instrument panel INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 519 of 3924

ATC-114

< SERVICE INFORMATION >

AIR MIX DOOR MOTOR

AIR MIX DOOR MOTOR

Removal and InstallationINFOID:0000000001328214

REMOVAL

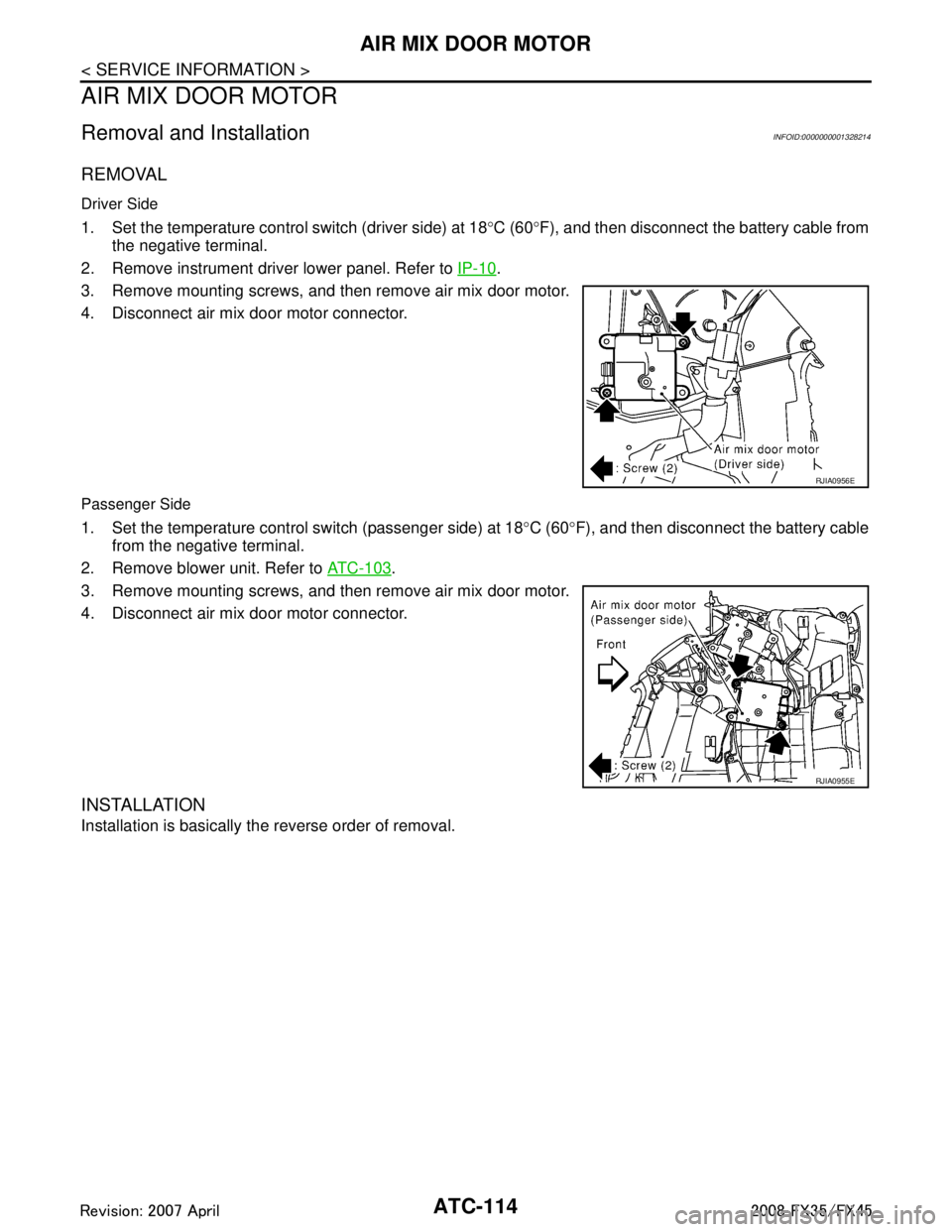

Driver Side

1. Set the temperature control switch (driver side) at 18°C (60 °F), and then disconnect the battery cable from

the negative terminal.

2. Remove instrument driver lower panel. Refer to IP-10

.

3. Remove mounting screws, and then remove air mix door motor.

4. Disconnect air mix door motor connector.

Passenger Side

1. Set the temperature control switch (passenger side) at 18 °C (60 °F), and then disconnect the battery cable

from the negative terminal.

2. Remove blower unit. Refer to ATC-103

.

3. Remove mounting screws, and then remove air mix door motor.

4. Disconnect air mix door motor connector.

INSTALLATION

Installation is basically the reverse order of removal.

RJIA0956E

RJIA0955E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 521 of 3924

ATC-116

< SERVICE INFORMATION >

DUCTS AND GRILLES

DUCTS AND GRILLES

Removal and InstallationINFOID:0000000001328216

COMPONENT LAYOUT

REMOVAL

Removal of Center Ventilator Grilles

1. Remove cluster lid C. Refer to IP-10.

2. Remove mounting screws, and then remove center ventilator grilles.

Removal of Side Ventilation

Remove side ventilation. Refer to IP-10.

Removal of Rear Ventilator Grilles

1. Remove center pillar lower garnish. Refer to IP-10.

1. Defroster nozzle 2. Side defroster duct (left) 3. Side ventilator duct (left)

4. Instrument panel 5. Side ventilation (left) 6. Center ventilator grille (left)

7. Center ventilator grille (right) 8. Side ventilation (right) 9. Center ventilator duct (right)

10. Side ventilator duct (right) 11. Side defroster duct (right) 12. Center ventilator duct

13. Center ventilator duct (left)

PJIA0166E

RJIA2048E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 522 of 3924

DUCTS AND GRILLESATC-117

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

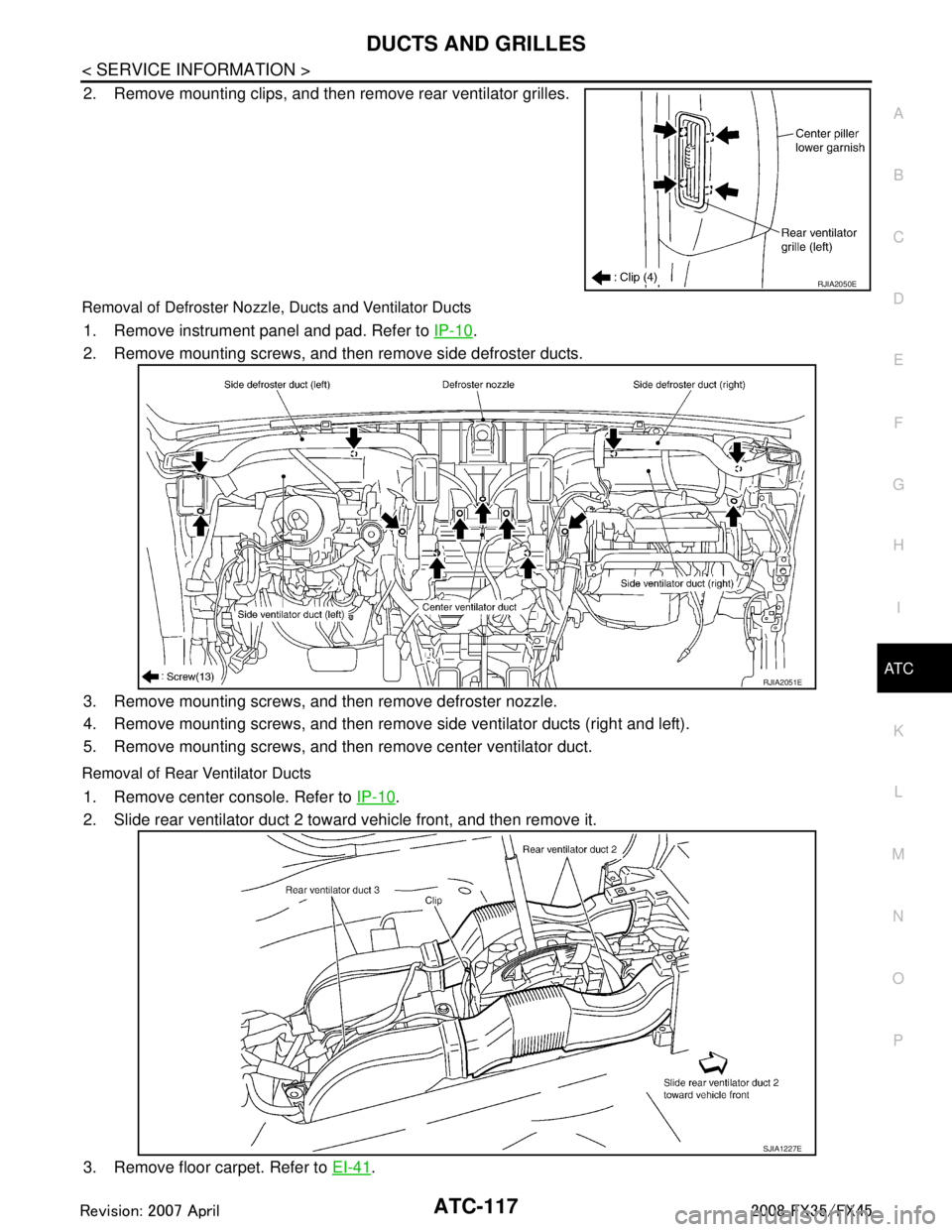

2. Remove mounting clips, and then remove rear ventilator grilles.

Removal of Defroster Nozzle, Ducts and Ventilator Ducts

1. Remove instrument panel and pad. Refer to IP-10.

2. Remove mounting screws, and then remove side defroster ducts.

3. Remove mounting screws, and then remove defroster nozzle.

4. Remove mounting screws, and then remove side ventilator ducts (right and left).

5. Remove mounting screws, and then remove center ventilator duct.

Removal of Rear Ventilator Ducts

1. Remove center console. Refer to IP-10.

2. Slide rear ventilator duct 2 toward vehicle front, and then remove it.

3. Remove floor carpet. Refer to EI-41

.

RJIA2050E

RJIA2051E

SJIA1227E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 523 of 3924

ATC-118

< SERVICE INFORMATION >

DUCTS AND GRILLES

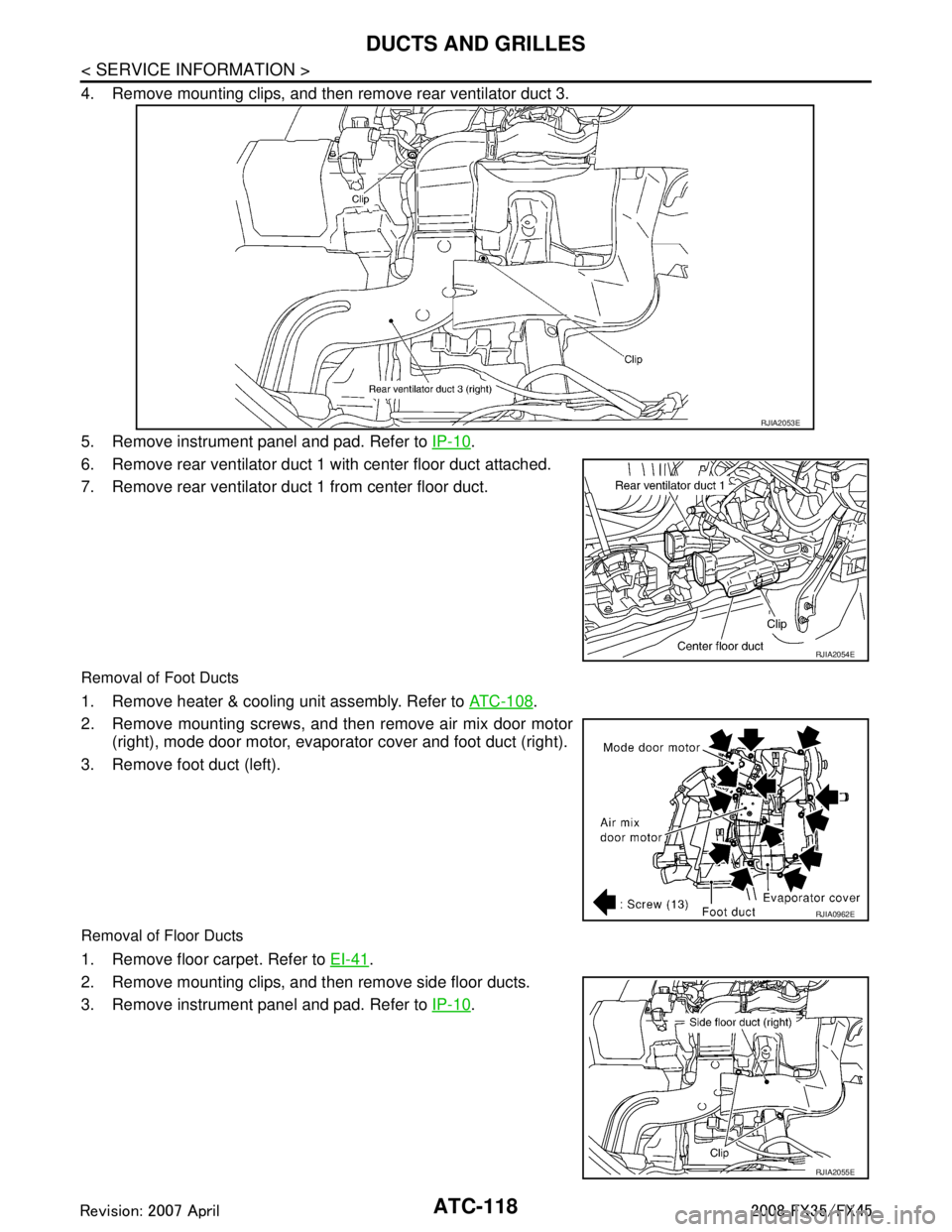

4. Remove mounting clips, and then remove rear ventilator duct 3.

5. Remove instrument panel and pad. Refer to IP-10

.

6. Remove rear ventilator duct 1 with center floor duct attached.

7. Remove rear ventilator duct 1 from center floor duct.

Removal of Foot Ducts

1. Remove heater & cooling unit assembly. Refer to ATC-108.

2. Remove mounting screws, and then remove air mix door motor (right), mode door motor, evaporator cover and foot duct (right).

3. Remove foot duct (left).

Removal of Floor Ducts

1. Remove floor carpet. Refer to EI-41.

2. Remove mounting clips, and then remove side floor ducts.

3. Remove instrument panel and pad. Refer to IP-10

.

RJIA2053E

RJIA2054E

RJIA0962E

RJIA2055E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 588 of 3924

AUDIOAV-41

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

AV

N

O P

3. Check the signal between audio unit harness connector M60 terminal 22 and ground with CONSULT-III or oscilloscope.

OK or NG

OK >> INSPECTION END (System is OK.)

NG >> Replace unified meter and A/C amp.

Locking CD Auto-Changer MechanismINFOID:0000000001328690

CAUTION:

Prior to removing a malfunctioning CD auto-changer unit that will be shipped for repair, the changer mechanism MUST BE LOCKED to prevent the mech anism from being damaged during shipping.

If a CD is jammed or unable to be removed from th e unit, do NOT lock the changer mechanism. If the

unit is to be shipped for repair, carefully package the unit to prevent vibration and shock.

DAMPER LOCK PROCEDURE

1. Eject and remove any CDs from the audio unit.

2. Turn ignition switch OFF. Wait until audio unit display is off and mechanism stops moving (mechanism

sound stops).

3. Press any one of the disc selection buttons once. When a display shows on the audio unit, press the

same disc selection button again within 5 seconds.

The changer mechanism will lock itself within 10 seconds.

4. After mechanism stops moving (mechanism s ound stops), open the driver and passenger window, and

then disconnect negative battery cable.

NOTE:

After installing a new or remanufactured audio unit, switching the audio unit ON will automatically unlock the

mechanism. A special unlocking procedure is not required.

Removal and Installation of Audio UnitINFOID:0000000001328691

REMOVAL

1. Perform damper lock operation. Refer to AV-41, "Locking CD Auto-Changer Mechanism".

2. Remove cluster lid C. Refer to IP-10

.

3. Remove screws (6) with power tool, and remove audio unit with display and unified meter and A/C amp. from instrument panel.

4. Remove screws and remove audio unit.

INSTALLATION

Te r m i n a l Condition Reference

signal

(+) (–)

22 Ground When vehicle speed is ap-

prox. 40 km/h (25 MPH)

SKIA6809E

ELF1080D

SKIA5800E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 590 of 3924

AUDIOAV-43

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

AV

N

O P

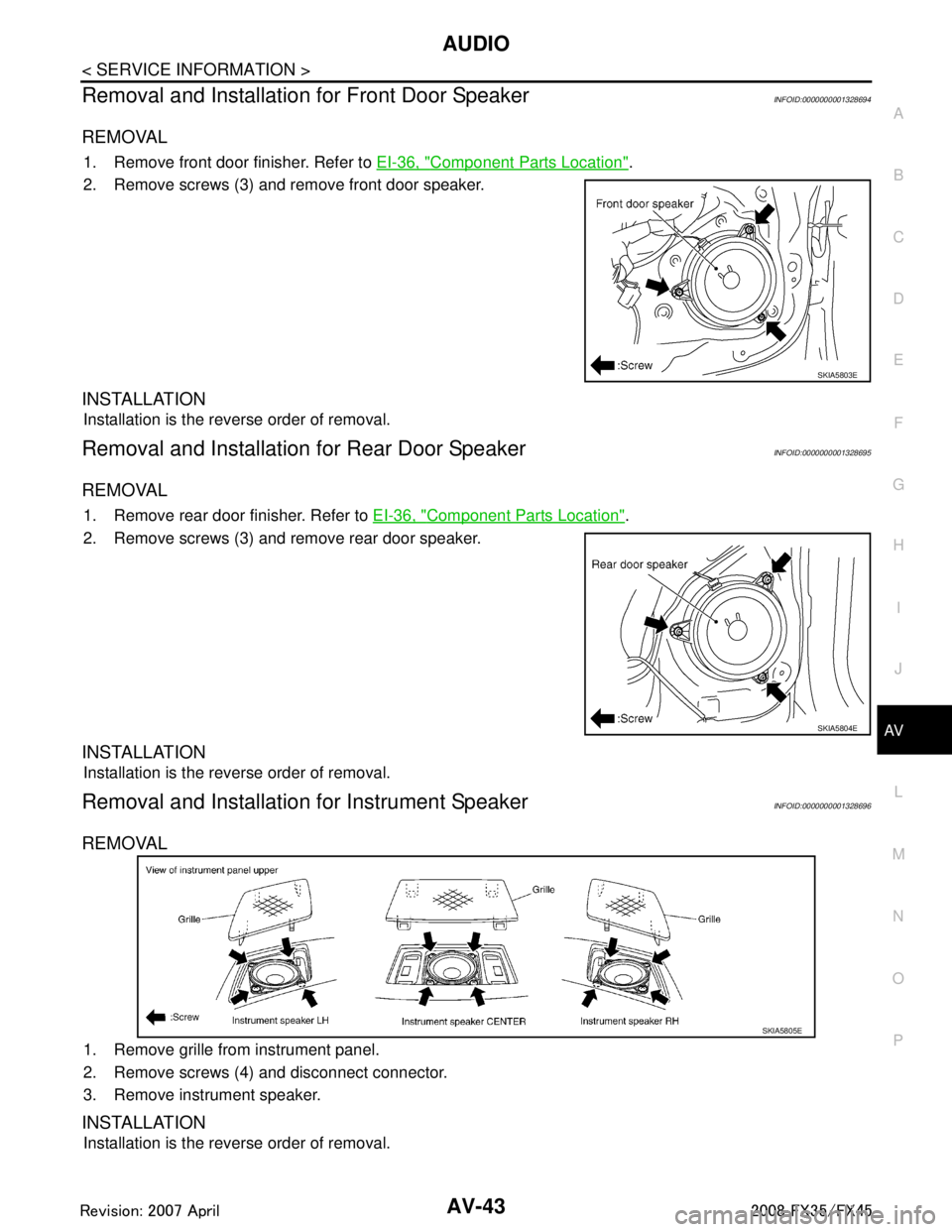

Removal and Installation for Front Door SpeakerINFOID:0000000001328694

REMOVAL

1. Remove front door finisher. Refer to EI-36, "Component Parts Location".

2. Remove screws (3) and remove front door speaker.

INSTALLATION

Installation is the reverse order of removal.

Removal and Installation for Rear Door SpeakerINFOID:0000000001328695

REMOVAL

1. Remove rear door finisher. Refer to EI-36, "Component Parts Location".

2. Remove screws (3) and remove rear door speaker.

INSTALLATION

Installation is the reverse order of removal.

Removal and Installation for Instrument SpeakerINFOID:0000000001328696

REMOVAL

1. Remove grille from instrument panel.

2. Remove screws (4) and disconnect connector.

3. Remove instrument speaker.

INSTALLATION

Installation is the reverse order of removal.

SKIA5803E

SKIA5804E

SKIA5805E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 598 of 3924

ANTENNAAV-51

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

AV

N

O P

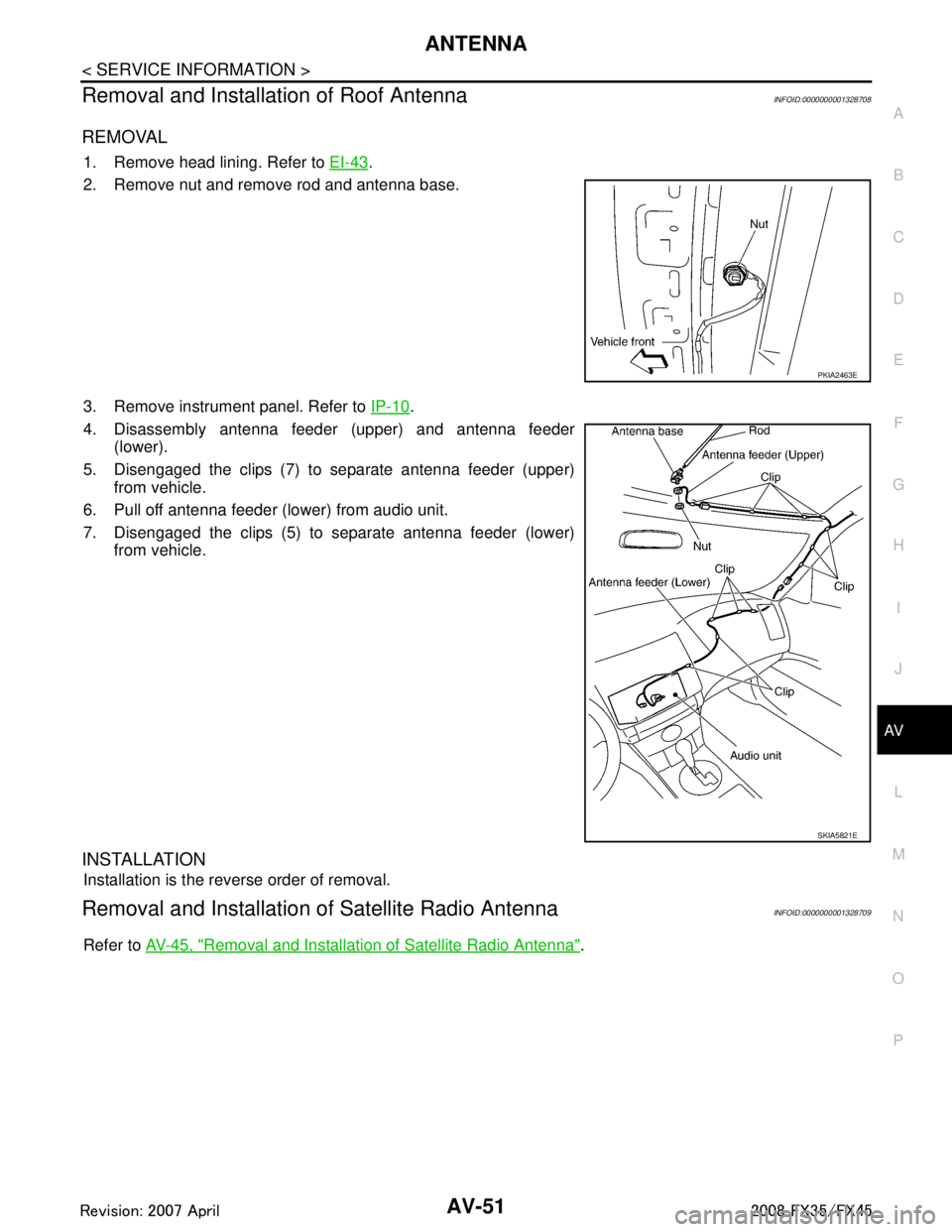

Removal and Installati on of Roof AntennaINFOID:0000000001328708

REMOVAL

1. Remove head lining. Refer to EI-43.

2. Remove nut and remove rod and antenna base.

3. Remove instrument panel. Refer to IP-10

.

4. Disassembly antenna feeder (upper) and antenna feeder (lower).

5. Disengaged the clips (7) to separate antenna feeder (upper) from vehicle.

6. Pull off antenna feeder (lower) from audio unit.

7. Disengaged the clips (5) to separate antenna feeder (lower) from vehicle.

INSTALLATION

Installation is the reverse order of removal.

Removal and Installation of Satellite Radio AntennaINFOID:0000000001328709

Refer to AV-45, "Removal and Installation of Satellite Radio Antenna".

PKIA2463E

SKIA5821E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 633 of 3924

AV-86

< SERVICE INFORMATION >

INTEGRATED DISPLAY SYSTEM

Example of Symptom Poss ible No Malfunction

INFOID:0000000001328735

For system operation informati on, refer to Owner's Manual.

DISPLAY

Removal and Installation of DisplayINFOID:0000000001328736

Refer to AV-42, "Disassembly and Assembly of Audio Unit".

Removal and Installation of Display Control UnitINFOID:0000000001328737

REMOVAL

1. Remove instrument passenger lower panel. Refer to IP-10.

2. Remove screws (A) with power tool and remove display control unit (1).

3. Remove screws (4) with power tool and remove brackets.

INSTALLATION

Installation is the reverse order of removal.

Removal and Installation of A/C and AV SwitchINFOID:0000000001328738

Refer to AV-42, "Removal and Installation for A/C and AV Switch".

Symptom Possible cause Possible solution

No image is displayed. The brightness is at the lowest setting. Adjust the brightness of the display.

The display is turned off.

Press and hold the button to turn on the

display.

The screen is too dim.

The movement is slow. The temperature in the interior of the vehicle is

low. Wait until the interior of the vehicle has warmed

up.

Some pixels in the display are

darker or brighter than others. This condition is an inherent characteristic of liq-

uid crystal displays.

This is not a malfunction.

Some menu items cannot be se-

lected. Some menu items become unavailable while

the vehicle is driven. Park the vehicle in a safe location, then operate

the navigation system.

The screen does not switch to the

night screen even after turning on

the headlights. The daytime screen was set the last time the

headlights were turned on.

Set the screen to the night screen mode using

button when turning on the headlights.

SKIB8667E

SKIA5826E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 719 of 3924

AV-172

< SERVICE INFORMATION >

TELEPHONE

3. Check voltage between TEL adapter unit harness connectorM102 terminal 11 and ground.

OK or NG

OK >> GO TO 4.

NG >> Replace audio unit.

4.CHECK TEL VOICE SIGNAL

1. Check signal between TEL adapter unit harness connector M102 terminals 9 and 10.

OK or NG

OK >> Replace audio unit.

NG >> Replace TEL adapter unit.

Removal and Installation of TEL Adapter UnitINFOID:0000000001328798

REMOVAL

1. Remove instrument passenger lower panel. Refer to IP-10.

2. Remove screws (A) with power tool and remove display control unit (1)and TEL adapter unit (2).

3. Remove TEL adapter unit screws, display control unit screws, and remove brackets.

INSTALLATION

Installation is the reverse order of removal.

Removal and Installation for TEL AntennaINFOID:0000000001328799

REMOVAL

1. Remove TEL adapter unit, display control unit. Refer to AV-172, "Removal and Installation of TEL Adapter

Unit".

11 – Ground : Approx. 5 V

SKIB7352E

9 – 10:

When giving a voice

SKIB7353ESKIB3609E

SKIB8667E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 742 of 3924

BL-8

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle "twist".

5) At idle, apply engine load (electrical load, half- clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will only be eliminated tem-

porarily.

feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

placing a piece of paper between components that you suspect are causing the noise.

looking for loose components and contact marks. Refer to BL-9, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A Nissan Squeak and Rattle Kit (J-43980) is av ailable through your authorized Nissan Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Departm ent for the latest parts information.

The following materials are contained in the Nissan Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 × 135 mm (3.94 × 5.31 in)/76884-71L01: 60 × 85 mm (2.36 × 3.35 in)/76884-71L02: 15 ×

25 mm(0.59 × 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 × 50 mm (1.97 × 1.97 in)/73982-50Y00: 10 mm (0.39 in) thick, 50

× 50 mm (1.97 × 1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 × 50 mm (1.18 × 1.97 in)

FELT CLOTHTAPE

Used to insulate where movement does not occu r. Ideal for instrument panel applications.

68370-4B000: 15 × 25 mm (0.59 × 0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll The following

materials, not found in the kit, can al so be used to repair squeaks and rattles.

UHMW(TEFLON) TAPE

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C