fuel INFINITI FX35 2008 Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 781 of 3924

POWER DOOR LOCK SYSTEMBL-47

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

OK >> Replace fuel lid lock actuator.

NG >> Repair or replace harness.

Check Front Door Key Cylinder Switch (Lock)INFOID:0000000001327809

1.CHECK FRONT DOOR KEY CYLINDER SWITCH INPUT SIGNAL (LOCK SIGNAL)

With CONSULT-III

Check front door key cylinder switch LH (“KEY CYL LK SW”) in “DATA MONITOR” mode with CONSULT-III.

When key cylinder switch is turned to “LOCK”.

Without CONSULT-III

Check voltage between power window main switch (door lock and

unlock switch) connector and ground.

OK or NG

OK >> Front door key cylinder switch ci rcuit driver side (lock) is OK.

NG >> GO TO 2.

2.CHECK FRONT DOOR KEY CYLINDER SWITCH

1. Disconnect front door key cylinder switch driver side connector.

2. Check continuity between front door key cylinder switch driver side terminals 1 and 5.

OK or NG

OK >> Check the following. Front door key cylinder switch driver side ground circuit.

Harness for open or short between power window main switch (door lock and unlock switch)and front door key cylinder switch driver side.

NG >> Replace front door key cylinder switch driver side.

Check Front Door Key Cylinder Switch (Unlock)INFOID:0000000001327810

1.CHECK FRONT DOOR KEY CYLINDER SWITCH INPUT SIGNAL (UNLOCK SIGNAL)

With CONSULT-III

Check front door key cylinder switch driver side (“KEY CYL UN-SW”) in “DATA MONITOR” mode with CON-

SULT-III.

When key cylinder switch is turned to “UNLOCK”. KEY CYL LK-SW : ON

Connector

Terminal (Wire color)

Front door key cylinder

switch position Voltage (V)

(Approx.)

(+) (-)

D6 4 (P) Ground Neutral / Unlock 5

Lock 0

PIIA6203E

Terminal Front door key cylinder switch position Continuity

15 Neutral / Unlock No

Lock Yes

PIIA6543E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 938 of 3924

BL-204

< SERVICE INFORMATION >

BODY REPAIR

BODY REPAIR

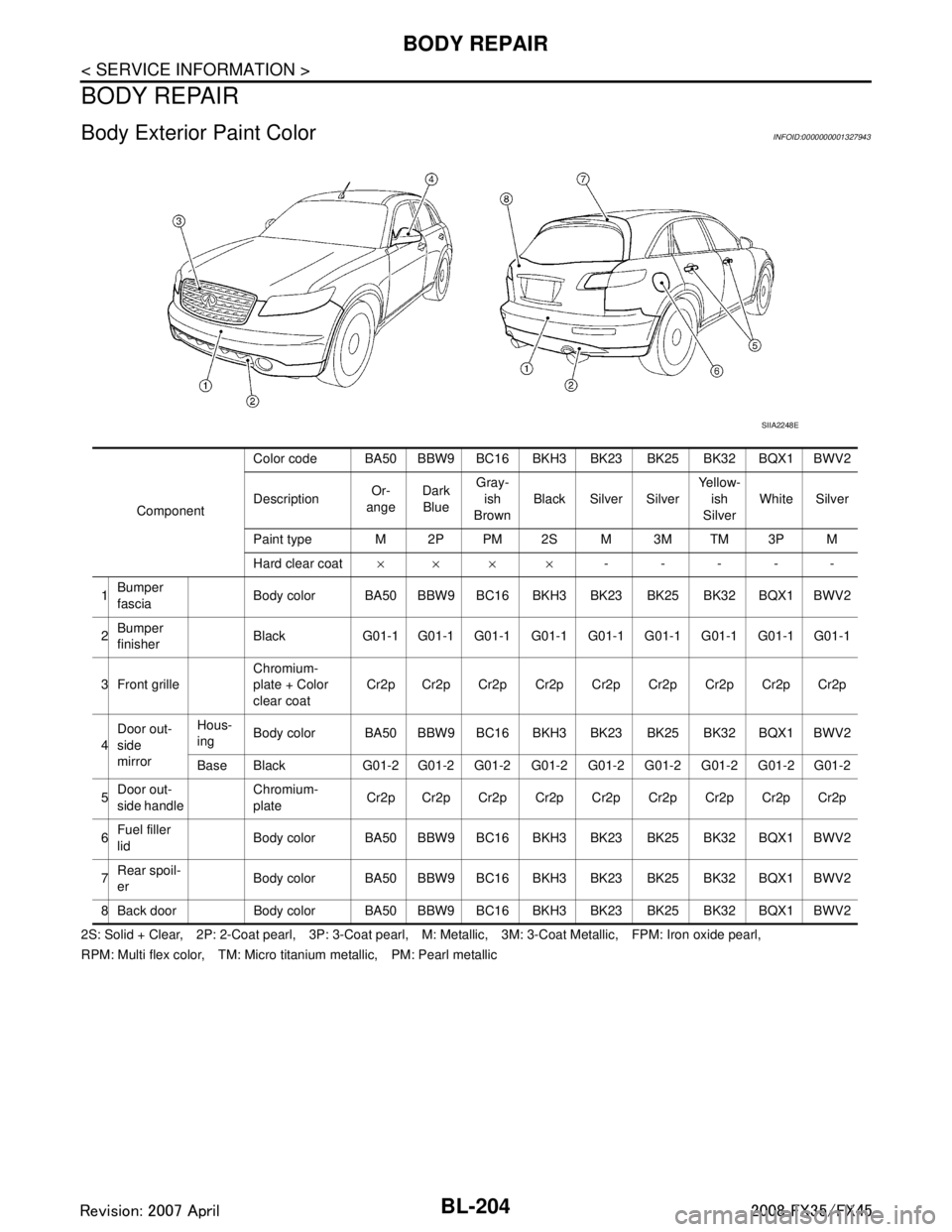

Body Exterior Paint ColorINFOID:0000000001327943

2S: Solid + Clear, 2P: 2-Coat pearl, 3P: 3-Coat pearl, M: Metallic, 3M: 3-Coat Metallic, FPM: Iron oxide pearl,

RPM: Multi flex color, TM: Micro titanium metallic, PM: Pearl metallic

SIIA2248E

ComponentColor code BA50 BBW9 BC16 BKH

3 BK23 BK25 BK32 BQX1 BWV2

Description Or-

ange Dark

Blue Gray-

ish

Brown Black Silver Silver Yellow-

ish

Silver White Silver

Paint type M 2P PM 2S M 3M TM 3P M

Hard clear coat ×× × × -----

1 Bumper

fascia Body color BA50 BBW9 BC16

BKH3 BK23 BK25 BK32 BQX1 BWV2

2 Bumper

finisher Black G01-1 G01-1 G01-1 G01-1 G01-1 G01-1 G01-1 G01-1 G01-1

3 Front grille Chromium-

plate + Color

clear coatCr2p Cr2p Cr2p Cr2p Cr2p Cr2p Cr2p Cr2p Cr2p

4 Door out-

side

mirror Hous-

ing

Body color BA50 BBW9 BC16

BKH3 BK23 BK25 BK32 BQX1 BWV2

Base Black G01-2 G01-2 G01-2 G01-2 G01-2 G01-2 G01-2 G01-2 G01-2

5 Door out-

side handle Chromium-

plate

Cr2p Cr2p Cr2p Cr2p Cr2p Cr2p Cr2p Cr2p Cr2p

6 Fuel filler

lid Body color BA50 BBW9 BC16

BKH3 BK23 BK25 BK32 BQX1 BWV2

7 Rear spoil-

er Body color BA50 BBW9 BC16

BKH3 BK23 BK25 BK32 BQX1 BWV2

8 Back door Body color BA50 BBW9 B C16 BKH3 BK23 BK25 BK32 BQX1 BWV2

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1025 of 3924

![INFINITI FX35 2008 Owners Manual

BRC-10

< SERVICE INFORMATION >[VDC/TCS/ABS]

SYSTEM DESCRIPTION

SYSTEM DESCRIPTION

SchematicINFOID:0000000001327660

FunctionsINFOID:0000000001327661

VDC

In addition to the TCS/ABS function, the driv INFINITI FX35 2008 Owners Manual

BRC-10

< SERVICE INFORMATION >[VDC/TCS/ABS]

SYSTEM DESCRIPTION

SYSTEM DESCRIPTION

SchematicINFOID:0000000001327660

FunctionsINFOID:0000000001327661

VDC

In addition to the TCS/ABS function, the driv](/img/42/57017/w960_57017-1024.png)

BRC-10

< SERVICE INFORMATION >[VDC/TCS/ABS]

SYSTEM DESCRIPTION

SYSTEM DESCRIPTION

SchematicINFOID:0000000001327660

FunctionsINFOID:0000000001327661

VDC

In addition to the TCS/ABS function, the driver

steering amount and brake operation amount are detected

from steering angle sensor and pressure sensor, and the vehicle's driving status (amount of under steering /

over steering) is determined from information from G s ensor, wheel sensor, etc., and this information is used

to improve vehicle stability by controlling the braking and engine power to all four wheels.

SLIP indicator lamp flashes to inform the driver of VDC operation.

During VDC operation, body and brake pedal lightly vibrate and mechanical noises may be heard. This is

normal.

ABS warning lamp, VDC OFF indicator lamp, and SLIP indicator lamp might turn on when vehicle is subject

to strong shaking or large vibration, such as when vehi cle is on a turn table, a ship or a steep slope such as

bank while engine is running. In this case, restart engine on a normal road, and if ABS warning lamp, VDC

OFF indicator lamp, and SLIP indicator lamp turn off, there is no malfunction.

TCS

The wheel spin of the drive wheels is detected by ABS actuator and electric unit (control unit) from the wheel

speed signals from four wheels, so if wheel spin occurs , drive wheel right and left brake fluid pressure con-

trol and engine fuel cut are performed while throttle value is restricted to reduce the engi\

ne torque and

decrease the amount of wheel spin. In addition, the degree throttle is opened is controlled to achieve the

optimum engine torque.

Depending on road circumstances, the driver may have a sluggish feel. This is normal, because the opti-

mum traction has the highest priority under TCS operation.

TCS may be activated any time vehicle suddenly accelerates, suddenly down/upshifts, or is driven on a road with a varying surface friction coefficient.

During TCS operation, it informs a driver of sy stem operation by flashing SLIP indicator lamp.

ABS

The Anti-Lock Braking System is a function that detec ts wheel revolution while braking, and it improves han-

dling stability during sudden braking by electrically prev enting 4 wheel lock. Maneuverability is also improved

for avoiding obstacles.

If the electrical system malfunc tions, then the fail-safe function star ts, the ABS becomes inoperative, and

ABS warning lamp turns on.

Electrical system diagnosis by CONSULT-III is available.

During ABS operation, brake pedal lightly vibrates and a mechanical noise may be heard. This is normal.

When starting engine, or just after starting vehicle, brake pedal may vibrate or motor operating noises may be heard from engine compartment. This is a normal status of operation check.

SFIA1160E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1042 of 3924

![INFINITI FX35 2008 Owners Manual

TROUBLE DIAGNOSISBRC-27

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

DISPLAY ITEM LIST

Self-diagnostic item Malfunction detecting condition Check system

RR RH SENSOR- 1

[C1 INFINITI FX35 2008 Owners Manual

TROUBLE DIAGNOSISBRC-27

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

DISPLAY ITEM LIST

Self-diagnostic item Malfunction detecting condition Check system

RR RH SENSOR- 1

[C1](/img/42/57017/w960_57017-1041.png)

TROUBLE DIAGNOSISBRC-27

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

DISPLAY ITEM LIST

Self-diagnostic item Malfunction detecting condition Check system

RR RH SENSOR- 1

[C1101] (Note 1) Circuit of rear RH wheel sensor is open, shorted or sensor power volt-

age is unusual. BRC-34, "

DTC C1101 RR RH

SENSOR-1"

RR LH SENSOR- 1

[C1102] (Note 1)

Circuit of rear LH wheel sensor is open, shorted or sensor power volt-

age is unusual. BRC-35, "DTC C1102 RR LH

SENSOR-1"

FR RH SENSOR- 1

[C1103] (Note 1)Circuit of front RH wheel sensor is open, shorted or sensor power volt-

age is unusual. BRC-35, "DTC C1103 FR RH

SENSOR-1"

FR LH SENSOR- 1

[C1104] (Note 1)Circuit of front LH wheel sensor is open, shorted or sensor power volt-

age is unusual. BRC-35, "DTC C1104 FR LH

SENSOR-1"

RR RH SENSOR- 2

[C1105] (Note 1)

ABS actuator and electric unit (control unit) can not identify sensor puls-

es, because of large gap between wheel sensor and sensor rotor. BRC-36, "DTC C1105 RR RH

SENSOR-2"

RR LH SENSOR- 2

[C1106] (Note 1)ABS actuator and electric unit (control unit) can not identify sensor puls-

es, because of large gap between wheel sensor and sensor rotor. BRC-36, "DTC C1106 RR LH

SENSOR-2"

FR RH SENSOR- 2

[C1107] (Note 1)ABS actuator and electric unit (control unit) can not identify sensor puls-

es, because of large gap between wheel sensor and sensor rotor. BRC-36, "DTC C1107 FR RH

SENSOR-2"

FR LH SENSOR- 2

[C1108] (Note 1)

ABS actuator and electric unit (control unit) can not identify sensor puls-

es, because of large gap between wheel sensor and sensor rotor. BRC-36, "DTC C1108 FR LH

SENSOR-2"

BATTERY VOLTAGE

[ABNORMAL]

[C1109]ABS actuator and electric unit (control unit) power voltage is too low. BRC-36, "DTC C1109 BAT-

TERY VOLTAGE [ABNOR-

MAL]"

CONTROLLER FAILURE

[ C 111 0 ]

Internal malfunction of ABS actuator and electric unit (control unit) BRC-37, "DTC C1110 CON-

TROLLER FAILURE"

PUMP MOTOR

[ C 1111 ] ( N o t e 3 )During actuator motor operation with ON, when actuator motor turns

OFF or when control line for actuator motor relay is open.

BRC-37, "D T C C 1111 P U M P

MOTOR"During actuator motor operation with OFF, when actuator motor turns

ON or when control line for relay is shorted to ground.

G - SENSOR

[C1113] (Note 4) Decel G sensor is malfunctioning, or signal line of decel G sensor is

open or shorted. BRC-38, "

DTC C1113 G-SEN-

SOR"

ABS SENSOR

[ABNORMAL SIGNAL]

[C1115] (Note 1)Wheel sensor input is malfunction. BRC-39, "DTC C1115 ABS

SENSOR [ABNORMAL SIG-

NAL]"

STOP LAMP SW

[ C 111 6 ]

Stop lamp switch circuit is open or shorted. BRC-39, "DTC C1116 STOP

LAMP SW"

FR LH IN ABS SOL

[C1120]Circuit of front LH IN ABS solenoid is open or shorted, or control line is

open or shorted to power supply or ground. BRC-40, "DTC C1120 FR LH IN

ABS SOL"

FR LH OUT ABS SOL

[C1121]Circuit of front LH OUT ABS solenoid is

open or shorted, or control line

is open or shorted to power supply or ground. BRC-41, "DTC C1121 FR LH

OUT ABS SOL"

FR RH IN ABS SOL

[C1122]Circuit of front RH IN ABS solenoid is op

en or shorted, or control line is

open or shorted to power supply or ground. BRC-41, "DTC C1122 FR RH IN

ABS SOL"

FR RH OUT ABS SOL

[C1123]

Circuit of front RH OUT ABS solenoid is

open or shorted, or control line

is open or shorted to power supply or ground. BRC-42, "DTC C1123 FR RH

OUT ABS SOL"

RR LH IN ABS SOL

[C1124]Circuit of rear LH IN ABS solenoid is open or shorted, or control line is

open or shorted to power supply or ground. BRC-42, "DTC C1124 RR LH IN

ABS SOL"

RR LH OUT ABS SOL

[C1125] Circuit of rear LH OUT ABS solenoid is open or shorted, or control line

is open or shorted to power supply or ground. BRC-42, "DTC C1125 RR LH

OUT ABS SOL"

RR RH IN ABS SOL

[C1126]

Circuit of rear RH IN ABS solenoid is

open or shorted, or control line is

open or shorted to power supply or ground. BRC-42, "DTC C1126 RR RH IN

ABS SOL"

RR RH OUT ABS SOL

[C1127]Circuit of rear RH OUT ABS solenoid is open or shorted, or control line

is open or shorted to power supply or ground. BRC-42, "DTC C1127 RR RH

OUT ABS SOL"

ENGINE SIGNAL 1

[C1130]Based on the signal from ECM, ABS ac

tuator and electric unit (control

unit) judges that engine fuel cut system is malfunctioning. BRC-42, "DTC C1130 ENGINE

SIGNAL 1"

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1127 of 3924

DI-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION DI

A

B

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................3

DTC INDEX ..................................................... .....3

U1000 - U1010 .................................................... ......3

B2202 - B2205 ..........................................................3

C1B00 - C1B03 .........................................................3

PRECAUTION .....................................................4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

COMBINATION METERS ...................................5

System Description ............................................. ......5

Component Parts and Harness Connector Loca-

tion ............................................................................

8

Arrangement of Combination Meter ..........................9

Circuit Diagram .......................................................10

Wiring Diagram - METER - .....................................11

Terminal and Reference Value for Combination

Meter .......................................................................

13

Terminal and Reference Value for Unified Meter

and A/C Amp ...........................................................

14

Self-Diagnosis Mode of Combination Meter ............14

CONSULT-III Function (METER/M&A) ...................15

Trouble Diagnosis ...................................................15

Symptom Chart .......................................................16

Power Supply and Ground Circuit Inspection .........16

Vehicle Speed Signal Inspection .............................17

Engine Speed Signal Inspection .............................18

Engine Coolant Temperature Signal Inspection ......19

Fuel Level Sensor Signal Inspection .......................19

Fuel Gauge Pointer Fluctuates, Indicator Wrong

Value or Varies ........................................................

21

Fuel Gauge Does Not Move to FULL Position ........21

Odo/Trip Meter and Illumination Control Switch In-

spection ............................................................... ....

21

Electrical Component Inspection .............................21

Removal and Installation of Combination Meter .....22

Disassembly and Assembly of Combination Meter

....

23

Removal and Installation of Odo/Trip Meter and Il-

lumination Control Switch .................................... ....

24

UNIFIED METER AND A/C AMP ......................26

System Description ..................................................26

Schematic ................................................................27

CONSULT-III Function (METER/M&A) ....................27

Power Supply and Ground Circuit Inspection ..........29

DTC [U1000] CAN Communication Circuit ..............30

DTC [B2202] Meter Commun ication Circuit ............30

DTC [B2205] Vehicle Speed Circuit .................... ....32

Removal and Installation of Unified Meter and A/C

Amp .........................................................................

32

WARNING LAMPS ............................................34

System Description .............................................. ....34

Schematic ................................................................35

Wiring Diagram - WARN - .......................................36

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

43

Oil Pressure Warning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

45

Component Inspection .............................................46

A/T INDICATOR ................................................47

System Description ..................................................47

Wiring Diagram - AT/IND - .......................................48

A/T Indicator Is Malfunction .....................................49

WARNING CHIME .............................................51

System Description .............................................. ....51

Component Parts and Harness Connector Loca-

tion ...........................................................................

53

Schematic ................................................................54

Wiring Diagram - CHIME - .......................................55

Terminal and Reference Value for BCM ..................57

Terminal and Reference Value for Unified Meter

and A/C Amp. ...................................................... ....

59

Terminal and Reference Value for Combination

Meter .......................................................................

59

CONSULT-III Function (METER/M&A) ....................60

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1131 of 3924

COMBINATION METERSDI-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

COMBINATION METERS

System DescriptionINFOID:0000000001328433

UNIFIED METER CONTROL UNIT

Speedometer, odo/trip meter, tachometer, fuel gauge and water temperature gauge are controlled by the

unified meter control unit, which is built into the comb ination meter. Unified meter control unit receives sig-

nals from unified meter and A/C amp.

Warning lamp and indicator lamp of combination meter are controlled by signals drawn from the unified meter and A/C amp.

Odo/trip meter, A/T indicator and ICC system disp lay segments can be checked in self-diagnosis mode.

Meters/gauges can be checked in self-diagnosis mode.

UNIFIED METER AND A/C AMP.

Refer to DI-26, "System Description" in “UNIFIED METER AND A/C AMP”.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

through 10A fuse [No. 19, located in the fuse block (J/B)]

to combination meter terminal 8, and

to unified meter and A/C amp. terminal 21.

With the ignition switch in the ON or START position, power is supplied

through 10A fuse [No. 14, located in the fuse block (J/B)]

to combination meter terminal 7,

through 10A fuse [No. 12, located in the fuse block (J/B)]

to unified meter and A/C amp. terminal 22.

With the ignition switch in the ACC or ON position, power is supplied

through 10A fuse [No. 6, located in the fuse block (J/B)]

to combination meter terminal 4,

through 15A fuse [No. 10, located in the fuse block (J/B)], and

through 15A fuse [No. 11, located in the fuse block (J/B)]

to unified meter and A/C amp. terminal 46.

Ground is supplied

to combination meter terminals 5, 6 and 15

through grounds M35, M45 and M85,

to unified meter and A/C amp. terminals 29 and 30

through grounds M35, M45 and M85.

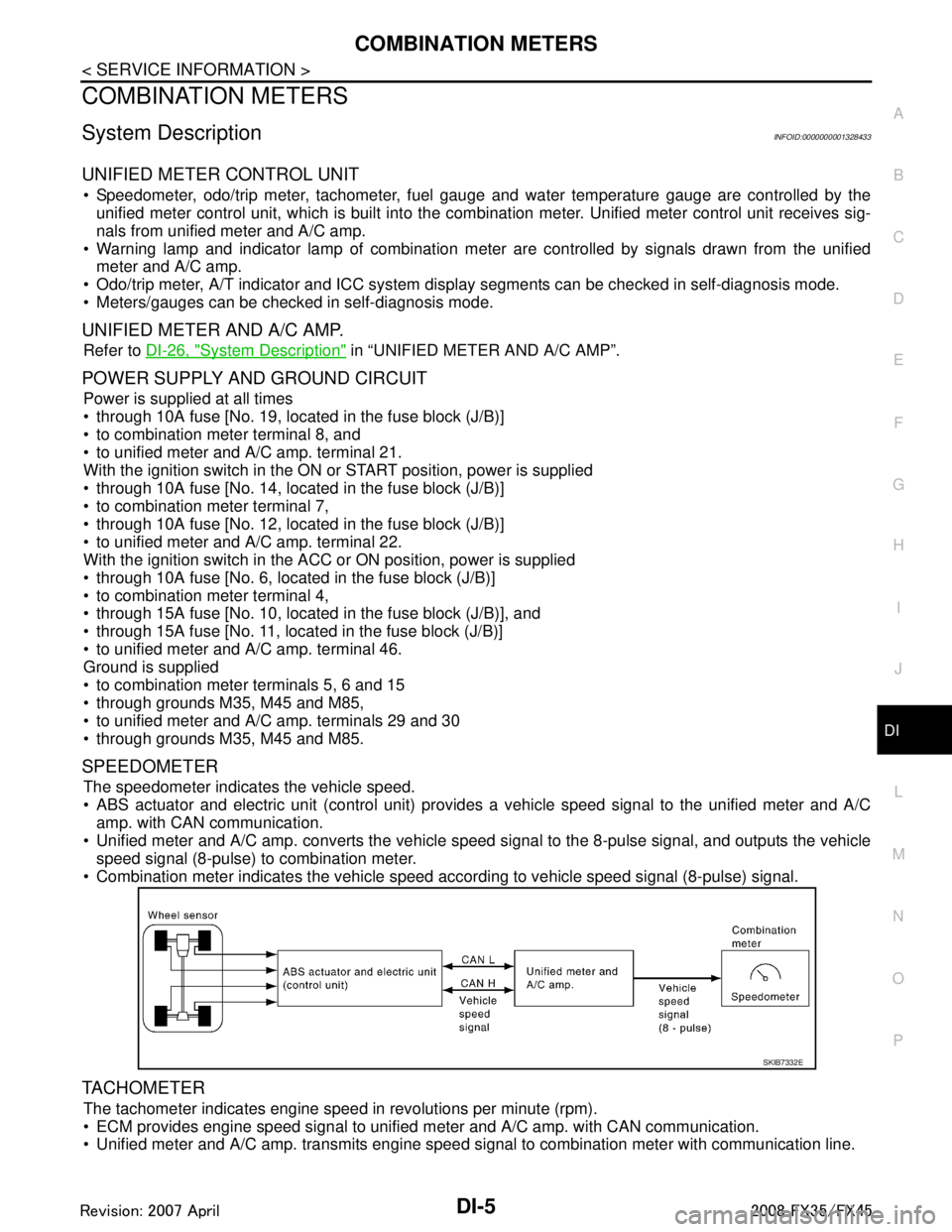

SPEEDOMETER

The speedometer indicates the vehicle speed.

ABS actuator and electric unit (control unit) provides a vehicle speed signal to the unified meter and A/C amp. with CAN communication.

Unified meter and A/C amp. converts the vehicle s peed signal to the 8-pulse signal, and outputs the vehicle

speed signal (8-pulse) to combination meter.

Combination meter indicates the vehicle speed according to vehicle speed signal (8-pulse) signal.

TACHOMETER

The tachometer indicates engine speed in revolutions per minute (rpm).

ECM provides engine speed signal to unified meter and A/C amp. with CAN communication.

Unified meter and A/C amp. transmits engine speed signal to combination meter with communication line.

SKIB7332E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1132 of 3924

DI-6

< SERVICE INFORMATION >

COMBINATION METERS

Combination meter indicates the engine speed according to engine speed signal.

WATER TEMPERATURE GAUGE

The water temperature gauge indicates the engine coolant temperature.

ECM provides engine coolant temperature signal to unified meter and A/C amp. with CAN communication.

Unified meter and A/C amp. transmits engine coolant temperature signal to combination meter with commu-

nication line.

Combination meter indicates the engine coolant temper ature according to engine coolant temperature sig-

nal.

FUEL GAUGE

The fuel gauge indicates the approximate fuel level in the fuel tank.

Unified meter and A/C amp. reads a resistor signal from fuel level sensor.

Signal is supplied- from unified meter and A/C amp. terminal 36

- through the fuel level sensor unit and fuel pump (main) terminals 5 and 2, and

- through the fuel level sensor unit (sub) terminals 2 and 1

- to unified meter and A/C amp. terminal 28 for the fuel gauge.

Unified meter and A/C amp. provides a fuel level signal to combination meter with communication line.

Combination meter indicates the approximate fuel level according to the fuel level signal.

ODO/TRIP METER

ABS actuator and electric unit (control unit) provi des a vehicle speed signal to the unified meter and A/C

amp. with CAN communication.

Unified meter and A/C amp. converts the vehicle s peed signal to the 8-pulse signal, and outputs the vehicle

speed signal (8-pulse) to combination meter.

Combination meter uses the vehicle speed signal (8- pulse) to calculate the mileage, and displays it.

How to Change The Display For Odo/trip Meter

PKIB7631E

PKIB7632E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1133 of 3924

COMBINATION METERSDI-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

Switch modes with following procedure.

When trip transfer switch is pressed, trip meter display changes.

If trip reset switch is pressed for 1 second or more while “trip A” is displayed, only “trip A” is reset.

NOTE:

The record of the odo meter is kept even if the battery cable is dis-

connected. The record of the trip meter is erased when the battery

cable is disconnected.

COMBINATION METER ILLUMINATION CONTROL

Daytime Mode

When ignition switch is turned ON, combination meter il lumination is turned ON by unified meter control unit.

Nighttime Mode

Unified meter control unit is transferred to nighttime mode, with ignitio\

n switch turned ON and position light

request signal from BCM with CAN communication.

When nighttime mode, illumination c ontrol switch illumination turns

ON by unified meter control unit. Each illumination is controlled by

unified meter control unit.

Each illumination can be adjusted to 16 step by illumination control switch in nighttime mode.

NOTE:

For further details of illumination circuit, refer to LT-169, "

System

Description".

FA I L - S A F E

Combination meter performs fail-safe operation when unified meter and A/C amp. communication is malfunc-

tioning.

SKIB8760E

SKIA4817E

SKIA4795E

Function Fail-safe operation

Speedometer

Return to zero.

Tachometer

Fuel gauge

Water temperature gauge

Illumination control Combination meter illumination Change to nighttime mode.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1140 of 3924

DI-14

< SERVICE INFORMATION >

COMBINATION METERS

Terminal and Reference Value for Unified Meter and A/C Amp

INFOID:0000000001328439

Self-Diagnosis Mode of Combination MeterINFOID:0000000001328440

SELF-DIAGNOSIS FUNCTION

Odo/trip meter, A/T indicator and ICC system disp lay segments operation can be checked in self-diagnosis

mode.

Meters/gauges can be checked in self-diagnosis mode.

OPERATION PROCEDURE

1. Turn ignition switch ON, and switch the odo/trip meter to “trip A” or “trip B”. NOTE:

If the self-diagnosis function is activated with the “t rip A” displayed, only “trip A” display is reset.

2. Turn ignition switch OFF.

Te r m i n a l No. Wire

color Item Condition

Reference value

Ignition

switch Operation or condition

1 L CAN-H — — —

9PU TX communication line (To

combination meter) ON —

11 P C A N - L — — —

19 L/B RX communication line (From

combination meter) ON —

21 R/W Battery power supply OFF — Battery voltage

22 W Ignition power supply ON — Battery voltage

26 G Vehicle speed signal

(8-pulse)

ONSpeedometer operated

[When vehicle speed is ap-

prox. 40 km/h (25 MPH)] NOTE:

Maximum voltage may be 5 V due to

specifications (connected units).

28 W/B Fuel level sensor signal — — Refer to

DI-21, "

Electrical Compo-

nent Inspection".

29 B Ground (For power) ON — Approx. 0 V

30 B Ground ON — Approx. 0 V

36 B/W Fuel level sensor ground ON — Approx. 0 V

46 L/W ACC power supply ACC — Battery voltage

SKIA3362E

SKIA3361E

PKIA1935E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1141 of 3924

COMBINATION METERSDI-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

3. Turn ignition switch ON while pressing trip transfer switch and trip reset switch at the same time.

4. After ignition switch is turned ON, release trip transfer switch and trip reset switch (within 7 seconds after the ignition switch is

turned ON).

5. All the segments on the odo/trip meter, A/T indi cator and ICC system display illuminates, and simulta-

neously the low-fuel warning lamp indicator illuminates. At this time, the unified meter control unit is turned

to self-diagnosis mode.

NOTE:

Check odo/trip meter switch and combination meter power supply and ground circuit when self-diagno-

sis mode of combination meter does not start. Replace combination meter if the results of the check are

normal.

If any of the segments are not disp layed, replace combination meter.

6. Each meter/gauge activates during pressing trip reset switch. (Then low-fuel warning lamp turns OFF.)

NOTE:

If any of the meters/gauges are not activated, replace thecombination meter.

The figure is reference.

CONSULT-III Function (METER/M&A)INFOID:0000000001328441

Refer to DI-27, "CONSULT-III Function (METER/M&A)" in “UNIFIED METER AND A/C AMP”.

Trouble DiagnosisINFOID:0000000001328442

HOW TO PERFORM TROUBLE DIAGNOSIS

1. Confirm the symptom or customer complaint.

2. Perform preliminary check. Refer to "PRELIMINARY CHECK".

3. According to the symptom chart, repair or replace the cause of the symptom. Refer to DI-16, "

Symptom

Chart".

4. Does the meter operate normally? If so, GO TO 5. If not, GO TO 2.

5. INSPECTION END

PRELIMINARY CHECK

1.CHECK OPERATION OF SELF-DIAGNOSIS MODE (COMBINATION METER)

SKIA4817E

SKIA6170E

SKIA4831E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C