suspension INFINITI FX35 2008 Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2723 of 3924

![INFINITI FX35 2008 Owners Manual

ENGINE ASSEMBLYEM-239

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

10. Disconnect steering lower joint at power steering gear

assembly side, and release steering lower shaft.

Ref INFINITI FX35 2008 Owners Manual

ENGINE ASSEMBLYEM-239

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

10. Disconnect steering lower joint at power steering gear

assembly side, and release steering lower shaft.

Ref](/img/42/57017/w960_57017-2722.png)

ENGINE ASSEMBLYEM-239

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

10. Disconnect steering lower joint at power steering gear

assembly side, and release steering lower shaft.

Refer to PS-12, "

Removal and Installation".

11. Remove rear propeller shaft. Refer to PR-7, "

On-Vehicle Inspection".

After disconnection, plug the opening on transmission side.

12. Remove front drive shaft (both side). Refer to FAX-13, "

On-Vehicle Inspection".

13. Remove front propeller shaft. Refer to PR-4, "

On-Vehicle Inspection".

14. Remove three way catalyst (both bank). Refer to EM-179, "

Component".

Removal Work

1. Install engine slingers into front of cylinder head (left bank) and

front of cylinder head (right bank).

2. Lift with hoist and secure engine in position.

3. Use manual lift table caddy (commercial service tool) or equivalently rigid tool such as transmission jack. Securely support bottom of suspension member and transmission.

CAUTION:

Put a piece of wood or something similar as the supporting surface, secure a completely stable

condition.

4. Remove engine rear member mounting bolts.

5. Remove front suspension member mounting nuts with power tool. Refer to FSU-5, "

On-Vehicle Inspection

and Service".

6. Carefully lower jack, or raise lift to remove engine, transmission front final drive and front suspension member assembly. When

performing work, observe the following caution:

CAUTION:

Confirm there is no interference with vehicle.

Make sure that all connectio n points have been discon-

nected.

Keep in mind the center of veh icle gravity changes. If nec-

essary, use jack(s) to support vehicle at rear jacking

point(s) to prevent it from falling it off the lift.

Separation Work

1. Change engine slinger installing to cylinder head (right bank).

NOTE:

In order to keep secure position when hoisting engine.

2. Remove engine mounting insulators (RH and LH) under side nut with power tool.

3. Lift with hoist and separate engine and transmission assembly from front suspension member. CAUTION:

Before and during this lifting, always make sure that any harnesses are left connected.

Slinger bolts:

: 33.4 N·m (3.4 kg-m, 25 ft-lb)

PBIC1556E

PBIC1557E

Slinger bolts: : 33.4 N·m (3.4 kg-m, 25 ft-lb)

PBIC2447E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2726 of 3924

![INFINITI FX35 2008 Owners Manual

EM-242

< SERVICE INFORMATION >[VK45DE]

CYLINDER BLOCK

Refer to

GI-8, "Component" for symbols in the figure.

Disassembly and AssemblyINFOID:0000000001325804

DISASSEMBLY

NOTE:

Explained here is how INFINITI FX35 2008 Owners Manual

EM-242

< SERVICE INFORMATION >[VK45DE]

CYLINDER BLOCK

Refer to

GI-8, "Component" for symbols in the figure.

Disassembly and AssemblyINFOID:0000000001325804

DISASSEMBLY

NOTE:

Explained here is how](/img/42/57017/w960_57017-2725.png)

EM-242

< SERVICE INFORMATION >[VK45DE]

CYLINDER BLOCK

Refer to

GI-8, "Component" for symbols in the figure.

Disassembly and AssemblyINFOID:0000000001325804

DISASSEMBLY

NOTE:

Explained here is how to disassemble with engine stand supporting transmission surface. When using differ-

ent type of engine stand, note with difference in steps and etc.

1. Remove engine assembly from vehicle, and separa te front suspension member, transmission and front

final drive from engine. Refer to EM-237, "

Component".

2. Remove the parts that may restrict installation of engine to widely use engine stand. NOTE:

The procedure is described assuming that you use wi dely use engine holding the surface, to which trans-

mission is installed.

a. Remove drive plate. Holding ring gear with ring gear stopper (SST).

Loosen mounting bolts diagonally order.

CAUTION:

Do not disassemble drive plate.

Do not place drive plate with signal plate facing down.

When handling signal plate, take care not to damage or scratch it.

Handle signal plate in a manner that prevents it from becoming magnetized.

b. Remove engine rear plate.

3. Lift engine with hoist to install it onto widely use engine stand. CAUTION:

Use engine stand that has a load capacity [approximately 240 kg ( 529 lb) or more] large enough for

supporting the engine weight.

If the load capacity of stand is not adequate, remo ve the following parts beforehand to reduce the poten-

tial risk of overturning stand.

- Intake manifolds (upper and lower): Refer to EM-175, "

Component".

- Exhaust manifold: Refer to EM-179, "

Component".

- Fuel tube and fuel injector assembly: Refer to EM-190, "

Component".

22. Main bearing 23. Rear plate 24. Crankshaft

25. Pilot converter 26. Drive plate 27. Thrust bearing

28. Side bolt 29. Reinforcement plate 30. Crankshaft position sensor (POS)

31. O-ring 32. Rear oil seal 33. Rear oil seal retainer

A.Refererence: Installed on transmis-

sion B. Refer to

EM-242

C. Right bank

D. Cylinder block heater (For Canada) E. Chamfered F. Crankshaft side : Engine front

PBIC1656E

PBIC2367E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2775 of 3924

![INFINITI FX35 2008 Owners Manual

FAX-10

< SERVICE INFORMATION >[AWD]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000001327512

Use cha INFINITI FX35 2008 Owners Manual

FAX-10

< SERVICE INFORMATION >[AWD]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000001327512

Use cha](/img/42/57017/w960_57017-2774.png)

FAX-10

< SERVICE INFORMATION >[AWD]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000001327512

Use chart below to help you find the cause of the symp tom. If necessary, repair or replace these parts.

×: ApplicableReference page

—

FA X - 1 8—

FAX-11—

FAX-11

NVH in FFD section

NVH in FAX and FSU section

Refer to FRONT AXLE in this chart. NVH in WT section

NVH in WT section

Refer to DRIVE SHAFT in this chart. NVH in BR sectionNVH in PS section

Possible cause and SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

Wheel bearing damage

FRONT DIFFERENTIAL

FRONT AXLE AND FRONT SUSPENSION

FRONT AXLE

TIRE

ROAD WHEEL

DRIVE SHAFT

BRAKE

STEERING

Symptom DRIVE

SHAFT

Noise

×× ×××××× ××

Shake ×× ×××××××

FRONT

AXLE Noise

×××× ××××××

Shake ××× ××××××

Vibration ××× ××××

Shimmy ×× ××× ××

Judder × ××× ××

Poor quality ride or handling ×× ×××

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2797 of 3924

FFD-6

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000001327479

Use the chart below to help you find the cause of the sy mptom. If necessary, repair or replace these parts.

×: ApplicableReference page

Refer to

FFD-17, "

Disassembly and Assembly

".

Refer to FFD-17, "

Disassembly and Assembly

".

Refer to FFD-17, "

Disassembly and Assembly

".

Refer to FFD-17, "

Disassembly and Assembly

".

Refer to FFD-17, "

Disassembly and Assembly

".

Refer to FFD-8, "

Checking Differential Gear Oil

".

NVH in PR section.

NVH in FAX, RAX, FSU and RSU sections.

NVH in WT section.

NVH in WT section.

NVH in FAX and RAX section.

NVH in BR section.

NVH in PS section.

Possible cause and SUSPECTED PARTS

Gear tooth rough

Gear contact improper

Tooth surfaces worn

Backlash incorrect

Companion flange excessive runout

Gear oil improper

PROPELLER SHAFT

AXLE AND SUSPENSION

TIRE

ROAD WHEEL

DRIVE SHAFT

BRAKE

STEERING

Symptom Noise ×××××××××××××

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2805 of 3924

FFD-14

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

FRONT FINAL DRIVE ASSEMBLY

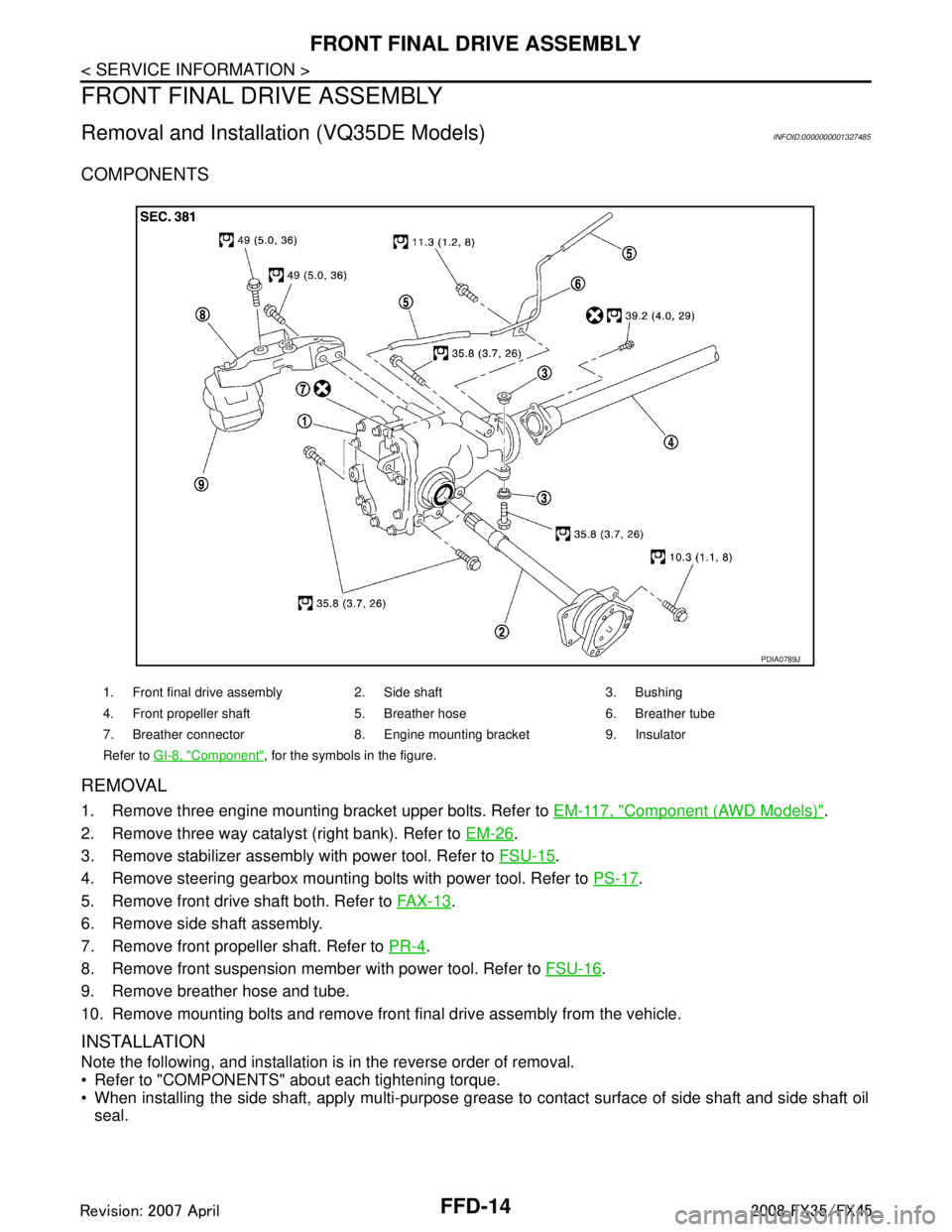

Removal and Installation (VQ35DE Models)INFOID:0000000001327485

COMPONENTS

REMOVAL

1. Remove three engine mounting bracket upper bolts. Refer to EM-117, "Component (AWD Models)".

2. Remove three way catalyst (right bank). Refer to EM-26

.

3. Remove stabilizer assembly with power tool. Refer to FSU-15

.

4. Remove steering gearbox mounting bolts with power tool. Refer to PS-17

.

5. Remove front drive shaft both. Refer to FA X - 1 3

.

6. Remove side shaft assembly.

7. Remove front propeller shaft. Refer to PR-4

.

8. Remove front suspension member with power tool. Refer to FSU-16

.

9. Remove breather hose and tube.

10. Remove mounting bolts and remove front final drive assembly from the vehicle.

INSTALLATION

Note the following, and installation is in the reverse order of removal.

Refer to "COMPONENTS" about each tightening torque.

When installing the side shaft, apply multi-purpose grease to contact surface of side shaft and side shaft oil

seal.

1. Front final drive assembly 2. Side shaft 3. Bushing

4. Front propeller shaft 5. Breather hose 6. Breather tube

7. Breather connector 8. Engine mounting bracket 9. Insulator

Refer to GI-8, "

Component", for the symbols in the figure.

PDIA0789J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2807 of 3924

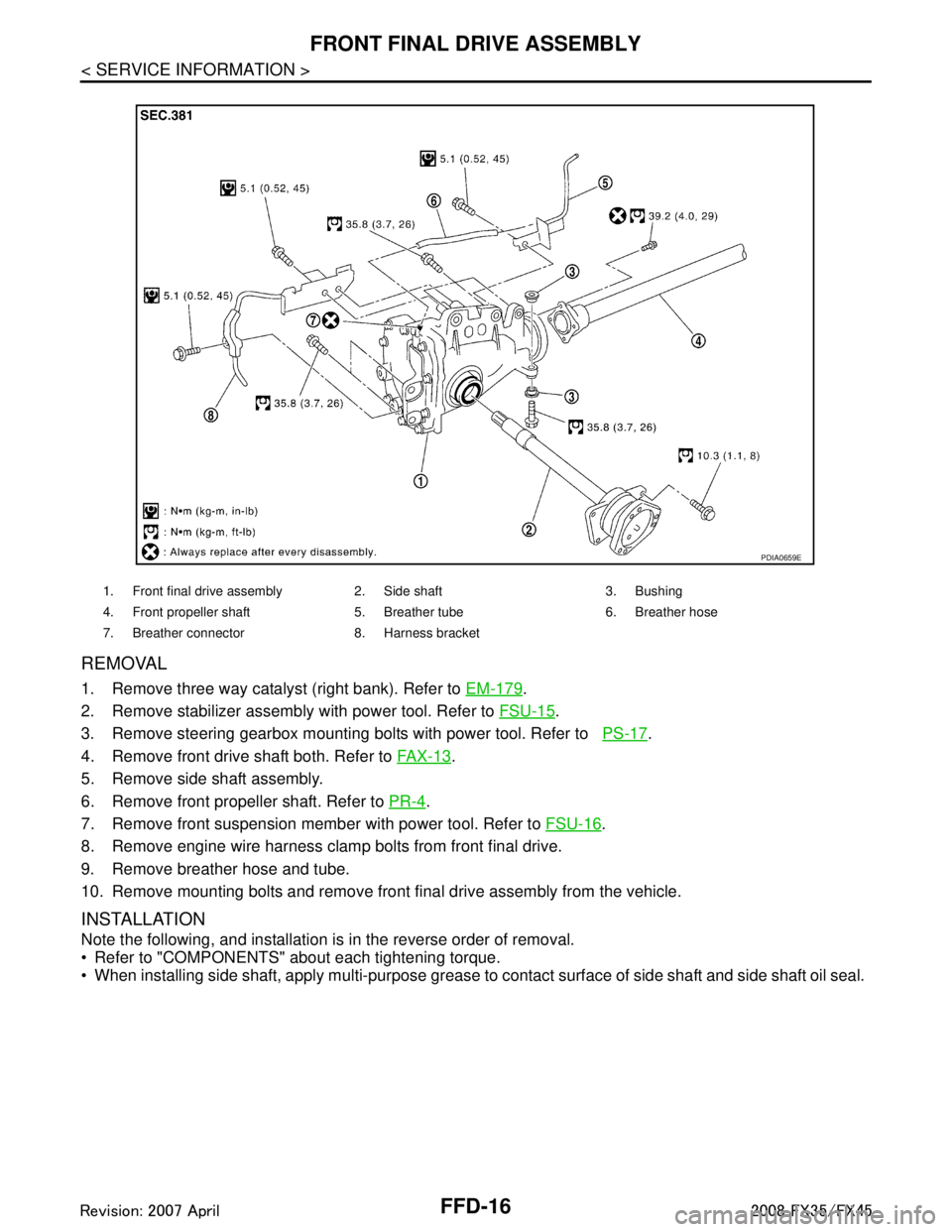

FFD-16

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

REMOVAL

1. Remove three way catalyst (right bank). Refer to EM-179.

2. Remove stabilizer assembly with power tool. Refer to FSU-15

.

3. Remove steering gearbox mounting bolts with power tool. Refer to PS-17

.

4. Remove front drive shaft both. Refer to FA X - 1 3

.

5. Remove side shaft assembly.

6. Remove front propeller shaft. Refer to PR-4

.

7. Remove front suspension member with power tool. Refer to FSU-16

.

8. Remove engine wire harness clamp bolts from front final drive.

9. Remove breather hose and tube.

10. Remove mounting bolts and remove front final drive assembly from the vehicle.

INSTALLATION

Note the following, and installation is in the reverse order of removal.

Refer to "COMPONENTS" about each tightening torque.

When installing side shaft, apply multi-purpose grease to contact surface of side shaft and side shaft oil seal.

1. Front final drive assembly 2. Side shaft 3. Bushing

4. Front propeller shaft 5. Breather tube 6. Breather hose

7. Breather connector 8. Harness bracket

PDIA0659E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2842 of 3924

FL-10

< SERVICE INFORMATION >

FUEL TANK

FUEL TANK

ComponentINFOID:0000000001327110

Removal and InstallationINFOID:0000000001327111

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on the fuel system. Refer to FL-3, "

General Pre-

caution".

Drain fuel from fuel tank if necessary. Refer to FL-4, "

Removal and Installation".

Perform work on level place.

1. Perform steps 2 to 7 of “REMOVAL” in “ FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP

ASSEMBLY” on main and sub fuel level sensor units. Refer to FL-4, "

Removal and Installation".

2. Remove tunnel stay. Refer to RSU-5, "

On-Vehicle Inspection and Service".

3. Remove exhaust front tube, center muffler and main muffler. Refer to EX-3, "

Checking Exhaust System".

4. Remove insulator.

5. Remove propeller shaft. Refer to PR-7, "

On-Vehicle Inspection".

6. Remove parking rear brake cables. Refer to PB-4, "

Component".

7. Compress coil spring and remove coil spring.

8. Remove rear suspension assembly.

9. Remove fuel tank protector.

1. Grommet 2. Fuel filler cap 3. Clip

4. Fuel filler tube protector 5. Fuel tank mounting band 6. Fuel tank protector

7. Insulator 8. Fuel tank 9. Vent tube

10. Vent hose 11. EVAP hose 12. Vent hose

13. Fuel filler hose 14. Fuel filler tube

PBIC1580E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2845 of 3924

FSU-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION FSU

A

B

FSU

N

O PCONTENTS

FRONT SUSPENSION

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Caution ................................................................ ......2

PREPARATION ...................................................3

Special Service Tool ........................................... ......3

Commercial Service Tool ..........................................3

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

4

NVH Troubleshooting Chart ................................ ......4

FRONT SUSPENSION ASSEMBLY ...................5

On-Vehicle Inspection and Service ..................... ......5

Wheel Alignment Inspection ......................................5

Removal and Installation ...........................................6

COIL SPRING AND STRUT ..............................10

Removal and Installation ..................................... ....10

Disassembly and Assembly .....................................11

TRANSVERSE LINK .........................................13

Removal and Installation ..................................... ....13

STABILIZER BAR .............................................15

Removal and Installation .........................................15

FRONT SUSPENSION MEMBER .....................16

Removal and Installation .........................................16

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

17

Wheel Alignment (Unladen*) ...................................17

Ball Joint ..................................................................17

Wheelarch Height (Unladen*) ..................................17

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2846 of 3924

FSU-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

CautionINFOID:0000000001327533

• When installing rubber bushings, final tightening must be carried out under unladen conditions with tires on

ground. Oil will shorten the life of rubber bushings. Be sure to wipe off any spilled oil.

Unladen conditions mean that fuel, engine coolant and l ubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

After servicing suspension parts, be sure to check wheel alignment.

Caulking nuts are not reusable. Always use new ones w hen installing. Since new caulking nuts are pre-oiled,

tighten as they are.

Avoid burden to front cross bar.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2848 of 3924

FSU-4

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000001327536

Use chart below to help you find the cause of the symp tom. If necessary, repair or replace these parts.

×: ApplicableReference page

FSU-6FSU-11

—

—

—

FSU-6FSU-5FSU-15

NVH in PR section

NVH in RFD section

NVH in FAX and FSU section

NVH in WT section

NVH in WT section

NVH in FAX section NVH in BR sectionNVH in PS section

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Strut deformation, damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

Stabilizer bar fatigue

PROPELLER SHAFT (For AWD models)

DIFFERENTIAL (For AWD models)

FRONT AXLE AND FRONT SUSPENSION

TIRE

ROAD WHEEL

DRIVE SHAFT (For AWD models)

BRAKE

STEERING

Symptom FRONT SUSPENSION Noise

××××× × ××× ×××××

Shake ×××× × × × ×××××

Vibration ××××× × ×× × ×

Shimmy ×××× × ××× ××

Judder ××× ××× ××

Poor quality ride or han-

dling ×× × × × ×× × × ×

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C