service interval INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3324 of 3924

PERIODIC MAINTENANCEMA-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

NOTE:

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) fl uid (A/T, trans-

fer)/oil at every 30,000 miles (48,000 km) or 24 months. Using automatic transmission fluid other than Genuine Nissan Matic J

ATF will cause deterioration in driveability and automatic transmission durability, and may damage the automatic transmis-

sion, which is not covered by the INFINITI new vehicle limited warranty.

(2) Refer to “Tire rotation” under the “GENERAL MAINTENANCE” heading earlier in this section.

Schedule 2INFOID:0000000001328896

EMISSION COMTROL SYSTEM MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or r eplace if necessary. [ ]: At the mileage intervals only

Drive shaft boots and pro-

peller shaft (AWD models) IIII

MA-34,

MA-29

Exhaust system IIII MA-26

In-cabin microfilter

RRAT C - 1 0 7

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section -

Page or - Con- tent Title

Perform at number of miles,

kilometers or months,

whichever comes first. Miles x 1,000

(km x 1,000)

Months 3.75

(6)

3 7.50

(12)

6 11 . 2 5

(18)

9 15

(24)

12 18.75

(30)

15 22.5

(36)

18 26.25

(42)

21 30

(48)

24

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section - Page

or - Content Title

Perform at number of miles,

kilometers or months,

whichever comes first. Miles x 1,000

(km x 1,000) Months 33.75

(54)27 37.5

(60) 30 41.25

(66)33 45

(72) 36 48.75

(78)39 52.5

(84) 42 56.25

(90)45 60

(96) 48

Brake lines & cables IIMA-32

Brake pads & rotors

IIII MA-32

Automatic transmission &

transfer fluid & differential

gear oilNOTE (1) I I

MA-26,

MA-28

,

MA-29

Steering gear, linkage &

transfer gear, axle & sus-

pension parts IIII

MA-33

, MA-34

Tire rotation NOTE (2) MA-3,

MA-31

Drive shaft boots and pro-

peller shaft (AWD models) IIII MA-34,

MA-29

Exhaust system IIII MA-26

In-cabin microfilter

RRAT C - 1 0 7

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Sec-

tion - Page or - Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000) Months 7.5

(12) 6 15

(24) 12 22.5

(36) 18 30

(48) 24 37.5

(60) 30 45

(72) 36 52.5

(84) 42 60

(96) 48

Drive belts NOTE (1) I* MA-11

, MA-19

Air cleaner filter [R] [R] MA-15, MA-22

EVAP vapor lines I* I* MA-18, MA-25

Fuel lines I* I* MA-15, MA-22

Fuel filter NOTE (2) -

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3325 of 3924

MA-8

< SERVICE INFORMATION >

PERIODIC MAINTENANCE

NOTE:

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts if found

damaged or if the auto belt tensioner reading (only for VK45DE engine) reaches the maximum limit.

(2) Maintenance-free item. For service procedures, refer to FL section.

(3) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(4) If valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by INFINITI for reliable vehicle operation. The owner need not perfo rm

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required

CHASSIS AND BODY MAINTENANCE

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary.

NOTE:

(1) Using automatic transmission fluid other than Genuine NISSAN Matic J ATF will cause deterioration in driveability and

automatic transmission durability, and may damage the automatic transmission, which is not covered by the INFINITI new

vehicle limited warranty.

(2) Refer to “Tire rotation” under the “GENERAL MAINTENANCE” heading earlier in this section.

Engine coolant NOTE (3) R*

MA-12

, MA-19

Engine oil R R R R R R R R MA-15, MA-22

Engine oil filter (Use genuine

NISSAN engine oil filter or equiv-

alent.) RRRR R RRR

MA-16

, MA-23

Spark plugs (PLATINUM-

TIPPED type) Replace every 105,000 miles (169,000 km).

MA-17, MA-24

Intake & exhaust valve clear-

ance* NOTE (4)

EM-91, EM-218

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Sec-

tion - Page or -

Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000)

Months 7.5

(12)

6 15

(24)

12 22.5

(36)

18 30

(48)

24 37.5

(60)

30 45

(72)

36 52.5

(84)

42 60

(96)

48

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Sec-

tion - Page or - Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000) Months 7.5

(12) 6 15

(24) 12 22.5

(36) 18 30

(48) 24 37.5

(60) 30 45

(72) 36 52.5

(84) 42 60

(96) 48

Brake lines & cables IIIIMA-32

Brake pads & rotors

IIIIMA-32

Automatic transmission & trans-

fer fluid & differential gear oilNOTE (1) IIII MA-26,

MA-28,

MA-29

Steering gear, linkage & transfer

gear, axle & suspension parts I I MA-33,

MA-34

Tire rotation NOTE (2) MA-3,

MA-31

Drive shaft boots and propeller

shaft (AWD models) IIII

MA-34, MA-29

Exhaust system

IIMA-26

In-cabin microfilter

RRRRAT C - 1 0 7

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3332 of 3924

ENGINE MAINTENANCE (VQ35DE ENGINE)MA-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

4. Run the engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop the engine and wait until it cools down.

7. Drain water from the system. Refer to CO-10, "

Changing Engine Coolant".

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

Checking Fuel LineINFOID:0000000001328903

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections , chafing or deterioration.

If necessary, repair or replace damaged parts.

Changing Air Cleaner FilterINFOID:0000000001328904

VISCOUS PAPER TYPE

The viscous paper type filter does not need cleaning between

replacement intervals. Refer to MA-5

.

Changing Engine OilINFOID:0000000001328905

WARNING:

Be careful not to burn yoursel f, as engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thorough ly with soap or hand cleaner as

soon as possible.

1. Remove front engine undercover with power tool.

2. Warm up the engine, and check for engine oil leakage from engine components. Refer to LU-5, "

Inspec-

tion".

3. Stop the engine and wait for 10 minutes.

4. Loosen oil filler cap and then remove drain plug.

5. Drain engine oil.

6. Install drain plug with new washer. Refer to EM-30

.

CAUTION:

Be sure to clean drain plug and install with new washer.

7. Refill with new engine oil. Engine oil specificat ion and viscosity:

Refer to MA-9

.

SMA803A

SBIA0463E

Oil pan drain plug:

: 34.3 N·m (3.5 kg-m, 25 ft-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3335 of 3924

MA-18

< SERVICE INFORMATION >

ENGINE MAINTENANCE (VQ35DE ENGINE)

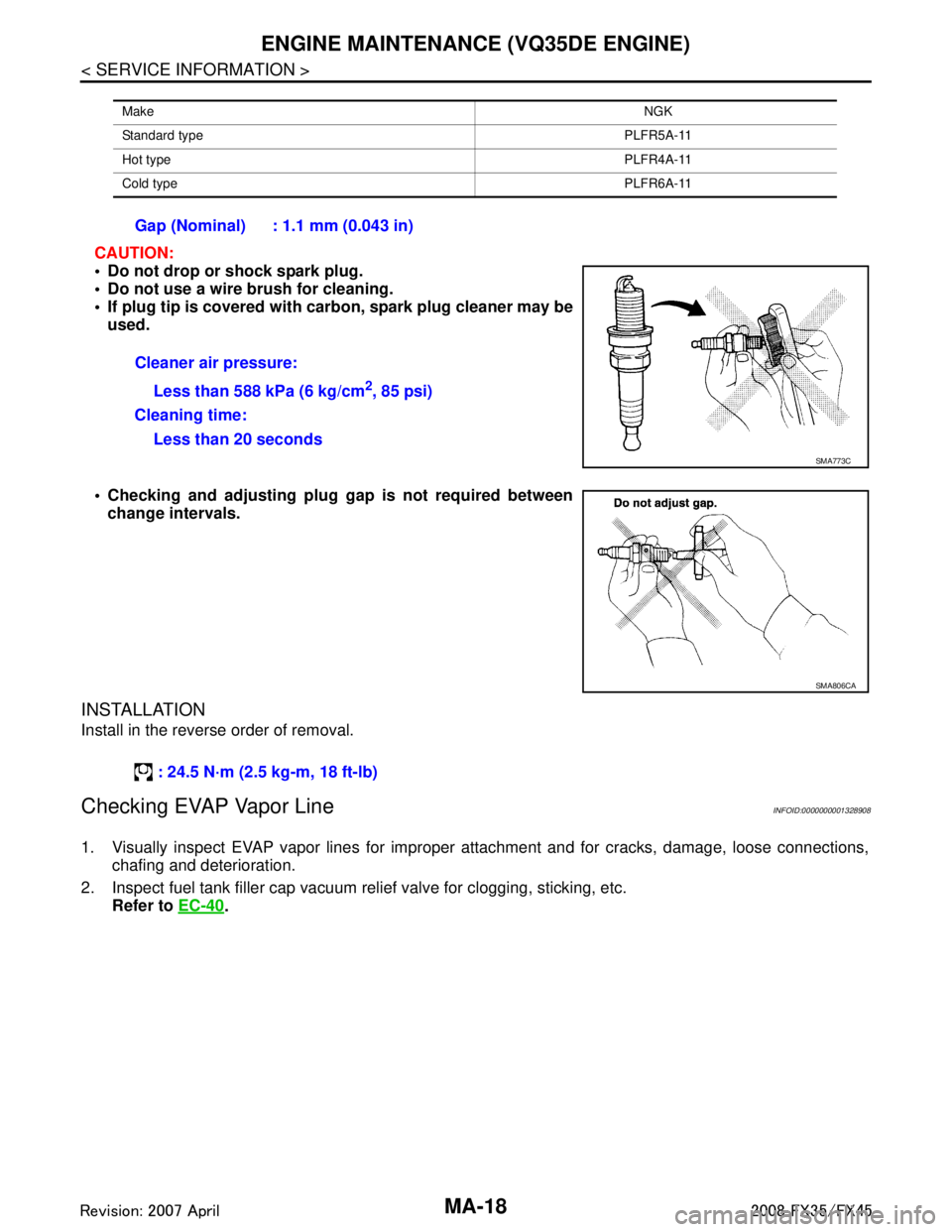

CAUTION:

Do not drop or shock spark plug.

Do not use a wire brush for cleaning.

If plug tip is covered with carbon, spark plug cleaner may be

used.

Checking and adjusting plug gap is not required between

change intervals.

INSTALLATION

Install in the reverse order of removal.

Checking EVAP Vapor LineINFOID:0000000001328908

1. Visually inspect EVAP vapor lines for improper attachment and for cracks, damage, loose connections,

chafing and deterioration.

2. Inspect fuel tank filler cap vacuum relief valve for clogging, sticking, etc.

Refer to EC-40

.

Make NGK

Standard type PLFR5A-11

Hot type PLFR4A-11

Cold type PLFR6A-11

Gap (Nominal) : 1.1 mm (0.043 in)

Cleaner air pressure:

Less than 588 kPa (6 kg/cm

2, 85 psi)

Cleaning time: Less than 20 seconds

SMA773C

SMA806CA

: 24.5 N·m (2.5 kg-m, 18 ft-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3339 of 3924

MA-22

< SERVICE INFORMATION >

ENGINE MAINTENANCE (VK45DE ENGINE)

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the system. Refer to "DRAINING ENGINE COOLANT".

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

Checking Fuel LineINFOID:0000000001328912

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

Changing Air Cleaner FilterINFOID:0000000001328913

VISCOUS PAPER TYPE

The viscous paper type filter does not need cleaning between replacement intervals. Refer to MA-5.

1. Remove air duct (inlet), air cleaner case and mass air flow sensor assembly. Refer to EM-173

.

2. Remove air cleaner filter from air cleaner case.

Changing Engine OilINFOID:0000000001328914

WARNING:

Be careful not to burn yoursel f, as engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause ski n cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1. Remove front engine undercover with power tool.

2. Warm up engine, put vehicle horizontally and check for engine oil leakage from engine components. Refer

to LU-23, "

Inspection".

3. Stop engine and wait for 15 minutes.

4. Loosen oil filler cap, and then remove drain plug.

5. Drain engine oil.

6. Install drain plug with new washer. Refer to EM-183

.

CAUTION:

Be sure to clean drain plug and install with new washer.

7. Refill with new engine oil. Engine oil specification and viscosity:

Refer to MA-9

.

Engine oil capacity (Approximate):

Unit: (US qt, Imp qt)

CAUTION:

SMA803A

Oil pan drain plug:

: 34.3 N·m (3.5 kg-m, 25 ft-lb)

PBIC0993E

Drain and refill With oil filter change 5.8 (6-1/8, 5-1/8)

Without oil filter change 5.2 (5-1/2, 4-5/8)

Dry engine (engine overhaul) 7.0 (7-3/8, 6-1/8)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3342 of 3924

ENGINE MAINTENANCE (VK45DE ENGINE)MA-25

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

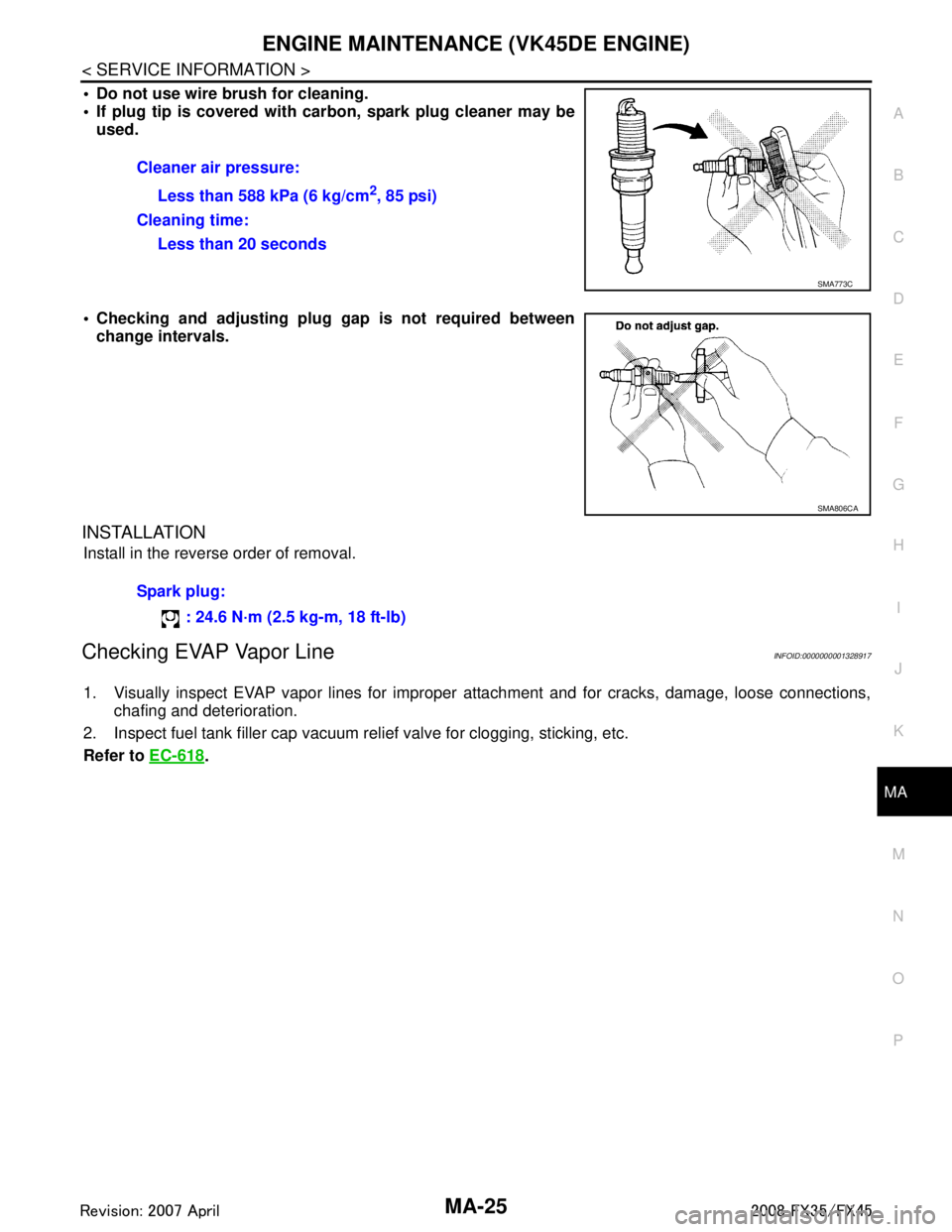

Do not use wire brush for cleaning.

If plug tip is covered with car bon, spark plug cleaner may be

used.

Checking and adjusting plug gap is not required between

change intervals.

INSTALLATION

Install in the reverse order of removal.

Checking EVAP Vapor LineINFOID:0000000001328917

1. Visually inspect EVAP vapor lines for improper attachment and for cracks, damage, loose connections,

chafing and deterioration.

2. Inspect fuel tank filler cap vacuum relief valve for clogging, sticking, etc.

Refer to EC-618

.

Cleaner air pressure:

Less than 588 kPa (6 kg/cm

2, 85 psi)

Cleaning time: Less than 20 seconds

SMA773C

SMA806CA

Spark plug:

: 24.6 N·m (2.5 kg-m, 18 ft-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3462 of 3924

POWER STEERING FLUIDPS-7

< SERVICE INFORMATION >

C

DE

F

H I

J

K L

M A

B

PS

N

O P

POWER STEERING FLUID

Checking Fluid LevelINFOID:0000000001327709

Stop engine before performing a fluid level check.

Ensure that fluid level is between the MAX range and MIN level.

Because fluid level differs within the HOT range and the COLD range, check it carefully.

CAUTION:

Do not overfill the Max level.

Do not reuse any used power steering fluid.

For recommended fluid, refer to MA-9, "

Fluids and Lubricants".

Checking Fluid LeakageINFOID:0000000001327710

Check the hydraulic piping lines for improper attachment and for

leaks, cracks, damage, loose connections, chafing or deterioration.

1. Run engine until fluid temperature reaches 50 to 80 ° C (122 to

176 °F) in reservoir tank. Keep engine speed idle.

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each “lock” position for five seconds to check fluid leakage.

CAUTION:

Do not hold steering wheel in a locked position for more

than 10 seconds. (There is the possibility that oil pump may

be damaged.)

4. If fluid leakage at connections is noticed, then loos en flare nut and then retighten. Do not over tighten con-

nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer to PS-27

.

6. Check steering gear boots for accumulation of fluid indicating a from steering gear.

Air Bleeding Hydraulic SystemINFOID:0000000001327711

Incomplete air bleeding causes the following. When this happens, bleed air again.

Generation of air bubbles in reservoir tank.

Generation of clicking noise in oil pump.

Excessive buzzing in oil pump. NOTE:

When vehicle is stationary or while steering wheel is being turned slowly, some noise may be heard from oil

pump or gear. This noise is normal and does not affect any system.

1. Stop engine, and then turn steering wheel fully to right and left several times. CAUTION:

Do not allow steering fluid reservoir tank to go below the low-level line. Check tank frequently and

add fluid as needed.

2. Run engine at idle speed. Turn steering wheel fully to the right and then fully to the left, and keep for about

three seconds. Then check whether a fluid leakage has occurred.

3. Repeat the 2nd procedure several times at about three seconds intervals. CAUTION:

Do not hold steering wheel in the locked position more than 10 seconds. (There is the possibility

that oil pump may be damaged.)

4. Check generation of air bubbles and cloud in fluid.

5. If air bubbles and the cloud don't fade, stop engine, hold air bleeding until air bubbles and the cloud fade.

Perform the 2nd and the 3rd procedures again. HOT : Fluid temperatures from 50 to 80

°C (122 to

176 °F)

COLD : Fluid temperatures from 0 to 30 °C (32 to 86 °F)

SGIA0232J

SGIA0506E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3849 of 3924

ROAD WHEEL TIRE ASSEMBLYWT-9

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

d. If calculated balance weight value exceeds 50 g (1.76 oz), install two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Do not install one balance weig ht sheet on top of another.

3. Start tire balance machine again.

4. Install drive-in balance weight on inner side of road wheel in the tire balance machine indication position (angle).

CAUTION:

Do not install more than two balance weights.

5. Start tire balance machine. Make sure that inner and outer resid- ual unbalance values are 5 g (0.2 oz) each or below.

6. If either residual unbalance value exceeds 5 g (0.2 oz), repeat installation procedures.

Tire RotationINFOID:0000000001327575

1. Follow the maintenance schedule for tire rotation service intervals. Refer to MA-5, "Introduction of Peri-

odic Maintenance".

2. Do not include the spare tire when rotating the tires.

3. When installing the wheel, tighten wheel nuts to the specified torque.

CAUTION:

When installing wheels, tighten th em diagonally by dividing the work two to three times in order

to prevent the wheels from developing any distortion.

Be careful not to tighten wheel nut at torque exceeding the criteria for preventing strain of disc

rotor.

4. Perform the ID registration, after tire rotation. Refer to WT-19, "

ID Registration Procedure".

Wheel balance Dynamic (At rim flange) Static (At rim flange)

Maximum allowable un-

balance 5 g (0.2 oz) (one side) 20 g (0.7 oz)

SMA056D

Wheel nuts : 108 N·m (11 kg-m, 80 ft-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3876 of 3924

WW-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION WW

A

B

WW

N

O P

CONTENTS

WIPER, WASHER & HORN

SERVICE INFORMATION .. ..........................3

PRECAUTION ................................................ .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Procedure without Cowl Top Cover ......3

FRONT WIPER AND WASHER SYSTEM ..........4

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

4

System Description ...................................................4

CAN Communication System Description .................6

CAN Communication Unit .........................................7

Schematic .................................................................7

Wiring Diagram - WIPER - ........................................8

Terminal and Reference Value for BCM .................10

Terminal and Reference Value for IPDM E/R .........14

How to Proceed with Trouble Diagnosis .................14

Preliminary Check ...................................................14

CONSULT-III Functions (BCM) ...............................15

CONSULT-III Functions (IPDM E/R) .......................16

Front Wiper Does Not Operate ...............................17

Front Wiper Does Not Return to Stop Position .......18

Only Front Wiper Low Does Not Operate ...............19

Only Front Wiper High Does Not Operate ...............20

Only Front Wiper Intermittent Does Not Operate ....21

Front Wiper Interval Time Is Not Controlled by Ve-

hicle Speed .............................................................

21

Front Wiper Intermittent Operation Switch Posi-

tion Cannot Be Adjusted .........................................

22

Wiper Does Not Wipe When Front Washer Oper-

ates .........................................................................

22

After Front Wiper Operate for 10 Seconds, They

Stop for 20 Seconds, and After Repeating the Op-

eration Five Times, They Become Inoperative ........

22

Front Wiper Does Not Stop .....................................23

Removal and Installation of Front Wiper Arms, Ad-

justment of Wiper Arms Stop Location ....................

23

Removal and Installation of Front Wiper Drive As-

sembly ................................................................. ....

24

Disassembly and Assembly of Front Wiper Drive

Assembly ............................................................. ....

25

Washer Nozzle Adjustment .....................................25

Washer Tube Layout ...............................................27

Removal and Installation of Front Washer Nozzle ....27

Removal and Installation of Front Washer Tube

Joint .........................................................................

27

Inspection of Washer Nozzle ...................................27

Inspection of Front Wiper and Washer Switch Cir-

cuit ...........................................................................

28

Removal and Installation of Front Wiper and

Washer Switch .........................................................

28

Removal and Installation of Washer Tank ...............28

Removal and Installation of Front and Rear Wash-

er Pump ...................................................................

29

REAR WIPER AND WASHER SYSTEM ..........30

Component Parts and Harness Connector Loca-

tion ...........................................................................

30

System Description ..................................................30

Wiring Diagram - WIP/ R - .......................................32

Terminal and Reference Value for BCM ..................33

How to Proceed with Trouble Diagnosis ..................35

Preliminary Check ...................................................36

CONSULT-III Functions (BCM) ...............................36

Rear Wiper Does Not Operate ................................37

Rear Wiper Does Not Return to Stop Position ........39

Only Rear Wiper ON Does Not Operate ..................40

Only Rear Wiper INT Does Not Operate .................40

Wiper Does Not Wipe When Rear Washer Oper-

ates ..........................................................................

40

Rear Wipers Do Not Stop ........................................40

Removal and Installation of Rear Wiper Arm, Ad-

justment of Wiper Arms Stop Location ....................

40

Removal and Installation of Rear Wiper Blade ........41

Removal and Installation of Rear Wiper Motor ........42

Washer Nozzle Adjustment .....................................43

Washer Tube Layout ...............................................43

Removal and Installation of Washer Nozzle ............43

Check Valve ............................................................44

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3880 of 3924

FRONT WIPER AND WASHER SYSTEMWW-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

to BCM terminals 49 and 52

through grounds M35, M45 and M85,

to IPDM E/R terminals 38 and 60

through grounds E21, E50 and E51,

to combination switch terminal 12

through grounds M35, M45 and M85.

LOW SPEED WIPER OPERATION

When wiper switch is in LOW position, BCM detects low speed wiper ON signal by BCM wiper switch reading

function.

BCM sends front wiper request signal (LO) through CAN communication

from BCM terminals 39 and 40

to IPDM E/R terminals 48 and 49.

When IPDM E/R receives front wiper request signal (LO), it turns ON front wiper relay located in IPDM E/R,

power is supplied

through front wiper relay

through front wiper high relay

through IPDM E/R terminal 21

to front wiper motor terminal 1.

Ground is supplied

to front wiper motor terminal 2

through grounds E21, E50 and E51.

With power and ground supplied, the front wiper motor operates at low speed.

HIGH SPEED WIPER OPERATION

When wiper switch is in HI position, BCM detects high speed wiper ON signal by BCM wiper switch reading

function.

BCM sends front wiper request signal (HI) through CAN communication

from BCM terminals 39 and 40

to IPDM E/R terminals 48 and 49.

When IPDM E/R receives front wiper r equest signal (HI), it turns ON front wiper relay (located in IPDM E/R),

power is supplied

through front wiper relay

through front wiper high relay

through IPDM E/R terminal 31

to front wiper motor terminal 4.

Ground is supplied

to front wiper motor terminal 2

through grounds E21, E50 and E51.

With power and ground supplied, the front wiper motor operates at high speed.

INTERMITTENT OPERATION

Front wiper intermittent operation delay interval is det ermined from a combination of 3 switches (intermittent

operation dial position 1, 2, and 3) and vehicle speed signal.

Speed dependent wiper controlled mode can be changed by the function setting of CONSULT-III or display.

During each intermittent operation delay interval, BCM sends front wiper request signal to IPDM E/R.

Wiper Dial Position Setting

Example: For wiper intermittent dial position 1

Wiper intermittent dial position Intermittent operation

interval Combination switch

INT VOLUME 1 INT VOLUME 2 INT VOLUME 3

1Short

↑

↓

Long ON ON ON

2ONONOFF

3ONOFFOFF

4 OFF OFF OFF

5OFFOFFON

6OFFONON

7 OFF ON OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C