service interval INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 452 of 3924

TROUBLE DIAGNOSISATC-47

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

10.CHECK IN-VEHICLE SENSOR

Press (DEF) switch for the second time. Temperature detected

by in-vehicle sensor is indicated on the display.

NOTE:

If the temperature indicated on the display greatly differs from the

actual temperature, check sensor circuit first, and then check sensor.

OK or NG

OK >> GO TO 11.

NG >> Go to In-vehicle Sensor Circuit. Refer to ATC-88, "

In-

vehicle Sensor Circuit".

11 .CHECK INTAKE SENSOR

Press (DEF) switch for the third time. Temperature detected by

intake sensor is indicated on the display.

NOTE:

If the temperature indicated on the display greatly differs from the

actual temperature, check sensor circuit first, and then check sensor.

OK or NG

OK >> GO TO 12.

NG >> Go to Intake Sensor Circuit. Refer to ATC-94, "

Intake

Sensor Circuit".

12.CHECK CAN COMMUNICATION ERROR

1. Press intake switch.

2. CAN communication error between the unified meter and A/C amp. and the display control unit can be detected as self-diag-

nosis results. (If plural errors occur, the display of each error will

blink twice for 0.5 second intervals.)

OK or NG

OK >> 1. Turn ignition switch OFF or AUTO switch ON. 2. INSPECTION END

NG >> Go to CAN communication. Refer to BCS-11, "

CON-

SULT-III Function (BCM)".

Unified meter and A/C amp. - Display control unit

13.CHECK MALFUNCTIONING SENSOR AND DOOR MOTOR

Refer to the following chart for malfunctioning code No.

(If two or more sensors and door motors malfuncti on, corresponding code Nos. indicates 1 second each.)

*1: Perform self-diagnosis STEP-2 under sunshine.

PJIA0152E

PJIA0153E

SJIA1611E

Code No. Malfunctioning sensor and door motor (Including circuits) Reference page 21 / −21 Ambient sensor ATC-86, "

Ambient Sensor Circuit"

22 / −22 In-vehicle sensor AT C - 8 8 , "In-vehicle Sensor Circuit"

24 / −24 Intake sensor AT C - 9 4 , "Intake Sensor Circuit"

25 / −25

Sunload sensor*1AT C - 9 1 , "Sunload Sensor Circuit"

26 / −26 Air mix door motor PBR (Driver side)

AT C - 6 2 , "Air Mix Door Motor PBR Circuit"27 / −27 Air mix door motor PBR (Passenger side)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 725 of 3924

BCM (BODY CONTROL MODULE)BCS-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BCS

N

O P

BCM reads operation status of combination swit ch using combinations shown in table below.

NOTE:

Headlamp system has a dual switch.

Sample Operation: (When Lighting Switch 1ST Position Turned ON)

When lighting switch 1ST position is turned ON, contact in combination switch turns ON. At this time if OUT-

PUT 4 transistor is activated, BCM detects that voltage changes in INPUT 5.

When OUTPUT 4 transistor is ON, BCM detects that voltage changes in INPUT 5, and judges that lighting

switch 1ST position is ON. Then BCM sends tail lamp and clearance lamp request signal to IPDM E/R using

CAN communication.

When OUTPUT 4 transistor is activated again, BCM detects that voltage changes in INPUT 5, and recog-

nizes that lighting switch 1S T position is continuously ON.

NOTE:

Each OUTPUT terminal transistor is activated at 10 ms intervals. Therefore after switch is turned ON, electri-

cal loads are activated with time delay. But this time delay is so short that it cannot be detected by human

senses.

Operation Mode

Combination switch reading function has operation modes shown below.

1. Normal status When BCM is not in sleep status, OUTPUT terminals (1-5) send out ON signal every 10 ms.

2. Sleep status

SKIA4959E

PKID0854E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 998 of 3924

BR-14

< SERVICE INFORMATION >

BRAKE BOOSTER

BRAKE BOOSTER

On-Vehicle ServiceINFOID:0000000001327621

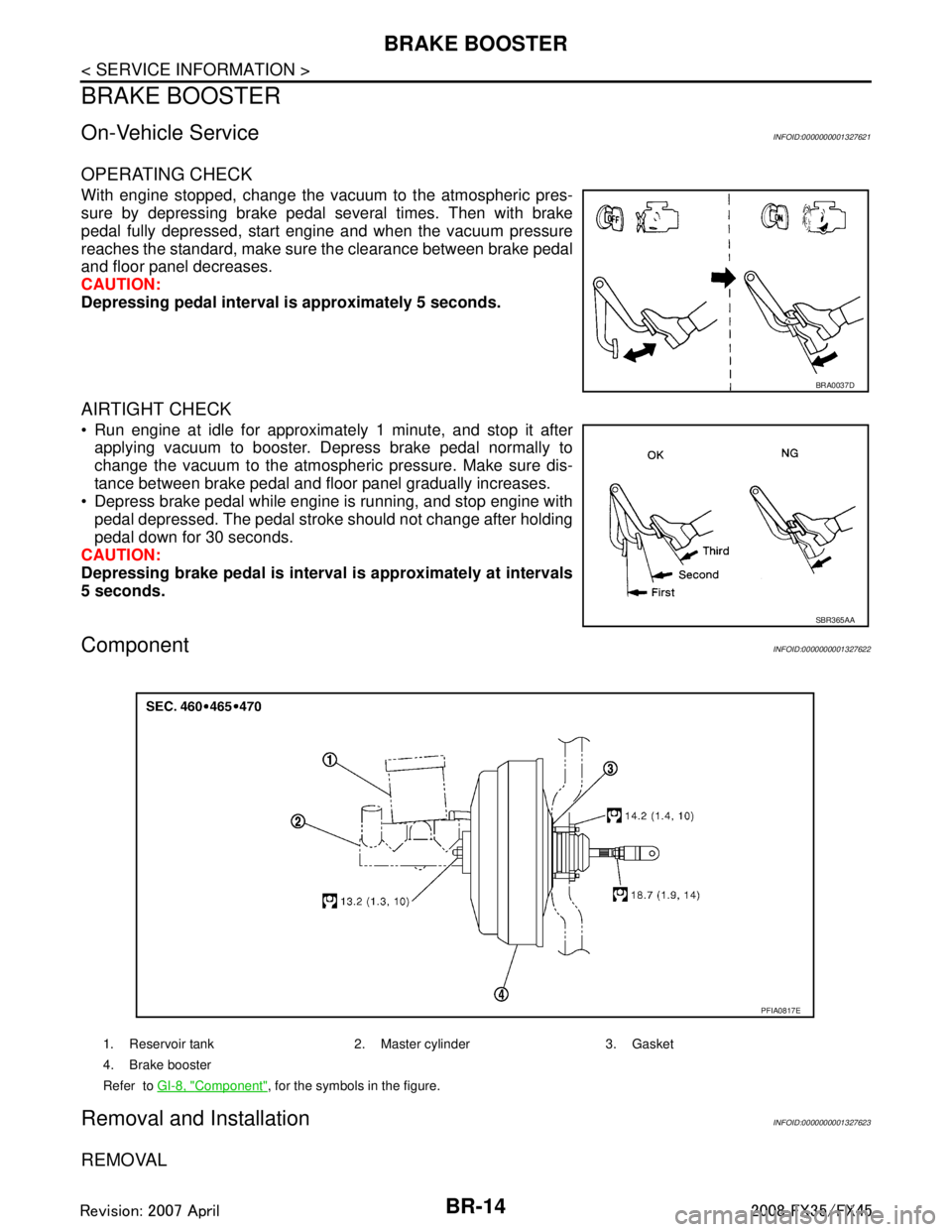

OPERATING CHECK

With engine stopped, change the vacuum to the atmospheric pres-

sure by depressing brake pedal several times. Then with brake

pedal fully depressed, start engine and when the vacuum pressure

reaches the standard, make sure the clearance between brake pedal

and floor panel decreases.

CAUTION:

Depressing pedal interval is approximately 5 seconds.

AIRTIGHT CHECK

Run engine at idle for approximately 1 minute, and stop it afterapplying vacuum to booster. Depress brake pedal normally to

change the vacuum to the atmospheric pressure. Make sure dis-

tance between brake pedal and floor panel gradually increases.

Depress brake pedal while engine is running, and stop engine with

pedal depressed. The pedal stroke should not change after holding

pedal down for 30 seconds.

CAUTION:

Depressing brake pedal is interval is approximately at intervals

5 seconds.

ComponentINFOID:0000000001327622

Removal and InstallationINFOID:0000000001327623

REMOVAL

BRA0037D

SBR365AA

1. Reservoir tank 2. Master cylinder 3. Gasket

4. Brake booster

Refer to GI-8, "

Component", for the symbols in the figure.

PFIA0817E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1314 of 3924

![INFINITI FX35 2008 Service Manual

EC-74

< SERVICE INFORMATION >[VQ35DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

tified codes can be identified by using the CONSULT-II

I or GST. A DTC will be used as an example for how to

read a code.

A part INFINITI FX35 2008 Service Manual

EC-74

< SERVICE INFORMATION >[VQ35DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

tified codes can be identified by using the CONSULT-II

I or GST. A DTC will be used as an example for how to

read a code.

A part](/img/42/57017/w960_57017-1313.png)

EC-74

< SERVICE INFORMATION >[VQ35DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

tified codes can be identified by using the CONSULT-II

I or GST. A DTC will be used as an example for how to

read a code.

A particular trouble code can be identified by the number of four-digit numeral flashes. The “zero” is indicated

by the number of ten flashes. The “A” is indicated by the number of eleven flash. The length of time the

1,000th-digit numeral flashes on and off is 1.2 seconds consisting of an ON (0.6-second) - OFF (0.6-second)

cycle.

The 100th-digit numeral and lower digit numerals cons ist of a 0.3-second ON and 0.3-second OFF cycle.

A change from one digit numeral to another occurs at an inte rval of 1.0-second OFF. In other words, the later

numeral appears on the display 1.3 seconds after the former numeral has disappeared.

A change from one trouble code to another occu rs at an interval of 1.8-second OFF.

In this way, all the detected malfunctions are classi fied by their DTC numbers. The DTC 0000 refers to no mal-

function. (See EC-17

)

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

The DTC can be erased from the back up memory in t he ECM by depressing accelerator pedal. Refer to "How

to Set Diagnostic Test Mode II (Self-diagnostic Results)".

If the battery is disconnected, the DTC will be lost from the backup memory within 24 hours.

Be careful not to erase the stored memo ry before starting trouble diagnoses.

OBD System Operation ChartINFOID:0000000001325918

RELATIONSHIP BETWEEN MIL, 1ST TRIP DTC, DTC, AND DETECTABLE ITEMS

When a malfunction is detected for the 1st time, the 1st trip DTC and the 1st trip freeze frame data are

stored in the ECM memory.

When the same malfunction is detected in two consec utive trips, the DTC and the freeze frame data are

stored in the ECM memory, and the MIL will come on. For details, refer to EC-54, "

Two Trip Detection Logic".

The MIL will go off after the vehicle is driven 3 time s (drive pattern B) with no malfunction. The drive is

counted only when the recorded driving pattern is met (as stored in the ECM). If another malfunction occurs

while counting, the counter will reset.

The DTC and the freeze frame data will be stored until the vehicle is driven 40 times (driving pattern A) with-

out the same malfunction recurring (except for Misfire and Fuel Injection System). For Misfire and Fuel Injec-

tion System, the DTC and freez e frame data will be stored until the vehicle is driven 80 times (driving pattern

PBIB3005E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1892 of 3924

![INFINITI FX35 2008 Service Manual

EC-652

< SERVICE INFORMATION >[VK45DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

tified codes can be identified by using the CONSULT-II

I or GST. A DTC will be used as an example for how to

read a code.

A par INFINITI FX35 2008 Service Manual

EC-652

< SERVICE INFORMATION >[VK45DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

tified codes can be identified by using the CONSULT-II

I or GST. A DTC will be used as an example for how to

read a code.

A par](/img/42/57017/w960_57017-1891.png)

EC-652

< SERVICE INFORMATION >[VK45DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

tified codes can be identified by using the CONSULT-II

I or GST. A DTC will be used as an example for how to

read a code.

A particular trouble code can be identified by the number of four-digit numeral flashes. The “zero” is indicated

by the number of ten flashes. The “A ” is indicated by the number of eleven flashes. The length of time the

1,000th-digit numeral flashes on and off is 1.2 seconds consisting of an ON (0.6-second) - OFF (0.6-second)

cycle.

The 100th-digit numeral and lower digit numerals cons ist of a 0.3-second ON and 0.3-second OFF cycle.

A change from one digit numeral to another occurs at an inte rval of 1.0-second OFF. In other words, the later

numeral appears on the display 1.3 seconds after the former numeral has disappeared.

A change from one trouble code to another occu rs at an interval of 1.8-second OFF.

In this way, all the detected malfunctions are classi fied by their DTC numbers. The DTC 0000 refers to no mal-

function. (See EC-595

)

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

The DTC can be erased from the back up memory in t he ECM by depressing accelerator pedal. Refer to "How

to Erase Diagnostic Test Mode II (Self-diagnostic Results)".

If the battery is disconnected, the DTC will be lost from the backup memory within 24 hours.

Be careful not to erase the stored memo ry before starting trouble diagnoses.

OBD System Operation ChartINFOID:0000000001326514

RELATIONSHIP BETWEEN MIL, 1ST TRIP DTC, DTC, AND DETECTABLE ITEMS

When a malfunction is detected for the first time, the 1st trip DTC and the 1st trip freeze frame data are

stored in the ECM memory.

When the same malfunction is detected in two consec utive trips, the DTC and the freeze frame data are

stored in the ECM memory, and the MIL will come on. For details, refer to EC-632, "

Two Trip Detection

Logic".

The MIL will go off after the vehicle is driven 3 time s (driving pattern B) with no malfunction. The drive is

counted only when the recorded driving pattern is met (as stored in the ECM). If another malfunction occurs

while counting, the counter will reset.

The DTC and the freeze frame data will be stored until the vehicle is driven 40 times (driving pattern A) with-

out the same malfunction recurring (except for Misfire and Fuel Injection System). For Misfire and Fuel Injec-

PBIB3005E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2528 of 3924

![INFINITI FX35 2008 Service Manual

EM-44

< SERVICE INFORMATION >[VQ35DE]

SPARK PLUG (PLATI

NUM-TIPPED TYPE)

CAUTION:

Do not drop or shock spark plug.

Do not use a wire brush for cleaning.

If plug tip is covered with car bon, spa INFINITI FX35 2008 Service Manual

EM-44

< SERVICE INFORMATION >[VQ35DE]

SPARK PLUG (PLATI

NUM-TIPPED TYPE)

CAUTION:

Do not drop or shock spark plug.

Do not use a wire brush for cleaning.

If plug tip is covered with car bon, spa](/img/42/57017/w960_57017-2527.png)

EM-44

< SERVICE INFORMATION >[VQ35DE]

SPARK PLUG (PLATI

NUM-TIPPED TYPE)

CAUTION:

Do not drop or shock spark plug.

Do not use a wire brush for cleaning.

If plug tip is covered with car bon, spark plug cleaner may be

used.

Checking and adjusting plug gap is not required between

change intervals.

INSTALLATION

Installation is the reverse order of removal.

Hot type PLFR4A-11

Cold type PLFR6A-11

Gap (Nominal) : 1.1 mm (0.043 in)

Cleaner air pressure:

Less than 588 kPa (6 kg/cm

2, 85 psi)

Cleaning time: Less than 20 seconds

SMA773C

SMA806CA

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2572 of 3924

![INFINITI FX35 2008 Service Manual

EM-88

< SERVICE INFORMATION >[VQ35DE]

CAMSHAFT

If the calculated value is out of the standard, referri

ng to each standard of valve lifter outer diameter and

valve lifter hole diameter, replace eit INFINITI FX35 2008 Service Manual

EM-88

< SERVICE INFORMATION >[VQ35DE]

CAMSHAFT

If the calculated value is out of the standard, referri

ng to each standard of valve lifter outer diameter and

valve lifter hole diameter, replace eit](/img/42/57017/w960_57017-2571.png)

EM-88

< SERVICE INFORMATION >[VQ35DE]

CAMSHAFT

If the calculated value is out of the standard, referri

ng to each standard of valve lifter outer diameter and

valve lifter hole diameter, replace either or both valve lifter and cylinder head.

INSTALLATION

1. Install timing chain tensioners (secondary) on both sides of cyl- inder head.

Install timing chain tensioner with its stopper pin attached.

Install timing chain tensioner with sliding part facing downwardon right-side cylinder head, and with sliding part facing upward

on left-side cylinder head.

Install new O-ring as shown in the figure.

2. Install valve lifter. Install it in the original position.

3. Install camshafts. Install camshaft with dowel pin attached to its front end face on

the exhaust side.

Follow your identification marks made during removal, or fol- low the identification marks that are present on new camshafts

for proper placement and direction.

Install camshaft so that dowel pin hole and dowel pin on front end face are positioned as shown in the figure. (No. 1 cylinder

TDC on its compression stroke)

NOTE:

Large and small pin holes are located on front end face ofcamshaft (INT), at intervals of 180 degrees. Face small dia.

side pin hole upward (in cylinder head upper face direction).

Though camshaft does not stop at the portion as shown in the figure, for the placement of cam nose, it is generally

accepted camshaft is placed for the same direction of the fig-

ure. Identification (stamped) mark “V”

: 0.010 - 0.036 mm (0.0004 - 0.0014 in)

PBIC2111E

KBIA1071E

Bank INT/EXH Dowel pin Paint marks

Identification

mark

M1 M2

RH EXH Yes No Orange RE

INT No Pink No RE

LH INT No Pink No LH

EXH Yes No Orange LH

KBIA1009E

PBIC2478E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2673 of 3924

![INFINITI FX35 2008 Service Manual

SPARK PLUG (PLATINUM-TIPPED TYPE)EM-189

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

Do not drop or shock spark plug.

Do not use wire brush for cleaning.

If plug ti INFINITI FX35 2008 Service Manual

SPARK PLUG (PLATINUM-TIPPED TYPE)EM-189

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

Do not drop or shock spark plug.

Do not use wire brush for cleaning.

If plug ti](/img/42/57017/w960_57017-2672.png)

SPARK PLUG (PLATINUM-TIPPED TYPE)EM-189

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

Do not drop or shock spark plug.

Do not use wire brush for cleaning.

If plug tip is covered with car

bon, spark plug cleaner may be

used.

Checking and adjusting plug gap is not required between

change intervals.

INSTALLATION

Install in the reverse order of removal. Gap (Nominal) : 1.1 mm (0.043 in)

Cleaner air pressure:

Less than 588 kPa (6 kg/cm

2, 85 psi)

Cleaning time: Less than 20 seconds

SMA773C

SMA806CA

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3322 of 3924

PERIODIC MAINTENANCEMA-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

PERIODIC MAINTENANCE

Introduction of Periodic MaintenanceINFOID:0000000001328894

Two different maintenance schedules are provi ded, and should be used, depending upon the conditions in

which the vehicle is mainly operated. After 60,000 miles (96,000 km) or 48 months, continue the periodic

maintenance at the same mileage/time intervals.

Schedule 1INFOID:0000000001328895

EMISSION CONTROL SYSTEM MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or r eplace if necessary. [ ]: At the mileage intervals only

Schedule 1Follow Periodic Maintenance Schedule 1 if the driving habits frequently include

one or more of the following driving conditions:

Repeated short trips of less than 5 miles (8 km).

Repeated short trips of less than 10 miles (16 km) with outside temperatures

remaining below freezing.

Operating in hot weather in stop-and-go “rush hour” traffic.

Extensive idling and/or low speed driving for long distances, such as police, taxi or door-to-door delivery use.

Driving in dusty conditions.

Driving on rough, muddy, or salt spread roads.

Towing a trailer, using a camper or a car-top carrier. Emission Control Sys-

tem Maintenance

MA-5

Chassis and Body

MaintenanceMA-5

Schedule 2Follow Periodic Maintenance Schedule 2 if none of driving conditions shown in

Schedule 1 apply to the driving habits.

Emission Control Sys-

tem Maintenance

MA-7Chassis and Body

Maintenance

MA-7

MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title

Perform at number of miles,

kilometers or months, which-

ever comes first. Miles x 1,000

(km x 1,000) Months 3.75

(6)3 7.50

(12) 6 11 . 2 5

(18) 9 15

(24) 12 18.75

(30)15 22.5

(36) 18 26.25

(42)21 30

(48) 24

Drive belts NOTE (1) MA-11

,

MA-

19

Air cleaner filter NOTE (2) [R] MA-15,

MA-

22

EVAP vapor lines I*MA-18,

MA-

25

Fuel lines I*MA-15,

MA-

22

Fuel filter NOTE (3) -

Engine coolant NOTE (4) MA-12

,

MA-

19

Engine oil R R R R R R R R MA-15,

MA-

22

Engine oil filter (Use genuine

NISSAN engine oil filter or

equivalent.) R R RRRRR R

MA-16,

MA-

23

Spark plugs (PLATINUM-

TIPPED type) Replace every 105,000 miles (169,000 km).

MA-17,

MA-

24

Intake & exhaust valve clear-

ance* NOTE (5) EM-91,

EM-

218

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3323 of 3924

MA-6

< SERVICE INFORMATION >

PERIODIC MAINTENANCE

NOTE:

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts if found

damaged or if the auto belt tensioner reading (only for VK45DE engine) reaches the maximum limit.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, refer to FL section.

(4) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(5) If valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by INFINITI for reliable vehicle operation. The owner need not perfo rm

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required.

CHASSIS AND BODY MAINTENANCE

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary.

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title

Perform at number of miles,

kilometers or months, which-

ever comes first. Miles x 1,000

(km x 1,000) Months 33.75

(54)27 37.5

(60) 30 41.25

(66)33 45

(72) 36 48.75

(78)39 52.5

(84) 42 56.25

(90)45 60

(96) 48

Drive belts NOTE (1) I* MA-11

,

MA-

19

Air cleaner filter NOTE (2) [R] MA-15,

MA-

22

EVAP vapor lines I*MA-18,

MA-

25

Fuel lines I*MA-15,

MA-

22

Fuel filter NOTE (3) -

Engine coolant NOTE (4) R* MA-12

,

MA-

19

Engine oil R R R R R R R R MA-15,

MA-

22

Engine oil filter (Use genuine

NISSAN engine oil filter or

equivalent.) R R RRRRRR

MA-16,

MA-

23

Spark plugs (PLATINUM-

TIPPED type) Replace every 105,000 miles (169,000 km).MA-17,

MA-

24

Intake & exhaust valve clear-

ance* NOTE (5) EM-91,

EM-

218

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section -

Page or - Con-

tent Title

Perform at number of miles,

kilometers or months,

whichever comes first. Miles x 1,000

(km x 1,000) Months 3.75

(6)3 7.50

(12) 6 11 . 2 5

(18) 9 15

(24) 12 18.75

(30)15 22.5

(36) 18 26.25

(42)21 30

(48) 24

Brake lines & cables IIMA-32

Brake pads & rotors

IIII MA-32

Automatic transmission &

transfer fluid & differential

gear oilNOTE (1) I I MA-26,

MA-28

,

MA-29

Steering gear, linkage &

transfer gear, axle & sus-

pension parts IIII

MA-33

,

MA-34

Tire rotation NOTE (2) MA-3,

MA-31

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C