radiator INFINITI FX35 2004 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2004, Model line: FX35, Model: INFINITI FX35 2004Pages: 4449, PDF Size: 99.66 MB

Page 818 of 4449

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

BL-11

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2004 November 2004 FX35/FX45

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger room.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting securing, or

insulating the component causing the noise.

Page 823 of 4449

BL-16

HOOD

Revision: 2004 November 2004 FX35/FX45

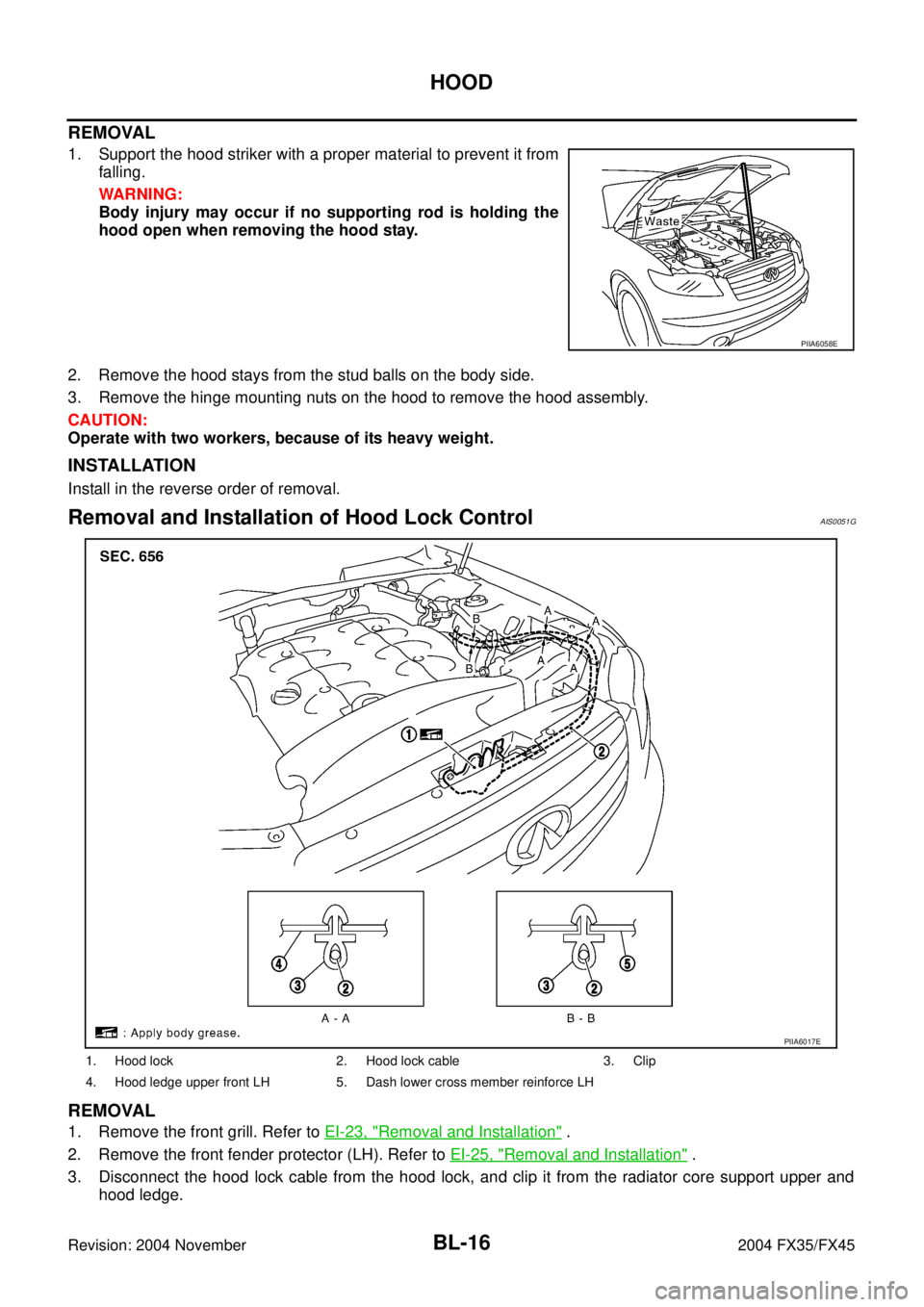

REMOVAL

1. Support the hood striker with a proper material to prevent it from

falling.

WARNING:

Body injury may occur if no supporting rod is holding the

hood open when removing the hood stay.

2. Remove the hood stays from the stud balls on the body side.

3. Remove the hinge mounting nuts on the hood to remove the hood assembly.

CAUTION:

Operate with two workers, because of its heavy weight.

INSTALLATION

Install in the reverse order of removal.

Removal and Installation of Hood Lock ControlAIS0051G

REMOVAL

1. Remove the front grill. Refer to EI-23, "Removal and Installation" .

2. Remove the front fender protector (LH). Refer to EI-25, "

Removal and Installation" .

3. Disconnect the hood lock cable from the hood lock, and clip it from the radiator core support upper and

hood ledge.

PIIA6058E

1. Hood lock 2. Hood lock cable 3. Clip

4. Hood ledge upper front LH 5. Dash lower cross member reinforce LH

PIIA6017E

Page 826 of 4449

RADIATOR CORE SUPPORT

BL-19

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2004 November 2004 FX35/FX45

RADIATOR CORE SUPPORTPFP:62500

Removal and InstallationAIS004LL

REMOVAL

1. Remove the front fender protector. Refer to EI-25, "Removal and Installation" .

2. Remove the front bumper. Refer to EI-14, "

Removal and Installation" .

3. Remove the ICC. Refer to ACS-67, "

REMOVAL AND INSTALLATION" .

4. Remove the headlamp. Refer to LT- 3 6 , "

Removal and Installation" .

5. Remove the washer tank. Refer to WW-33, "

Removal and Installation of Washer Tank" .

6. Remove the resonator.

7. Remove the power steering oil cooler. Refer to PS-41, "

HYDRAULIC LINE" .

8. Remove the ambient sensor. Refer to AT C - 11 7 , "

Removal and Installation" .

9. Remove the crash zone sensor. Refer to SRS-45, "

Removal and Installation" .

10. Remove the horn connector, blower fan connector and harness clip.

11. Remove the hood lock and disconnect hood lock control cable. Refer to BL-16, "

Removal and Installation

of Hood Lock Control" .

12. Remove the reservoir tank.

13. Remove mounting blots and remove radiator core support. Remove mounting bolts with power tool.

14. After remove radiator core support, remove the horn, cooling fan.

1. Radiator core support assembly 2. Bolt 3. Bolt

4. Horn (High) 5. Air guide (RH) 6. Cooling fan

7. Air guide (LH) 8. Horn (Low)

PIIA6018E

Page 827 of 4449

BL-20

RADIATOR CORE SUPPORT

Revision: 2004 November 2004 FX35/FX45

INSTALLATION

Install in the reverse order of removal.

Page 1190 of 4449

CO-1

ENGINE COOLING SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION CO

A

CO

Revision: 2004 November 2004 FX35/FX45

ENGINE COOLING SYSTEM

VQ35DE

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for Liquid Gasket .................................. 3

REMOVAL OF LIQUID GASKET SEALING .......... 3

LIQUID GASKET APPLICATION PROCEDURE ..... 3

PREPARATION ........................................................... 5

Special Service Tools ............................................... 5

Commercial Service Tools ........................................ 6

OVERHEATING CAUSE ANALYSIS .......................... 7

Troubleshooting Chart .............................................. 7

COOLING SYSTEM .................................................... 9

Cooling Circuit .......................................................... 9

System Drawing ..................................................... 10

ENGINE COOLANT ...................................................11

Inspection ................................................................ 11

LEVEL CHECK .................................................... 11

CHECKING COOLING SYSTEM FOR LEAKS .... 11

Changing Engine Coolant ....................................... 11

DRAINING ENGINE COOLANT .......................... 11

REFILLING ENGINE COOLANT ........................ 12

FLUSHING COOLING SYSTEM ......................... 13

RADIATOR ................................................................ 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 15

INSPECTION AFTER INSTALLATION ............... 15

Checking Radiator Cap .......................................... 15

Checking Radiator .................................................. 16

RADIATOR (ALUMINUM TYPE) .............................. 17

Disassembly and Assembly ................................... 17

PREPARATION ................................................... 17

DISASSEMBLY ................................................... 17

ASSEMBLY ......................................................... 18

INSPECTION ...................................................... 20

COOLING FAN ......................................................... 21

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21INSTALLATION ................................................... 21

Disassembly and Assembly .................................... 21

DISASSEMBLY ................................................... 21

ASSEMBLY ......................................................... 21

WATER PUMP .......................................................... 22

Removal and Installation ........................................ 22

REMOVAL ........................................................... 22

INSPECTION AFTER REMOVAL ....................... 24

INSTALLATION ................................................... 24

INSPECTION AFTER INSTALLATION ................ 25

WATER INLET AND THERMOSTAT ASSEMBLY .... 26

Removal and Installation ........................................ 26

REMOVAL ........................................................... 26

INSPECTION AFTER REMOVAL ....................... 27

INSTALLATION ................................................... 27

INSPECTION AFTER INSTALLATION ................ 27

WATER OUTLET AND WATER PIPING ................... 28

Removal and Installation ........................................ 28

REMOVAL ........................................................... 28

INSTALLATION ................................................... 28

INSPECTION AFTER INSTALLATION ................ 28

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 29

Standard and Limit .................................................. 29

ENGINE COOLANT CAPACITY (APPROXI-

MATE) .................................................................. 29

THERMOSTAT .................................................... 29

RADIATOR .......................................................... 29

VK45DE

PRECAUTIONS ........................................................ 30

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................. 30

PREPARATION ......................................................... 31

Special Service Tools ............................................. 31

Commercial Service Tools ...................................... 31

OVERHEATING CAUSE ANALYSIS ........................ 32

Troubleshooting Chart ............................................ 32

Page 1191 of 4449

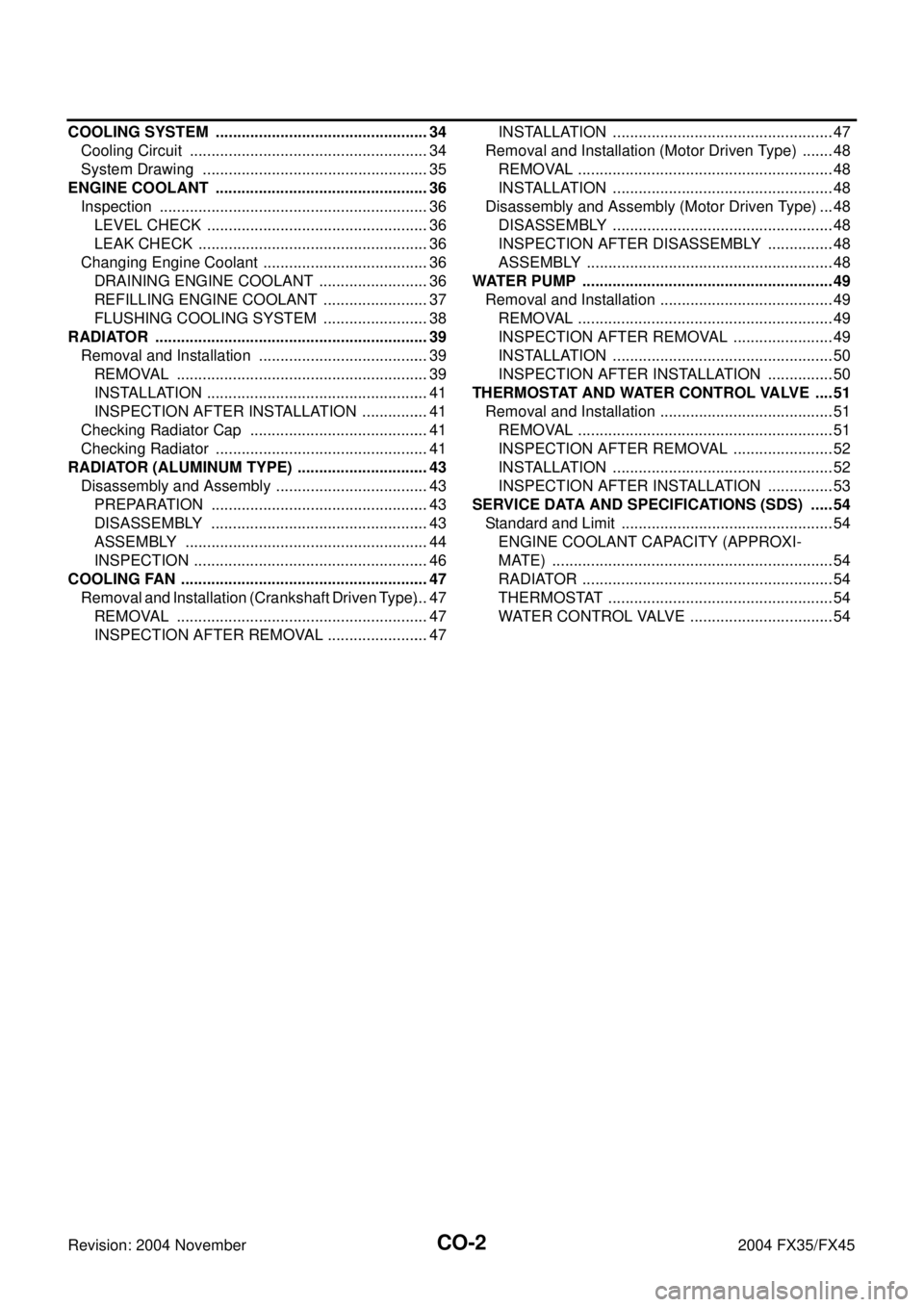

CO-2Revision: 2004 November 2004 FX35/FX45 COOLING SYSTEM .................................................. 34

Cooling Circuit ........................................................ 34

System Drawing ..................................................... 35

ENGINE COOLANT .................................................. 36

Inspection ............................................................... 36

LEVEL CHECK .................................................... 36

LEAK CHECK ...................................................... 36

Changing Engine Coolant ....................................... 36

DRAINING ENGINE COOLANT .......................... 36

REFILLING ENGINE COOLANT ......................... 37

FLUSHING COOLING SYSTEM ......................... 38

RADIATOR ................................................................ 39

Removal and Installation ........................................ 39

REMOVAL ........................................................... 39

INSTALLATION .................................................... 41

INSPECTION AFTER INSTALLATION ................ 41

Checking Radiator Cap .......................................... 41

Checking Radiator .................................................. 41

RADIATOR (ALUMINUM TYPE) ............................... 43

Disassembly and Assembly .................................... 43

PREPARATION ................................................... 43

DISASSEMBLY ................................................... 43

ASSEMBLY ......................................................... 44

INSPECTION ....................................................... 46

COOLING FAN .......................................................... 47

Removal and Installation (Crankshaft Driven Type) ... 47

REMOVAL ........................................................... 47

INSPECTION AFTER REMOVAL ........................ 47INSTALLATION .................................................... 47

Removal and Installation (Motor Driven Type) ........ 48

REMOVAL ............................................................ 48

INSTALLATION .................................................... 48

Disassembly and Assembly (Motor Driven Type) ... 48

DISASSEMBLY .................................................... 48

INSPECTION AFTER DISASSEMBLY ................ 48

ASSEMBLY .......................................................... 48

WATER PUMP ........................................................... 49

Removal and Installation ......................................... 49

REMOVAL ............................................................ 49

INSPECTION AFTER REMOVAL ........................ 49

INSTALLATION .................................................... 50

INSPECTION AFTER INSTALLATION ................ 50

THERMOSTAT AND WATER CONTROL VALVE ..... 51

Removal and Installation ......................................... 51

REMOVAL ............................................................ 51

INSPECTION AFTER REMOVAL ........................ 52

INSTALLATION .................................................... 52

INSPECTION AFTER INSTALLATION ................ 53

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 54

Standard and Limit .................................................. 54

ENGINE COOLANT CAPACITY (APPROXI-

MATE) .................................................................. 54

RADIATOR ........................................................... 54

THERMOSTAT ..................................................... 54

WATER CONTROL VALVE .................................. 54

Page 1194 of 4449

![INFINITI FX35 2004 User Guide PREPARATION

CO-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2004 November 2004 FX35/FX45

PREPARATIONPFP:00002

Special Service ToolsABS004T4

The actual shapes of Kent-Moore tools may from those of sp INFINITI FX35 2004 User Guide PREPARATION

CO-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2004 November 2004 FX35/FX45

PREPARATIONPFP:00002

Special Service ToolsABS004T4

The actual shapes of Kent-Moore tools may from those of sp](/img/42/57021/w960_57021-1193.png)

PREPARATION

CO-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2004 November 2004 FX35/FX45

PREPARATIONPFP:00002

Special Service ToolsABS004T4

The actual shapes of Kent-Moore tools may from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

WS39930000

( – )

Tube presserPressing tube of liquid gasket

KV10111100

(J-37228)

Seal cutterRemoving chain tensioner cover and water

pump cover

EG17650301

(J-33984-A)

Radiator cap tester adapterAdapting radiator cap tester to radiator cap

and radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

KV99103510

( – )

Radiator plate pliers AInstalling radiator upper and lower tanks

KV99103520

( – )

Radiator plate pliers BRemoving radiator upper and lower tanks

S-NT052

NT046

S-NT564

S-NT224

S-NT225

Page 1195 of 4449

![INFINITI FX35 2004 User Guide CO-6

[VQ35DE]

PREPARATION

Revision: 2004 November 2004 FX35/FX45

Commercial Service ToolsABS004T5

Tool nameDescription

Power toolLoosening bolts and nuts

Radiator cap tester Checking radiator and radi INFINITI FX35 2004 User Guide CO-6

[VQ35DE]

PREPARATION

Revision: 2004 November 2004 FX35/FX45

Commercial Service ToolsABS004T5

Tool nameDescription

Power toolLoosening bolts and nuts

Radiator cap tester Checking radiator and radi](/img/42/57021/w960_57021-1194.png)

CO-6

[VQ35DE]

PREPARATION

Revision: 2004 November 2004 FX35/FX45

Commercial Service ToolsABS004T5

Tool nameDescription

Power toolLoosening bolts and nuts

Radiator cap tester Checking radiator and radiator cap

PBIC0190E

PBIC1982E

Page 1196 of 4449

![INFINITI FX35 2004 User Guide OVERHEATING CAUSE ANALYSIS

CO-7

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2004 November 2004 FX35/FX45

OVERHEATING CAUSE ANALYSISPFP:00012

Troubleshooting ChartABS004UZ

Symptom Check items

Cooling INFINITI FX35 2004 User Guide OVERHEATING CAUSE ANALYSIS

CO-7

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2004 November 2004 FX35/FX45

OVERHEATING CAUSE ANALYSISPFP:00012

Troubleshooting ChartABS004UZ

Symptom Check items

Cooling](/img/42/57021/w960_57021-1195.png)

OVERHEATING CAUSE ANALYSIS

CO-7

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2004 November 2004 FX35/FX45

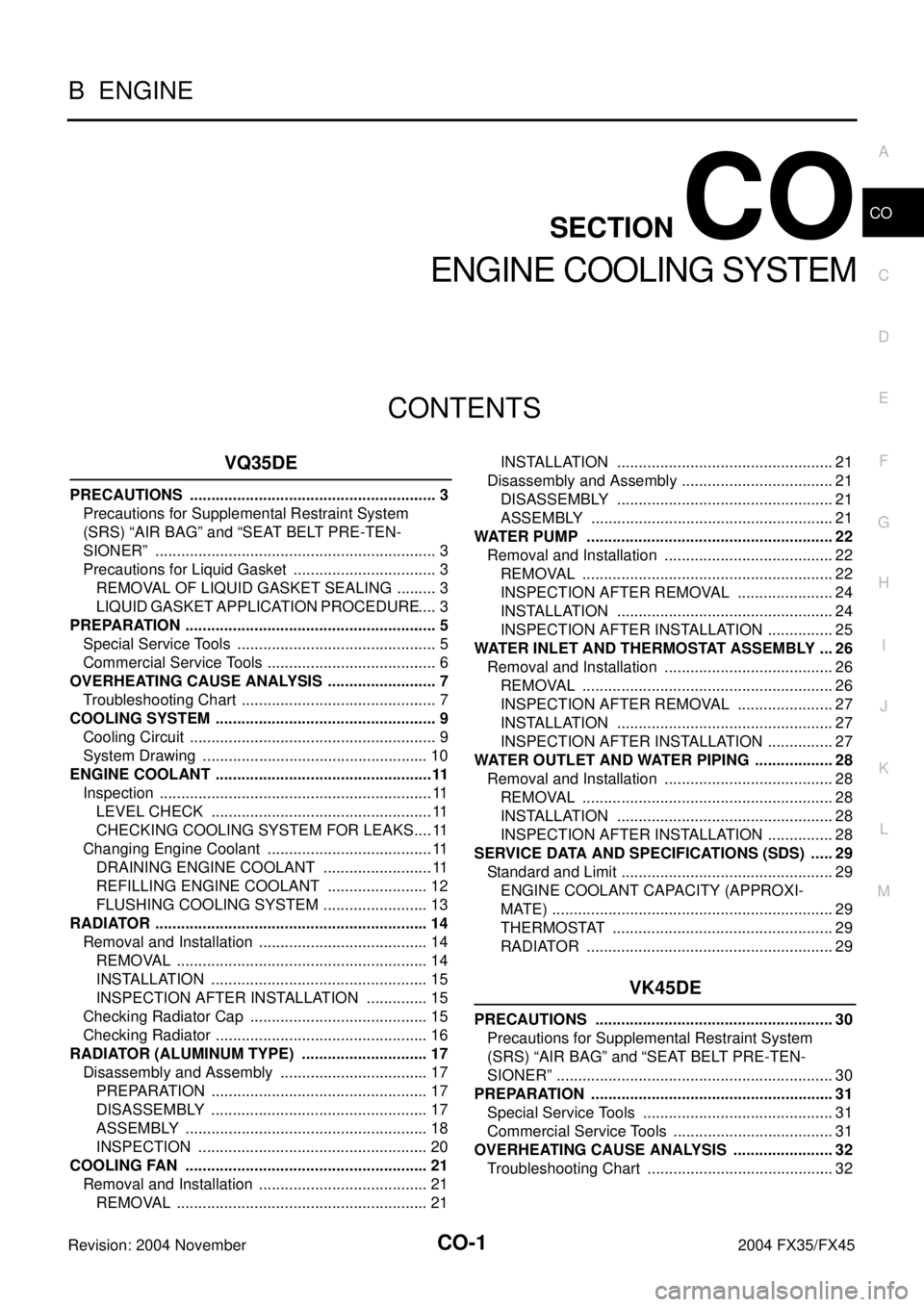

OVERHEATING CAUSE ANALYSISPFP:00012

Troubleshooting ChartABS004UZ

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

— Thermostat stuck closed —

Damaged finsDust contamination or

paper clogging

Physical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

Fan assembly — High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud — — —

Improper engine coolant

mixture ratio—— —

Poor engine coolant quality — Engine coolant density —

Insufficient engine coolantEngine coolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deterioration

Cylinder head gasket dete-

rioration

Page 1197 of 4449

![INFINITI FX35 2004 User Guide CO-8

[VQ35DE]

OVERHEATING CAUSE ANALYSIS

Revision: 2004 November 2004 FX35/FX45

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving INFINITI FX35 2004 User Guide CO-8

[VQ35DE]

OVERHEATING CAUSE ANALYSIS

Revision: 2004 November 2004 FX35/FX45

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving](/img/42/57021/w960_57021-1196.png)

CO-8

[VQ35DE]

OVERHEATING CAUSE ANALYSIS

Revision: 2004 November 2004 FX35/FX45

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system mal-

function

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator —

Blocked condenser

Blocked air flow

Installed large fog lamp Symptom Check items