engine coolant Hyundai Terracan 2006 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2006, Model line: Terracan, Model: Hyundai Terracan 2006Pages: 539, PDF Size: 18.11 MB

Page 371 of 539

1

CONTROLS AND EQUIPMENT

63

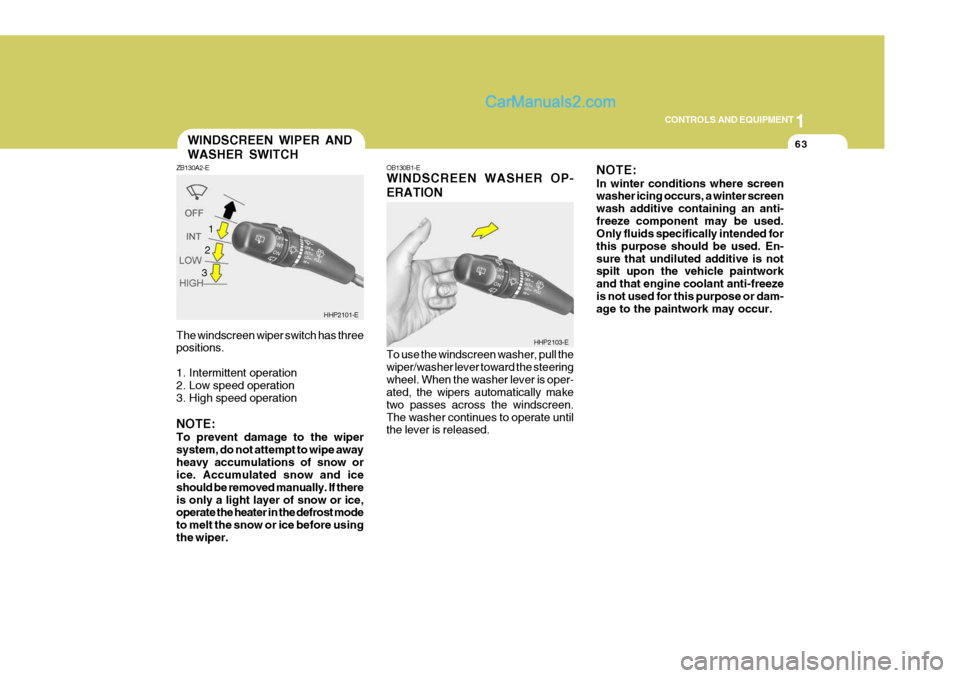

The windscreen wiper switch has three positions.

1. Intermittent operation

2. Low speed operation

3. High speed operation NOTE: To prevent damage to the wiper system, do not attempt to wipe awayheavy accumulations of snow or ice. Accumulated snow and ice should be removed manually. If thereis only a light layer of snow or ice, operate the heater in the defrost mode to melt the snow or ice before usingthe wiper.WINDSCREEN WIPER AND WASHER SWITCH

ZB130A2-E

HHP2101-E

1

OB130B1-E WINDSCREEN WASHER OP- ERATION To use the windscreen washer, pull the wiper/washer lever toward the steeringwheel. When the washer lever is oper- ated, the wipers automatically make two passes across the windscreen.The washer continues to operate until the lever is released. NOTE: In winter conditions where screen washer icing occurs, a winter screen wash additive containing an anti-freeze component may be used. Only fluids specifically intended for this purpose should be used. En-sure that undiluted additive is not spilt upon the vehicle paintwork and that engine coolant anti-freezeis not used for this purpose or dam- age to the paintwork may occur.

HHP2103-E

2 3

Page 443 of 539

2

DRIVING YOUR HYUNDAI

27

!

CAUTION:

o Never connect a trailer brake sys- tem directly to the vehicle brake system.

o When towing a trailer on steep grades (in excess of 6%) pay closeattention to the engine coolanttemperature gauge to ensure the engine does not overheat. If the needle of the coolant temperaturegauge moves across the dial to- wards "H" (HOT), pull over and stop as soon as it is safe to do so,and allow the engine to idle until it cools down. You may proceed once the engine has cooled suffi-ciently. YC200D2-E Safety Cables Should the towbar connection between your car and the trailer or vehicle youare towing fail, the trailer or vehicle could wander dangerously across other lanes of traffic and ultimately leave theroadway. To eliminate this potentially dangerous situation, a safety cable, attached between your car and thetrailer or towed vehicle, are required.

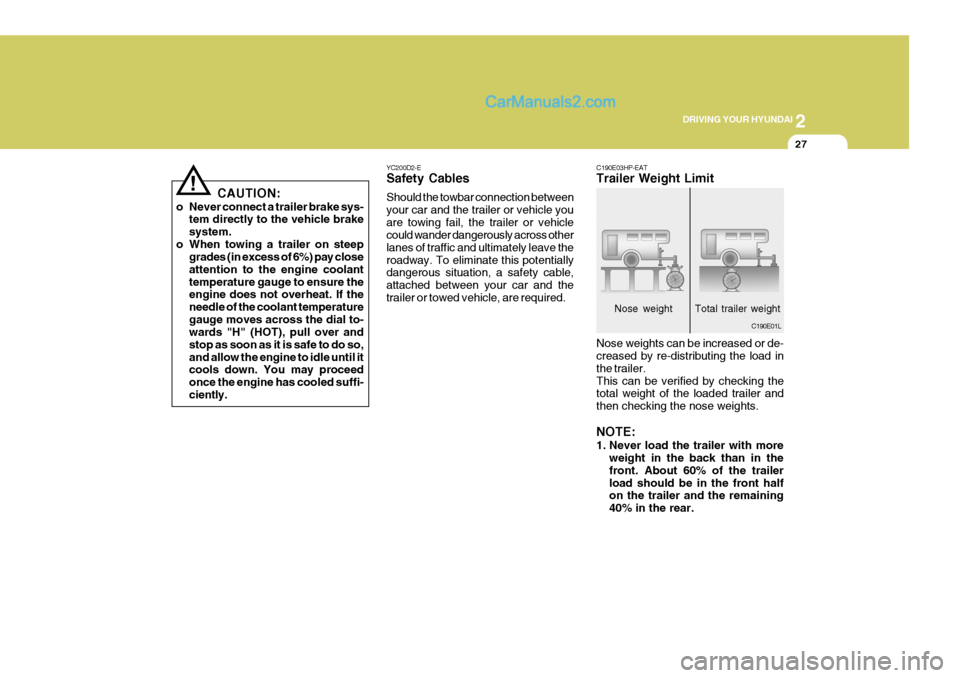

C190E03HP-EAT Trailer Weight Limit Nose weights can be increased or de- creased by re-distributing the load in the trailer.This can be verified by checking the total weight of the loaded trailer and then checking the nose weights. NOTE:

1. Never load the trailer with more

weight in the back than in the front. About 60% of the trailerload should be in the front half on the trailer and the remaining 40% in the rear.

C190E01L

Nose weight Total trailer weight

Page 450 of 539

3 IN CASE OF EMERGENCY

4

!

1. Ensure that the booster battery is 12

volt type. If the booster battery is installed in another vehicle, ensure that the two vehicles are not touch- ing.

2. Turn off all unnecessary electrical equipment in both vehicles.

3. Ensure that the engine of the ve- hicle providing the jump start is run- ning prior to connection of the jump cables.

4. Connect the red jump cable to the positive (+) terminal of the boosterbattery and the other end to thepositive (+) terminal of the dis- charged battery.

5. Attach the black jump cable to the negative (-) terminal of the boosterbattery, and the other end to a ground point within the engine compartmentof the vehicle with the flat bat-tery. Do not connect to the negative bat- tery terminal of the flat battery sincesparks may be generated with the subsequent risk of explosion.

6. Raise the booster vehicle engine speed to 2,000 r.p.m. and start theengine of the vehicle with the flat battery. 7. Switch "ON" the main beam

headlamps before carefully remov-ing the jumper cables in the reverse order of attachment. Once the jumper cables have been removed,switch "OFF" the main beam headlamps.

CAUTION:

If the jump cables are incorrectly installed, damage to the vehicle elec- trical system may occur, in particu- lar the electronic components suchas the Fuel Injection system com- puter and the Automatic transmis- sion computer. The battery mustnever be disconnected whilst the engine is running.

IF THE ENGINE OVERHEATS

HPD040A2-E If the temperature gauge indicates overheating:

1. Pull off the road and stop as soon as it is safe to do so.

2. Place the gear selector lever in "P"

(automatic), or neutral (manual trans- mission) and set the parking brake. If the air conditioning is on, turn it off.

3. If coolant is running out under the car or steam is coming out from underthe bonnet, stop the engine. Do not open the bonnet until the coolant hasstopped running or the steaming has stopped. If there is no visible loss of coolant and no steam, leave theengine running and check to be sure the engine cooling fan is operating. If the fan is not running, turn theengine off.

4. Check to see if the water pump drive

belt is broken. If it is not missing,check to see that it is tight. If the drive belt seems to be satisfactory, check for coolant leaking from theradiator, hoses or under the car. (If the air conditioning had been in use, it is normal for cold water to bedraining from it).

Page 451 of 539

3

IN CASE OF EMERGENCY

5

!

!

!WARNING:

Whilst the engine is running, keep hands and clothing away from mov- ing parts such as the fan and drive belts to prevent injury.

WARNING (Diesel only):

Never work on injection system withengine running or within 30 seconds after shutting off engine. High pres- sure pump, rail, injectors and highpressure pipes are subject to high pressure even after the engine stopped. The fuel jet produced byfuel leaks may cause serious in- jury, if it contacts the body. People using pacemakers should ensure thatthey keep a distance of 30cm from the ECU or wiring harness within the engine room while engine is run-ning, since the high currents in the Common Rail system produce con- siderable magnetic fields. 5. If the water pump drive belt is broken

or coolant is leaking out, stop theengine immediately and call the near- est Hyundai authorised repairer for assistance.

WARNING:

Do not remove the radiator cap when the engine is hot since steam and boiling water may be ejected fromthe radiator resulting in burns or scalding.

6. If the cause of the overheating can- not be found, wait until the engine temperature has returned to normal. Then, if coolant has been lost, care-fully remove the radiator cap and add water to bring the fluid level in the reservoir(page 6-10) up to the baseof the radiator fill opening. Fill the coolant expansion tank to the half- way mark.

7. Proceed with caution until it is estab- lished that the engine is operatingnormally. If the engine overheatsrepeatedly, the advice of a Hyundai authorised repairer should be sought.! CAUTION:

Serious loss of coolant indicates there is a leak in the cooling system and this should be checked as soon as possible by a Hyundai authorisedrepairer.

Page 473 of 539

5

VEHICLE MAINTENANCE REQUIREMENTS

5

20 24

I

R II I I

RR II I I I I I I I I I I I I I I I

R

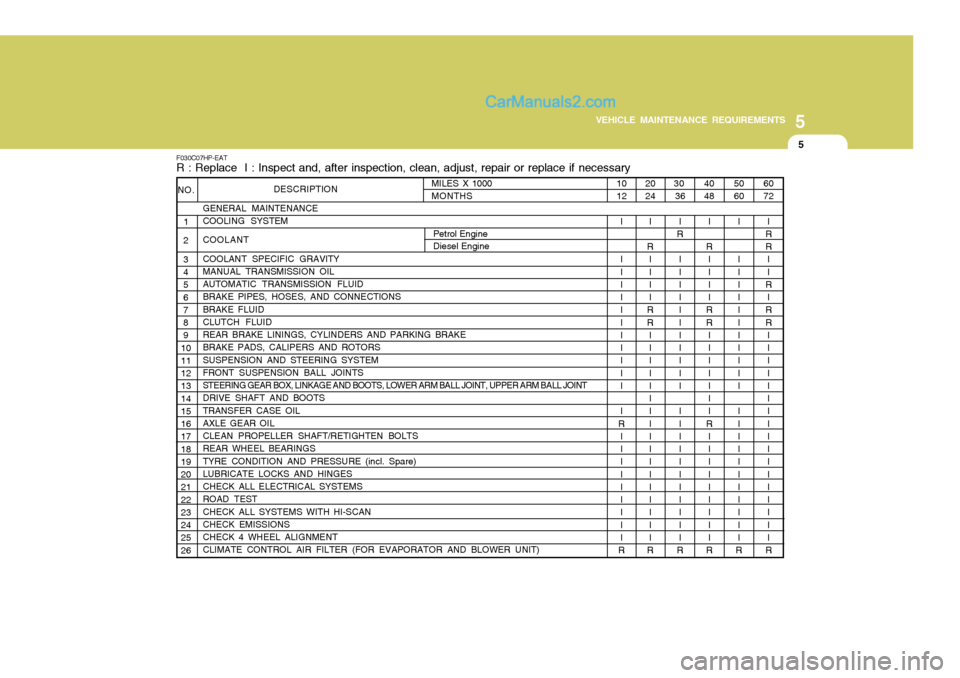

F030C07HP-EAT R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

DESCRIPTION

GENERAL MAINTENANCE COOLING SYSTEM COOLANT COOLANT SPECIFIC GRAVITY MANUAL TRANSMISSION OIL AUTOMATIC TRANSMISSION FLUID BRAKE PIPES, HOSES, AND CONNECTIONS BRAKE FLUID CLUTCH FLUID

REAR BRAKE LININGS, CYLINDERS AND PARKING BRAKE BRAKE PADS, CALIPERS AND ROTORS SUSPENSION AND STEERING SYSTEM FRONT SUSPENSION BALL JOINTS

STEERING GEAR BOX, LINKAGE AND BOOTS, LOWER ARM BALL JOINT, UPPER ARM BALL JOINT

DRIVE SHAFT AND BOOTS TRANSFER CASE OIL AXLE GEAR OIL CLEAN PROPELLER SHAFT/RETIGHTEN BOLTS REAR WHEEL BEARINGS TYRE CONDITION AND PRESSURE (incl. Spare) LUBRICATE LOCKS AND HINGES CHECK ALL ELECTRICAL SYSTEMS ROAD TEST CHECK ALL SYSTEMS WITH HI-SCAN CHECK EMISSIONS CHECK 4 WHEEL ALIGNMENT CLIMATE CONTROL AIR FILTER (FOR EVAPORATOR AND BLOWER UNIT)

NO.

1

2 3 4 5 6 7 8 9

1011 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

60 72

I

RR II

R

I

RR II I I I I I I I I I I I I I I I

R

50 60

I I I I I I I I I I I I I I I I I I I I I I I

R

40 48

I

R II I I

RR II I I I I I

R I I I I I I I I I

R

30

36

I

R

I I I I I I I I I I I I I I I I I I I I I I

R

10 12

I I I I I I I I I I I I I

R I I I I I I I I I

R

MILES X 1000MONTHS

Petrol Engine Diesel Engine

Page 476 of 539

5VEHICLE MAINTENANCE REQUIREMENTS

8

F060E01A-AAT

o Timing belt Inspect all parts related to the timing belt for damage and deformation. Replace any damaged parts immedi- ately. F060G01A-EAT

o Vapour hose and fuel filler cap The vapour hose and fuel filler cap should be inspected at those intervals specified in the maintenance sched-ule. Make sure that a new vapour hose or fuel filler cap is correctly replaced. F060F02A-AAT

o Crankcase ventilation hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical dam-age. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessiveswelling indicate deterioration. Particu- lar attention should be paid to examine those hose surfaces nearest to highheat sources, such as the exhaust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact with any heat source, sharp edges or mov-ing component which might cause heat damage or mechanical wear. Inspect all hose connections, such as clampsand couplings, to make sure they are secure, and that no leaks are present. Hoses should be replaced immedi-ately if there is any evidence of dete- rioration or damage. F060H01A-AAT

o Air cleaner filter

A Genuine Hyundai air cleaner filter is

recommended when the filter is re-placed.

F060J01A-EAT

o Spark plugs (For petrol engine)

Make sure to install new spark plugs

of the correct heat range. F070B01A-AAT

o Cooling system

Check the cooling system, such as radiator, coolant reservoir, hoses andconnections for leakage and damage. Replace any damaged parts.

Page 477 of 539

5

VEHICLE MAINTENANCE REQUIREMENTS

9

F070C01A-AAT

o Coolant

The coolant should be changed at

the intervals specified in the mainte- nance schedule. F070D01HP-AAT

o Manual transmission oil

Inspect the manual transmission oil according to the maintenance sched- ule.

NOTE: If the oil level is low, check forpossible leaks before adding oil. Do not overfill. F070E03HP-GAT

o Automatic transmission fluid

The fluid level should be in the "HOT"

range of the dipstick, after engine andtransmission and filter are at normal operating temperature. Check the Au-tomatic and filter Transmission and filter Fluid level with the engine running and the transmission and filter inneutral, with the parking brake properly applied. Use MOBIL DEXRON-II when adding or changing fluid. Refer to the chapter6. F070F01A-AAT

o Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and any leakage. Replace any deteriorated or damaged parts immediately. F070G02A-AAT o Brake fluid Check brake fluid level in the brake fluid reservoir. The level should be between "MIN" and "MAX" marks on the side of the reservoir. Use onlyhydraulic brake fluid conforming to DOT 3 or DOT 4. F070H01HP-AAT

o Rear brake linings, pad and parking brake Check the rear brake linings and pads for scoring, burning, leaking fluid, bro-ken parts, and excessive wear. In- spect the parking brake system in- cluding the parking brake lever andcables. For detailed service proce- dures, refer to the Shop Manual.

Page 479 of 539

Engine Compartment ................................................... 6-2

Daily Operating Checks ............................................... 6-4

Engine Oil ..................................................................... 6-4

Engine Oil and Filter Replacement .............................. 6-8

Engine Coolant Checking and Replacing .................... 6-9

Changing the Air Cleaner Filter ...................................6-12

Manual Transmission Lubricant ..................................6-15

Automatic Transmission Lubricant ..............................6-16

Brake System Checking ............................................. 6-18

Checking the Clutch Fluid ........................................... 6-19

Air Conditioning System Maintenance ........................ 6-20

Changing the Climate Control Air Filter .. ....................6-22

Checking Engine Drive Belts ...................................... 6-24

Fusible Links ............................................................... 6-25

Battery Mai ntenance ................................................... 6-27

Checking Electric Cooling Fans .................................6-29

Power Steering Fluid Level ......................................... 6-29

Fuel Filter ..................................................................... 6-30

Replacing Headlight Bulbs .......................................... 6-31

Headlight Aiming Adjustment ...................................... 6-33

Bulb Wattages ............................................................. 6-35

Fuse Panel D escription ............................................... 6-36

OWNER MAINTENANCE

6

6

Page 480 of 539

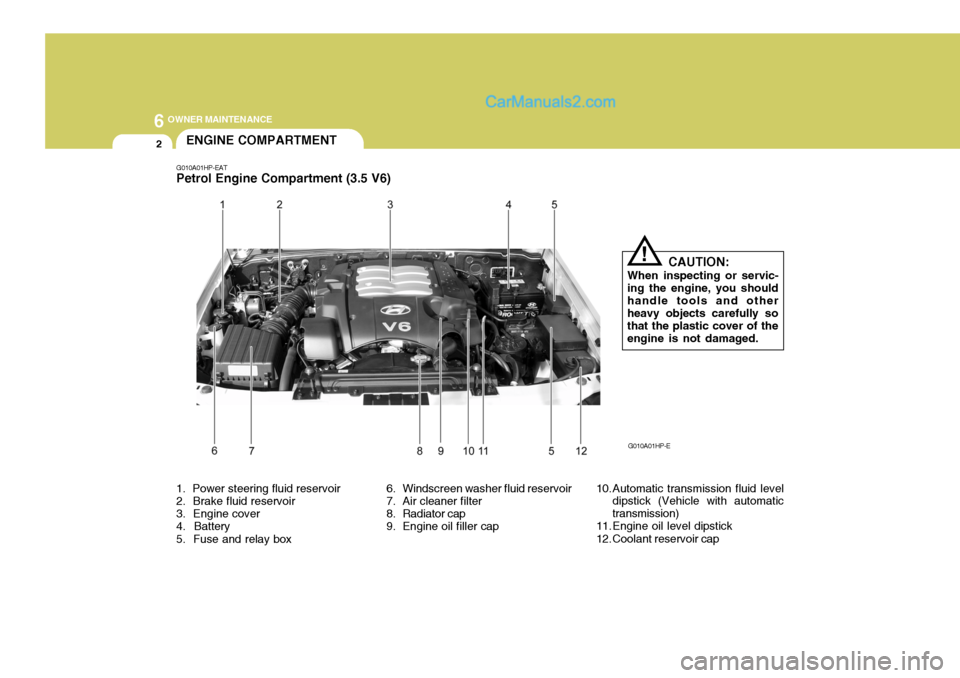

6 OWNER MAINTENANCE

2

1. Power steering fluid reservoir 2. Brake fluid reservoir 3. Engine cover 4. Battery 5. Fuse and relay box 6. Windscreen washer fluid reservoir

7. Air cleaner filter

8. Radiator cap

9. Engine oil filler cap

10. Automatic transmission fluid level

dipstick (Vehicle with automatictransmission)

11. Engine oil level dipstick

12. Coolant reservoir cap

G010A01HP-EAT Petrol Engine Compartment (3.5 V6)

CAUTION:

When inspecting or servic-

ing the engine, you should handle tools and other heavy objects carefully so that the plastic cover of theengine is not damaged.

!

ENGINE COMPARTMENT

G010A01HP-E

Page 481 of 539

6

OWNER MAINTENANCE

3

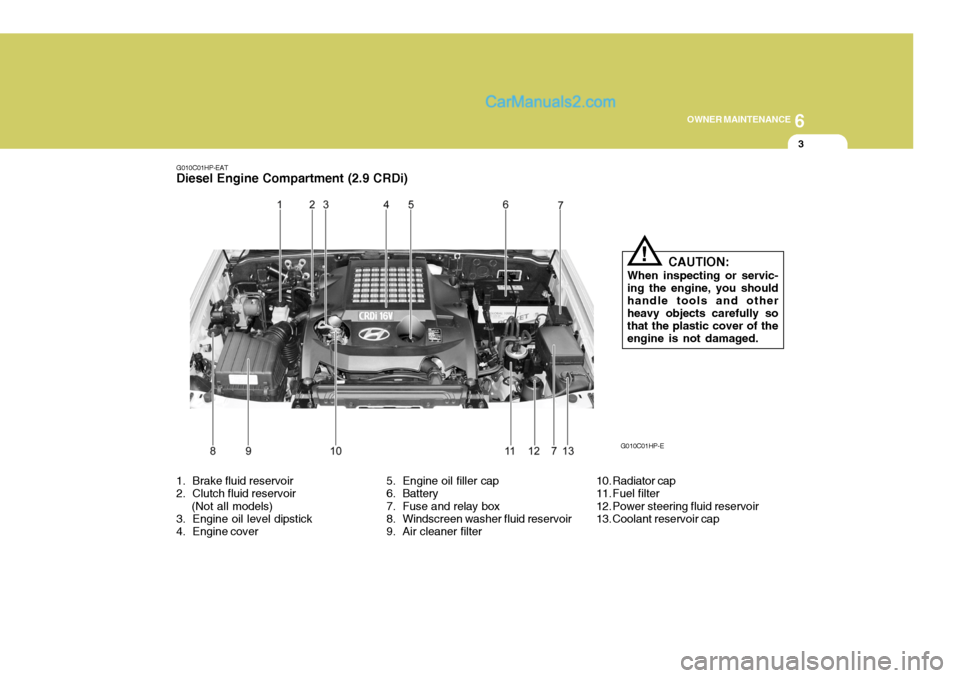

G010C01HP-EAT

Diesel Engine Compartment (2.9 CRDi)

1. Brake fluid reservoir

2. Clutch fluid reservoir (Not all models)

3. Engine oil level dipstick

4. Engine cover 5. Engine oil filler cap

6. Battery

7. Fuse and relay box

8. Windscreen washer fluid reservoir

9. Air cleaner filter10. Radiator cap

11. Fuel filter

12. Power steering fluid reservoir

13. Coolant reservoir capCAUTION:

When inspecting or servic-ing the engine, you shouldhandle tools and other heavy objects carefully so that the plastic cover of theengine is not damaged.

!

G010C01HP-E