engine coolant Hyundai Terracan 2005 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2005, Model line: Terracan, Model: Hyundai Terracan 2005Pages: 539, PDF Size: 18.03 MB

Page 256 of 539

6 DO-IT-YOURSELF MAINTENANCE

34

Gasoline Engine or Diesel Engine (2.5 TCI)

POWER STEERING FLUID LEVEL

G220B01A-AAT

Checking Engine Cooling Fan

The engine cooling fan should come

on automatically if the engine coolant temperature is high.

G220C01A-AAT

Checking Condenser Cooling Fan

The condenser cooling fan should

come on automatically whenever the air conditioning is in operation. G230A03A-AAT The power steering fluid level should

be checked daily. G230A01HP

HHP5014CHECKING ELECTRIC COOLING FANS

!

G220A01A-AAT WARNING:

The cooling fan is controlled by engine coolant temperature and may sometimes operate even whenthe engine is not running. Use extreme caution when working near the blades of the cooling fan,so that you are not injured by a rotating fan blade. As the engine coolant temperature decreases thefan will automatically shut off. This is a normal condition.

Diesel Engine (2.9 CRDi)

Page 263 of 539

6

DO-IT-YOURSELF MAINTENANCE

41

1. Keep all tires inflated to the correct

pressure.

2. Place the vehicle on level ground and press the front bumper & rear bumper down several times. Placevehicle at a distance of 3m (118.1 in.) from the test wall.

3. See that the vehicle is unloaded (except for full levels of coolant, engine oil and fuel, and spare tire,jack, and tools). Have the driver or equivalent weight placed in driver's seat.

4. Clean the headlight lens and turn on the headlight.

5. Open the hood.

6. Draw the vertical line (through the center of each headlight) and thehorizontal line (through the center of each headlight) on the aiming screen.

(1) Horizontal line dimension from

ground : Low Beam : 894 mm (35.1 in.) High Beam : 839 mm (33 in.)

(2) Distance between each vertical line : Low Beam : 1,316 mm (51.8 in.) High Beam : 1,076 mm (42.4 in.) And then, draw a parallel line at 38

mm (1.50 in.) under the horizontalline in case of adjusting the low beam or at 21 mm (0.83 in.) under the horizontal line in case of adjusting thehigh beam.

7. Adjust each cut-off line of the low beam to the parallel line with a phillips screwdriver - VERTICALAIMING.

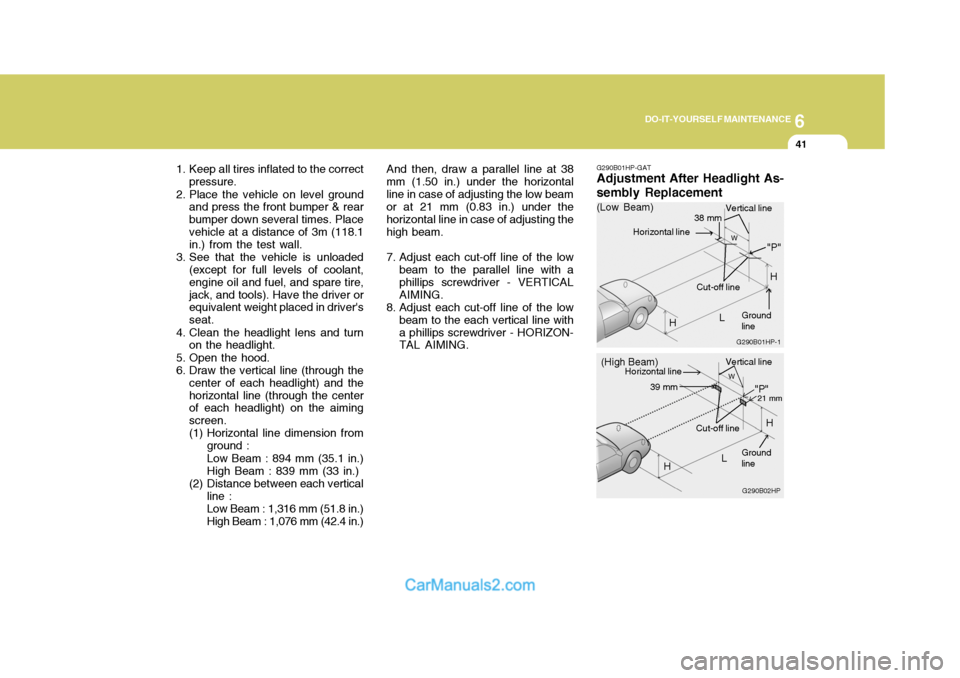

8. Adjust each cut-off line of the low beam to the each vertical line witha phillips screwdriver - HORIZON- TAL AIMING. G290B01HP-GAT Adjustment After Headlight As- sembly Replacement

G290B02HP

LW

H Cut-off line

"P"

Vertical line

Horizontal line

Ground line

21 mm39 mm

(High Beam)

H

G290B01HP-1

LW

"P"

38 mm

H

H

(Low Beam)

Vertical line

Ground line

Cut-off line

Horizontal line

Page 272 of 539

7EMISSION CONTROL SYSTEMS

2EMISSION CONTROL SYSTEMS

H010A01A-GAT

(If Installed)

Your Hyundai is equipped with an

emission control system to meet all requirements of the Emission prohibi- tion rules of your province.

There are three emission control sys-

tems which are as follows.

(1) Crankcase emission control sys- tem (For a Gasoline Engine)

(2) Evaporative emission control sys- tem (For a Gasoline Engine)

(3) Exhaust emission control system

In order to assure the proper function

of the emission control systems, it is recommended that you have your carinspected and maintained by an au- thorized Hyundai dealer in accordance with the maintenance schedule in thismanual. H010B01A-AAT

1. Crankcase Emission Control

System ; For a Gasoline Engine

The positive crankcase ventilation

system is employed to prevent air pollution caused by blow-by gasesbeing emitted from the crankcase. This system supplies fresh filtered air to the crankcase through the air in-take hose. Inside the crankcase, which the fresh air mixes with blow-by gases, which then pass through the PCVvalve into the induction system.

H010C02Y-GAT

2. Evaporative Emission

Control System ; For a Gasoline Engine

The Evaporative Emission Control

System is designed to prevent fuel vapors from escaping into the atmo- sphere. Canister

While the engine is inoperative, fuel

vapors generated inside the fuel tankare absorbed and stored in the canis- ter. When the engine is running, thefuel vapors absorbed in the canister are drawn into the induction system through the purge control solenoidvalve. Purge Control Solenoid Valve

The purge control solenoid valve is

controlled by the ECM; when the en- gine coolant temperature is low, and during idling, it closes, so that evapo- rated fuel is not taken into the surgetank. After engine warm-up, during ordinary driving, it opens so as to introduce evaporated fuel to the surgetank. H010D01A-AAT

3. Exhaust Emission Control

System

The Exhaust Emission Control Sys- tem is a highly effective system whichcontrols exhaust emissions while maintaining good vehicle performance.

Page 290 of 539

10

INDEX

3

Corrosion protection Cleaning the interior ................................................. 4-6

Protecting your Hyundai from corrosion .................. 4-2

Washing and waxing ................................................ 4-4

Cruise Control ......................................................... 1-100

D Defrosting/Defogging ............................................... 1-109

Door

Locking and unlocking front door with a key ........1-11

Drink Holder .............................................................. 1-82

Drive Belts ...................................................... 6-25, 6-29

Driving

Driving for econom y ............................................... 2-23

Smooth cornering ................................................... 2-25

Winter driving ......................................................... 2-25

E Emission Control Syst em ........................................... 7-1

Catalytic converter ................................................... 7-3

EGR System ............................................................ 7-5

Engine Before starting the engine ....................................... 2-3 Compartment (3.5 V6) ............................................. 6-2

Compartment (2.5 TCI) ............................................ 6-3

Compartment (2.9 CRDi) ......................................... 6-4 Coolant ................................................................... 6-11

Coolant temper ature gauge ................................... 1-65If the engine

overheats ............................................ 3-4

Number .................................................................... 8-2

Oil ............................................................................. 6-6

Starting ..................................................................... 2-5

Engine Exhaust Can Be Dangerous ........................... 2-2

FFan Speed Control ...................................... 1-104, 1-115

Fog Light Switch

Front ....................................................................... 1-75

Rear ....................................................................... 1-75

Four-Wheel Drive (4WD) ........... ............................... 2-14

Front Seats

Adjustable front seats ............................................ 1-18

Adjustable headrest s .............................................. 1-19

Adjusting seat forward and rear ward..................... 1-18

Adjusting seatback angle .......................................1-19

Front/Rear Window Defroster Sw itch....................... 1-78

Fuel

Capacity ................................................................... 9-2

Diesel ....................................................................... 1-2

Gauge .................................................................... 1-65

Unleaded gasolin e ................................................... 1-2

Fuel Filler Lid Remote release ...................................................... 1-96

Full-time 4WD Operation ............... ........................... 2-17

Fuses ........................................................................ 6-30

Page 308 of 539

1

CONTROLS AND EQUIPMENT

3

ZB010D1-E Operation in Foreign Countries Drivers of vehicles which are to be operated in foreign countries mustsatisfy themselves that:

o The vehicle meets all local regula- tions with respect to insurance, speci- fications etc..

o The correct types and grades of fuel are available for satisfactory opera-tion of the vehicle.

ZB010F2-A FUELS FOR CLEANER AIR To help contribute to cleaner air, Hyundai recommends that you use fuels treated with detergent additives,which help to prevent deposit forma- tion in the engine. These fuels will help the engines run cleaner and the Emis-sion Control System performance.BEFORE ENTERING THE VE- HICLE

YB020A1-E

o Ensure that all windows, mirrors

and lamps are clean.

o Check condition of all tyres.

o Ensure that no fluid leaks are evi-

dent.

o Ensure that the area around the

vehicle is clear before driving off.AFTER ENTERING THE VE- HICLE

YB020B1-E

o Ensure that all occupants fasten

and correctly adjust seat belts.

o Ensure that seat and headrestraint

positions are adjusted for optimum safety, control and comfort.

o Adjust interior and exterior rear view

mirrors.

o Verify correct operation of lamps, horn and other electrical equipment.

o Ensure that warning lamps illumi- nate when ignition is turned on.

NOTE: Fluid levels such as engine oil, en- gine coolant, brake and windscreenwasher fluid should be checked daily or at each refuelling, whichever occurs sooner.

Page 362 of 539

1

CONTROLS AND EQUIPMENT

57

!

B270A01A-GAT BRAKE PAD WEAR WARNING SOUND The front disc brake pads have wear indicators that should make a high-pitched squealing or scraping noise when new pads are needed. The sound may come and go or be heard all thetime when the vehicle is moving. It may also be heard when the brake pedal is pushed down firmly. Exces-sive rotor damage will result if the worn pads are not replaced. See your Hyundai dealer immediately. B290A02A-EAT COOLANT TEMPERATURE GAUGE

The needle on the gauge indicates the approximate fuel level in the fuel tank. The fuel capacity is given in Section 9. WARNING:

Never remove the radiator cap when the engine is hot. The coolant is under pressure and could erupt and cause severe burns. Wait until theengine is cool before removing the radiator cap.

INSTRUMENT CLUSTER

B280A01A-AAT FUEL GAUGE

HHP2080

HHP2081

Page 363 of 539

1CONTROLS AND EQUIPMENT

58

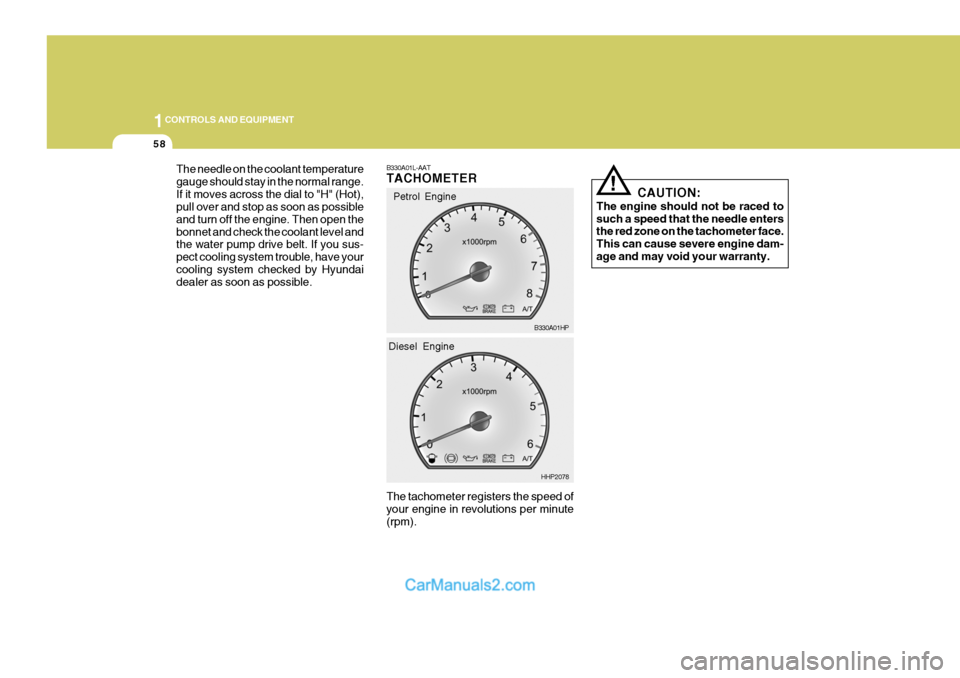

The needle on the coolant temperature gauge should stay in the normal range.If it moves across the dial to "H" (Hot), pull over and stop as soon as possible and turn off the engine. Then open thebonnet and check the coolant level and the water pump drive belt. If you sus- pect cooling system trouble, have yourcooling system checked by Hyundai dealer as soon as possible.

! CAUTION:

The engine should not be raced to such a speed that the needle enters the red zone on the tachometer face. This can cause severe engine dam-age and may void your warranty.

B330A01L-AAT TACHOMETER The tachometer registers the speed of your engine in revolutions per minute (rpm).Petrol Engine

B330A01HP

HHP2078

Diesel Engine

Page 368 of 539

1

CONTROLS AND EQUIPMENT

63

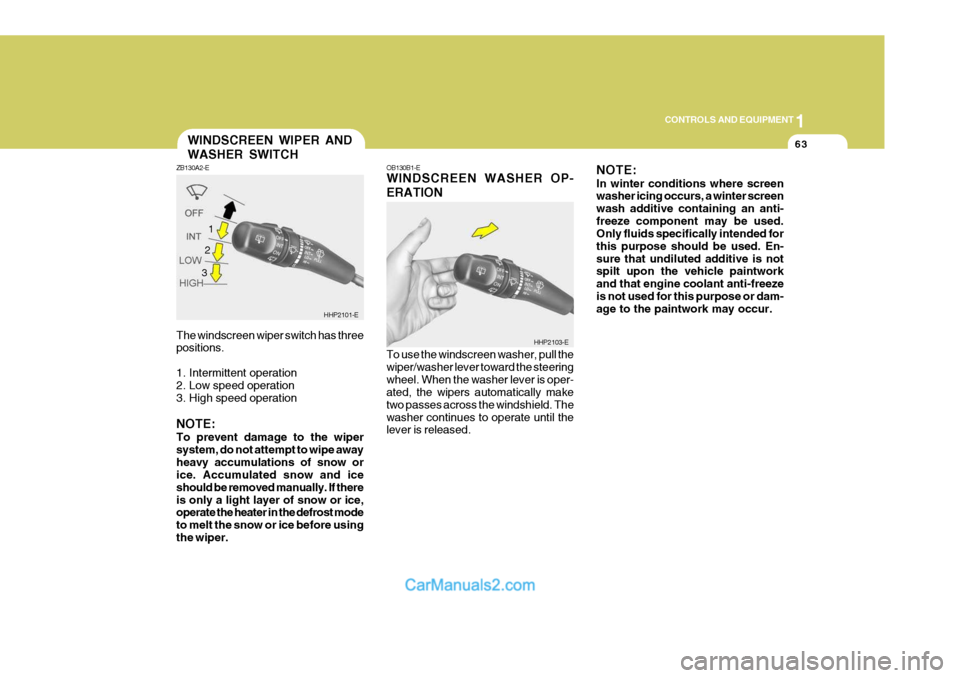

The windscreen wiper switch has three positions.

1. Intermittent operation

2. Low speed operation

3. High speed operation NOTE: To prevent damage to the wiper system, do not attempt to wipe awayheavy accumulations of snow or ice. Accumulated snow and ice should be removed manually. If thereis only a light layer of snow or ice, operate the heater in the defrost mode to melt the snow or ice before usingthe wiper.WINDSCREEN WIPER AND WASHER SWITCH

ZB130A2-E

HHP2101-E

1

OB130B1-E WINDSCREEN WASHER OP- ERATION To use the windscreen washer, pull the wiper/washer lever toward the steeringwheel. When the washer lever is oper- ated, the wipers automatically make two passes across the windshield. Thewasher continues to operate until the lever is released. NOTE: In winter conditions where screen washer icing occurs, a winter screen wash additive containing an anti-freeze component may be used. Only fluids specifically intended for this purpose should be used. En-sure that undiluted additive is not spilt upon the vehicle paintwork and that engine coolant anti-freezeis not used for this purpose or dam- age to the paintwork may occur.

HHP2103-E

2 3

Page 440 of 539

2

DRIVING YOUR HYUNDAI

27

!

YC200C3-A Trailer Brakes If your trailer is equipped with a braking system, make sure it conforms to fed-eral and/or local regulations and that it is properly installed and operating cor- rectly. NOTE: If you tow a trailer or vehicle, your car will require more frequent main-tenance due to the additional load. See Maintenance Under Severe Usage Conditions" on page 5-6. CAUTION:

o Never connect a trailer brake sys- tem directly to the vehicle brakesystem.

o When towing a trailer on steep grades (in excess of 12%) payclose attention to the engine cool-ant temperature gauge to ensure the engine does not overheat. If the needle of the coolant tem-perature gauge moves across the dial towards "H" (HOT), pull over and stop as soon as it is safe todo so, and allow the engine to idle until it cools down. You may proceed once the engine hascooled sufficiently. YC200D2-E Safety Cables Should the towbar connection between your car and the trailer or vehicle youare towing fail, the trailer or vehicle could wander dangerously across other lanes of traffic and ultimately leave theroadway. To eliminate this potentially dangerous situation, safety cables, attached between your car and thetrailer or towed vehicle, are required.

Page 448 of 539

3 IN CASE OF EMERGENCY

4

!

1. Ensure that the booster battery is 12

volt type. If the booster battery is installed in another vehicle, ensure that the two vehicles are not touch- ing.

2. Turn off all unnecessary electrical equipment in both vehicles.

3. Ensure that the engine of the ve- hicle providing the jump start is run- ning prior to connection of the jump cables.

4. Connect the red jump cable to the positive (+) terminal of the boosterbattery and the other end to thepositive (+) terminal of the dis- charged battery.

5. Attach the black jump cable to the negative (-) terminal of the boosterbattery, and the other end to a ground point within the engine compartmentof the vehicle with the flat bat-tery. Do not connect to the negative bat- tery terminal of the flat battery sincesparks may be generated with the subsequent risk of explosion.

6. Raise the booster vehicle engine speed to 2,000 r.p.m. and start theengine of the vehicle with the flat battery. 7. Switch "ON" the main beam

headlamps before carefully remov-ing the jumper cables in the reverse order of attachment. Once the jumper cables have been removed,switch "OFF" the main beam headlamps.

CAUTION:

If the jump cable is incorrectly in- stalled, damage to the vehicle elec- trical system may occur, in particu- lar the electronic components suchas the Fuel Injection system com- puter and the Automatic transmis- sion computer. The battery mustnever be disconnected whilst the engine is running.

IF THE ENGINE OVERHEATS

HPD040A2-E If the temperature gauge indicates overheating:

1. Pull off the road and stop as soon as it is safe to do so.

2. Place the gear selector lever in "P"

(automatic), or neutral (manual trans- mission) and set the parking brake. If the air conditioning is on, turn it off.

3. If coolant is running out under the car or steam is coming out from underthe bonnet, stop the engine. Do not open the bonnet until the coolant hasstopped running or the steaming has stopped. If there is no visible loss of coolant and no steam, leave theengine running and check to be sure the engine cooling fan is operating. If the fan is not running, turn theengine off.

4. Check to see if the water pump drive

belt is missing. If it is not missing,check to see that it is tight. If the drive belt seems to be satisfactory, check for coolant leaking from theradiator, hoses or under the car. (If the air conditioning had been in use, it is normal for cold water to bedraining from it).