sensor INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3155 of 3924

AUTO LIGHT SYSTEMLT-53

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

Te r m i n a l No. Wire

color Signal name Measuring condition

Reference value

Ignition

switch Operation or condition

4Pu/W Combination switch in-

put 3

ONLighting, turn, wiper

switch

(Wiper intermittent

dial position 4) OFF Approx. 0 V

Lighting switch

AUTO

Approx. 1.0 V

11 LG Ignition switch (ACC) ACC — Battery voltage

12 P/B Front door switch

(Passenger side) signal OFFFront door switch

(Passenger side) ON (open) Approx. 0 V

OFF (closed)

Approx. 7.5 - 8.0 V

13 P/L Rear door switch RH

signal OFFRear door switch RH

(Personal lamp RH

ON or OFF position) ON (open) Approx. 0 V

OFF (closed) Battery voltage

14 P Optical sensor signal ON When optical sensor is illuminated

3.1 V or more

Note

When optical sensor is not illuminated 0.6 V or less

17 Y/G Optical sensor power

supply ON — Approx. 5 V

18 B Sensor ground ON — Approx. 0 V

33 G Combination switch

output 4 ONLighting, turn, wiper

switch

(Wiper intermittent

dial position 4) OFF

Approx. 7.2 V

Lighting switch

AUTO Approx. 1.2 V

38 W/L Ignition switch (ON) ON — Battery voltage

39 L CAN − H— — —

40 P CAN − L— — —

42 L/R Battery power supply OFF — Battery voltage

PKIB4959J

SKIB3419J

PKIB4960J

PKIB4958J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3156 of 3924

LT-54

< SERVICE INFORMATION >

AUTO LIGHT SYSTEM

NOTE:

Optical sensor must be securely subjected to work lamp light. If optical sensor is insufficiently illuminated, the measured value may not

satisfy standard.

Terminal and Reference Value for IPDM E/RINFOID:0000000001328314

How to Proceed with Trouble DiagnosisINFOID:0000000001328315

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer to LT-47, "

System Description".

3. Perform Preliminary Check. Refer to LT-55, "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction. Refer to LT-58, "

Symptom Chart".

49 B Ground ON — Approx. 0 V

52 B Ground ON — Approx. 0 V

55 G Battery power supply OFF — Battery voltage

58 L Back door switch signal OFF Back door closure

motor (door switch)ON (open) Approx. 0 V

OFF (closed) Battery voltage

62 W Front door switch

(Driver side) signal OFFFront door switch

(Driver side) ON (open) Approx. 0 V

OFF (closed)

Approx. 7.0 - 7.5 V

63 P Rear door switch LH

signal OFF Rear door switch LH ON (open) Approx. 0 V

OFF (closed) Battery voltage

Te r m i n a l

No. Wire

color Signal name Measuring condition

Reference value

Ignition

switch Operation or condition

PKIB4960J

Te r m i n a l

No. Wire

color Signal name Measuring condition

Reference value

Ignition

switch Operation or condition

20 LG Headlamp low (RH) ON Lighting switch 2ND

positionOFF Approx. 0 V

ON Battery voltage

22 R Parking, license plate, side

marker and tail lamps ON

Lighting switch 1ST po-

sition OFF Approx. 0 V

ON Battery voltage

27 BR Headlamp high (RH) ON Lighting switch HIGH

or PASS positionOFF Approx. 0 V

ON Battery voltage

28 SB Headlamp high (LH) ON Lighting switch HIGH

or PASS positionOFF Approx. 0 V

ON Battery voltage

30 GY Headlamp low (LH) ON Lighting switch 2ND

positionOFF Approx. 0 V

ON Battery voltage

38 B Ground ON — Approx. 0 V

48 L CAN − H—— —

49 R CAN − L—— —

60 B Ground ON — Approx. 0 V

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3159 of 3924

AUTO LIGHT SYSTEMLT-57

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

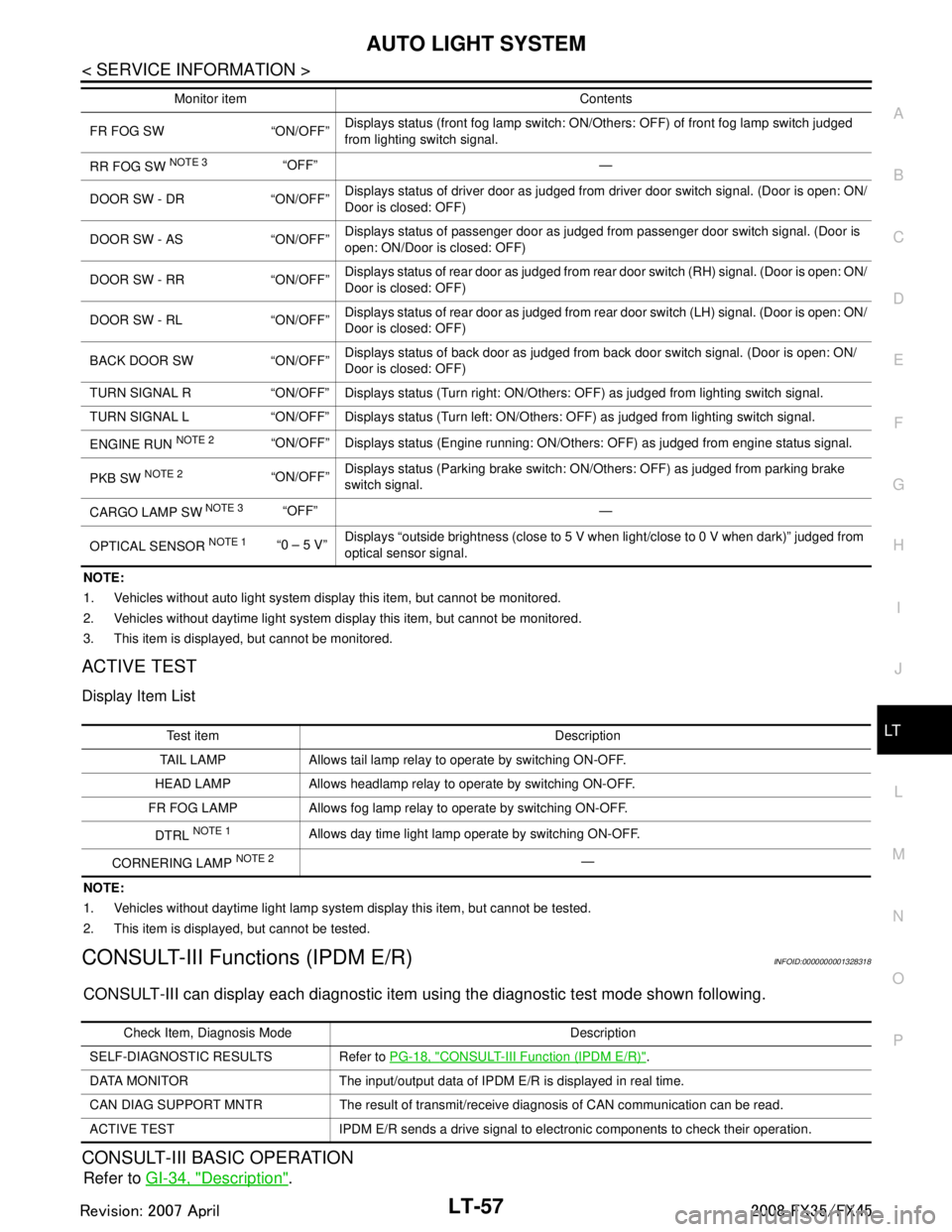

NOTE:

1. Vehicles without auto light system display this item, but cannot be monitored.

2. Vehicles without daytime light system display this item, but cannot be monitored.

3. This item is displayed, but cannot be monitored.

ACTIVE TEST

Display Item List

NOTE:

1. Vehicles without daytime light lamp system display this item, but cannot be tested.

2. This item is displayed, but cannot be tested.

CONSULT-III Functions (IPDM E/R)INFOID:0000000001328318

CONSULT-III can display each diagnostic item using the diagnostic test mode shown following.

CONSULT-III BASIC OPERATION

Refer to GI-34, "Description".

FR FOG SW “ON/OFF” Displays status (front fog lamp switch: ON/Oth

ers: OFF) of front fog lamp switch judged

from lighting switch signal.

RR FOG SW

NOTE 3“OFF” —

DOOR SW - DR “ON/OFF” Displays status of driver door as judged from driver door switch signal. (Door is open: ON/

Door is closed: OFF)

DOOR SW - AS “ON/OFF” Displays status of passenger door as judged from passenger door switch signal. (Door is

open: ON/Door is closed: OFF)

DOOR SW - RR “ON/OFF” Displays status of rear door as judged from rear door switch (RH) signal. (Door is open: ON/

Door is closed: OFF)

DOOR SW - RL “ON/OFF” Displays status of rear door as judged from rear door switch (LH) signal. (Door is open: ON/

Door is closed: OFF)

BACK DOOR SW “ON/OFF” Displays status of back door as judged from back door switch signal. (Door is open: ON/

Door is closed: OFF)

TURN SIGNAL R “ON/OFF” Display s status (Turn right: ON/Others: OFF) as judged from lighting switch signal.

TURN SIGNAL L “ON/OFF” Display s status (Turn left: ON/Others: OFF) as judged from lighting switch signal.

ENGINE RUN

NOTE 2“ON/OFF” Displays status (Engine running: ON/Others: OFF) as judged from engine status signal.

PKB SW

NOTE 2“ON/OFF” Displays status (Parking brake switch: ON/Others: OFF) as judged from parking brake

switch signal.

CARGO LAMP SW

NOTE 3 “OFF” —

OPTICAL SENSOR

NOTE 1 “0 – 5 V” Displays “outside brightness (close to 5 V when light/close to 0 V when dark)” judged from

optical sensor signal.

Monitor item Contents

Te s t i t e m D e s c r i p t i o n

TAIL LAMP Allows tail lamp relay to operate by switching ON-OFF.

HEAD LAMP Allows headlamp relay to operate by switching ON-OFF.

FR FOG LAMP Allows fog lamp relay to operate by switching ON-OFF.

DTRL

NOTE 1Allows day time light lamp operate by switching ON-OFF.

CORNERING LAMP

NOTE 2—

Check Item, Diagnosis Mode Description

SELF-DIAGNOSTIC RESULTS Refer to PG-18, "

CONSULT-III Function (IPDM E/R)".

DATA MONITOR The input/output data of IPDM E/R is displayed in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST IPDM E/R sends a drive signal to electronic components to check their operation.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3160 of 3924

LT-58

< SERVICE INFORMATION >

AUTO LIGHT SYSTEM

DATA MONITOR

All Signals, Main Signals, Selection From Menu

NOTE:

Perform monitoring of IPDM E/R data with ignition switch ON. When ignition switch is at ACC, the display may

not be correct.

ACTIVE TEST

Symptom ChartINFOID:0000000001328319

Lighting Switch InspectionINFOID:0000000001381749

1.CHECK LIGHTING SWITCH INPUT SIGNAL

CONSULT-III DATA MONITOR

1. Select “AUTO LIGHT SW” of BCM (HEAD LAMP) data monitor item.

2. With operating the lighting switch AUTO, check the monitor status.

CHECK THE COMBINATION SWITCH

Refer to LT-104, "

Combination Switch Inspection".

OK or NG

OK >> INSPECTION END

NG >> Check combination switch (lighting switch). Refer to LT-104, "

Combination Switch Inspection".

Item nameCONSULT-III

screen display Display

or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Position lights reques t TAIL & CLR REQ ON/OFF ×× ×Signal status input from BCM

Headlamp low beam request HL LO REQ ON/OFF ×× ×Signal status input from BCM

Headlamp high beam request HL HI REQ ON/OFF ×× ×Signal status input from BCM

Front fog lights request FR FOG REQ ON/OFF ×× ×Signal status input from BCM

Te s t i t e mCONSULT-III

screen display Description

Headlamp relay (HI, LO) output LAMPSAllows headlamp relay (HI, LO) to operate by switching operation (OFF, HI ON,

LO ON) at your option (Head lamp high beam repeats ON-OFF every 1 second).

Front fog lamp relay output Allows fog lamp relay to operate by switching operation ON-OFF at your option.

Tail lamp relay output TAIL LAMP Allows tail lamp relay to operate by switching operation ON-OFF at your option.

Trouble phenomenon Malfunction system and reference

Parking, license plate, side marker and tail lamps and head- lamps will not illuminate when outside of the vehicle be-

comes dark. (Lighting switch 1ST position and 2ND position

operate normally.)

Parking, license plate, side marker and tail lamps and head-

lamp will not go out when outside of the vehicle becomes

light. (Lighting switch 1ST position and 2nd position operate

normally.)

Headlamps go out when outside of the vehicle becomes light, but parking lamps stay on. Refer to

LT- 5 6 , "

CONSULT-III Functions (BCM)".

Refer to LT- 5 8 , "

Lighting Switch Inspection".

Refer to LT- 5 9 , "

Optical sensor System Inspection".

If above systems are normal, replace BCM.

Shut off delay feature will not operate. CAN communication line inspection between BCM and combination

meter. Refer to PG-24, "

U1000 CAN COMM CIRCUIT".

Refer to BL-38, "

Check Door Switch".

If above system is normal, replace BCM.

When lighting switch is AUTO

position : AUTO LIGHT SW ON

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3161 of 3924

AUTO LIGHT SYSTEMLT-59

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

Optical sensor System InspectionINFOID:0000000001381750

1.CHECK OPTICAL SENSOR INPUT SIGNAL

CONSULT-III DATA MONITOR

1. Turn ignition switch ON.

2. Select “OPTICAL SENSOR” of BC M (HEAD LAMP) data monitor item.

3. Turn the lighting switch AUTO.

4. With the optical sensor illuminat ing, check the monitor status.

CAUTION:

Optical sensor must be securely subject ed to work lamp light. If optical sensor is insufficiently illumi-

nated, the measured value may not satisfy the standard.

CHECK BCM

1. Turn ignition switch ON.

2. Check voltage between BCM harness connector M3 terminal 14

and ground.

CAUTION:

Optical sensor must be securely su bjected to work lamp light. If

optical sensor is insufficiently illuminated, the measured value

may not satisfy the standard.

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

2.CHECK OPTICAL SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector and optical sensor connector.

3. Check continuity (open circuit) between BCM harness connector M3 terminal 17 and optical sensor harness connector M37 ter-

minal 1.

4. Check continuity (short circuit) between BCM harness connector M3 terminal 17 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK OPTICAL SENS OR SIGNAL CIRCUIT

Illuminated

OPTICAL SENSOR : 3.1 V or more

Not illuminated

OPTICAL SENSOR : 0.6 V or less

Illuminated

OPTICAL SENSOR : 3.1 V or more

Not illuminated

OPTICAL SENSOR : 0.6 V or less

PKIB6163E

17 – 1 : Continui

ty should exist.

17 – Ground : Continuity should not exist.

SKIA5891E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3162 of 3924

LT-60

< SERVICE INFORMATION >

AUTO LIGHT SYSTEM

1. Check continuity (open circuit) between BCM harness connectorM3 terminal 14 and optical sensor harness connector M37 ter-

minal 2.

2. Check continuity (short circuit) between BCM harness connector M3 terminal 14 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK OPTICAL SENSOR GROUND CIRCUIT

1. Check continuity (open circuit) between BCM harness connector M3 terminal 18 and optical sensor harness connector M37 ter-

minal 3.

2. Check continuity (short circuit) between BCM harness connector M3 terminal 18 and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5.CHECK OPTICAL SENSOR VOLTAGE

1. Connect BCM connector.

2. Turn ignition switch ON.

3. Check voltage between BCM harness connector M3 terminal 17 and ground.

OK or NG

OK >> Replace optical sensor.

NG >> Replace BCM. Refer to BCS-13, "

Removal and Installa-

tion of BCM".

Removal and Installation of Optical SensorINFOID:0000000001328322

REMOVAL

1. Insert a screwdriver or similar tool and remove front defroster

grill (LH). Refer to IP-11, "

Removal and Installation".

2. Disconnect optical sensor connector.

3. Remove optical sensor.

INSTALLATION

Installation is the reverse order of removal. 14 – 2 : Continuity should exist.

14 – Ground : Continuity should not exist.

SKIA5892E

18 – 3 : Continuity should exist.

18 – Ground : Continuity should not exist.

SKIA5893E

17 – Ground : Approx. 5 V

SKIA5894E

PKIA5275E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3290 of 3924

![INFINITI FX35 2008 Service Manual

ENGINE OILLU-5

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

ENGINE OIL

InspectionINFOID:0000000001325813

ENGINE OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally an INFINITI FX35 2008 Service Manual

ENGINE OILLU-5

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

ENGINE OIL

InspectionINFOID:0000000001325813

ENGINE OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally an](/img/42/57017/w960_57017-3289.png)

ENGINE OILLU-5

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

ENGINE OIL

InspectionINFOID:0000000001325813

ENGINE OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally and check

the engine oil level. If engine is already started, stop

it and allow 10 minutes before checking.

1. Pull out oil level gauge and wipe it clean.

2. Insert oil level gauge and make sure the engine oil level is within the range shown in the figure.

3. If it is out of range, adjust it.

NOTE:

When checking the engine oil level, insert oil level gauge with its

tip aligned with oil level gauge guide on cylinder head. (In figure,

air cleaner case and air duct are removed.)

ENGINE OIL APPEARANCE

Check engine oil for white turbidity or heavy contamination.

If engine oil becomes turbid and white, it is highl y probable that it is contaminated with engine coolant.

Repair or replace damaged parts.

ENGINE OIL LEAKAGE

Check for engine oil leakage around the following areas:

Oil pans (lower and upper)

Oil pan drain plug

Oil pressure switch

Oil filter

Oil filter bracket (AWD models)

Oil cooler

Water pump cover

Chain tensioner cover

Intake valve timing control cover and intake valve timing control solenoid valve

Mating surface between cylinder head and rocker cover

Mating surface between front timing chain case and rear timing chain case

Mating surface between rear timing chain case and cylinder head

Mating surface between rear timing chain case and cylinder block

Mating surface between rear timing chain case and oil pan (upper)

Mating surface between cylinder block and cylinder head

Crankshaft oil seals (front and rear)

Camshaft position sensor (PHASE)

OIL PRESSURE CHECK

PBIC3101E

KBIA1343E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3291 of 3924

![INFINITI FX35 2008 Service Manual

LU-6

< SERVICE INFORMATION >[VQ35DE]

ENGINE OIL

WARNING:

• Be careful not to get burn your

self, as engine oil may be hot.

Oil pressure check should be done in “Parking position”.

1. Check t INFINITI FX35 2008 Service Manual

LU-6

< SERVICE INFORMATION >[VQ35DE]

ENGINE OIL

WARNING:

• Be careful not to get burn your

self, as engine oil may be hot.

Oil pressure check should be done in “Parking position”.

1. Check t](/img/42/57017/w960_57017-3290.png)

LU-6

< SERVICE INFORMATION >[VQ35DE]

ENGINE OIL

WARNING:

• Be careful not to get burn your

self, as engine oil may be hot.

Oil pressure check should be done in “Parking position”.

1. Check the engine oil level. Refer to "ENGINE OIL LEVEL".

2. Remove front engine undercover with power tool.

3. Disconnect harness connector at oil pressure sensor, and remove oil pressure sensor using deep socket (commercial ser-

vice tool).

CAUTION:

Do not drop or shock oil pressure switch.

4. Install the oil pressure gauge (SST) and hose (SST).

5. Start the engine and warm it up to normal operating temperature.

6. Check the engine oil pressure with engine running under no-load. NOTE:

When the engine oil temperature is low, the engine oil pressure becomes high.

Engine oil pressure [Engi ne oil temperature at 80 °C (176 °F)]

Unit: kPa (kg/cm2, psi)

If difference is extreme, check engine oil passage and oil pump for engine oil leaks.

7. After the inspections, install oil pressure switch as follows:

a. Remove old liquid gasket adhering to oil pressure switch and the mating surface.

b. Apply liquid gasket and tighten oil pressure switch to the specification. Use Genuine RTV Silicone Seal ant or equivalent. Refer to GI-44, "

Recommended Chemical Prod-

uct and Sealant".

SBIA0452E

SBIA0453E

SLC926

Engine speed Approximate discharge pressure

Idle speed More than 98 (1.0, 14)2,000 rpm More than 294 (3.0, 43)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3295 of 3924

![INFINITI FX35 2008 Service Manual

LU-10

< SERVICE INFORMATION >[VQ35DE]

OIL FILTER BRACKET (AWD)

OIL FILTER BRACKET (AWD)

ComponentINFOID:0000000001325816

Removal and InstallationINFOID:0000000001325817

REMOVAL

WARNING:

Be careful no INFINITI FX35 2008 Service Manual

LU-10

< SERVICE INFORMATION >[VQ35DE]

OIL FILTER BRACKET (AWD)

OIL FILTER BRACKET (AWD)

ComponentINFOID:0000000001325816

Removal and InstallationINFOID:0000000001325817

REMOVAL

WARNING:

Be careful no](/img/42/57017/w960_57017-3294.png)

LU-10

< SERVICE INFORMATION >[VQ35DE]

OIL FILTER BRACKET (AWD)

OIL FILTER BRACKET (AWD)

ComponentINFOID:0000000001325816

Removal and InstallationINFOID:0000000001325817

REMOVAL

WARNING:

Be careful not to get burn yourself, as engine oil may be hot.

1. Remove front engine undercover with power tool.

2. Using the oil filter wrench [SST: KV10115801 (J38956)], remove oil filter. Refer to

LU-8, "

Removal and

Installation".

CAUTION:

Do not spill engine oil on drive belt.

3. Remove oil cooler connector bolt, and then oil cooler with water hoses connected.

4. Disconnect oil temperature sensor and oi l pressure switch harness connectors.

5. Remove oil filter bracket from oil pan (upper).

6. Remove oil temperature sensor and oil pr essure switch from oil filter bracket.

INSTALLATION

Note the following, and install in the reverse order of removal.

Install oil pressure switch and oil temperature sensor as follows:

- Remove old liquid gasket adhering to oil pressure switch and oil filter bracket.

- Apply liquid gasket and install oil pressure switch, and then oil temperature sensor with a new washer.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to GI-44, "

Recommended Chemical Product

and Sealant".

1. Oil filter 2. Connector bolt 3. Oil cooler

4. O-ring 5. Relief valve 6. Oil filter bracket

7. Gasket 8. Oil pressure switch 9. Oil temperature sensor

10. Washer 11. Oil pan (upper)

SBIA0593E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3339 of 3924

MA-22

< SERVICE INFORMATION >

ENGINE MAINTENANCE (VK45DE ENGINE)

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the system. Refer to "DRAINING ENGINE COOLANT".

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

Checking Fuel LineINFOID:0000000001328912

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

Changing Air Cleaner FilterINFOID:0000000001328913

VISCOUS PAPER TYPE

The viscous paper type filter does not need cleaning between replacement intervals. Refer to MA-5.

1. Remove air duct (inlet), air cleaner case and mass air flow sensor assembly. Refer to EM-173

.

2. Remove air cleaner filter from air cleaner case.

Changing Engine OilINFOID:0000000001328914

WARNING:

Be careful not to burn yoursel f, as engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause ski n cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1. Remove front engine undercover with power tool.

2. Warm up engine, put vehicle horizontally and check for engine oil leakage from engine components. Refer

to LU-23, "

Inspection".

3. Stop engine and wait for 15 minutes.

4. Loosen oil filler cap, and then remove drain plug.

5. Drain engine oil.

6. Install drain plug with new washer. Refer to EM-183

.

CAUTION:

Be sure to clean drain plug and install with new washer.

7. Refill with new engine oil. Engine oil specification and viscosity:

Refer to MA-9

.

Engine oil capacity (Approximate):

Unit: (US qt, Imp qt)

CAUTION:

SMA803A

Oil pan drain plug:

: 34.3 N·m (3.5 kg-m, 25 ft-lb)

PBIC0993E

Drain and refill With oil filter change 5.8 (6-1/8, 5-1/8)

Without oil filter change 5.2 (5-1/2, 4-5/8)

Dry engine (engine overhaul) 7.0 (7-3/8, 6-1/8)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C