ignition INFINITI FX35 2007 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: FX35, Model: INFINITI FX35 2007Pages: 4366, PDF Size: 55.42 MB

Page 544 of 4366

ATC-98

TROUBLE DIAGNOSIS

Revision: 2006 July 2007 FX35/FX45

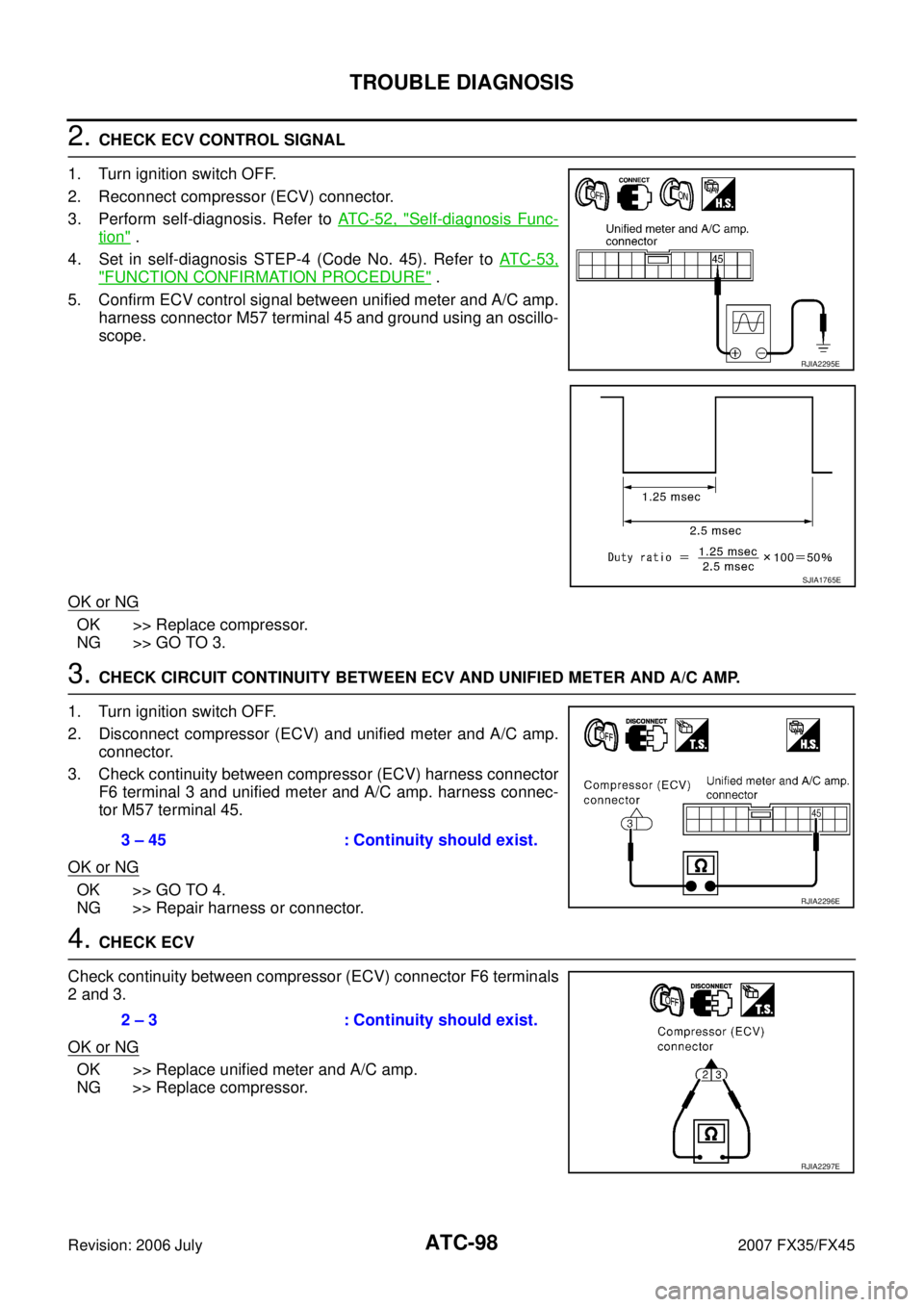

2. CHECK ECV CONTROL SIGNAL

1. Turn ignition switch OFF.

2. Reconnect compressor (ECV) connector.

3. Perform self-diagnosis. Refer to AT C - 5 2 , "

Self-diagnosis Func-

tion" .

4. Set in self-diagnosis STEP-4 (Code No. 45). Refer to AT C - 5 3 ,

"FUNCTION CONFIRMATION PROCEDURE" .

5. Confirm ECV control signal between unified meter and A/C amp. harness connector M57 terminal 45 and ground using an oscillo-

scope.

OK or NG

OK >> Replace compressor.

NG >> GO TO 3.

3. CHECK CIRCUIT CONTINUITY BETWEEN ECV AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect compressor (ECV) and unified meter and A/C amp. connector.

3. Check continuity between compressor (ECV) harness connector F6 terminal 3 and unified meter and A/C amp. harness connec-

tor M57 terminal 45.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4. CHECK ECV

Check continuity between compressor (ECV) connector F6 terminals

2 and 3.

OK or NG

OK >> Replace unified meter and A/C amp.

NG >> Replace compressor.

RJIA2295E

SJIA1765E

3 – 45 : Continuity should exist.

RJIA2296E

2 – 3 : Continuity should exist.

RJIA2297E

Page 549 of 4366

TROUBLE DIAGNOSIS ATC-103

C

D E

F

G H

I

K L

M A

B

AT C

Revision: 2006 July 2007 FX35/FX45

Ambient Sensor CircuitNJS000EF

COMPONENT DESCRIPTION

Ambient Sensor

The ambient sensor is attached on the hood lock stay. It detects

ambient temperature and converts it into a resistance value which is

then input into the unified meter and A/C amp.

AMBIENT TEMPERATURE INPUT PROCESS

The unified meter and A/C amp. includes a processing circuit for the ambient sensor input. However, when the

temperature detected by the ambient sensor increases quickly, the processing circuit retards the unified meter

and A/C amp. function. It only allows the unified meter and A/C amp. to recognize an ambient temperature

increase of 0.33 °C (0.6 °F) per 100 seconds.

As an example, consider stopping for a few minutes after high speed driving. Although the actual ambient tem-

perature has not changed, the temperature detected by the ambient sensor will increase. This is because the

heat from the engine compartment can radiate to the front grille area, location of the ambient sensor.

DIAGNOSIS PROCEDURE FOR AMBIENT SENSOR

SYMPTOM: Ambient sensor circuit is open or shorted. (21 or −21 is

indicated on unified meter and A/C amp. as a result of performing

self-diagnosis STEP-2.)

1. CHECK VOLTAGE BETWEEN AMBIENT SENSOR AND GROUND

1. Disconnect ambient sensor connector.

2. Turn ignition switch ON.

3. Check voltage between ambient sensor harness connector E34 terminal 1 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

RJIA2016E

RJIA1461E

1 – Ground : Approx. 5 V

RJIA2017E

Page 550 of 4366

ATC-104

TROUBLE DIAGNOSIS

Revision: 2006 July 2007 FX35/FX45

2. CHECK CIRCUIT CONTINUITY BETWEEN AMBIENT SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between ambient sensor harness connector E34 terminal 2 and unified meter and A/C amp. harness connec-

tor M57 terminal 49.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK AMBIENT SENSOR

Refer to ATC-105, "

Ambient Sensor" .

OK or NG

OK >> 1. Replace unified meter and A/C amp. 2. Go to self-diagnosis AT C - 5 3 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> 1. Replace ambient sensor. 2. Go to self-diagnosis AT C - 5 3 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

4. CHECK CIRCUIT CONTINUITY BETWEEN AMBIENT SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between ambient sensor harness connector E34 terminal 1 and unified meter and A/C amp. harness connec-

tor M57 terminal 39.

4. Check continuity between ambient sensor harness connector E34 terminal 1 and ground.

OK or NG

OK >> 1. Replace unified meter and A/C amp. 2. Go to self-diagnosis AT C - 5 3 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> Repair harness or connector. 2 – 49 : Continuity should exist.

RJIA2018E

1 – 39 : Continuity should exist.

1 – Ground : Continuity should not exist.

RJIA2019E

Page 553 of 4366

TROUBLE DIAGNOSIS ATC-107

C

D E

F

G H

I

K L

M A

B

AT C

Revision: 2006 July 2007 FX35/FX45

DIAGNOSIS PROCEDURE FOR IN-VEHICLE SENSOR

SYMPTOM: In-vehicle sensor circuit is open or shorted. (22 or −22 is

indicated on unified meter and A/C amp. as a result of performing

self-diagnosis STEP-2.)

1. CHECK VOLTAGE BETWEEN IN-VEHICLE SENSOR AND GROUND

1. Disconnect in-vehicle sensor connector.

2. Turn ignition switch ON.

3. Check voltage between in-vehicle sensor harness connector M46 terminal 1 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2. CHECK CIRCUIT CONTINUITY BETWEEN IN-VEHICLE SENSOR AND UNIFIED METER AND A/C

AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between in-vehicle sensor harness connector M46 terminal 2 and unified meter and A/C amp. harness con-

nector M57 terminal 49.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK IN-VEHICLE SENSOR

Refer to ATC-108, "

In-vehicle Sensor" .

OK or NG

OK >> 1. Replace unified meter and A/C amp. 2. Go to self-diagnosis AT C - 5 3 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> 1. Replace in-vehicle sensor. 2. Go to self-diagnosis AT C - 5 3 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

RJIA1452E

1 – Ground : Approx. 5 V

RJIA2022E

2 – 49 : Continuity should exist.

RJIA2023E

Page 554 of 4366

ATC-108

TROUBLE DIAGNOSIS

Revision: 2006 July 2007 FX35/FX45

4. CHECK CIRCUIT CONTINUITY BETWEEN IN-VEHICLE SENSOR AND UNIFIED METER AND A/C

AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between in-vehicle sensor harness connector M46 terminal 1 and unified meter and A/C amp. harness con-

nector M57 terminal 40.

4. Check continuity between in-vehicle sensor harness connector M46 terminal 1 and ground.

OK or NG

OK >> 1. Replace unified meter and A/C amp. 2. Go to self-diagnosis AT C - 5 3 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> Repair harness or connector.

COMPONENT INSPECTION

In-vehicle Sensor

After disconnecting in-vehicle sensor connector M46, measure resis-

tance between terminals 1 and 2 at sensor side. Refer to the table

below.

If NG, replace in-vehicle sensor. 1 – 40 : Continuity should exist.

1 – Ground : Continuity should not exist.

RJIA2024E

Temperature °C ( °F) Resistance k Ω

− 15 (5) 12.73

− 10 (14) 9.92

− 5 (23) 7.80

0 (32) 6.19

5 (41) 4.95

10 (50) 3.99

15 (59) 3.24

20 (68) 2.65

25 (77) 2.19

30 (86) 1.81

35 (95) 1.51

40 (104) 1.27 45 (113) 1.07

RJIA2025E

Page 555 of 4366

TROUBLE DIAGNOSIS ATC-109

C

D E

F

G H

I

K L

M A

B

AT C

Revision: 2006 July 2007 FX35/FX45

Sunload Sensor CircuitNJS000EH

COMPONENT DESCRIPTION

Sunload Sensor

The sunload sensor is located on the passenger’s side front

defroster grille. It detects sunload entering through windshield by

means of a photo diode. The sensor converts the sunload into a cur-

rent value which is then input into the unified meter and A/C amp.

SUNLOAD INPUT PROCESS

The unified meter and A/C amp. also includes a processing circuit which averages the variations in detected

sunload over a period of time. This prevents drastic swings in the ATC system operation due to small or quick

variations in detected sunload.

For example, consider driving along a road bordered by an occasional group of large trees. The sunload

detected by the sunload sensor will vary whenever the trees obstruct the sunlight. The processing circuit aver-

ages the detected sunload over a period of time, so that the (insignificant) effect of the trees momentarily

obstructing the sunlight does not cause any change in the ATC system operation. On the other hand, shortly

after entering a long tunnel, the system will recognize the change in sunload, and the system will react accord-

ingly.

DIAGNOSIS PROCEDURE FOR SUNLOAD SENSOR

SYMPTOM: Sunload sensor circuit is open or shorted. (25 or −25 is

indicated on unified meter and A/C amp. as a result of performing

self-diagnosis STEP-2.)

1. CHECK VOLTAGE BETWEEN SUNLOAD SENSOR AND GROUND

1. Disconnect sunload sensor connector.

2. Turn ignition switch ON.

3. Check voltage between sunload sensor harness connector M87 terminal 1 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

RJIA2026E

RJIA1455E

1 – Ground : Approx. 5 V

RJIA2027E

Page 556 of 4366

ATC-110

TROUBLE DIAGNOSIS

Revision: 2006 July 2007 FX35/FX45

2. CHECK CIRCUIT CONTINUITY BETWEEN SUNLOAD SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between sunload sensor harness connector M87 terminal 2 and unified meter and A/C amp. harness con-

nector M57 terminal 49.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK SUNLOAD SENSOR

1. Reconnect sunload sensor connector and unified meter and A/C amp. connector.

2. Refer to AT C - 111 , "

Sunload Sensor" .

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 3 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> 1. Replace sunload sensor. 2. Go to self-diagnosis AT C - 5 3 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

4. CHECK CIRCUIT CONTINUITY BETWEEN SUNLOAD SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between sunload sensor harness connector M87 terminal 1 and unified meter and A/C amp. harness con-

nector M57 terminal 50.

4. Check continuity between sunload sensor harness connector M87 terminal 1 and ground.

OK or NG

OK >> 1. Replace unified meter and A/C amp. 2. Go to self-diagnosis AT C - 5 3 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> Repair harness or connector. 2 – 49 : Continuity should exist.

RJIA2028E

1 – 50 : Continuity should exist.

1 – Ground : Continuity should not exist.

RJIA2029E

Page 558 of 4366

ATC-112

TROUBLE DIAGNOSIS

Revision: 2006 July 2007 FX35/FX45

Intake Sensor CircuitNJS000EI

COMPONENT DESCRIPTION

Intake Sensor

The intake sensor is located on the heater & cooling unit assembly. It

converts temperature of air after it passes through the evaporator

into a resistance value which is then input to the unified meter and A/

C amp.

DIAGNOSIS PROCEDURE FOR INTAKE SENSOR

SYMPTOM: Intake sensor circuit is open or shorted. (24 or −24 is

indicated on unified meter and A/C amp. as a result of performing

self-diagnosis STEP-2.)

1. CHECK VOLTAGE BETWEEN INTAKE SENSOR AND GROUND

1. Disconnect intake sensor connector.

2. Turn ignition switch ON.

3. Check voltage between intake sensor harness connector M254 terminal 2 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2. CHECK CIRCUIT CONTINUITY BETWEEN INTAKE SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between intake sensor harness connector M254 terminal 1 and unified meter and A/C amp. harness con-

nector M57 terminal 49.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

RJIA0928E

RJIA1458E

2 – Ground : Approx. 5 V

RJIA2031E

1 – 49 : Continuity should exist.

RJIA2032E

Page 559 of 4366

TROUBLE DIAGNOSIS ATC-113

C

D E

F

G H

I

K L

M A

B

AT C

Revision: 2006 July 2007 FX35/FX45

3. CHECK INTAKE SENSOR

Refer to AT C - 11 3 , "

Intake Sensor" .

OK or NG

OK >> 1. Replace unified meter and A/C amp. 2. Go to self-diagnosis AT C - 5 3 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> 1. Replace intake sensor. 2. Go to self-diagnosis AT C - 5 3 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

4. CHECK CIRCUIT CONTINUITY BETWEEN INTAKE SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between intake sensor harness connector M254 terminal 2 and unified meter and A/C amp. harness con-

nector M57 terminal 41.

4. Check continuity between intake sensor harness connector M254 terminal 2 and ground.

OK or NG

OK >> 1. Replace unified meter and A/C amp. 2. Go to self-diagnosis AT C - 5 3 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> Repair harness or connector.

COMPONENT INSPECTION

Intake Sensor

After disconnecting intake sensor connector M254, measure resis-

tance between terminals 1 and 2 at sensor side. Refer to the table

below.

If NG, replace intake sensor. 2 – 41 : Continuity should exist.

2 – Ground : Continuity should not exist.

RJIA2033E

Temperature °C ( °F) Resistance k Ω

− 15 (5) 12.34

− 10 (14) 9.62

− 5 (23) 7.56

0 (32) 6.00

5 (41) 4.80

10 (50) 3.87

15 (59) 3.15

20 (68) 2.57

25 (77) 2.12

30 (86) 1.76

35 (95) 1.47

40 (104) 1.23 45 (113) 1.04

RJIA2034E

Page 606 of 4366

ATC-160

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 July 2007 FX35/FX45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

CompressorNJS000FI

LubricantNJS000FJ

RefrigerantNJS000FK

Engine Idling SpeedNJS000FL

Refer to EC-675, "Idle Speed and Ignition Timing" (VQ35DE) or EC-1366, "Idle Speed and Ignition Timing"

(VK45DE).

Belt TensionNJS000FM

Refer to EM-15, "DRIVE BELTS" (VQ35DE) or EM-174, "DRIVE BELTS" (VK45DE).

Model Calsonic Kansei make CWV-618

Ty p e V-6 variable displacement

Displacement

cm

3 (cu in)/rev Max. 184 (11.228)

Min. 14.5 (0.885)

Cylinder bore × stroke

mm (in) 37 (1.46)

× [2.3 - 28.6 (0.091 - 1.126)]

Direction of rotation Clockwise (viewed from drive end)

Drive belt Poly V

ModelCalsonic Kansei make CWV-618

Name Nissan A/C System Oil Type S (DH-PS)

Capacity

m (US fl oz, lmp fl oz) Total in system 180 (6.0, 6.3)

Compressor (Service part) charg-

ing amount 180 (6.0, 6.3)

Ty p e

HFC-134a (R-134a)

Capacity

kg (lb) 0.55 (1.21)