

Do not allow anyone to remain

in the vehicle while it is on the

jack.

Keep children away from the

road and the vehicle.

WARNING

OLF064005

Page 388 of 522

6-17

What to do in an emergency

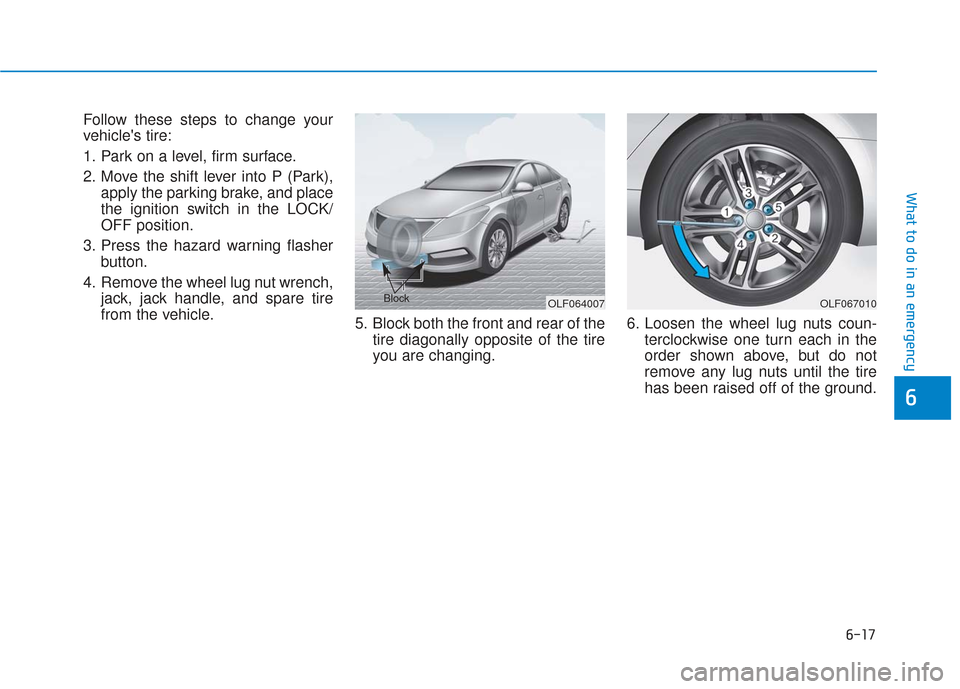

Follow these steps to change your

vehicle's tire:

1. Park on a level, firm surface.

2. Move the shift lever into P (Park),apply the parking brake, and place

the ignition switch in the LOCK/

OFF position.

3. Press the hazard warning flasher button.

4. Remove the wheel lug nut wrench, jack, jack handle, and spare tire

from the vehicle. 5. Block both the front and rear of the

tire diagonally opposite of the tire

you are changing. 6. Loosen the wheel lug nuts coun-

terclockwise one turn each in the

order shown above, but do not

remove any lug nuts until the tire

has been raised off of the ground.

6

OLF064007BlockOLF067010

Page 396 of 522

6-25

What to do in an emergency

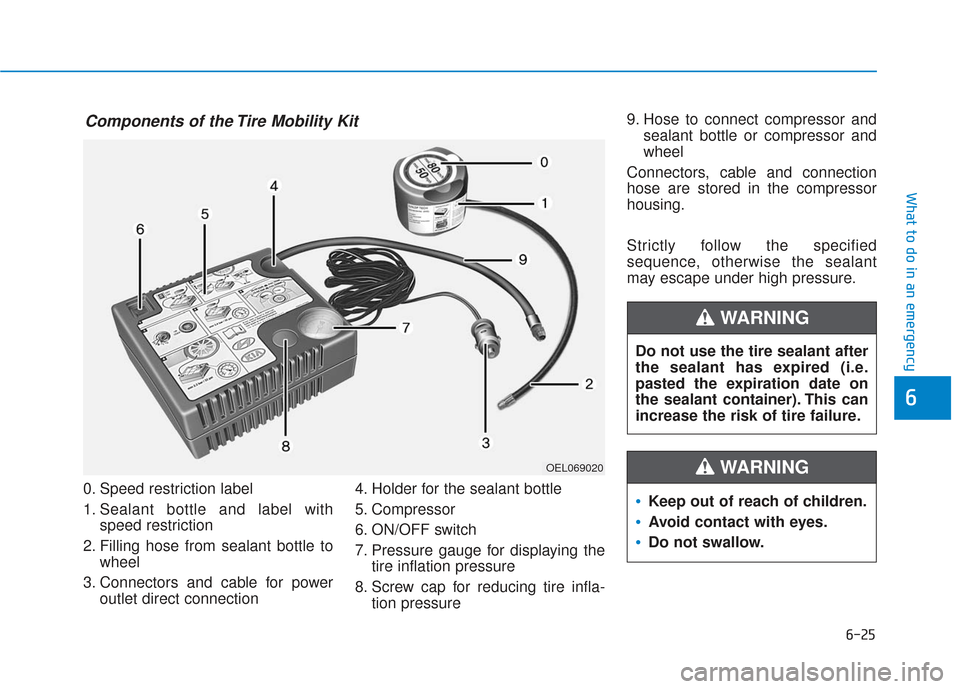

0. Speed restriction label

1. Sealant bottle and label withspeed restriction

2. Filling hose from sealant bottle to wheel

3. Connectors and cable for power outlet direct connection 4. Holder for the sealant bottle

5. Compressor

6. ON/OFF switch

7. Pressure gauge for displaying the

tire inflation pressure

8. Screw cap for reducing tire infla- tion pressure 9. Hose to connect compressor and

sealant bottle or compressor and

wheel

Connectors, cable and connection

hose are stored in the compressor

housing.

Strictly follow the specified

sequence, otherwise the sealant

may escape under high pressure.

6

Components of the Tire Mobility Kit

OEL069020

Do not use the tire sealant after

the sealant has expired (i.e.

pasted the expiration date on

the sealant container). This can

increase the risk of tire failure.

WARNING

Keep out of reach of children.

Avoid contact with eyes.

Do not swallow.

WARNING

Page 398 of 522

6-27

What to do in an emergency

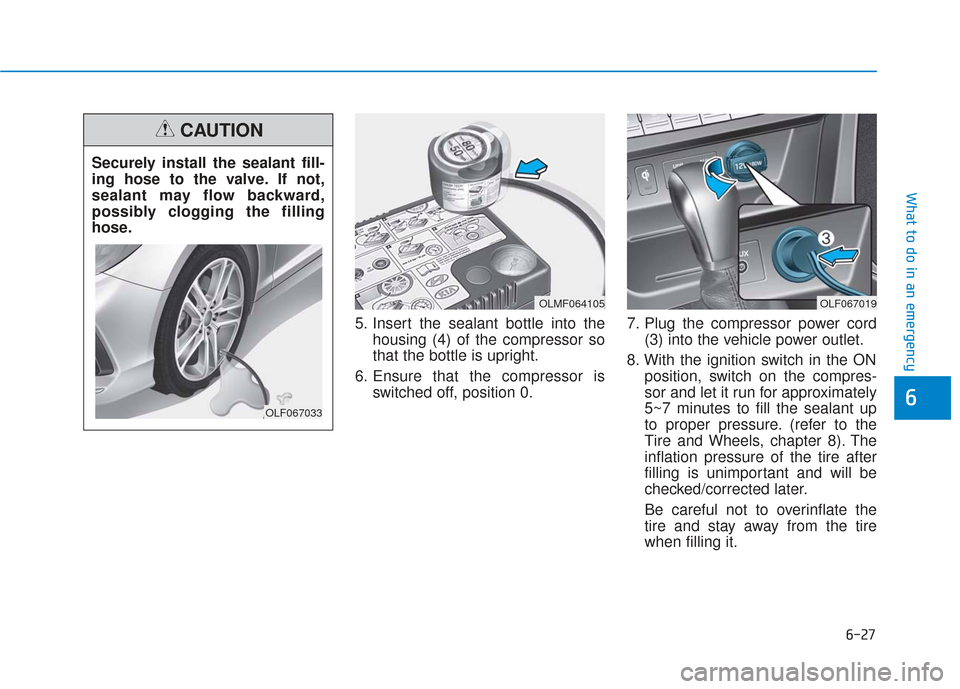

5. Insert the sealant bottle into thehousing (4) of the compressor so

that the bottle is upright.

6. Ensure that the compressor is switched off, position 0. 7. Plug the compressor power cord

(3) into the vehicle power outlet.

8. With the ignition switch in the ON position, switch on the compres-

sor and let it run for approximately

5~7 minutes to fill the sealant up

to proper pressure. (refer to the

Tire and Wheels, chapter 8). The

inflation pressure of the tire after

filling is unimportant and will be

checked/corrected later.

Be careful not to overinflate the

tire and stay away from the tire

when filling it.

6

OLMF064105OLF067019

Securely install the sealant fill-

ing hose to the valve. If not,

sealant may flow backward,

possibly clogging the filling

hose.

CAUTION

OLF067033

Page 399 of 522

6-28

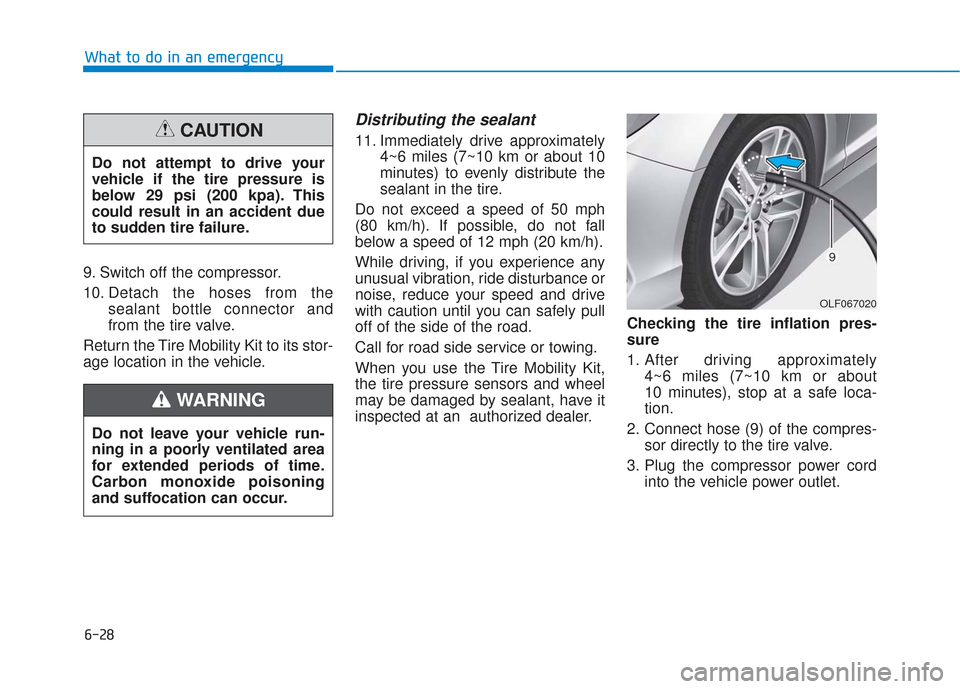

9. Switch off the compressor.

10. Detach the hoses from thesealant bottle connector and

from the tire valve.

Return the Tire Mobility Kit to its stor-

age location in the vehicle.

Distributing the sealant

11. Immediately drive approximately 4~6 miles (7~10 km or about 10

minutes) to evenly distribute the

sealant in the tire.

Do not exceed a speed of 50 mph

(80 km/h). If possible, do not fall

below a speed of 12 mph (20 km/h).

While driving, if you experience any

unusual vibration, ride disturbance or

noise, reduce your speed and drive

with caution until you can safely pull

off of the side of the road.

Call for road side service or towing.

When you use the Tire Mobility Kit,

the tire pressure sensors and wheel

may be damaged by sealant, have it

inspected at an authorized dealer. Checking the tire inflation pres-

sure

1. After driving approximately

4~6 miles (7~10 km or about

10 minutes), stop at a safe loca-

tion.

2. Connect hose (9) of the compres- sor directly to the tire valve.

3. Plug the compressor power cord into the vehicle power outlet.

What to do in an emergency

OLF067020

Do not attempt to drive your

vehicle if the tire pressure is

below 29 psi (200 kpa). This

could result in an accident due

to sudden tire failure.

CAUTION

Do not leave your vehicle run-

ning in a poorly ventilated area

for extended periods of time.

Carbon monoxide poisoning

and suffocation can occur.

WARNING

Page 400 of 522

6-29

What to do in an emergency

4. Adjust the tire inflation pressure tothe recommended tire inflation.

With the ignition switched on, pro- ceed as follows.

- To increase the inflation pres- sure:

Switch on the compressor, posi-

tion to [I]. To check the current

inflation pressure setting, briefly

switch off the compressor.

- To reduce the inflation pres- sure:

Loosen the screw cap (8) on the

compressor hose.

Information

The pressure gauge may show higher

than actual reading when the com-

pressor is running. To get an accurate

tire pressure, the compressor needs to

be turned off.

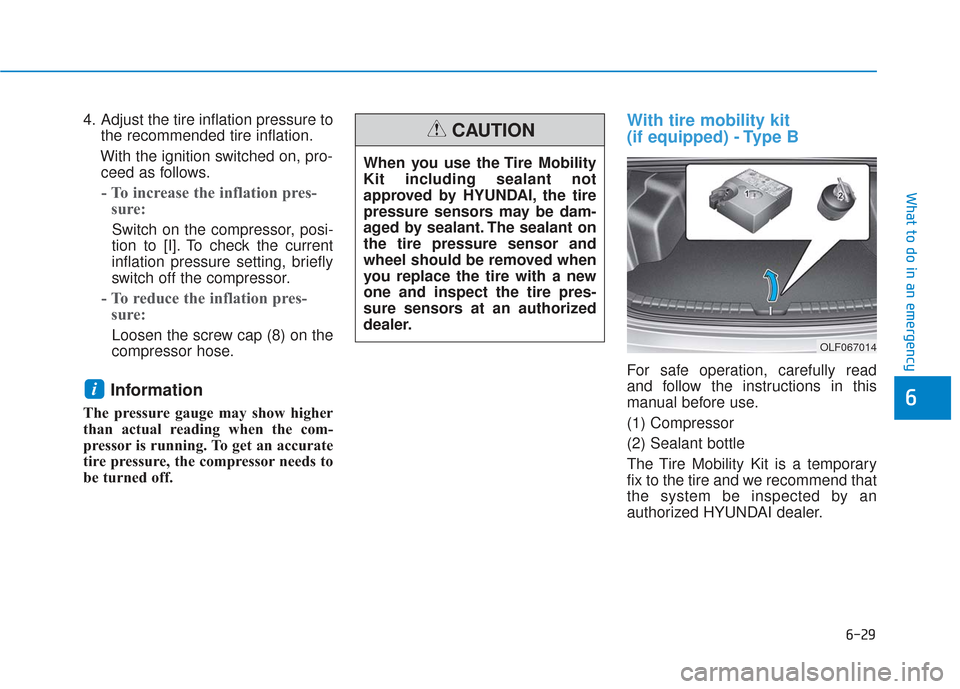

With tire mobility kit

(if equipped) - Type B

For safe operation, carefully read

and follow the instructions in this

manual before use.

(1) Compressor

(2) Sealant bottle

The Tire Mobility Kit is a temporary

fix to the tire and we recommend that

the system be inspected by an

authorized HYUNDAI dealer.

i6

When you use the Tire Mobility

Kit including sealant not

approved by HYUNDAI, the tire

pressure sensors may be dam-

aged by sealant. The sealant on

the tire pressure sensor and

wheel should be removed when

you replace the tire with a new

one and inspect the tire pres-

sure sensors at an authorized

dealer.

CAUTION

OLF067014

Page 403 of 522

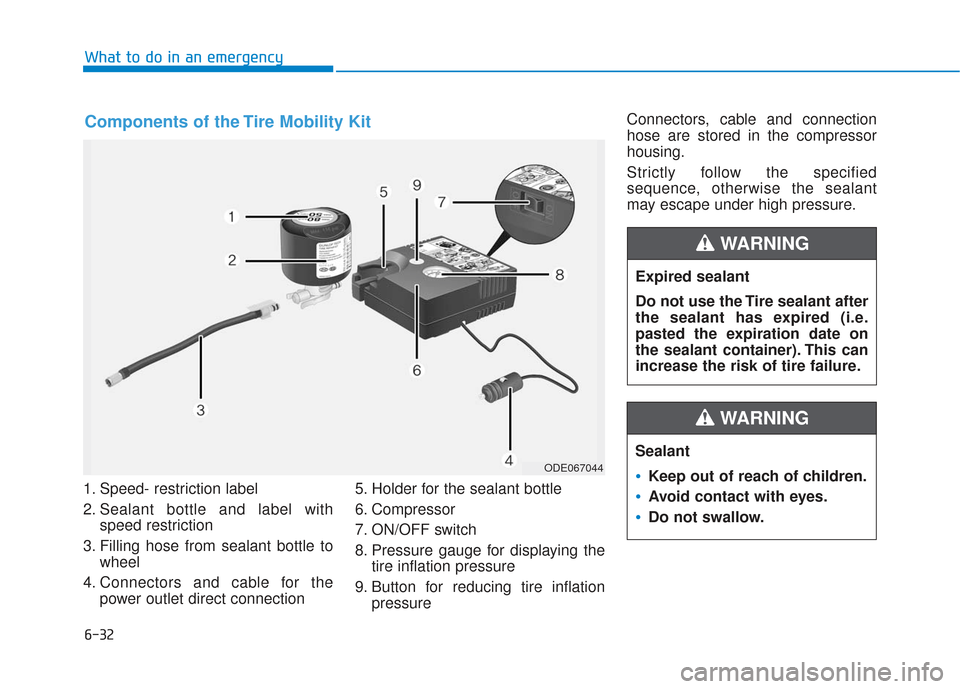

6-32

1. Speed- restriction label

2. Sealant bottle and label withspeed restriction

3. Filling hose from sealant bottle to wheel

4. Connectors and cable for the power outlet direct connection 5. Holder for the sealant bottle

6. Compressor

7. ON/OFF switch

8. Pressure gauge for displaying the

tire inflation pressure

9. Button for reducing tire inflation pressure Connectors, cable and connection

hose are stored in the compressor

housing.

Strictly follow the specified

sequence, otherwise the sealant

may escape under high pressure.

What to do in an emergency

ODE067044

Expired sealant

Do not use the Tire sealant after

the sealant has expired (i.e.

pasted the expiration date on

the sealant container). This can

increase the risk of tire failure.

WARNING

Sealant

Keep out of reach of children.

Avoid contact with eyes.

Do not swallow.

WARNING

Components of the Tire Mobility Kit