check oil INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 77 of 3924

AT-4

BRAKE SIGNAL CIRCUIT ..............................165

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

165

Diagnosis Procedure .............................................165

A/T INDICATOR CIRCUIT ...............................166

Description ........................................................... ..166

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

166

Diagnosis Procedure .............................................166

TROUBLE DIAGNOSIS FOR SYMPTOMS .....167

Wiring Diagram - AT - NONDTC .......................... ..167

A/T Check Indicator Lamp Does Not Come On .....170

Engine Cannot Be Started in "P" or "N" Position ...170

In "P" Position, Vehicle Moves When Pushed .......171

In "N" Position, Vehicle Moves ..............................172

Large Shock ("N" to "D" Position) ..........................173

Vehicle Does Not Creep Backward in "R" Position ..175

Vehicle Does Not Creep Forward in "D" Position ..178

Vehicle Cannot Be Started from D1 .......................180

A/T Does Not Shift: D1→ D2 ................................ ..182

A/T Does Not Shift: D2→ D3 ................................ ..184

A/T Does Not Shift: D3→ D4 ................................ ..186

A/T Does Not Shift: D4→ D5 ................................ ..188

A/T Does Not Lock-up ......................................... ..190

A/T Does Not Hold Lock-up Condition ...................192

Lock-up Is Not Released .......................................194

Engine Speed Does Not Return to Idle .................194

Cannot Be Changed to Manual Mode ...................195

A/T Does Not Shift: 5th Gear → 4th Gear ........... ..196

A/T Does Not Shift: 4th Gear → 3rd Gear ........... ..197

A/T Does Not Shift: 3rd Gear → 2nd Gear .......... ..199

A/T Does Not Shift: 2nd Gear → 1st Gear ........... ..201

Vehicle Does Not Decelerate by Engine Brake ... ..202

SHIFT CONTROL SYSTEM ............................205

Control Device Removal and Installation ............. ..205

Control Rod Removal and Installation ...................206

Adjustment of A/T Position ....................................207

Checking of A/T Position .......................................207

A/T SHIFT LOCK SYSTEM .............................208

Description ........................................................... ..208

Shift Lock System Electrical Parts Location ..........208

Wiring Diagram - AT - SHIFT .................................209

Diagnosis Procedure .............................................209

KEY INTERLOCK CABLE ...............................212

Component .......................................................... ..212

Removal and Installation .......................................212

ON-VEHICLE SERVICE ...................................215

Control Valve with TCM and A/T Fluid Tempera-

ture Sensor 2 ....................................................... .

215

Parking Component (2WD Models Only) ..............226

Rear Oil Seal .........................................................233

Revolution Sensor Component (2WD Models

Only) .....................................................................

233

AIR BREATHER HOSE ....................................239

Removal and Installation ...................................... .239

TRANSMISSION ASSEMBLY ..........................241

Removal and Installation (2WD Models) .............. .241

Removal and Installation (AWD Models) ..............243

OVERHAUL ......................................................249

Component .......................................................... .249

Oil Channel ...........................................................261

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ......................... .

264

DISASSEMBLY .............................................. ..267

Disassembly ......................................................... .267

REPAIR FOR COMPONENT PARTS ..............285

Oil Pump .............................................................. .285

Front Sun Gear, 3rd One-Way Clutch ...................287

Front Carrier, Input Clutch, Rear Internal Gear .....289

Mid Sun Gear, Rear Sun Gear, High and Low Re-

verse Clutch Hub ..................................................

295

High and Low Reverse Clutch ..............................301

Direct Clutch .........................................................303

ASSEMBLY .................................................... ..306

Assembly (1) ........................................................ .306

Adjustment ............................................................320

Assembly (2) .........................................................323

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

330

General Specification ........................................... .330

Vehicle Speed at Which Gear Shifting Occurs .....330

Vehicle Speed at Which Lock-up Occurs/Releas-

es ..........................................................................

331

Stall Speed ............................................................331

Line Pressure ........................................................331

A/T Fluid Temperature Sensor ..............................332

Turbine Revolution Sensor ...................................332

Vehicle Speed Sensor A/T (Revolution Sensor) ...332

Reverse Brake ......................................................332

Total End Play .......................................................332

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 81 of 3924

AT-8

< SERVICE INFORMATION >

PRECAUTIONS

After performing each TROUBLE DIAGNOSIS, perform “DTC

(Diagnostic Trouble Code) Confirmation Procedure”.

If the repair is completed the DTC should not be displayed in

the “DTC Confirmation Procedure”.

Always use the specified brand of ATF. Refer to MA-9, "

Fluids and Lubricants".

Use lint-free paper not cloth rags during work.

After replacing the ATF, dispose of the waste oil using the methods prescribed by law, ordinance, etc.

Before proceeding with disassembly, thoroughly clean the out side of the transmission. It is important to pre-

vent the internal parts from becoming cont aminated by dirt or other foreign matter.

Disassembly should be done in a clean work area.

Use lint-free paper or towels for wiping parts clean. Common shop rags can leave fibers that could interfere

with the operation of the transmission.

Place disassembled parts in order for easier and proper assembly.

All parts should be carefully cleansed with a general purpose, non-flammable solvent before inspection or

reassembly.

Gaskets, seals and O-rings should be replaced any time the transmission is disassembled.

It is very important to perform functional tests whenever they are indicated.

The valve body contains precision parts and requires extreme care when parts are removed and serviced. Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent springs

and small parts from becoming scattered or lost.

Properly installed valves, sleeves, plugs, etc. will s lide along bores in valve body under their own weight.

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Do not use grease.

Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

After overhaul, refill the transmission with new ATF.

When the A/T drain plug is removed, only some of t he ATF is drained. Old ATF will remain in torque con-

verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

AT- 11 , "

Changing A/T Fluid", AT- 11 , "Checking A/T Fluid".

Service Notice or PrecautionINFOID:0000000001327125

ATF COOLER SERVICE

If ATF contains frictional material (clutches, bands, etc. ), or if an A/T is repaired, overhauled, or replaced,

inspect and clean the A/T fluid cooler mounted in the radiat or or replace the radiator. Flush cooler lines using

cleaning solvent and compressed air after repair. For A/T fluid cooler cleaning procedure, refer to AT-13, "

A/T

Fluid Cooler Cleaning". For radiator replacement, refer to CO-13 (for VQ35DE), CO-40 (for VK45DE).

OBD-II SELF-DIAGNOSIS

A/T self-diagnosis is performed by the TCM in comb ination with the ECM. The results can be read through

the blinking pattern of the A/T CHECK indicator or the malfunction indicator lamp (MIL). Refer to the table on

AT-84, "

CONSULT-III Function (TRANSMISSION)" for the indicator used to display each self-diagnostic

result.

The self-diagnostic results indicated by the MIL ar e automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure on AT-38, "

OBD-II Diagnostic Trouble Code (DTC)" to complete the

repair and avoid unnecessary blinking of the MIL.

For details of OBD-II, refer to EC-54

(for VQ35DE) or EC-632 (for VK45DE).

Certain systems and components, especially those re lated to OBD, may use the new style slide-lock-

ing type harness connector. For descrip tion and how to disconnect, refer to PG-68

.

SEF217U

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 123 of 3924

AT-50

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

A/T Fluid Condition Check

Inspect the A/T fluid condition.

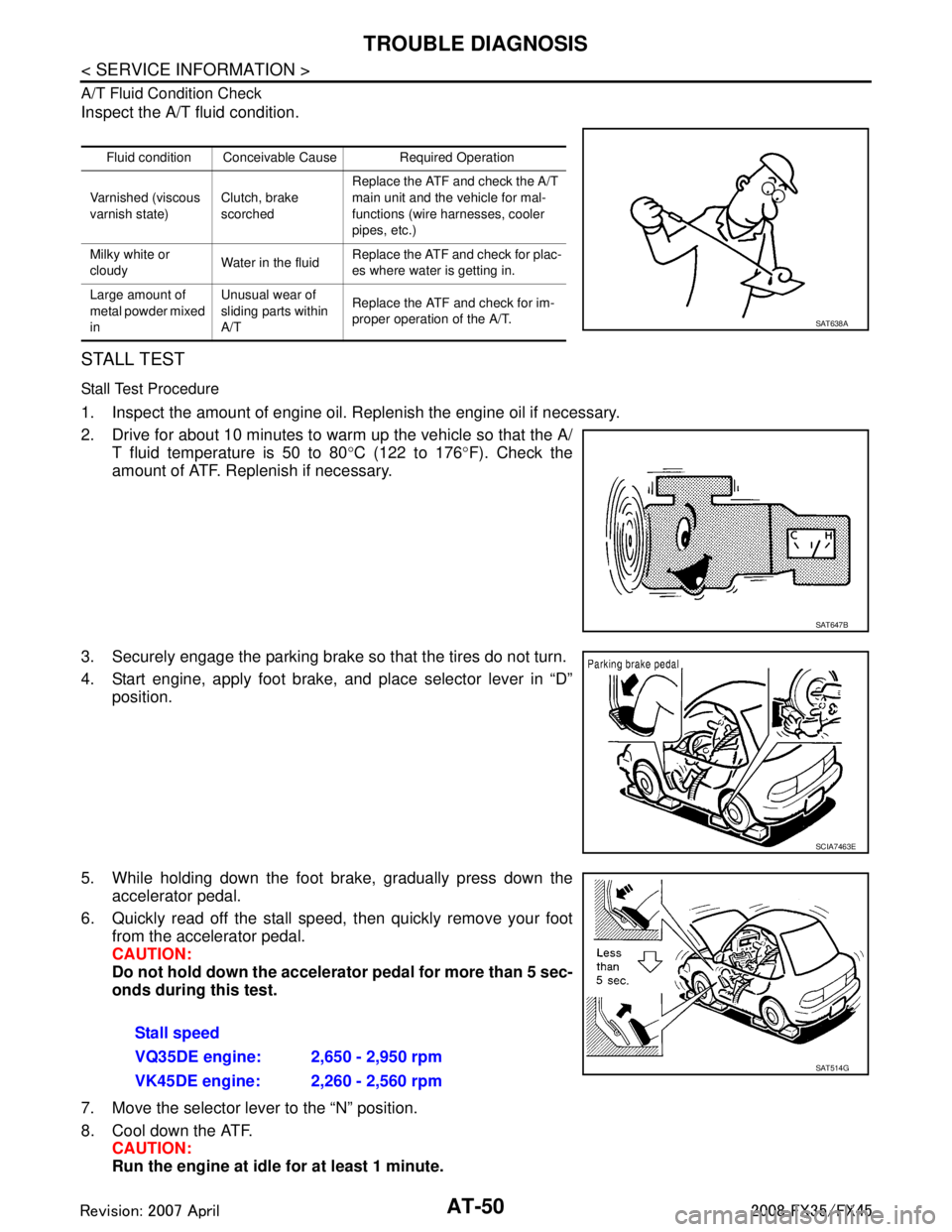

STALL TEST

Stall Test Procedure

1. Inspect the amount of engine oil. Replenish the engine oil if necessary.

2. Drive for about 10 minutes to warm up the vehicle so that the A/T fluid temperature is 50 to 80 °C (122 to 176 °F). Check the

amount of ATF. Replenish if necessary.

3. Securely engage the parking brake so that the tires do not turn.

4. Start engine, apply foot brake, and place selector lever in “D” position.

5. While holding down the foot brake, gradually press down the accelerator pedal.

6. Quickly read off the stall speed, then quickly remove your foot from the accelerator pedal.

CAUTION:

Do not hold down the accelerator pedal for more than 5 sec-

onds during this test.

7. Move the selector lever to the “N” position.

8. Cool down the ATF. CAUTION:

Run the engine at idle for at least 1 minute.

Fluid condition Conceivable Cause Required Operation

Varnished (viscous

varnish state) Clutch, brake

scorchedReplace the ATF and check the A/T

main unit and the vehicle for mal-

functions (wire harnesses, cooler

pipes, etc.)

Milky white or

cloudy Water in the fluidReplace the ATF and check for plac-

es where water is getting in.

Large amount of

metal powder mixed

in Unusual wear of

sliding parts within

A/T

Replace the ATF and check for im-

proper operation of the A/T.

SAT638A

SAT647B

SCIA7463E

Stall speed

VQ35DE engine: 2,650 - 2,950 rpm

VK45DE engine: 2,260 - 2,560 rpm

SAT514G

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 126 of 3924

TROUBLE DIAGNOSISAT-53

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

Road TestINFOID:0000000001425855

DESCRIPTION

The road test checks overall performance of the A/T and analyzes possible malfunction causes.

The road test is carried out in the following three stages.

1. Check before engine is started.

2. Check at idle.

3. Cruise test

Inspect all the items Part 1 to Part 3.

Before beginning the road test, che ck the procedure and inspection items.

Test all inspection items until the symptom is uncov ered. Diagnose NG items when all road tests are com-

plete.

CHECK BEFORE ENGINE IS STARTED

1.CHECK A/T CHECK INDICATOR LAMP

1. Park vehicle on level surface.

2. Move selector lever to “P” position.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON.

Does A/T CHECK indicator lamp light up for about 2 seconds?

YES - 1>> With CONSULT-III

1. Perform self-diagnostics and record all NG items on the “Diagnostic Worksheet Chart”.

2. Go to “CHECK AT IDLE”.

YES - 2>> Without CONSULT-III

1. Perform self-diagnostics and record all NG it ems on the “Diagnostic Worksheet Chart”. Refer

to AT-91, "

Diagnosis Procedure without CONSULT-III".

2. Go to “CHECK AT IDLE”.

NO >> Stop the road test and go to AT-170, "

A/T Check Indicator Lamp Does Not Come On".

CHECK AT IDLE

1.CHECK STARTING THE ENGINE

1. Park vehicle on level surface.

2. Move selector lever to “P” or “N” position.

3. Turn ignition switch OFF.

4. Start engine.

Does the engine start?

YES >> GO TO 2.

NO >> Stop the road test and go to AT-170, "

Engine Cannot Be Started in "P" or "N" Position".

Stall speedLine pressure does

not rise higher than

the line pressure for

idle.

Possible causes include a sensor malfunction or malfunction in the pressure adjustment function.

For example

Accelerator pedal position signal malfunction

TCM breakdown

Line pressure solenoid malfunction (shorting, sticking in ON state)

Pressure regulator valve or plug sticking

Pilot valve sticking or pilot filter clogged

The pressure rises,

but does not enter

the standard posi-

tion. Possible causes include malfunctions in the pressure supply system and malfunction in the pres-

sure adjustment function.

For example

Accelerator pedal position signal malfunction

Line pressure solenoid malfunction (sticking, filter clog)

Pressure regulator valve or plug sticking

Pilot valve sticking or pilot filter clogged

Only low for a spe-

cific position Possible causes include an oil pressure leak in a passage or device related to the position after

the pressure is distributed by the manual valve.

Judgement Possible cause

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 127 of 3924

AT-54

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

2.CHECK STARTING THE ENGINE

1. Turn ignition switch ON. (Do not start engine.)

2. Move selector lever to “D”, “M” or “R” position.

3. Start engine.

Does the engine start in either position?

YES >> Stop the road test and go to AT-170, "Engine Cannot Be Started in "P" or "N" Position".

NO >> GO TO 3.

3.CHECK “P” POSITION FUNCTIONS

1. Move selector lever to “P” position.

2. Turn ignition switch OFF.

3. Disengage the parking brake.

4. Push the vehicle forward or backward.

5. Engage the parking brake.

When you push the vehicle with disengaging the parking brake, does it move?

YES >> Enter a check mark at AT-171, "In "P" Position, Vehicle Moves When Pushed" on the “Diagnostic

Worksheet Chart”, then continue the road test.

NO >> GO TO 4.

4.CHECK “N” POSITION FUNCTIONS

1. Start engine.

2. Move selector lever to “N” position.

3. Disengage the parking brake.

Does vehicle move forward or backward?

YES >> Enter a check mark at AT-172, "In "N" Position, Vehicle Moves" on the “Diagnostic Worksheet

Chart”, then continue the road test.

NO >> GO TO 5.

5.CHECK SHIFT SHOCK

1. Engage the brake.

2. Move selector lever to “D” position.

When the transmission is shifted from

“N” to “D”, is there an excessive shock?

YES >> Enter a check mark at AT-173, "Large Shock ("N" to "D" Position)"on the “Diagnostic Worksheet

Chart”, then continue the road test.

NO >> GO TO 6.

6.CHECK “R” POSITION FUNCTIONS

1. Engage the brake.

2. Move selector lever to “R” position.

3. Disengage the brake for 4 to 5 seconds.

Does the vehicle creep backward?

YES >> GO TO 7.

NO >> Enter a check mark at AT-175, "

Vehicle Does Not Creep Backward in "R" Position" on the “Diag-

nostic Worksheet Chart”, then continue the road test.

7.CHECK “D” POSITION FUNCTIONS

Inspect whether the vehicle creep forward when the A/T is put into the “D” position.

Does the vehicle creep forward in the

“D” position?

YES >> Go to AT-53, "Road Test".

NO >> Enter a check mark at AT-178, "

Vehicle Does Not Creep Forward in "D" Position"on the “Diagnos-

tic Worksheet Chart”, then continue the road test.

CRUISE TEST - PART 1

1.CHECK STARTING OUT FROM D1

1. Drive the vehicle for about 10 minutes to warm up the engine oil and ATF. Appropriate temperature for the ATF: 50 to 80 °C (122 to 176 °F)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 201 of 3924

AT-128

< SERVICE INFORMATION >

DTC P0745 LINE PRESSURE SOLENOID VALVE

DTC P0745 LINE PRESSURE SOLENOID VALVE

DescriptionINFOID:0000000001327221

The line pressure solenoid valve regulates the oil pump discharge pressure to suit the driving condition in

response to a signal sent from the TCM.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001327222

On Board Diagnosis LogicINFOID:0000000001327223

Diagnostic trouble code “P0745 L/PRESS SOL/CIRC” with CONSULT-III or 4th judgement flicker without

CONSULT-III is detected under the following conditions.

When TCM detects an improper voltage drop when it tries to operate the solenoid valve.

When TCM detects as irregular by comparing target value with monitor value.

Possible CauseINFOID:0000000001327224

Harness or connectors (Solenoid circuit is open or shorted.)

Line pressure solenoid valve

DTC Confirmation ProcedureINFOID:0000000001327225

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON.

2. Select “MAIN SIGNALS” in “DATA MONITO R” mode for “TRANSMISSION” with CONSULT-III.

3. Touch “START”.

4. Engine start and wait at least 5 seconds.

5. If DTC is detected, go to “ AT-128, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Diagnosis ProcedureINFOID:0000000001327226

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Turn ignition switch ON.

2. Select “MAIN SIGNALS” in “DATA MONITO R” mode for “TRANSMISSION” with CONSULT-III.

3. Start engine.

4. Read out the value of “LINE PRES SOL” while driving.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

2.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer to AT-160

.

Item name Condition Display value (Approx.)

LINE PRES SOL During driving 0.2 - 0.6 A

Item name Condition Display value (Approx.)

LINE PRES SOL During driving 0.2 - 0.6 A

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 244 of 3924

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-171

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

Check the A/T position. Refer to AT-207, "Checking of A/T Position".

OK or NG

OK >> GO TO 3.

NG >> Adjust A/T position. Refer to AT-207, "

Adjustment of A/T

Position".

3.CHECK STARTING SYSTEM

Check starting system. Refer to SC-8

.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

In "P" Position, Vehicle Moves When PushedINFOID:0000000001327363

SYMPTOM:

Even though the selector lever is set in the “P” position, the parking mechanism is not actuated,

allowing the vehicle to be moved when it is pushed.

DIAGNOSTIC PROCEDURE

1.CHECK A/T POSITION

Check the A/T position. Refer to AT-207, "

Checking of A/T Position".

OK or NG

OK >> GO TO 2.

NG >> Adjust A/T position. Refer to AT-207, "

Adjustment of A/T

Position".

2.CHECK PARKING COMPONENTS

Check parking components. Refer to AT-226, "

Parking Component (2WD Models Only)" (2WD models) or AT-

267, "Disassembly" (AWD models).

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-215, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

2. Check A/T fluid condition. Refer to AT-49, "

Inspections Before

Trouble Diagnosis".

OK or NG

OK >> INSPECTION END

NG >> Check the malfunction items. If any items are damaged, repair or replace damaged parts. Refer to AT-59, "

Symp-

tom Chart" (Symptom No.65).

SCIA2119E

SCIA2119E

SCIA5199E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 245 of 3924

AT-172

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

In "N" Position, Vehicle Moves

INFOID:0000000001327364

SYMPTOM:

Vehicle moves forward or backwar d when selecting “N” position.

DIAGNOSTIC PROCEDURE

1.CHECK PNP SWITCH CIRCUIT

With CONSULT-III

Perform self-diagnosis.

Without CONSULT-III

Perform self-diagnosis. Refer to AT-91, "

Diagnosis Procedure without CONSULT-III".

Do the self-diagnostic results indicate PNP switch?

YES >> Check the malfunctioning system. Refer to AT-102.

NO >> GO TO 2.

2.CHECK A/T POSITION

Check the A/T position. Refer to AT-207, "

Checking of A/T Position".

OK or NG

OK >> GO TO 3.

NG >> Adjust A/T position. Refer to AT-207, "

Adjustment of A/T

Position".

3.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT- 11 , "

Checking A/T Fluid".

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-215, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

2. Check A/T fluid condition. Refer to AT-49, "

Inspections Before

Trouble Diagnosis".

OK or NG

OK >> GO TO 5.

NG >> Check the malfunction items. If any items are damaged, repair or replace damaged parts. Refer to AT-59, "

Symp-

tom Chart" (Symptom No.67).

5.CHECK SYMPTOM

Check again. Refer to “CHECK AT IDLE”.

SCIA2119E

SAT638A

SCIA5199E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 247 of 3924

AT-174

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

Check the A/T fluid level. Refer to AT- 11 , "Checking A/T Fluid".

OK or NG

OK >> GO TO 5.

NG >> Refill ATF.

5.CHECK LINE PRESSURE

Check line pressure at idle with selector lever in “D” position. Refer

to AT-49, "

Inspections Before Trouble Diagnosis".

OK or NG

OK >> GO TO 8.

NG-1 >> Line pressure high: GO TO 6.

NG-2 >> Line pressure low: GO TO 7.

6.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-215, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-267

.

3. Check the following.

- Oil pump assembly. Refer to AT-285, "

Oil Pump".

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

7.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-215, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-267

.

3. Check the following.

- Oil pump assembly. Refer to AT-285, "

Oil Pump".

- Power train system. Refer to AT-267

.

- Transmission case. Refer to AT-267

.

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

8.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-215, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

SAT638A

SAT494G

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 250 of 3924

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-177

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

7.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-215, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-267

.

3. Check the following.

- Oil pump assembly. Refer to AT-285, "

Oil Pump".

OK or NG

OK >> GO TO 9.

NG >> Repair or replace damaged parts.

8.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-215, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-267

.

3. Check the following.

- Oil pump assembly. Refer to AT-285, "

Oil Pump".

- Power train system. Refer to AT-267

.

- Transmission case. Refer to AT-267

.

OK or NG

OK >> GO TO 9.

NG >> Repair or replace damaged parts.

9.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-215, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

2. Check A/T fluid condition. Refer to AT-49, "

Inspections Before

Trouble Diagnosis".

OK or NG

OK >> GO TO 10.

NG >> GO TO 13.

10.DETECT MALFUNCTIONING ITEM

Check the malfunction items. If any items are dam aged, repair or replace damaged parts. Refer to AT-59,

"Symptom Chart" (Symptom No.43).

OK or NG

OK >> GO TO 11.

NG >> Repair or replace damaged parts.

11 .CHECK SYMPTOM

Check again. Refer to “CHECK AT IDLE”.

OK or NG

OK >> INSPECTION END

NG >> GO TO 12.

12.CHECK TCM

1. Check TCM input/output signals. Refer to AT-83, "

TCM Input/Output Signal Reference Value".

2. If NG, recheck A/T assembly harness connector terminals for damage or loose connection with harness

connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

SCIA5199E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C