instrument panel INFINITI FX35 2008 Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 743 of 3924

SQUEAK AND RATTLE TROUBLE DIAGNOSISBL-9

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000001327781

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the Nissan Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 749 of 3924

HOODBL-15

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

1. Support the hood striker with a proper material to prevent it from falling.

WARNING:

Body injury may occur if no supporting rod is holding the

hood open when removi ng the hood stay.

2. Remove the hood stays from the stud balls on the body side.

3. Remove the hinge mounting nuts on the hood to remove the hood assembly.

CAUTION:

Operate with two workers, because of its heavy weight.

INSTALLATION

Install in the reverse order of removal.

Removal and Installation of Hood Lock ControlINFOID:0000000001327785

REMOVAL

1. Remove the front grill. Refer to EI-22, "Component Parts Location".

2. Remove the front fender protector (LH). Refer to EI-24, "

Component Parts Location".

3. Disconnect the hood lock cable from the hood lock, and c lip it from the radiator core support upper and

hood ledge.

4. Remove instrument driver lower panel. Refer to IP-11, "

Removal and Installation".

5. After the bolt of the case with the air cleaner is disconnected, and it is moved, the cable is pulled.

PIIA6058E

1. Hood lock 2. Hood lock cable 3. Clip

4. Hood ledge upper front (LH) 5. Dash lower cross member reinforce (LH)

PIIA6017E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 809 of 3924

REMOTE KEYLESS ENTRY SYSTEMBL-75

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

When registering an additional key fob, the existing ID c odes in memory may or may not be erased. If five ID

codes are stored in memory, when an additional code is registered, only the oldest code is erased. If less

than five ID codes are stored in memory, when an additional ID code is registered, the new ID code is added

and no ID codes are erased.

If you need to activate more than two additional new key fobs, repeat the procedure “Additional ID code entry” for each new key fob.

Entry of maximum five ID codes is allowed. When mo re than five ID codes are entered, the oldest ID code

will be erased.

Even if same ID code that is already in the memory is input, the same ID code can be entered. The code is

counted as an additional code.

Removal and Installation of Re mote keyless Entry receiverINFOID:0000000001327834

REMOVAL

1. Remove the instrument passenger lower panel. Refer to IP-16, "Disassembly and Assembly".

2. Disconnect remote keyless entry receiver harness connector, remove screw and remote keyless entry receiver.

INSTALLATION

Install in the reverse order of removal.

Key Fob Battery ReplacementINFOID:0000000001327835

PIIB4073E

PIIA4706E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 813 of 3924

INTELLIGENT KEY SYSTEMBL-79

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Unlock mode can be changed using “WORK SUPPORT ” mode in “SELECTIVE UNLOCK FUNCTION”.

Refer to BL-104, "

CONSULT-III Application Item".

Passenger side door request switch operation

When door request switch (passenger side) is pushed (unlock), passenger side door lock actuator is

unlocked.

When door request switch (passenger side) is pushed (unlock) for the second time with in 5 seconds after

the first operation, door lock actuators on driver's and other's doors are unlocked.

Unlock mode can be changed using “WORK SUPPORT ” mode in “SELECTIVE UNLOCK FUNCTION”.

Refer to BL-104, "

CONSULT-III Application Item".

Back door request switch operation

When back door request switch is pushed (unlo ck), back door lock actuator is unlocked.

When back door request switch is pushed (unlock) for the second time with in 5 seconds after the first oper-

ation, door lock actuators on driver's and passenger's doors are unlocked.

Unlock mode can be changed using “WORK SUPPORT ” mode in “SELECTIVE UNLOCK FUNCTION”.

Refer to BL-104, "

CONSULT-III Application Item".

Operation Condition

Auto Door Lock Function

After the door request switch in the driver or pa ssenger or back door is operated and the vehicle door is

unlocked, all the doors are automatica lly locked unless the mechanical key is inserted into the ignition knob,

the ignition knob is pressed, any door request switch is pressed, any one of the doors is opened, or an Intelli-

gent Key remote control button is operated within 30 seconds.

Key Reminder Function

The hazard lamps will flash and the Intelligent Key warning buzzer will sound several times when the door lock

is locked or unlocked by door request switch operation.

When ignition switch ON or any door is opened, key reminder function is not operate.

Intelligent Key Lock-in Prevention Function

When doors are locked using door lock and unlock switch or driver door lock knob while Intelligent key is in

vehicle and doors open, Intelligent Key unit sends door unlock request signal to BCM via CAN communication

to unlock all doors to prevent Intelligent Key from becoming locked in vehicle.

CAUTION:

The above function operates when the Intelligent Key is inside the vehicle. However, there are cases

that Intelligent Key cannot be detect ed and this function will not operate when Intelligent Key is on the

instrument panel, rear parcel shelf, or in the gl ove box. Also, this system sometimes does not operate

if the Intelligent Key is in th e door pocket for the open door.

REMOTE CONTROL ENTRY FUNCTIONS

Door Lock Function

Operating a remote controller button on the Intelligent Ke y sends the Intelligent Key-ID to the Intelligent Key

unit. Intelligent Key unit conducts a verification of the received key-ID, and if the verification is accepted, a

door lock or door unlock request signal is sent to BCM via CAN communication to lock/unlock the door.

When door lock/unlock is performed using Intelligent Ke y remote controller button operation, operation con-

firmation is conducted by making hazard lamps flash and Intelligent Key warning buzzer sound.

OPERATION CONDITION

Door lock/unlock operation is necessary for all doors close.

Map Lamp And Keyhole Illumination Function

When the following conditions come:

condition of map lamp switch is DOOR position;

Request switch operation Operating conditions (When all the conditions below are met)

Door request switch (Driver side) Closing all doors (door switch: OFF)

The Intelligent Key is in the antenna detection area for the door for which the door re-

quest switch (LOCK) was operated.

Door request switch (passenger side)

Door request switch (back door)

Vehicle operation Hazard lamp Intelligent Key warning buzzer

Door unlock operation Once Once

Door lock operation Twice Twice

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 814 of 3924

BL-80

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

door switch OFF (when all the doors are closed);

Remote control button of Intelligent Key turns on interior lamp (for 30 seconds) with input of UNLOCK signal

from Intelligent Key.

Panic Alarm Function

When key switch is OFF and ignition knob is not pushed (when mechanical key is not inserted in ignition

knob), BCM turns ON and OFF horn and headlamp intermit tently with input of PANIC ALARM signal from

Intelligent Key. The alarm automatically turns off after 25 seconds or when Intelligent Key unit receives any

signal from Intelligent Key.

Panic alarm operation mode can be changed using “WORK SUPPORT” mode in “PANIC ALARM DELAY”.

Refer to BL-104, "

CONSULT-III Application Item".

Remote Control Power Window Down (Open) Operation

When Intelligent Key unlock switch is turned ON with i gnition switch OFF, and Intelligent Key unlock switch is

detected to be on continuously for 3 seconds, the driver's door and passenger's door power windows are

simultaneously opened.

Power window is operated to open and the operation continues as long as the Intelligent Key unlock switch is

pressed.

Remote control power window down operation mode can be changed using “P/W DOWN DELAY” mode in

“WORK SUPPORT”. Refer to BL-104, "

CONSULT-III Application Item".

Key Reminder Function

As an operation verification function, when doors are lock ed or unlocked using Intelligent Key remote control-

ler button operation, hazard lamps flash and horn sounds.

ENGINE STARTUP FUNCTION

Operation Description

When ignition knob is pressed, Intelligent Key unit sends request signal from inside key antenna, key-ID ver- ification is conducted with Intelligent Key using two-wa y communication, and if verification is successful, an

ignition rotation prohibition latch release signal is sent to steering lock unit. Steering lock unit releases igni-

tion knob rotation prohibition latch. (Ignition knob can now be turned.)

When it becomes possible to rotate the ignition knob, “KEY” warning lamp in combination meter lights up green to notify driver that ignition knob can be turned.

NOTE:

When it becomes impossible to rotate the ignition knob, “KEY” warning lamp in combination meter lights up

red.

When key-ID verification is successful and ignition knob switch is in the ON state, Intelligent Key unit uses CAN communication to send engine start permission signal to BCM.

When BCM receives engine start permission signal, it uses CAN communication to sent starter request sig-

nal to IPDM E/R so that the engine will start when ignition knob is rotated to START position.

Operation Range

Engine can be started when Intelligent Key is in the v ehicle. However, sometimes engine might not start when

Intelligent Key is on instrument panel, rear parcel shelf, or in glove box.

NOTE:

luggage room can enable detection of Intelligent Key by a CONSULT-III function. Refer to BL-104, "

CON-

SULT-III Application Item".

Active Check Function

Confirm whether or not ignition knob can be rotated by checking the color of warning lamp in combination

meter.

WARNING AND ALARM FUNCTION

Vehicle operation Hazard lamp Horn

Door unlocking operation Once —

Door locking operation Twice Once

Condition Operation

Ignition knob rotation possib le “KEY” warning lamp in combin ation meter is lit up green.

Ignition rotation not possibl e “KEY” warning lamp in combin ation meter is lit up red.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 817 of 3924

INTELLIGENT KEY SYSTEMBL-83

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Intelligent Key remote controller button and door reques t switch operations change the engine startup function

settings (startup enabled/disabled) for each Intelligent Key independently.

Settings Change Procedure1. With the ignition switch is in the LOCK positi on (ignition knob not pressed), hold down both the LOCK and

UNLOCK remote control buttons on the Intelligent Key at the same time for at least 10 seconds (The yard-

stick is that the Intelligent Key LED flashes 20 times.)

2. Within 5 seconds of releasing the Intelligent Key remote controller buttons, press the driver door request

switch.

3. The KEY warning lamp in combination meter lights up for 3 seconds (engine starting enabled → starting

disabled: lights up red, engine starting disabled → flashes green). This completes the settings change.

Changing Settings Using CONSULT-III

The settings for the Intelligent Key system func tions can be changed using CONSULT-III (WORK SUPPORT).

Refer to BL-104, "

CONSULT-III Application Item".

NOTE:

Once a function setting is changed, it will remain effective even if the battery is disconnected.

Changing Settings Using Display Unit

The settings of the Intelligent Key system can be changed, using CONSULT-III, display unit, Intelligent Key

and door request switch in the cent er of the instrument panel.

NOTE:

Once a function setting is changed, it will remain effective even if the battery is disconnected.

INTELLIGENT KEY REGISTRATION

Intelligent Key-ID registration is executed using the CONSULT-III. Up to 4 can be registered.

CAUTION:

After a new Intelligent Key-ID is regi stered, be sure to check the function.

When registering an additional Intelligent Key-ID , take any Intelligent Keys already registered and

Intelligent Keys for any other vehicles out of the vehicle before starting.

CONSULT-III can be used to check and delete Intelligent Key-IDs.

For future information, see the CO NSULT-III Operation Manual NATS.

STEERING LOCK UNIT REGISTRATION

Steering Lock Unit ID Registration

CAUTION:

The method for registering a steering lock unit ID depends on the status of the steering lock unit and

Intelligent Key unit (new or old unit).

After registration is completed, press ignition knob with a portable unit in the vehicle so that it can

be rotated, and confirm that it cannot be rotated even when ignition switch is pressed without a por-

table unit in the vehicle.

For further information, see the CONS ULT-III Operation Manual NATS.

CAN Communication System DescriptionINFOID:0000000001327838

CAN (Controller Area Network) is a serial communication li ne for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

Setting item Description

Intelligent Key Lock Response-Sound The sound pattern of the Intelligent Key operation can be set as desired. (Setting value:

OFF, Beeper or Horn chirp)

Intelligent Key Unlock Response-Beep

Sound The beep sound when unlocking door with the Intelligent Key operation can be turned ON

or OFF.

Intelligent Key Engine Start Function This function can be performed to ON or OFF.

Intelligent Key Lock/Unlock Function The door handle request switch lock/unlock operation with the Intelligent Key can be can-

celed or activated.

Return All Settings to Default The all settings made by VEHICLE ELECTRONICS will return to default.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 864 of 3924

BL-130

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

Removal and Installation of Intelligent Key Unit

INFOID:0000000001327871

REMOVAL

1. Remove the instrument lower driver panel. Refer to IP-11, "Removal and Installation".

2. Disconnect the Intelligent Key unit connector, remove the screw and Intelligent Key unit.

INSTALLATION

Install in the reverse order of removal.

Intelligent Key Battery ReplacementINFOID:0000000001327872

INTELLIGENT KEY BATTERY INSPECTION

Check by connecting a resistance (approximately 300 Ω) so that the

current value becomes about 10 mA.

PIIA6371E

PIIB4646E

Standard : Approx. 2.5V - 3.0V

OCC0607D

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 990 of 3924

BR-6

< SERVICE INFORMATION >

BRAKE PEDAL

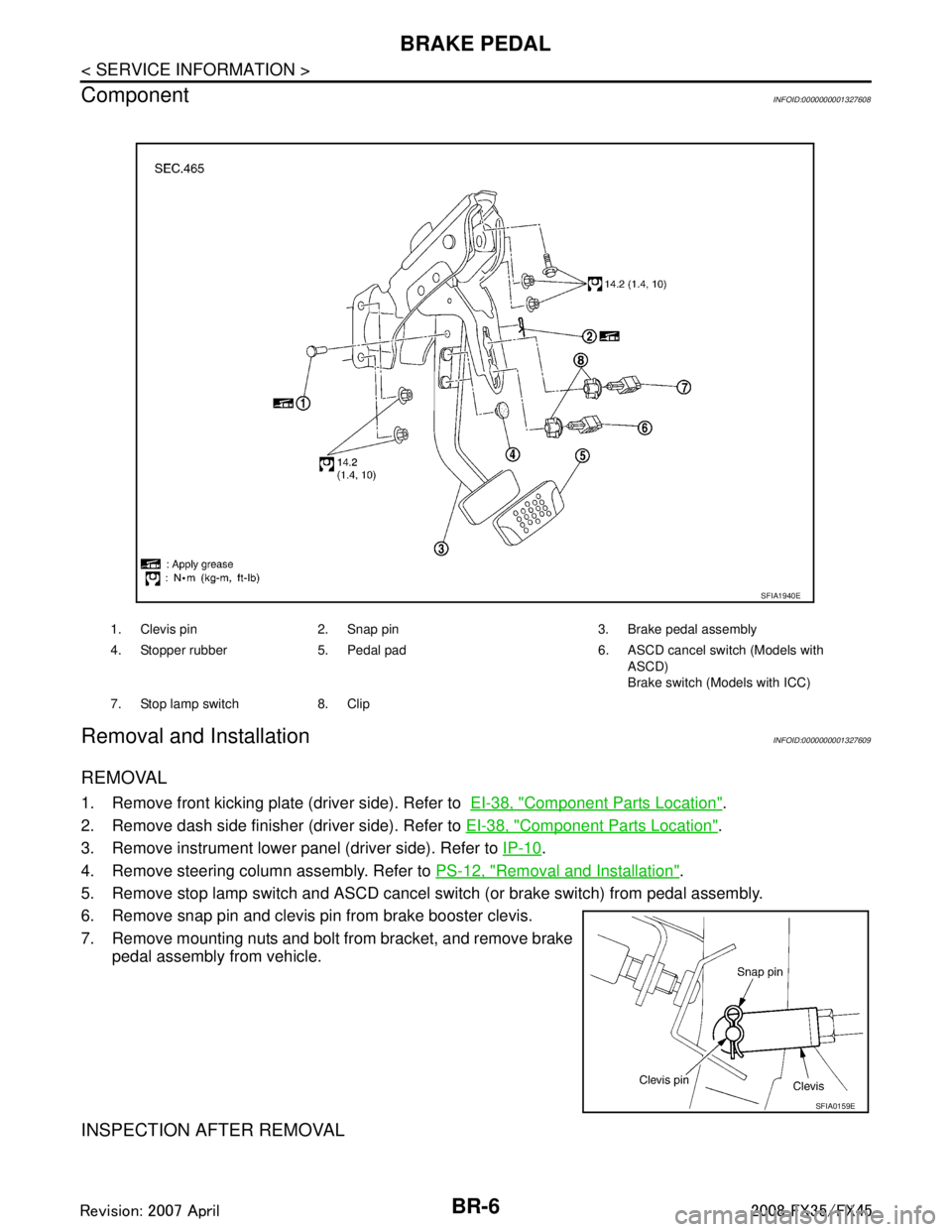

Component

INFOID:0000000001327608

Removal and InstallationINFOID:0000000001327609

REMOVAL

1. Remove front kicking plate (driver side). Refer to EI-38, "Component Parts Location".

2. Remove dash side finisher (driver side). Refer to EI-38, "

Component Parts Location".

3. Remove instrument lower panel (driver side). Refer to IP-10

.

4. Remove steering column assembly. Refer to PS-12, "

Removal and Installation".

5. Remove stop lamp switch and ASCD cancel s witch (or brake switch) from pedal assembly.

6. Remove snap pin and clevis pin from brake booster clevis.

7. Remove mounting nuts and bolt from bracket, and remove brake pedal assembly from vehicle.

INSPECTION AFTER REMOVAL

1. Clevis pin 2. Snap pin 3. Brake pedal assembly

4. Stopper rubber 5. Pedal pad 6. ASCD cancel switch (Models with

ASCD)

Brake switch (Models with ICC)

7. Stop lamp switch 8. Clip

SFIA1940E

SFIA0159E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1195 of 3924

LANE DEPARTURE WARNING SYSTEMDI-69

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

LANE DEPARTURE WARNING SYSTEM

Precaution for Lane Depa rture Warning (LDW) systemINFOID:0000000001328492

WARNING:

Lane Departure Warning (LDW) is only a warning d evice to inform the driver of an unintended lane

departure. It will not steer the vehicle or prevent loss of control. It is the driver's responsibility to stay

alert, drive safely, keep the vehicle in the traveling lane, and be in control of the vehicle at all times.

LDW system does not operate u nder the following conditions:

- At speeds below approx. 72 km/h (45 MPH).

- If it cannot detect lane markers.

LDW system may not function proper ly under the following conditions:

- On roads where a water puddle, dirt or snow is covering the lane markers.

- On roads where the lane markers are faded or are not painted clearly.

- On roads where the lane markers are painted yellow.

LDW system may not monitor the lane markers in certain road, weather or driving conditions.

- On roads where there are sharp curves.

- Where the traveling lane merges or separates.

- On roads where the discontinued lane marker s are present, such as near tollgates, etc.

- On roads where there are not general lane markers.

- On roads where the lane width is too narrow.

- During bad weather (rain, fog, snow, etc.).

- When strong light (for example, at sunrise or sunse t) is directly shining on the front of the vehicle.

- When entering or exiting a tunnel wher e sudden changes in brightness occur.

- When traveling close to the vehicle in front of you, which causes obstruction of the camera unit

range.

- When the vehicle's traveling direction does not align with the lane marker.

- When rain, snow or dirt adhere to the windshield in front of the camera unit.

Excessive noise interferes with warning system ch ime sound and the chime may not be heard.

CAUTION:

To keep the LDW system operating proper ly, be sure to observe the following:

Always keep the windshield clean. The sensing capability of the camera unit depends on the condi-

tion of the windshield. See “Appearan ce and care” for cleaning instruction.

Never strike or damage the areas around the camera unit.

Never touch the camera lens.

Never attach a sticker (including transparent mate rial) or install an accessory near the camera unit.

Never place reflective materials, such as a white pape r or mirrors on the instrument panel. Reflection

of the sunlight may adversely affect the camera unit's lane marker detection capability.

System DescriptionINFOID:0000000001328493

LDW SYSTEM OPERATION

The Lane Departure Warning (LDW) system warns the driver when the vehicle is traveling close to either the

left or the right of the traveling lane.

The system monitors lane markers of the traveling lane using the LDW camera unit. When the LDW camera

unit detects that the vehicle is traveli ng close to either the left or the right of the traveling lane, the LDW indi-

cator lamp flashes and a chime sounds to alert the driver.

NOTE:

When activating turn signal, LDW system does not give a warning to the lane marker on the turn signal side.

The LDW system can be turned on or off by pushing t he LDW switch. When the system is on, the LDW sys-

tem ON indicator illuminates.

The LDW system has an automatic mode and manual mode.

In the automatic mode

- LDW system automatically turns on, when the i gnition switch is turned to the ON position.

- LDW system ON indicator located on the LDW swit ch illuminates, indicating that the system is on.

- To cancel LDW system, push the LDW switch to turn off LDW system ON indicator.

- To turn on the system, push LDW switch again.

In the manual mode- LDW system is still off when the igniti on switch is turned to the ON position.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1197 of 3924

LANE DEPARTURE WARNING SYSTEMDI-71

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

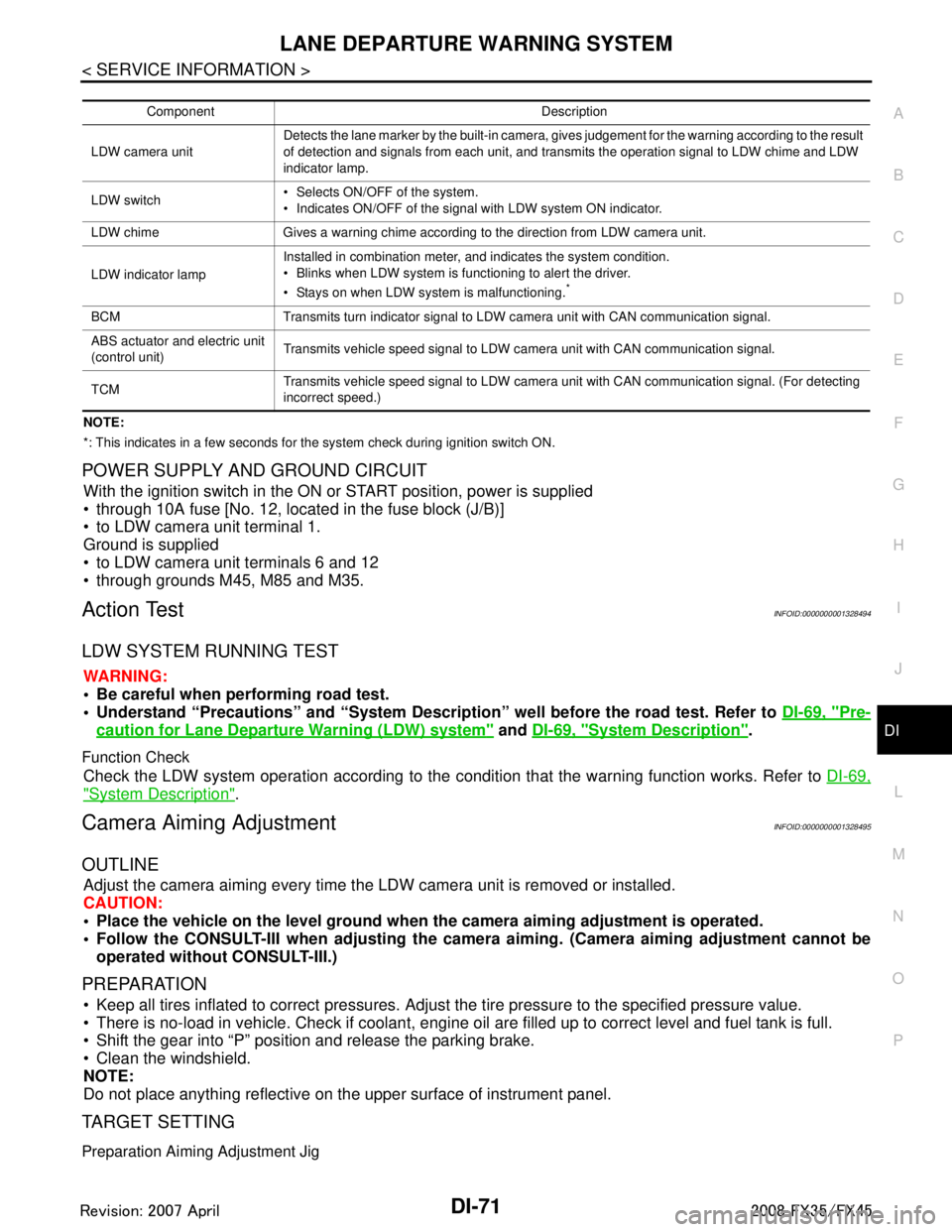

NOTE:

*: This indicates in a few seconds for the system check during ignition switch ON.

POWER SUPPLY AND GROUND CIRCUIT

With the ignition switch in the ON or START position, power is supplied

through 10A fuse [No. 12, located in the fuse block (J/B)]

to LDW camera unit terminal 1.

Ground is supplied

to LDW camera unit terminals 6 and 12

through grounds M45, M85 and M35.

Action TestINFOID:0000000001328494

LDW SYSTEM RUNNING TEST

WARNING:

Be careful when performing road test.

Understand “Precautions” and “System Description” well before the road test. Refer to DI-69, "

Pre-

caution for Lane Departure Warning (LDW) system" and DI-69, "System Description".

Function Check

Check the LDW system operation according to the c ondition that the warning function works. Refer to DI-69,

"System Description".

Camera Aiming AdjustmentINFOID:0000000001328495

OUTLINE

Adjust the camera aiming every time the LDW camera unit is removed or installed.

CAUTION:

Place the vehicle on the level ground when the camera aiming adjustment is operated.

Follow the CONSULT-III when ad justing the camera aiming. (Camera aiming adjustment cannot be

operated without CONSULT-III.)

PREPARATION

Keep all tires inflated to correct pressures. Adjust the tire pressure to the specified pressure value.

There is no-load in vehicle. Check if coolant, engine oil are filled up to correct level and fuel tank is full.

Shift the gear into “P” position and release the parking brake.

Clean the windshield.

NOTE:

Do not place anything reflective on t he upper surface of instrument panel.

TARGET SETTING

Preparation Aiming Adjustment Jig

Component Description

LDW camera unit Detects the lane marker by the built-in camera, gives judgement for the warning according to the result

of detection and signals from each unit, and transmits the operation signal to LDW chime and LDW

indicator lamp.

LDW switch Selects ON/OFF of the system.

Indicates ON/OFF of the signal with LDW system ON indicator.

LDW chime Gives a warning chime according to the direction from LDW camera unit.

LDW indicator lamp Installed in combination meter, and indicates the system condition.

Blinks when LDW system is functioning to alert the driver.

Stays on when LDW system is malfunctioning.

*

BCM Transmits turn indicator signal to LDW camera unit with CAN communication signal.

ABS actuator and electric unit

(control unit)

Transmits vehicle speed signal to LDW camera unit with CAN communication signal.

TCM Transmits vehicle speed signal to LDW camera unit with CAN communication signal. (For detecting

incorrect speed.)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C