air INFINITI FX35 2004 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2004, Model line: FX35, Model: INFINITI FX35 2004Pages: 4449, PDF Size: 99.66 MB

Page 538 of 4449

TROUBLE DIAGNOSIS

ATC-109

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2004 November 2004 FX35/FX45

4. CHECK CIRCUIT CONTINUITY BETWEEN IN-VEHICLE SENSOR AND UNIFIED METER AND A/C

AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between in-vehicle sensor harness connector

M46 terminal 1 (BR/W) and unified meter and A/C amp. harness

connector M57 terminal 40 (BR/W).

4. Check continuity between in-vehicle sensor harness connector

M46 terminal 1 (BR/W) and ground.

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 4 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> Repair harness or connector.

COMPONENT INSPECTION

In-vehicle Sensor

After disconnecting in-vehicle sensor connector M46, measure resis-

tance between terminals 1 and 2 at sensor side, using the table

below.

If NG, replace in-vehicle sensor.1 – 40 : Continuity should exist.

1 – Ground : Continuity should not exist.

RJIA2024E

Temperature °C (°F) Resistance kΩ

−15 (5) 12.73

−10 (14) 9.92

−5 (23) 7.80

0 (32) 6.19

5 (41) 4.95

10 (50) 3.99

15 (59) 3.24

20 (68) 2.65

25 (77) 2.19

30 (86) 1.81

35 (95) 1.51

40 (104) 1.27

45 (113) 1.07

RJIA2025E

Page 540 of 4449

TROUBLE DIAGNOSIS

ATC-111

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2004 November 2004 FX35/FX45

2. CHECK CIRCUIT CONTINUITY BETWEEN SUNLOAD SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between sunload sensor harness connector

M87 terminal 2 (W/G) and unified meter and A/C amp. harness

connector M57 terminal 49 (W/G).

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK SUNLOAD SENSOR

Refer to AT C - 11 2 , "

Sunload Sensor" .

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 4 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> 1. Replace sunload sensor.

2. Go to self-diagnosis AT C - 5 4 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

4. CHECK CIRCUIT CONTINUITY BETWEEN SUNLOAD SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between sunload sensor harness connector

M87 terminal 1 (LG) and unified meter and A/C amp. harness

connector M57 terminal 50 (LG).

4. Check continuity between sunload sensor harness connector

M87 terminal 1 (LG) and ground.

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 4 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> Repair harness or connector.2 – 49 : Continuity should exist.

RJIA2028E

1 – 50 : Continuity should exist.

1 – Ground : Continuity should not exist.

RJIA2029E

Page 542 of 4449

TROUBLE DIAGNOSIS

ATC-113

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2004 November 2004 FX35/FX45

Intake Sensor CircuitAJS00157

COMPONENT DESCRIPTION

Intake Sensor

The intake sensor is located on the heater & cooling unit. It converts

temperature of air after it passes through the evaporator into a resis-

tance value which is then input to the unified meter and A/C amp.

DIAGNOSTIC PROCEDURE FOR INTAKE SENSOR

SYMPTOM: Intake sensor circuit is open or shorted. (24 or −24 is

indicated on unified meter and A/C amp. as a result of performing

Self-diagnosis STEP-2.)

1. CHECK VOLTAGE BETWEEN INTAKE SENSOR AND GROUND

1. Disconnect intake sensor connector.

2. Turn ignition switch ON.

3. Check voltage between intake sensor harness connector M254

terminal 2 (R) and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2. CHECK CIRCUIT CONTINUITY BETWEEN INTAKE SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between intake sensor harness connector

M254 terminal 1 (W) and unified meter and A/C amp. harness

connector M57 terminal 49 (W/G).

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

RJIA0928E

RJIA1458E

2 – Ground : Approx. 5V

RJIA2031E

1 – 49 : Continuity should exist.

RJIA2032E

Page 543 of 4449

ATC-114

TROUBLE DIAGNOSIS

Revision: 2004 November 2004 FX35/FX45

3. CHECK INTAKE SENSOR

Refer to AT C - 11 4 , "

Intake Sensor" .

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 4 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> 1. Replace intake sensor.

2. Go to self-diagnosis AT C - 5 4 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

4. CHECK CIRCUIT CONTINUITY BETWEEN INTAKE SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between intake sensor harness connector

M254 terminal 2 (R) and unified meter and A/C amp. harness

connector M57 terminal 41 (P).

4. Check continuity between intake sensor harness connector

M254 terminal 2 (R) and ground.

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 4 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> Repair harness or connector.

COMPONENT INSPECTION

Intake Sensor

After disconnecting intake sensor connector M254, measure resis-

tance between terminals 1 and 2 at sensor side, using the table

below.

If NG, replace intake sensor.2 – 41 : Continuity should exist.

2 – Ground : Continuity should not exist.

RJIA2033E

Temperature °C (°F) Resistance kΩ

−15 (5) 12.34

−10 (14) 9.62

−5 (23) 7.56

0 (32) 6.00

5 (41) 4.80

10 (50) 3.87

15 (59) 3.15

20 (68) 2.57

25 (77) 2.12

30 (86) 1.76

35 (95) 1.47

40 (104) 1.23

45 (113) 1.04

RJIA2034E

Page 554 of 4449

IN-CABIN MICROFILTER

ATC-125

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2004 November 2004 FX35/FX45

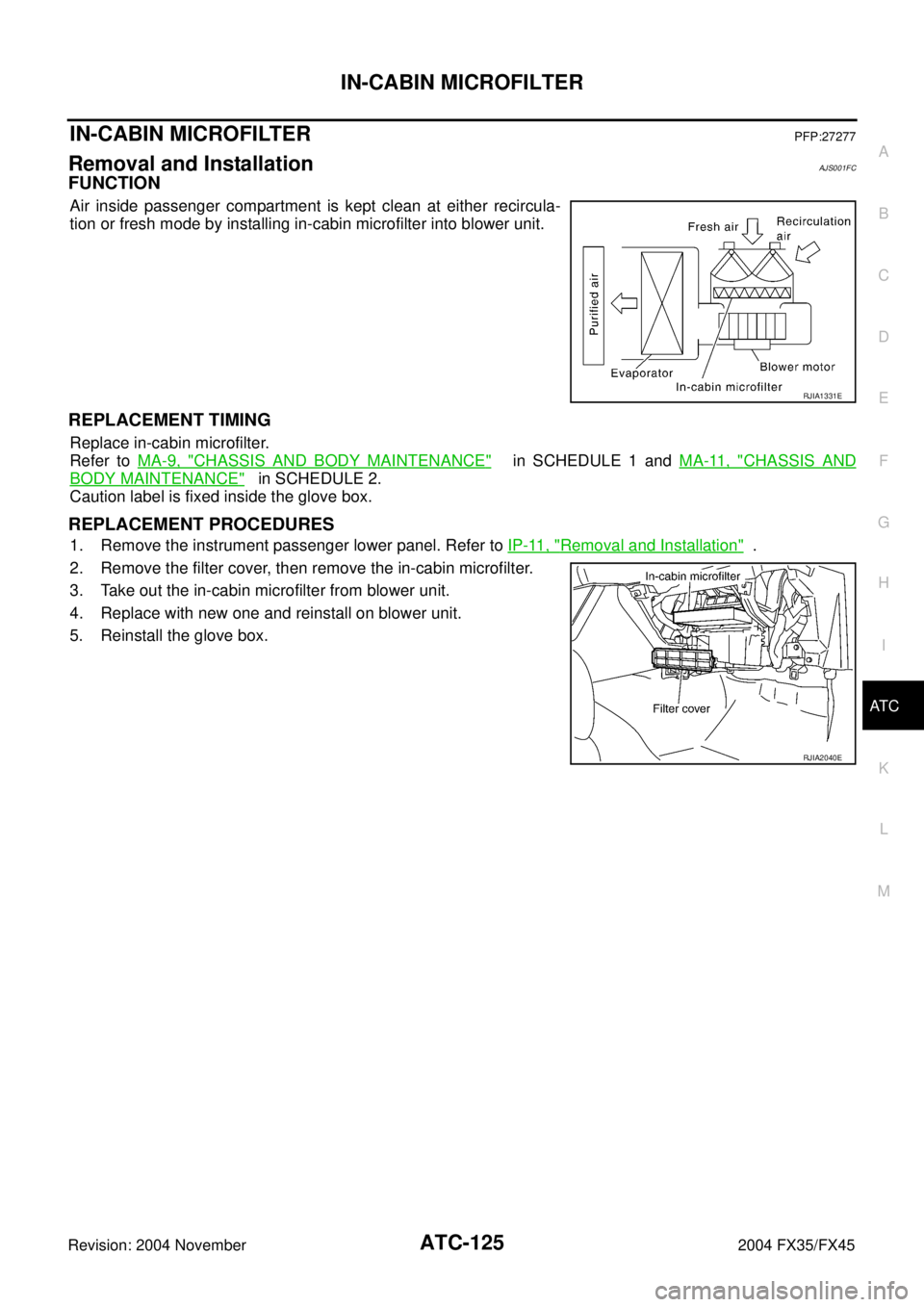

IN-CABIN MICROFILTERPFP:27277

Removal and InstallationAJS001FC

FUNCTION

Air inside passenger compartment is kept clean at either recircula-

tion or fresh mode by installing in-cabin microfilter into blower unit.

REPLACEMENT TIMING

Replace in-cabin microfilter.

Refer to MA-9, "

CHASSIS AND BODY MAINTENANCE" in SCHEDULE 1 and MA-11, "CHASSIS AND

BODY MAINTENANCE" in SCHEDULE 2.

Caution label is fixed inside the glove box.

REPLACEMENT PROCEDURES

1. Remove the instrument passenger lower panel. Refer to IP-11, "Removal and Installation" .

2. Remove the filter cover, then remove the in-cabin microfilter.

3. Take out the in-cabin microfilter from blower unit.

4. Replace with new one and reinstall on blower unit.

5. Reinstall the glove box.

RJIA1331E

RJIA2040E

Page 557 of 4449

ATC-128

HEATER & COOLING UNIT ASSEMBLY

Revision: 2004 November 2004 FX35/FX45

Disassembly and AssemblyAJS0015K

1. Heater pipe grommet 2. Heater core 3. Heater pipe cover

4. Aspirator 5. Aspirator hose 6. Air mix door motor (driver side)

7. Air mix door (slide door) 8. Max. cool door link 9. Max. cool door lever

10. Ventilator door lever 11. Ventilator door link 12. Air mix door motor (passenger side)

13. Intake sensor bracket 14. Intake sensor 15. Foot duct (right)

16. Evaporator cover 17. Evaporator cover adaptor 18. Heater pipe bracket

RJIA2045E

Page 560 of 4449

AIR MIX DOOR MOTOR

ATC-131

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2004 November 2004 FX35/FX45

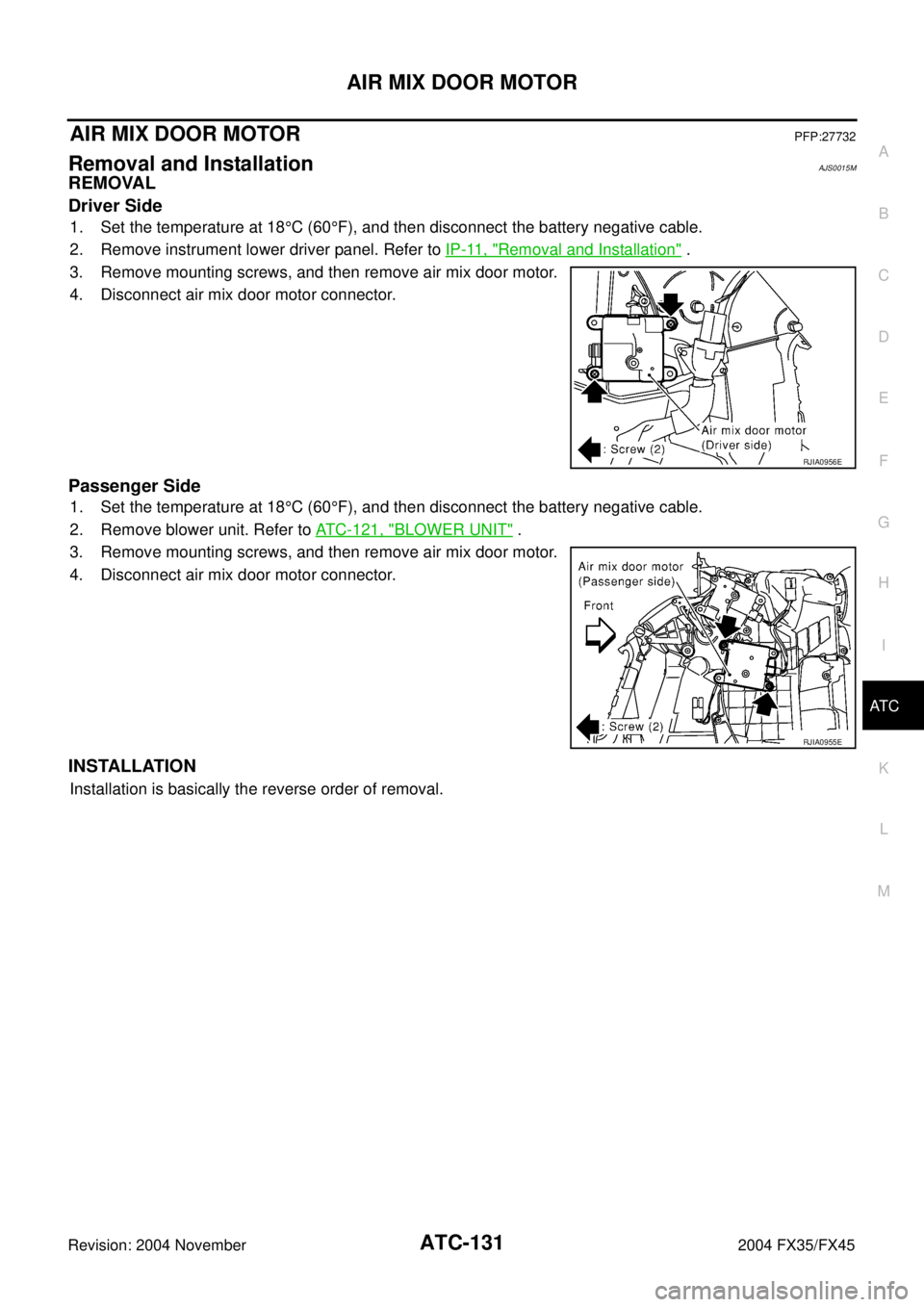

AIR MIX DOOR MOTOR PFP:27732

Removal and InstallationAJS0015M

REMOVAL

Driver Side

1. Set the temperature at 18°C (60°F), and then disconnect the battery negative cable.

2. Remove instrument lower driver panel. Refer to IP-11, "

Removal and Installation" .

3. Remove mounting screws, and then remove air mix door motor.

4. Disconnect air mix door motor connector.

Passenger Side

1. Set the temperature at 18°C (60°F), and then disconnect the battery negative cable.

2. Remove blower unit. Refer to ATC-121, "

BLOWER UNIT" .

3. Remove mounting screws, and then remove air mix door motor.

4. Disconnect air mix door motor connector.

INSTALLATION

Installation is basically the reverse order of removal.

RJIA0956E

RJIA0955E

Page 570 of 4449

REFRIGERANT LINES

ATC-141

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2004 November 2004 FX35/FX45

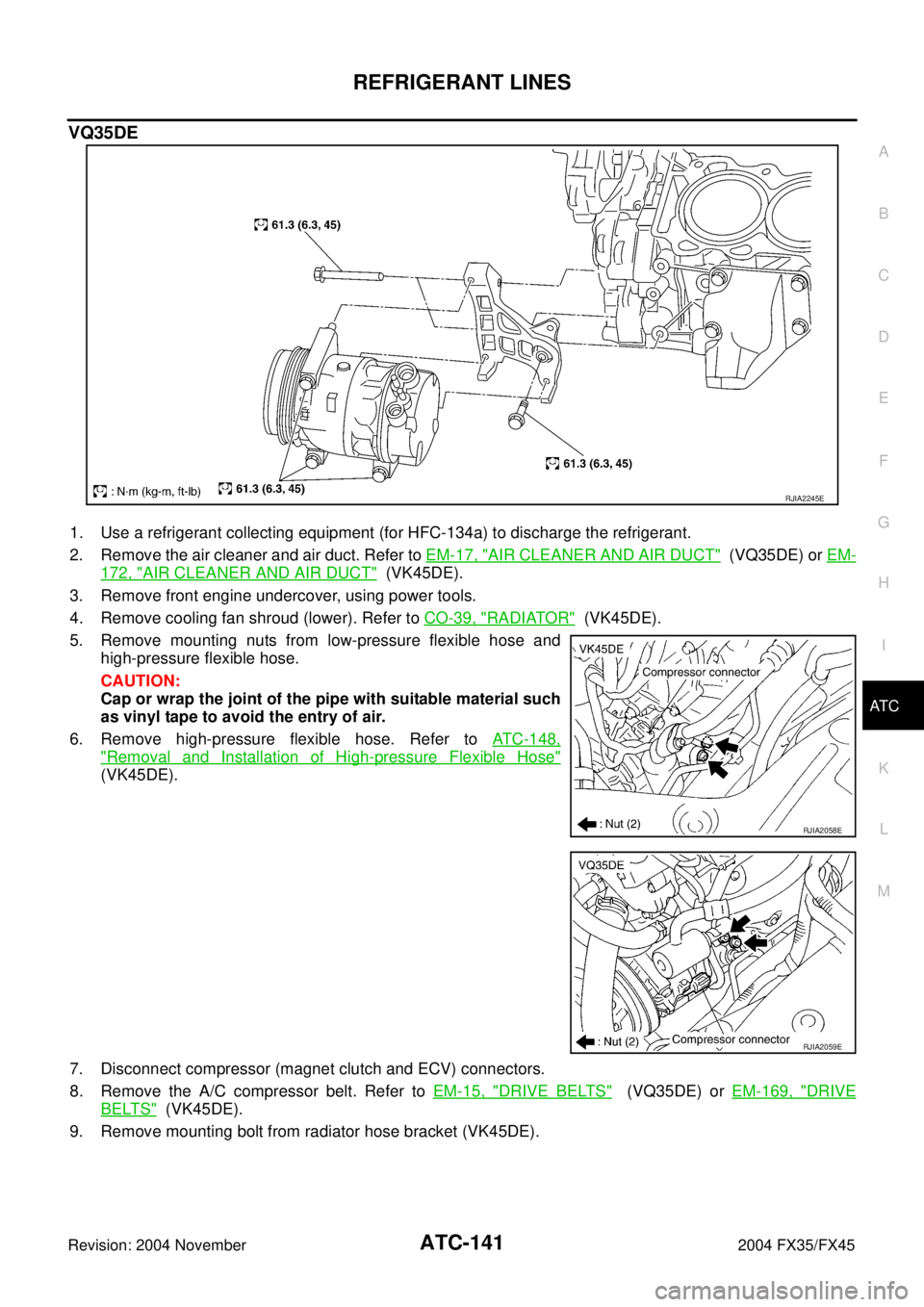

VQ35DE

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2. Remove the air cleaner and air duct. Refer to EM-17, "

AIR CLEANER AND AIR DUCT" (VQ35DE) or EM-

172, "AIR CLEANER AND AIR DUCT" (VK45DE).

3. Remove front engine undercover, using power tools.

4. Remove cooling fan shroud (lower). Refer to CO-39, "

RADIATOR" (VK45DE).

5. Remove mounting nuts from low-pressure flexible hose and

high-pressure flexible hose.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

6. Remove high-pressure flexible hose. Refer to ATC-148,

"Removal and Installation of High-pressure Flexible Hose"

(VK45DE).

7. Disconnect compressor (magnet clutch and ECV) connectors.

8. Remove the A/C compressor belt. Refer to EM-15, "

DRIVE BELTS" (VQ35DE) or EM-169, "DRIVE

BELTS" (VK45DE).

9. Remove mounting bolt from radiator hose bracket (VK45DE).

RJIA2245E

RJIA2058E

RJIA2059E

Page 573 of 4449

ATC-144

REFRIGERANT LINES

Revision: 2004 November 2004 FX35/FX45

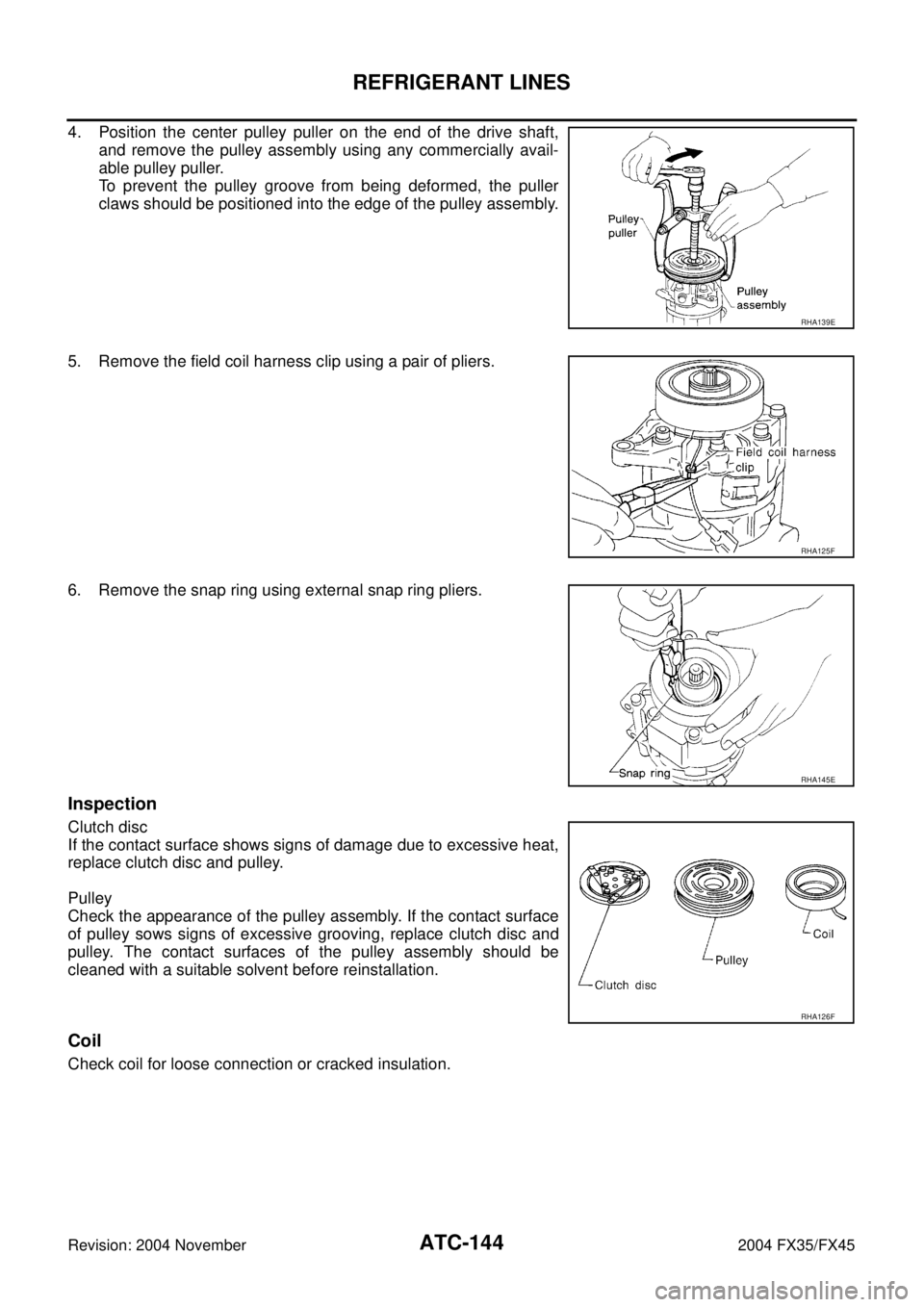

4. Position the center pulley puller on the end of the drive shaft,

and remove the pulley assembly using any commercially avail-

able pulley puller.

To prevent the pulley groove from being deformed, the puller

claws should be positioned into the edge of the pulley assembly.

5. Remove the field coil harness clip using a pair of pliers.

6. Remove the snap ring using external snap ring pliers.

Inspection

Clutch disc

If the contact surface shows signs of damage due to excessive heat,

replace clutch disc and pulley.

Pulley

Check the appearance of the pulley assembly. If the contact surface

of pulley sows signs of excessive grooving, replace clutch disc and

pulley. The contact surfaces of the pulley assembly should be

cleaned with a suitable solvent before reinstallation.

Coil

Check coil for loose connection or cracked insulation.

RHA139E

RHA125F

RHA145E

RHA126F

Page 576 of 4449

REFRIGERANT LINES

ATC-147

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2004 November 2004 FX35/FX45

Removal and Installation of Low-pressure Flexible HoseAJS001BG

REMOVAL

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2. Remove the air cleaner and air duct. Refer to EM-17, "

AIR CLEANER AND AIR DUCT" (VQ35DE) or EM-

172, "AIR CLEANER AND AIR DUCT" (VK45DE).

3. Remove mounting bolt for low-pressure flexible hose bracket.

4. Disconnect one-touch joint between low-pressure flexible hose

and low-pressure pipe 1.

a. Set a disconnector (92530-89916) on A/C piping.

b. Slide a disconnector toward vehicle front until it clicks.

c. Slide A/C piping toward vehicle front and disconnect it.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

5. Remove mounting nut from low-pressure flexible hose.

6. Remove low-pressure flexible hose.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

7. Remove low-pressure pipe (VK45DE).

RJIA2062E

RJIA2069E

RJIA2063E

RJIA2064E