exhaust Hyundai Sonata 2019 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2019, Model line: Sonata, Model: Hyundai Sonata 2019Pages: 522, PDF Size: 15.66 MB

Page 418 of 522

7-8

Maintenance

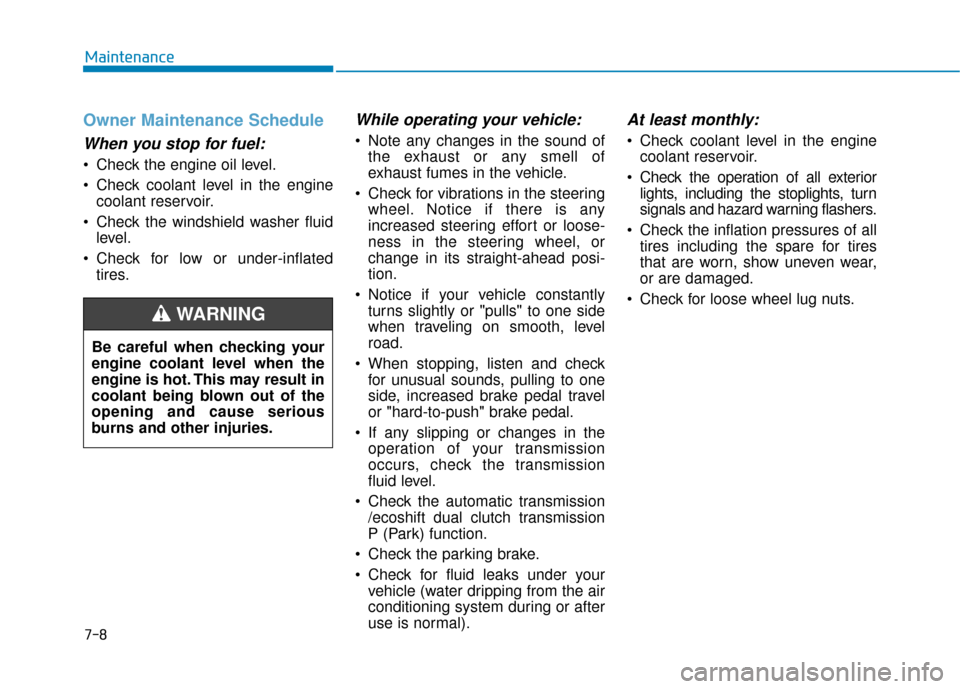

Owner Maintenance Schedule

When you stop for fuel:

Check the engine oil level.

Check coolant level in the enginecoolant reservoir.

Check the windshield washer fluid level.

Check for low or under-inflated tires.

While operating your vehicle:

Note any changes in the sound ofthe exhaust or any smell of

exhaust fumes in the vehicle.

Check for vibrations in the steering wheel. Notice if there is any

increased steering effort or loose-

ness in the steering wheel, or

change in its straight-ahead posi-

tion.

Notice if your vehicle constantly turns slightly or "pulls" to one side

when traveling on smooth, level

road.

When stopping, listen and check for unusual sounds, pulling to one

side, increased brake pedal travel

or "hard-to-push" brake pedal.

If any slipping or changes in the operation of your transmission

occurs, check the transmission

fluid level.

Check the automatic transmission /ecoshift dual clutch transmission

P (Park) function.

Check the parking brake.

Check for fluid leaks under your vehicle (water dripping from the air

conditioning system during or after

use is normal).

At least monthly:

Check coolant level in the enginecoolant reservoir.

Check the operation of all exterior lights, including the stoplights, turn

signals and hazard warning flashers.

Check the inflation pressures of all tires including the spare for tires

that are worn, show uneven wear,

or are damaged.

Check for loose wheel lug nuts.

Be careful when checking your

engine coolant level when the

engine is hot. This may result in

coolant being blown out of the

opening and cause serious

burns and other injuries.

WARNING

Page 419 of 522

7-9

7

Maintenance

At least twice a year:(i.e., every Spring and Fall)

Check radiator, heater and air condi-

tioning hoses for leaks or damage.

Check windshield washer spray and wiper operation. Clean wiper

blades with clean cloth dampened

with washer fluid.

Check headlamp alignment.

Check muffler, exhaust pipes, shields and clamps.

Check the seat belts for wear and function.

At least once a year:

Clean body and door drain holes.

Lubricate door hinges and hoodhinges.

Lubricate door and hood locks and latches.

Lubricate door rubber weather strips.

Check the air conditioning system.

Inspect and lubricate automatic transmission linkage and controls.

Clean the battery and terminals.

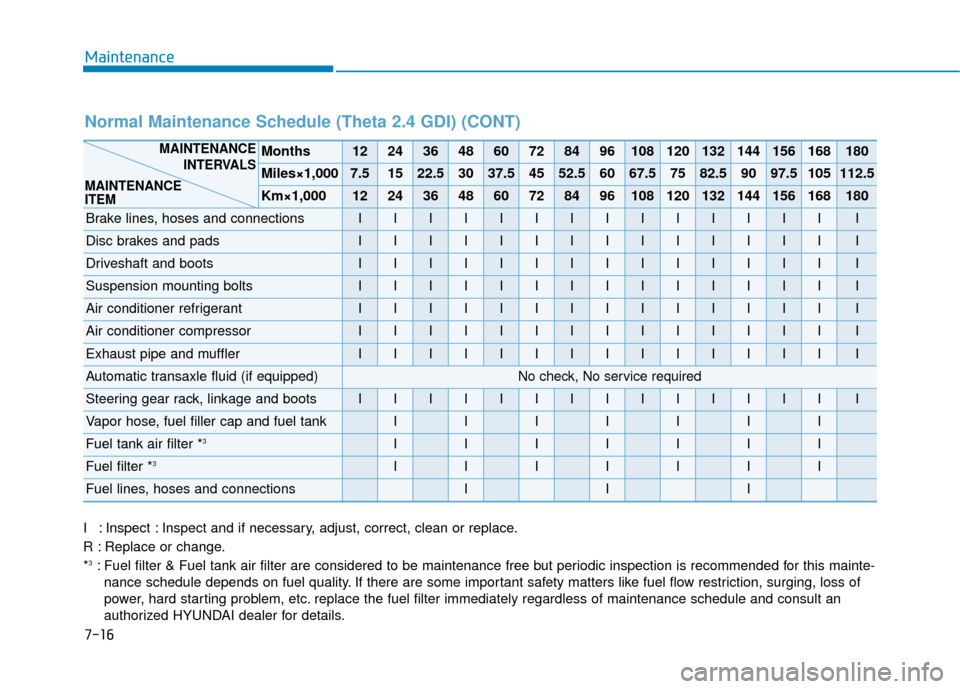

Check the brake fluid level. Follow Normal Maintenance Schedule

if the vehicle is usually operated where

none of the following conditions apply.

If any of the following conditions apply,

you must follow the Maintenance

Under Severe Usage Conditions.

Repeated short distance driving.

Driving in dusty conditions or

sandy areas.

Extensive use of brakes.

Driving in areas where salt or other corrosive materials are used.

Driving on rough or muddy roads.

Driving in mountainous areas.

Extended periods of idling or low speed operation.

Driving for a prolonged period in cold temperatures and/or extreme-

ly humid climates.

More than 50% driving in heavy city traffic during hot weather

above 90°F (32°C).

For additional information or assis-

tance see your authorized HYUNDAI

dealer.

S S C

C H

H E

ED

D U

U L

LE

E D

D

M

M A

AI

IN

N T

TE

EN

N A

AN

N C

CE

E

S

S E

E R

R V

V I

IC

C E

E S

S

Page 421 of 522

7

Maintenance

7-11

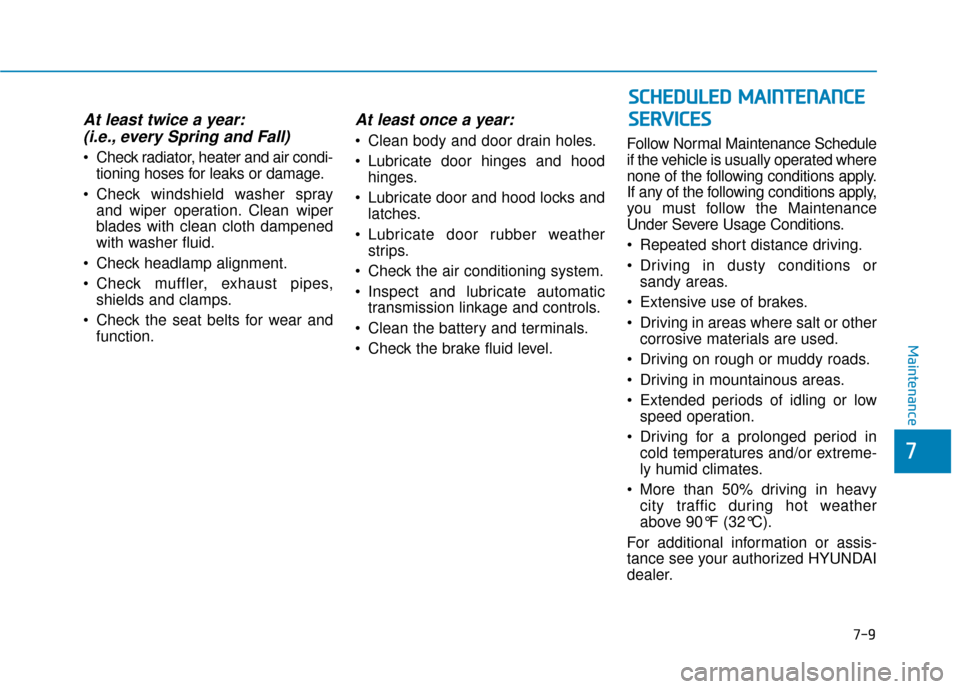

I : Inspect : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

Normal Maintenance Schedule (Gamma 1.6 T-GDI/Theta 2.0 T-GDI) (CONT)

Months1224364860728496108120132144156168180

Miles×1,00061218243036424854606672788490

Km×1,000102030405060708090100110120130140150

Battery conditionIIIIIIIIIIIIIII

Brake lines, hoses and connectionsIIIIIIIIIIIIIII

Disc brakes and padsIIIIIIIIIIIIIII

Driveshaft and bootsIIIIIIIIIIIIIII

Suspension mounting boltsIIIIIIIIIIIIIII

Air conditioner refrigerantIIIIIIIIIIIIIII

Air conditioner compressorIIIIIIIIIIIIIII

Exhaust pipe and mufflerIIIIIIIIIIIIIII

Automatic transaxle fluid (if equipped)No check, No service required

Ecoshift dual clutch transmission fluid

(if equipped)III

MAINTENANCEINTERVALS

MAINTENANCE

ITEM

Page 426 of 522

Maintenance

7-16

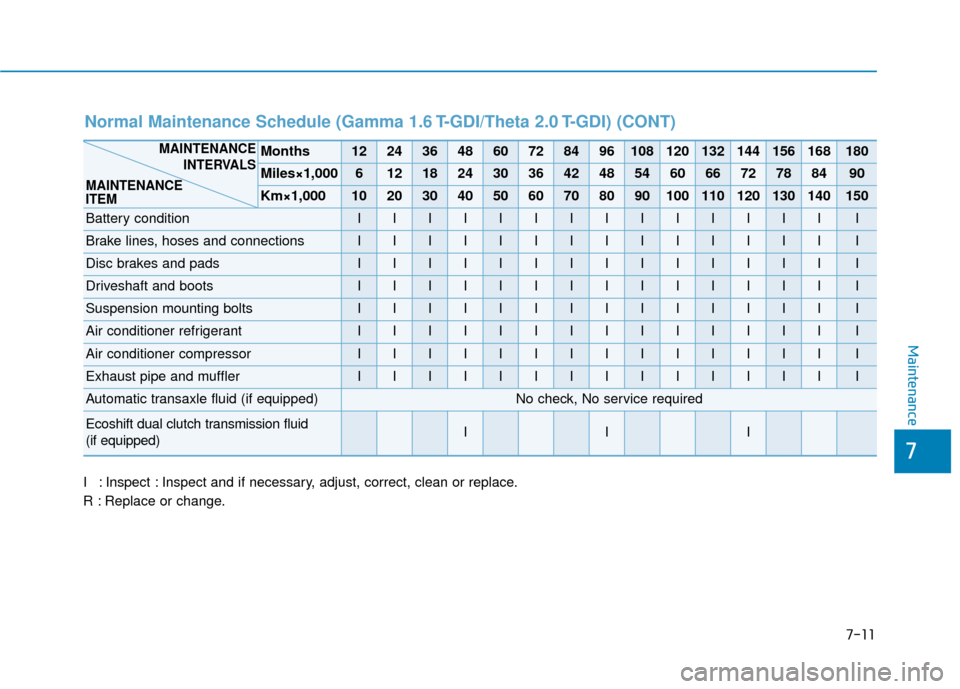

I : Inspect : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

*

3: Fuel filter & Fuel tank air filter are considered to be maintenance free\

but periodic inspection is recommended for this mainte-nance schedule depends on fuel quality. If there are some important safety matters like fuel flow restriction, surging, loss of

power, hard starting problem, etc. replace the fuel filter immediately regardless of maintenance schedule a\

nd consult an

authorized HYUNDAI dealer for details.

Normal Maintenance Schedule (Theta 2.4 GDI) (CONT)

Months1224364860728496108120132144156168180

Miles×1,0007.51522.53037.54552.56067.57582.59097.5105112.5

Km×1,0001224364860728496108120132144156168180

Brake lines, hoses and connectionsIIIIIIIIIIIIIII

Disc brakes and padsIIIIIIIIIIIIIII

Driveshaft and bootsIIIIIIIIIIIIIII

Suspension mounting boltsIIIIIIIIIIIIIII

Air conditioner refrigerantIIIIIIIIIIIIIII

Air conditioner compressorIIIIIIIIIIIIIII

Exhaust pipe and mufflerIIIIIIIIIIIIIII

Automatic transaxle fluid (if equipped)No check, No service required

Steering gear rack, linkage and bootsIIIIIIIIIIIIIII

Vapor hose, fuel filler cap and fuel tankIIIIIII

Fuel tank air filter *3IIIIIII

Fuel filter *3IIIIIII

Fuel lines, hoses and connectionsIII

MAINTENANCE INTERVALS

MAINTENANCE

ITEM

Page 432 of 522

7-22

Maintenance

Brake Hoses and Lines

Visually check for proper installation,

chafing, cracks, deterioration and

any leakage. Replace any deteriorat-

ed or damaged parts immediately.

Brake Fluid

Check brake fluid level in the brake

fluid reservoir. The level should be

between the MIN and the MAX

marks on the side of the reservoir.

Use only hydraulic brake fluid con-

forming to DOT 3 or DOT 4 specifi-

cation.

Parking Brake

Inspect the parking brake system

including the parking brake pedal

and cables.

Brake Discs, Pads, Calipers

and Rotors

Check the pads for excessive wear,

discs for run out and wear, and

calipers for fluid leakage.

Exhaust Pipe and Muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the

engine and listen carefully for any

exhaust gas leakage. Tighten con-

nections or replace parts as neces-

sary.

Suspension Mounting Bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering Gear Box, Linkage &

Boots/Lower Arm Ball Joint

With the vehicle stopped and the

engine off, check for excessive free-

play in the steering wheel. Check the

linkage for bends or damage. Check

the dust boots and ball joints for

deterioration, cracks, or damage.

Replace any damaged parts.

Drive Shafts and Boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air Conditioning Refrigerant

Check the air conditioning lines and

connections for leakage and damage.

Page 477 of 522

![Hyundai Sonata 2019 User Guide 7-67

7

Maintenance

Engine compartment main fuse panel - PCB Block

Fuse Name Fuse rating Protected Component

FUSE

2 VACUUM PUMP10A[G4KH/G4FJ] Vacuum Pump, Vacuum Switch

3 ECU10APCM/ECM

1 POWER OUTLET20 Hyundai Sonata 2019 User Guide 7-67

7

Maintenance

Engine compartment main fuse panel - PCB Block

Fuse Name Fuse rating Protected Component

FUSE

2 VACUUM PUMP10A[G4KH/G4FJ] Vacuum Pump, Vacuum Switch

3 ECU10APCM/ECM

1 POWER OUTLET20](/img/35/16774/w960_16774-476.png)

7-67

7

Maintenance

Engine compartment main fuse panel - PCB Block

Fuse Name Fuse rating Protected Component

FUSE

2 VACUUM PUMP10A[G4KH/G4FJ] Vacuum Pump, Vacuum Switch

3 ECU10APCM/ECM

1 POWER OUTLET20AFront Cigarette Lighter & Power Outlet #2

FUEL PUMP20AFuel Pump Relay

HORN20AHorn Relay, ICM Relay Box (Burglar Alarm Horn Relay)

WIPER30AFront Wiper (Low) Relay, Front Wiper (High) Relay

2 TCU15ATransmission Range Switch, TCM (G4FJ-DCT)

3 ABS10AESC Module

2 POWER OUTLET20ARear Power Outlet

B/UP LAMP10ATransmission Range Switch, PCM (G4KJ/G4KH-A/T), TCM (G4FJ-DCT),

Electro Chromic Mirror, Rear Combination Lamp (IN) LH/RH

1 SENSOR15AOxygen Sensor (Up/Down)

2 SENSOR15A

Purge Control Solenoid Valve, Canister Close Valve, RCV Control Solenoid Valve,

Fuel Pump Relay, E/R Junction Block (Cooling Fan High Relay, Fuel Pump Relay),

[G4KJ/G4KH] Variable Intake Solenoid Valve, Oil Control Valve (Exhaust),

[G4FJ] Oil Control Valve #1/#2 (Intake/Exhaust)

1 ECU10APCM/ECM

1 TCU10APCM (G4KJ/G4KH-A/T), TCM (G4FJ-DCT)

1 ECU10APCM/ECM

IGN COIL20AIgnition Coil #1/#2/#3/#4

INJECTOR15ANot Used

AMS10ABattery Sensor

Page 489 of 522

7-79

7

Maintenance

Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly

rust and may develop into a major

repair expense.

If your vehicle is damaged and

requires any metal repair or

replacement, be sure the body

shop applies anti-corrosion mate-

rials to the parts repaired or

replaced.

Bright-metal maintenance

To remove road tar and insects,use a tar remover, not a scraper or

other sharp object.

To protect the surfaces of bright- metal parts from corrosion, apply a

coating of wax or chrome preser-

vative and rub to a high luster.

During winter weather or in coastal areas, cover the bright metal parts

with a heavier coating of wax or

preservative. If necessary, coat the

parts with non-corrosive petroleum

jelly or other protective compound.

Underbody maintenance

Corrosive materials used for ice and

snow removal and dust control may

collect on the underbody. If these

materials are not removed, acceler-

ated rusting can occur on underbody

parts such as the fuel lines, frame,

floor pan and exhaust system, even

though they have been treated with

rust protection.

NOTICE

Wiping dust or dirt off the

body with a dry cloth will

scratch the finish.

Do not use steel wool, abra-

sive cleaners, or strong deter-

gents containing highly alka-

line or caustic agents on

chrome-plated or anodized

aluminum parts. This may

result in damage to the pro-

tective coating and cause dis-

coloration or paint deteriora-

tion.

CAUTION

Page 495 of 522

7-85

7

Maintenance

E

EM

M I

IS

S S

SI

IO

O N

N

C

C O

O N

NT

TR

R O

O L

L

S

S Y

Y S

ST

T E

EM

M

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty

information contained in the Owner’s

Handbook & Warranty Information

booklet in your vehicle.

Your vehicle is equipped with an

emission control system to meet all

applicable emission regulations.

There are three emission control

systems, as follows.

(1) Crankcase emission control sys-

tem

(2) Evaporative emission control sys- tem

(3) Exhaust emission control system

In order to assure the proper function

of the emission control systems, it is

recommended that you have your

vehicle inspected and maintained by

an authorized HYUNDAI dealer in

accordance with the maintenance

schedule in this manual.1. Crankcase Emission Control System

The positive crankcase ventilation

system is employed to prevent air

pollution caused by blow-by gases

being emitted from the crankcase.

This system supplies fresh filtered air

to the crankcase through the air

intake hose. Inside the crankcase,

the fresh air mixes with blow-by

gases, which then pass through the

PCV valve into the induction system.

2. Evaporative Emission ControlSystem Including Onboard

Refueling Vapor Recovery

(ORVR)

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere. The ORVR system is

designed to allow the vapors from

the fuel tank to be loaded into a can-

ister while refueling at the gas sta-

tion, preventing the escape of fuel

vapors into the atmosphere.

For the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

To prevent the vehicle from

misfiring during dynamome-

ter testing, turn the Electronic

Stability Control (ESC) sys-

tem off by pressing the ESC

switch (ESC OFF light illumi-

nated).

After dynamometer testing is

completed, turn the ESC sys-

tem back on by pressing the

ESC switch again.

CAUTION

Page 496 of 522

7-86

Maintenance

Canister

Fuel vapors generated inside the fuel

tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in

the canister are drawn into the surge

tank through the purge control sole-

noid valve.

Purge Control Solenoid Valve(PCSV)

The purge control solenoid valve is

controlled by the Engine Control

Module (ECM); when the engine

coolant temperature is low during

idling, the PCSV closes so that evap-

orated fuel is not taken into the

engine. After the engine warms-up

during ordinary driving, the PCSV

opens to introduce evaporated fuel to

the engine.

3. Exhaust Emission Control System

The Exhaust Emission Control

System is a highly effective system

which controls exhaust emissions

while maintaining good vehicle per-

formance.

When the engine starts or fails to

start, excessive attempts to restart

the engine may cause damage to the

emission system.

Vehicle modifications

This vehicle should not be modi-

fied. Modification of your vehicle

could affect its performance, safety

or durability and may even violate

governmental safety and emis-

sions regulations.

In addition, damage or performance

problems resulting from any modifi-

cation may not be covered under

warranty.

If you use unauthorized electronic devices, it may cause the vehicle to

operate abnormally, wire damage,

battery discharge and fire. For your

safety, do not use unauthorized

electronic devices.

Engine exhaust (carbon monox-ide) precautions

Carbon monoxide can be present

with other exhaust fumes. If you

smell exhaust fumes of any kind in

your vehicle, drive with all the win-

dows fully open. Have your vehicle

checked and repaired immediately.

Engine exhaust gases contain

carbon monoxide (CO). Though

colorless and odorless, it is

dangerous and could be lethal if

inhaled. Follow the instructions

on this page to avoid CO poi-

soning.

WARNING

Page 497 of 522

7-87

7

Maintenance

Do not operate the engine in con-fined or closed areas (such as

garages) any more than what is

necessary to move the vehicle in or

out of the area.

When the vehicle is stopped in an open area for more than a short

time with the engine running,

adjust the ventilation system (as

needed) to draw outside air into the

vehicle.

Never sit in a parked or stopped vehicle for any extended time with

the engine running.

When the engine stalls or fails to start, excessive attempts to restart

the engine may cause damage to

the emission control system.Operating precautions for cat-alytic converters (if equipped)

The exhaust system and cat-

alytic converter are very hot

during and immediately after

the engine has been running. To

avoid SERIOUS INJURY or

DEATH:

Do not park, idle, or drive the

vehicle over or near flamma-

ble objects, such as grass,

vegetation, paper, leaves, etc.

A hot exhaust system can

ignite flammable items under

your vehicle.

Keep away from the exhaust

system and catalytic convert-

er or you may get burned.

Also, Do not remove the heat

sink around the exhaust sys-

tem, do not seal the bottom of

the vehicle, and do not coat

the vehicle for corrosion con-

trol. It may present a fire risk

under certain conditions.

WARNING CALIFORNIA PROPOSITION 65

WARNING

Engine exhaust and a wide vari-

ety of automobile components

and parts, including compo-

nents found in the interior fur-

nishings in a vehicle, contain or

emit chemicals known to the

State of California to cause can-

cer and birth defects and repro-

ductive harm. In addition, cer-

tain fluids contained in vehicles

and certain products of compo-

nent wear contain or emit chem-

icals known to the State of

California to cause cancer and

birth defects or other reproduc-

tive harm.

WARNING