tow INFINITI FX35 2008 Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1220 of 3924

DI-94

< SERVICE INFORMATION >

COMPASS

COMPASS

Precaution for CompassINFOID:0000000001328520

NOTE:

Do not install the ski rack, antenna, etc. which is attach to the vehicle with a magnet base. It affects the oper-

ation of the compass.

When cleaning the mirror, use a paper towel or similar material dampened with glass cleaner. Do not spray glass cleaner directly on the mirror as it may c ause the liquid cleaner to enter the mirror housing.

System DescriptionINFOID:0000000001328521

This electronic compass is able to display 8 primary directions: N, NE, E, SE, S, SW, W, NW.

The inside mirror switch (2) is used to operate the compass and

automatic anti-glare system.

Switch Operation

NOTE:

For further details of the compass and automatic anti-glare system, refer to Owner's Manual

All standard compasses determine direction relative to Magnetic North; however, this electronic compass is

designed to display direction relative to True North.

The difference between Magnetic North and True North varies from place to place across the surface of the

earth.

This electronic compass must be “told” approximately w here it is on the earth’s surface so that the Magnetic

North reading can be properly converted into a True North display.

To tell the electronic compass where it’s at, the earth is separated into numbered “Zone Variances”. The

Zone Variance number in which the compass is to function must be entered into this electronic compass.

Each zone is magnetically about 4.2 ° wide. Typically, anything under 22.5 ° total zone change is not noticed

on the electronic compass display. However, over 22.5 °, a reading may be off by one or more primary direc-

tions.

On long trips, a vehicle may leave its original zone and enter one or more new zones. Generally, you do not need to reset the compass zone if you travel between 3 or 4 zones, such as business travel or vacation. The

typical driver will not notice any difference on the display within 3 or 4 zones. However, if the vehicle is “per-

manently” moved to a new location, it is recommended that the compass zone be reset.

TroubleshootingINFOID:0000000001328522

The electronic compass is highly protected from changes in most magnetic fields. However, some large changes in magnetic fields can affect it. Some examples are (but not limited to): high tension power lines,

large steel buildings, subways, steel bridges, automatic car washes, large piles of scrap metal, etc. While

this does not happen very often, it is possible.

1. Compass display

2. Inside mirror switch

SKIB8487E

Press Compass is turned ON/OFF

Press and hold

(for 3 – 6 sec.) Automatic anti-glare system turns ON/OFF

Press and hold

(for 6 – 9 sec.) Compass display turns to zone variation change

mode

Press and hold

(for more than 9 sec.) Compass display turns to calibration mode

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1233 of 3924

REAR VIEW MONITORDI-107

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

DATA MONITOR

Side Distance Guideline CorrectionINFOID:0000000001328535

This mode is used to modify the side distance guidelines if they are dislocated from the rear view monitor

image, because of variations of body/camera mounting conditions.

SIDE DISTANCE GUIDELINE CORRECTION PROCEDURE

1. Create a correction line to modify the screen.

Draw lines on the rearward of the vehicle passing through the

following points: 0.25 m (9.84 in) from both sides of the vehicle,

and 0.5 m (1.64 ft), 1 m (3.28 ft), 2 m (6.56 ft), and 3 m (9.84 ft)

from the rear end of the bumper.

2. Select “REARVIEW CAMERA” on CONSULT-III. CAUTION:

Stop engine for the safety when correcting side distance guideline.

3. Shift A/T selector lever to R position.

4. Select “SELCT GUIDELINE PATTERN”.

5. Select “UP” or “DOWN”, and select the guide line, “PATTERN NO. 0” or “PATTERN NO. 1”, which is the

closest to the corrected line.

SELCT GUIDELINE PATTERN Side distance guideline is optional from two patterns.

ADJ GUIDELINE POSITION Side distance guideline is adjustable toward up and down, right and left.

Display item [Unit] ALL

SIGNALS SELECTION

FROM MENU Contents

R POSI SIG [On/Off] X X Indicates [On/Off] condition of R range position signal input.

SKIB4106E

SKIA6103E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2483 of 3924

EI-46

< SERVICE INFORMATION >

LUGGAGE FLOOR TRIM

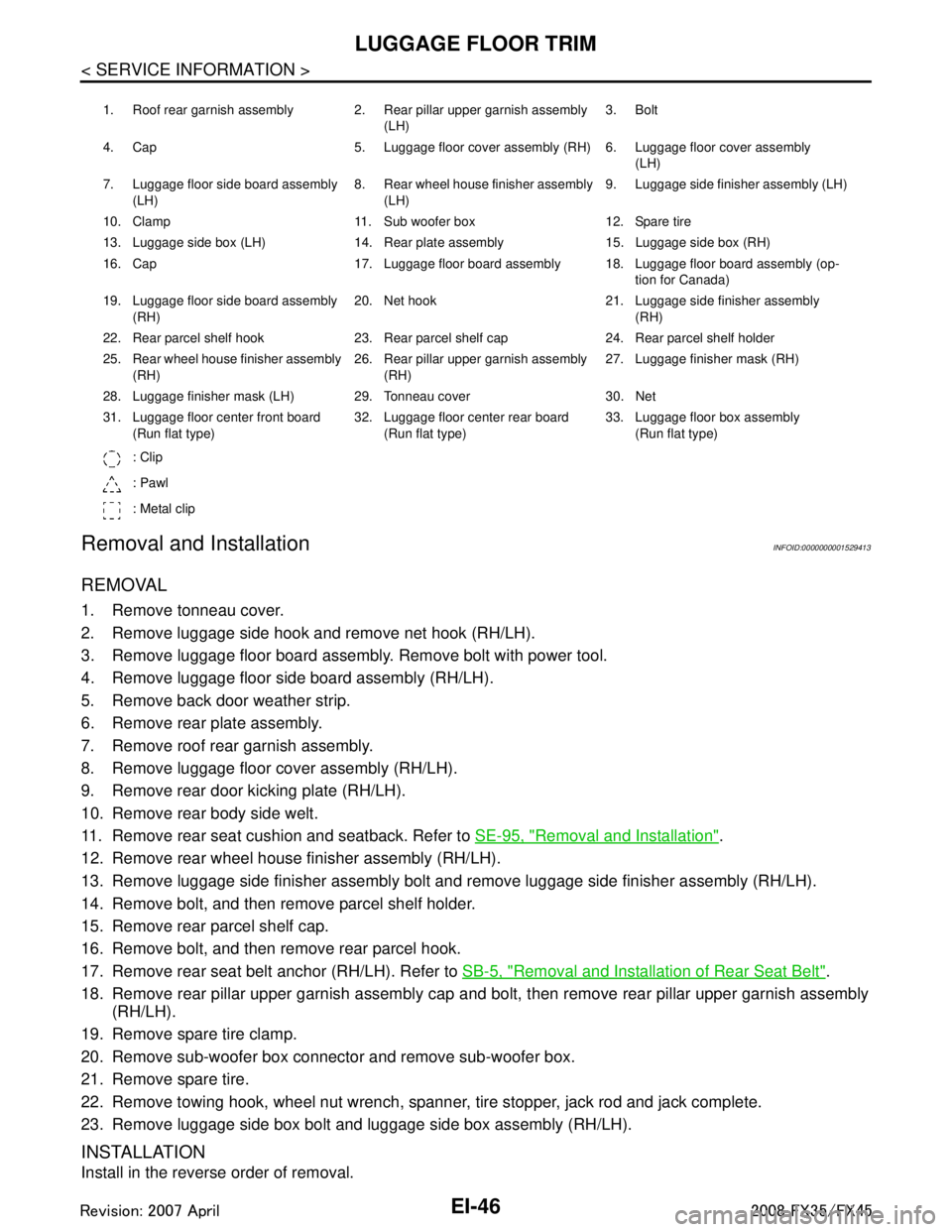

Removal and Installation

INFOID:0000000001529413

REMOVAL

1. Remove tonneau cover.

2. Remove luggage side hook and remove net hook (RH/LH).

3. Remove luggage floor board assembly. Remove bolt with power tool.

4. Remove luggage floor side board assembly (RH/LH).

5. Remove back door weather strip.

6. Remove rear plate assembly.

7. Remove roof rear garnish assembly.

8. Remove luggage floor cover assembly (RH/LH).

9. Remove rear door kicking plate (RH/LH).

10. Remove rear body side welt.

11. Remove rear seat cushion and seatback. Refer to SE-95, "

Removal and Installation".

12. Remove rear wheel house finisher assembly (RH/LH).

13. Remove luggage side finisher assembly bolt and remove luggage side finisher assembly (RH/LH).

14. Remove bolt, and then remove parcel shelf holder.

15. Remove rear parcel shelf cap.

16. Remove bolt, and then remove rear parcel hook.

17. Remove rear seat belt anchor (RH/LH). Refer to SB-5, "

Removal and Installation of Rear Seat Belt".

18. Remove rear pillar upper garnish assembly cap and bolt, then remove rear pillar upper garnish assembly (RH/LH).

19. Remove spare tire clamp.

20. Remove sub-woofer box connector and remove sub-woofer box.

21. Remove spare tire.

22. Remove towing hook, wheel nut wrench, spanner, tire stopper, jack rod and jack complete.

23. Remove luggage side box bolt and luggage side box assembly (RH/LH).

INSTALLATION

Install in the reverse order of removal.

1. Roof rear garnish assembly 2. Rear pillar upper garnish assembly (LH)3. Bolt

4. Cap 5. Luggage floor cover assembly (RH) 6. Luggage floor cover assembly (LH)

7. Luggage floor side board assembly (LH) 8. Rear wheel house finisher assembly

(LH) 9. Luggage side finisher assembly (LH)

10. Clamp 11. Sub woofer box 12. Spare tire

13. Luggage side box (LH) 14. Rear plate assembly 15. Luggage side box (RH)

16. Cap 17. Luggage floor board assembly 18. Luggage floor board assembly (op- tion for Canada)

19. Luggage floor side board assembly (RH) 20. Net hook 21. Luggage side finisher assembly

(RH)

22. Rear parcel shelf hook 23. Rear parcel shelf cap 24. Rear parcel shelf holder

25. Rear wheel house finisher assembly (RH) 26. Rear pillar upper garnish assembly

(RH) 27. Luggage finisher mask (RH)

28. Luggage finisher mask (LH) 29. Tonneau cover 30. Net

31. Luggage floor center front board (Run flat type) 32. Luggage floor center rear board

(Run flat type) 33. Luggage floor box assembly

(Run flat type)

: Clip

: Pawl

: Metal clip

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2778 of 3924

![INFINITI FX35 2008 Owners Manual

FRONT DRIVE SHAFTFAX-13

< SERVICE INFORMATION > [AWD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

FRONT DRIVE SHAFT

On-Vehicle InspectionINFOID:0000000001327515

Check drive shaft mounting point and joint for INFINITI FX35 2008 Owners Manual

FRONT DRIVE SHAFTFAX-13

< SERVICE INFORMATION > [AWD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

FRONT DRIVE SHAFT

On-Vehicle InspectionINFOID:0000000001327515

Check drive shaft mounting point and joint for](/img/42/57017/w960_57017-2777.png)

FRONT DRIVE SHAFTFAX-13

< SERVICE INFORMATION > [AWD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

FRONT DRIVE SHAFT

On-Vehicle InspectionINFOID:0000000001327515

Check drive shaft mounting point and joint for looseness and other damage.

Check boot for cracks and other damage. CAUTION:

Replace entire drive shaft assembly when noi se or vibration occur from drive shaft.

DRIVE SHAFT BOOT REPLACEMENT

1. Remove tires from vehicle with power tool.

2. Remove undercover with power tool.

3. Remove cotter pin. Then remove lock nut from drive shaft with power tool.

4. Remove wheel sensor harness fr om strut assembly. Refer to BRC-52

.

CAUTION:

Do not pull on wheel sensor harness.

5. Remove brake hose lock plate. Then remove brake hose from strut assembly. Refer to BR-10

.

6. Remove fixing bolts and nuts between strut assembly and steering knuckle with power tool.

7. Remove drive shaft from wheel hub and bearing assembly.

8. Using a puller (suitable tool), remove drive shaft from steering knuckle.

CAUTION:

When removing drive shaf t, do not apply an excessive

angle to drive shaft joint. Al so be careful not to excessively

extend slide joint.

9. Remove boot bands, and then remove boot from joint sub-assembly.

10. Screw a drive shaft puller (suitable tool) into joint sub-assembly screw part to a length of 30 mm (1.18 in) or more. Support drive

shaft with one hand and pull out joint sub-assembly with a slid-

ing hammer (suitable tool) from shaft.

CAUTION:

• Align a sliding hammer and drive shaft and remove them

by pulling firmly and uniformly.

If joint sub-assembly cannot be pulled out, try after

removing drive shaft from vehicle.

11. Remove the circular clip from shaft.

12. Remove boot from shaft.

13. Clean the old grease on joint sub-assembly with paper towels.

SDIA0972J

SDIA0881J

SDIA2489E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2784 of 3924

![INFINITI FX35 2008 Owners Manual

FRONT DRIVE SHAFTFAX-19

< SERVICE INFORMATION > [AWD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

4. Put matching marks on spider assembly and shaft. CAUTION:

Use paint for matching mark, but don’t damage to INFINITI FX35 2008 Owners Manual

FRONT DRIVE SHAFTFAX-19

< SERVICE INFORMATION > [AWD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

4. Put matching marks on spider assembly and shaft. CAUTION:

Use paint for matching mark, but don’t damage to](/img/42/57017/w960_57017-2783.png)

FRONT DRIVE SHAFTFAX-19

< SERVICE INFORMATION > [AWD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

4. Put matching marks on spider assembly and shaft. CAUTION:

Use paint for matching mark, but don’t damage to spider

assembly and drive shaft.

5. Remove snap ring, then remove spider assembly from shaft.

6. Remove boot from shaft.

7. Remove old grease on slide joint assembly with paper towels.

Wheel Side

1. Place drive shaft in a vice. CAUTION:

When retaining drive shaft in a vice, always u se copper or aluminum plates between a vise and

shaft.

2. Remove boot bands. Then remove boot from joint sub-assembly.

3. Screw a drive shaft puller (suitable tool) 30 mm (1.18 in) or more into threaded part of joint sub-assembly. Pull joint sub-assembly

out of shaft.

CAUTION:

If joint sub-assembly cannot be removed after five ormore unsuccessful attempts, replace shaft and joint sub-

assembly as a set.

Align sliding hammer and drive shaft and remove them by

pulling directly.

4. Remove boot from shaft.

5. Remove circular clip from shaft.

6. While rotating ball cage, remove old grease on joint sub-assem- bly with paper towels.

INSPECTION AFTER DISASSEMBLY

Shaft

Replace shaft if there is any runout, cracking, or other damage.

Joint Sub-Assembly

Make sure there is no rough rotation or unusual axial looseness.

Make sure there is no foreign material inside joint sub-assembly.

Check joint sub-assembly for compression scar, cracks or fractures.

CAUTION:

If there are any irregular conditions of joint sub-assembly components, replace the entire joint sub-

assembly.

Slide Joint Side

Housing and spider assembly

If roller or roller surface of spider assembly has scratch or wear, replace housing and spider assembly.

NOTE:

SFA963

SFA612

SDIA0606E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2787 of 3924

![INFINITI FX35 2008 Owners Manual

FAX-22

< SERVICE INFORMATION >[AWD]

FRONT DRIVE SHAFT

DISASSEMBLY

Front Final Drive Assembly Side

1. Press drive shaft in a vice.

CAUTION:

When retaining drive shaft in a vice, always u se copper or INFINITI FX35 2008 Owners Manual

FAX-22

< SERVICE INFORMATION >[AWD]

FRONT DRIVE SHAFT

DISASSEMBLY

Front Final Drive Assembly Side

1. Press drive shaft in a vice.

CAUTION:

When retaining drive shaft in a vice, always u se copper or](/img/42/57017/w960_57017-2786.png)

FAX-22

< SERVICE INFORMATION >[AWD]

FRONT DRIVE SHAFT

DISASSEMBLY

Front Final Drive Assembly Side

1. Press drive shaft in a vice.

CAUTION:

When retaining drive shaft in a vice, always u se copper or aluminum plates between a vise and

shaft.

2. Remove boot bands.

3. Put matching marks on spider assembly and shaft. CAUTION:

Use paint for matching mark, but don’t damage to spider

assembly and shaft.

4. Remove snap ring, then remove spider assembly from shaft.

5. Remove boot from shaft.

6. Remove old grease on slide joint assembly with paper towels.

1. Joint sub-assembly 2. Circular clip 3. Boot band

4. Boot 5. Shaft 6. Spider assembly

7. Snap ring 8. Housing 9. Dust shield

10. Circular clip

Refer to GI-8, "

Component" and the following for the symbols in the figure.

: Fill NiSSAN genuine grease or equivalent.

PDIA1221E

SFA963

SFA612

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2788 of 3924

![INFINITI FX35 2008 Owners Manual

FRONT DRIVE SHAFTFAX-23

< SERVICE INFORMATION > [AWD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

Wheel Side

1. Place drive shaft in a vice.

CAUTION:

When retaining drive shaft in a vice, always u se copper or INFINITI FX35 2008 Owners Manual

FRONT DRIVE SHAFTFAX-23

< SERVICE INFORMATION > [AWD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

Wheel Side

1. Place drive shaft in a vice.

CAUTION:

When retaining drive shaft in a vice, always u se copper or](/img/42/57017/w960_57017-2787.png)

FRONT DRIVE SHAFTFAX-23

< SERVICE INFORMATION > [AWD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

Wheel Side

1. Place drive shaft in a vice.

CAUTION:

When retaining drive shaft in a vice, always u se copper or aluminum plates between vise a and

shaft.

2. Remove boot bands. Then remove boot from joint sub-assembly.

3. Screw a drive shaft puller (suitable tool) 30 mm (1.18 in) or more into threaded part of joint sub-assembly. Pull joint sub-assembly

out of shaft.

CAUTION:

If joint sub-assembly cannot be removed after five ormore unsuccessful attempts, replace shaft and joint sub-

assembly as a set.

Align sliding hammer and drive shaft and remove them by

pulling directly.

4. Remove boot from shaft.

5. Remove circular clip from shaft.

6. While rotating ball cage, remove old grease on joint sub-assem- bly with paper towels.

INSPECTION AFTER DISASSEMBLY

Shaft

Replace shaft if there is any runout, cracking, or other damage.

Joint Sub-Assembly

Make sure there is no rough rotation or unusual axial looseness.

Make sure there is no foreign material inside joint sub-assembly.

Check joint sub-assembly for compression scar, cracks or fractures.

If there are any irregular conditions of joint sub-asse mbly components, replace the entire joint sub-assembly.

Slide Joint Side

Housing and spider assembly

If roller or roller surface of spider assembly has scratch or wear, replace housing and spider assembly.

NOTE:

Housing and spider assembly are components which are used as a set.

ASSEMBLY

Front Final Drive Assembly Side

1. Wind serrated part of drive s haft with tape. Install boot band and

boot to shaft. Be careful not to damage boot.

NOTE:

Discard old boot band and boot; replace with each new one.

2. Remove protective tape wound around serrated part of shaft.

SDIA0606E

SFA800

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2863 of 3924

GI-1

GENERAL INFORMATION

C

DE

F

G H

I

J

K L

M B

GI

SECTION GI

N

O P

CONTENTS

GENERAL INFORMATION

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Description .......................................................... ......2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

2

Precaution for Procedure without Cowl Top Cover ......3

General Precaution ...................................................3

Precaution for Three Way Catalyst ...........................4

Precaution for Fuel (Unleaded Premium Gasoline

Recommended) .........................................................

5

Precaution for Fuel (Unleaded Premium Gasoline

Required) ..................................................................

5

Precaution for Multiport Fuel Injection System or

Engine Control System .............................................

5

Precaution for Hoses .................................................5

Precaution for Engine Oils ........................................6

Precaution for the Environment .................................7

Precaution for Air Conditioning .................................7

HOW TO USE THIS MANUAL ............................8

Description .......................................................... ......8

Terms ........................................................................8

Units ..........................................................................8

Contents ....................................................................8

Component ................................................................8

How to Follow Trouble Diagnosis ..............................9

How to Read Wiring Diagram ..................................13

Abbreviations ..........................................................20

SERVICE INFORMATION FOR ELECTRICAL

INCIDENT ...........................................................

22

How to Check Terminal ....................................... ....22

How to Perform Efficient Diagnosis for an Electri-

cal Incident .......................................................... ....

25

Control Units and Electrical Parts ............................32

CONSULT-III/GST CHECKING SYSTEM .........34

Description ...............................................................34

CONSULT-III Function and System Application*1 ....34

CONSULT-III/GST Data Link Connector (DLC)

Circuit ......................................................................

35

Wiring Diagram - CONSULT-III/GST CHECKING

SYSTEM - ................................................................

36

LIFTING POINT .................................................37

Commercial Service Tool ........................................37

Garage Jack and Safety Stand ................................37

2-Pole Lift ................................................................38

Board-On Lift ...........................................................38

TOW TRUCK TOWING .....................................40

Tow Truck Towing ...................................................40

Vehicle Recovery (Freeing a Stuck Vehicle) ...........41

TIGHTENING TORQUE OF STANDARD

BOLTS ...............................................................

43

Tightening Torque Table .........................................43

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ...............................................

44

Recommended Chemical Product and Sealant .......44

IDENTIFICATION INFORMATION ....................45

Model Variation ........................................................45

Dimensions ..............................................................47

Wheels & Tires ........................................................47

TERMINOLOGY ................................................48

SAE J1930 Terminology List ...................................48

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2902 of 3924

GI-40

< SERVICE INFORMATION >

TOW TRUCK TOWING

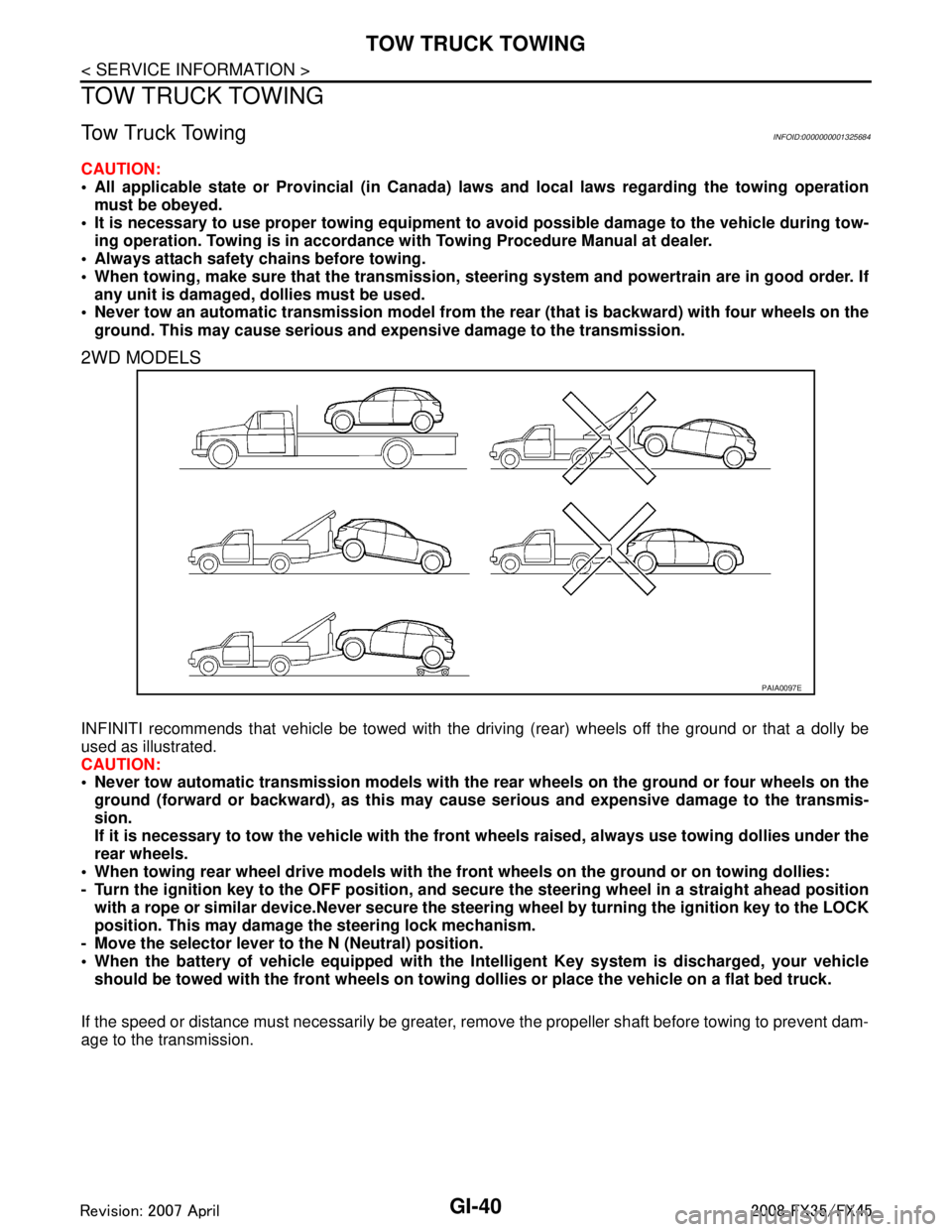

TOW TRUCK TOWING

Tow Truck TowingINFOID:0000000001325684

CAUTION:

All applicable state or Provincial (in Canada) laws and local laws regarding the towing operation

must be obeyed.

It is necessary to use proper towi ng equipment to avoid possible damage to the vehicle during tow-

ing operation. To wing is in accordance with Towing Procedure Manual at dealer.

Always attach safety chains before towing.

When towing, make sure that the transmission, steering system and powertrain are in good order. If

any unit is damaged, dollies must be used.

Never tow an automatic transmission model from the rear (that is backward) with four wheels on the

ground. This may cause serious and exp ensive damage to the transmission.

2WD MODELS

INFINITI recommends that vehicle be towed with the dr iving (rear) wheels off the ground or that a dolly be

used as illustrated.

CAUTION:

Never tow automatic transmission models with the r ear wheels on the ground or four wheels on the

ground (forward or backward), as this may cause serious and expensive damage to the transmis-

sion.

If it is necessary to tow the vehicle with the fron t wheels raised, always use towing dollies under the

rear wheels.

When towing rear wheel drive mo dels with the front wheels on the ground or on towing dollies:

- Turn the ignition key to the OFF position, and secure the steering wh eel in a straight ahead position

with a rope or similar device.Never secure the st eering wheel by turning the ignition key to the LOCK

position. This may damage the steering lock mechanism.

- Move the selector lever to the N (Neutral) position.

When the battery of vehicle equipped with the Intelligent Key system is discharged, your vehicle

should be towed with the front wh eels on towing dollies or place the vehicle on a flat bed truck.

If the speed or distance must necessarily be greater, re move the propeller shaft before towing to prevent dam-

age to the transmission.

PAIA0097E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2903 of 3924

TOW TRUCK TOWINGGI-41

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

AWD MODELS

INFINITI recommends that a dolly be used as illustrated when towing AWD models.

CAUTION:

Never tow AWD models with any of the wheels on the ground as this may cause serious and expen-

sive damage to the powertrain.

Vehicle Recovery (Freeing a Stuck Vehicle)INFOID:0000000001325685

Securely install the vehicle recovery hook stored with jacking tools.

Make sure that the hook is properly secured in the stored place after

use.

WARNING:

Stand clear of a stuck vehicle.

Do not spin your tires at high speed. This could cause them to

explode and result in serious injury. Parts of your vehicle

could also overheat and be damaged.

CAUTION:

Tow chains or cables must be attached only to the vehicle recovery hooks or main struct ural members of the vehicle.

Otherwise, the vehicle body will be damaged.

Do not use the vehicle tie downs to free a vehicle stuck in

sand, snow, mud, etc. Never to w the vehicle using the vehicle

tie downs or recovery hooks.

Always pull the cable straight out from the front of the vehicle.

Never pull on the hook at an angle.

Pulling devices should be rout ed so they do not touch any

part of the suspension, steer ing, brake or cooling systems.

Pulling devices such as ropes or canvas straps are not rec- ommended for use in vehicle towing or recovery.

AUTOMATIC TRANSMISSION

To tow a vehicle equipped with an automatic tr ansmission, an appropriate vehicle dolly MUST be placed under

the towed vehicle's drive wheels. Always follow the dolly manufacture's recommendations when using their

product.

If the vehicle is stuck in sand, snow , mud, etc., use the following procedure:

1. Turn off the Vehicle Dynamic Control System.

2. Make sure the area in front and behind the vehicle is clear of obstructions.

PAIA0098E

PAIA0099E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C