maintenance schedule Hyundai Tiburon 2006 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2006, Model line: Tiburon, Model: Hyundai Tiburon 2006Pages: 266, PDF Size: 10.94 MB

Page 206 of 266

6

DO-IT-YOURSELF MAINTENANCE

12

!

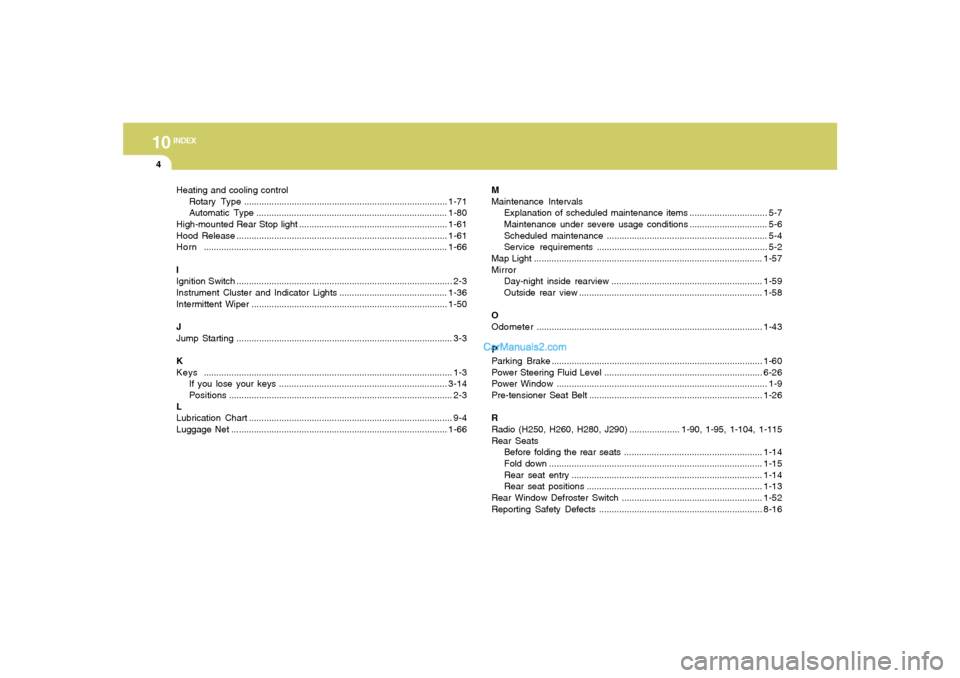

G100A04GK-AATTransaxle lubricant in the manual transaxle

should be checked at those intervals specified

in the vehicle maintenance schedule in Section

5.Recommended OilUse only HYUNDAI GENUINE PARTS MTF

75W/85 (API GL-4) or equivalents in the manual

transaxle.Manual Transaxle Oil CapacityThe oil capacity of the manual transaxle:

5 speed: 2.27 U.S. quarts (2.15L)

6 speed: 2.32 U.S. quarts (2.2L)

HGK5009

Filler plug

Drain plug

CHECKING THE TRANSAXLE OIL

(MANUAL)

CAUTION:

o Radiator anti-freeze (engine coolant)

should not be used in the washer system

because it will damage the car’s finish.

o The washer should not be operated if

the washer reservoir is empty. This can

damage the washer fluid pump.

o In areas where water freezes in winter,

use windshield washer antifreeze.

!

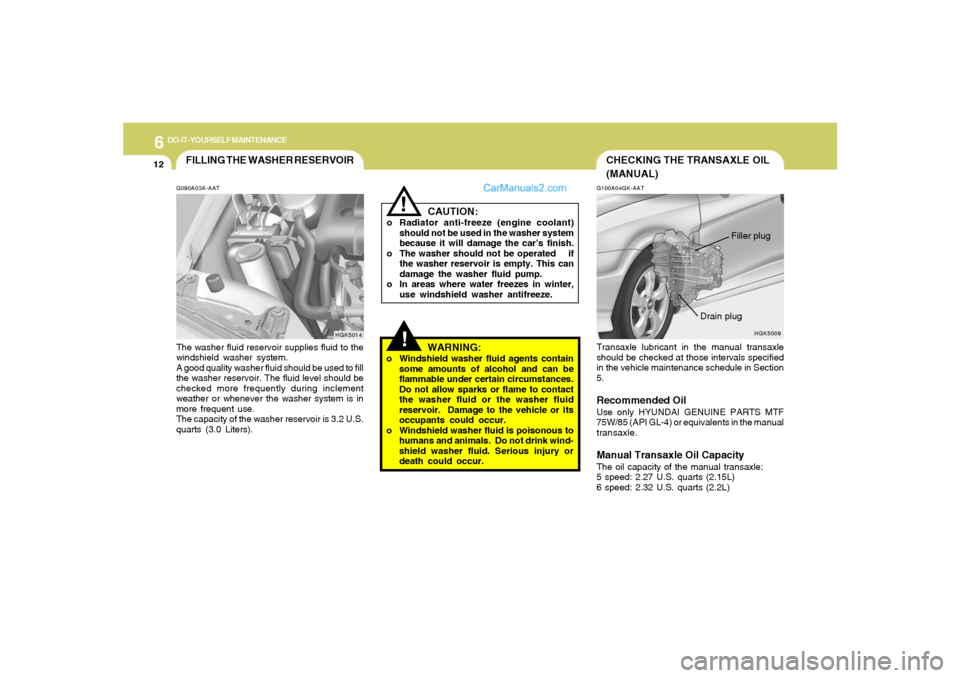

FILLING THE WASHER RESERVOIRG090A03A-AATThe washer fluid reservoir supplies fluid to the

windshield washer system.

A good quality washer fluid should be used to fill

the washer reservoir. The fluid level should be

checked more frequently during inclement

weather or whenever the washer system is in

more frequent use.

The capacity of the washer reservoir is 3.2 U.S.

quarts (3.0 Liters).

HGK5014

WARNING:

o Windshield washer fluid agents contain

some amounts of alcohol and can be

flammable under certain circumstances.

Do not allow sparks or flame to contact

the washer fluid or the washer fluid

reservoir. Damage to the vehicle or its

occupants could occur.

o Windshield washer fluid is poisonous to

humans and animals. Do not drink wind-

shield washer fluid. Serious injury or

death could occur.

Page 207 of 266

6

DO-IT-YOURSELF MAINTENANCE

13

!

WARNING:

It is always better to check the transaxle oil

level when the engine is cool or cold. If the

engine is hot, you should exercise great

caution to avoid burning yourself on hot

engine or exhaust parts.

CHECKING THE TRANSAXLE

FLUID (AUTOMATIC)G110A01E-AATTransaxle fluid in the automatic transaxle should

be checked at those intervals specified in the

vehicle maintenance schedule in Section 5.NOTE:Automatic transaxle fluid is basically red

color. As driving distance increases, the

fluid color turns darkish red gradually. It is

a normal condition and you should not

judge the need to replace based upon the

changing color.

You must replace the automatic transaxle

fluid in accordance with intervals specified

in the vehicle maintenance schedule in

section 5.

NOTE:It is recommended that the manual transaxle

fluid should be checked by an authorized

Hyundai dealer.

G110B05A-AATRecommended FluidYour Hyundai automatic transaxle is specially

designed to operate with HYUNDAI GENUINE

ATF SP III, DIAMOND ATF SP III, SK ATF SP

III or other brands meeting the SP III specifica-

tion approved by Hyundai Motor Co.. Damage

caused by a nonspecified fluid is not covered by

your new vehicle limited warranty.

CAUTION:

Use of aftermarket ATF additives may cause

damage to the automatic transaxle. Only

use HYUNDAI GENUINE ATF SP III, DIA-

MOND ATF SP III, SK ATF SP III or other

brands meeting the SP III specification ap-

proved by Hyundai Motor Co.. If you are

having your vehicle serviced at a facility

other than a Hyundai dealer, verify ATF is

used for your vehicle.

!

Page 209 of 266

6

DO-IT-YOURSELF MAINTENANCE

15

!

HGK5008

Fluid level should be within this range

WARNING:

The cooling fan is controlled by engine

coolant temperature and may sometimes

operate even when the engine is not run-

ning. Use extreme caution when working

near the blades of the cooling fan, so that

you are not injured by a rotating fan blade.

As the engine coolant temperature de-

creases, the fan will automatically shut off.

This is a normal condition.

CHECKING THE BRAKESG120A01A-AAT

CAUTION:

Because brakes are essential to the safe

operation of the car, it is suggested that

they be checked and inspected by your

Hyundai dealer. The brakes should be

checked and inspected for wear at those

intervals specified in the vehicle mainte-

nance schedule in Section 5.

!

!

G120B01A-AATChecking the Brake Fluid Level

WARNING:Use caution when handling brake fluid. It

can damage your vision if it gets into your

eyes. It will also damage your vehicle’s

paint if spilled on it and not removed imme-

diately.G120C02A-AATRecommended Brake FluidUse only hydraulic brake fluid conforming to

DOT 3 or DOT 4 specifications in your braking

system. Follow the instructions printed on the

container.

Page 237 of 266

7

EMISSION CONTROL SYSTEMS2

EMISSION CONTROL SYSTEM

H010D01A-AAT3. Exhaust Emission Control SystemThe Exhaust Emission Control System is a

highly effective system which controls exhaust

emissions while maintaining good vehicle per-

formance.

H010B01A-AAT1. Crankcase Emission Control

SystemThe Positive Crankcase Ventilation System is

employed to prevent air pollution caused by

blow-by gases being emitted from the crank-

case. This system supplies fresh filtered air to

the crankcase through the air intake hose.

Inside the crankcase, the fresh air mixes with

blow-by gases, which then pass through the

PCV valve and into the induction system.

H010A02GK-AATYour Hyundai is equipped with an emission

control system to meet all requirements of the

U.S. Environmental Protection Agency or Cali-

fornia Air Resources Board.

There are three emission control systems which

are as follows.

1) Crankcase Emission Control System

2) Evaporative Emission Control System

3) Exhaust Emission Control System

In order to ensure the proper function of the

emission control systems, it is recommended

that you have your car inspected and main-

tained by an authorized Hyundai dealer in ac-

cordance with the maintenance schedule in this

manual.

Caution for the Inspection and Maintenance

Test (Vehicle with Electronic Stability Pro-

gram)

o To prevent the vehicle from misfiring

during dynamometer testing, discon-

nect the ABS connector located inside

of the wheel guard (driver side).

o For more information, see shop manual

(BR Group, Wheel Speed Sensor).

CanisterFuel vapors generated inside the fuel tank are

absorbed and stored in the onboard canister.

When the engine is running, the fuel vapors

absorbed in the canister are drawn into the

induction system through the purge control

solenoid valve.Purge Control Solenoid Valve (PCSV)The purge control solenoid valve is controlled

by the Engine Control Module (ECM); when the

engine coolant temperature is low during idling,

the PCSV closes so that evaporated fuel is not

taken into the engine. After the engine warms-

up during ordinary driving, the PCSV opens to

introduce evaporated fuel to the engine.

H010C01S-AAT2. Evaporative Emission Control (Includ-

ing ORVR: Onboard Refueling Vapor

Recovery) SystemThe Evaporative Emission Control System is

designed to prevent fuel vapors from escaping

into the atmosphere.

(The ORVR system is designed to allow the

vapors from the fuel tank to be loaded into a

canister while refueling at the gas station, pre-

venting the escape of fuel vapors into the

atmosphere.)

Page 262 of 266

10

INDEX

4

Heating and cooling control

Rotary Type.................................................................................1-71

Automatic Type ............................................................................1-80

High-mounted Rear Stop light ...........................................................1-61

Hood Release....................................................................................1-61

Horn.................................................................................................1-66

I

Ignition Switch ...................................................................................... 2-3

Instrument Cluster and Indicator Lights...........................................1-36

Intermittent Wiper..............................................................................1-50

J

Jump Starting...................................................................................... 3-3

K

Keys................................................................................................... 1-3

If you lose your keys ...................................................................3-14

Positions......................................................................................... 2-3

L

Lubrication Chart................................................................................. 9-4

Luggage Net ......................................................................................1-66M

Maintenance Intervals

Explanation of scheduled maintenance items ............................... 5-7

Maintenance under severe usage conditions............................... 5-6

Scheduled maintenance................................................................ 5-4

Service requirements.................................................................... 5-2

Map Light...........................................................................................1-57

Mirror

Day-night inside rearview ............................................................1-59

Outside rear view .........................................................................1-58

O

Odometer..........................................................................................1-43

P

Parking Brake....................................................................................1-60

Power Steering Fluid Level ...............................................................6-26

Power Window.................................................................................... 1-9

Pre-tensioner Seat Belt .....................................................................1-26

R

Radio (H250, H260, H280, J290).................... 1-90, 1-95, 1-104, 1-115

Rear Seats

Before folding the rear seats .......................................................1-14

Fold down.....................................................................................1-15

Rear seat entry ............................................................................1-14

Rear seat positions......................................................................1-13

Rear Window Defroster Switch ........................................................1-52

Reporting Safety Defects .................................................................

8-16

Page 266 of 266

Seoul Korea

Printing: MAY. 29, 2006

Publication No.: A2CO-EU65I

Printed in Korea

SERVICE STATION INFORMATION

FUEL:UNLEADED gasoline only

Pump Octane Rating of 87 (Research Octane Number 91) or higher.FUEL TANK CAPACITYOriginal, U.S.gal (Imp.gal., liter) 14.5 (12, 55)TIRE PRESSURE:See the label on the driver side center pillar outer panel.OTHER TIRE INFORMATION:See pages 8-2 through 8-15.HOOD RELEASE:Pull handle under left side of dash.ENGINE OIL:API grade SJ, SL or ABOVE / ILSAC grade GF-3 or ABOVE and fuel

efficient oil. Use SAE 5W-20, 5W-30 or 10W-30 if normal temperatures

are above 0°F (-18°C). See page 6-5 or 9-4.

MANUAL TRANSAXLE:HYUNDAI GENUINE PARTS MTF 75W/85 (API GL-4) Oil level

should be up to filler-bolt hole in housing beside differential.AUTOMATIC TRANSAXLE:Apply the parking brake, with the engine running, shift the selector lever

through all ranges and return to “N” (Neutral) position. Then check the level

of fluid on the dipstick. Use only HYUNDAI GENUINE ATF SP III,

DIAMOND ATF SP III, SK ATF SP III or other brands meeting the SP

III specification approved by Hyundai Motor Co..QUICK INDEXo Car will not start ........................................................................ 3-2

o Flat tire ...................................................................................... 3-6

o Warning light/chime comes on ...................................... 1-36 ~ 1-39

o Engine overheats ....................................................................... 3-4

o Towing of your vehicle ............................................................. 3-11

o Starting the engine ..................................................................... 2-4

o Driving tips for first 1,200 miles (2,000 km) ............................ 1-3

o Scheduled maintenance ............................................................. 5-4

o Reporting safety defects .......................................................... 8-16