Body INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3640 of 3924

SE-1

BODY

C

DE

F

G H

J

K L

M

SECTION SE

A

B

SE

N

O P

CONTENTS

SEAT

SERVICE INFORMATION .. ..........................3

DTC INDEX ..................................................... .....3

U1000 .................................................................. ......3

B2112-B2128 ............................................................3

PRECAUTIONS ...................................................4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Service Notice ...........................................................4

PREPARATION ...................................................5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ................................................................

6

Work Flow ........................................................... ......6

Generic Squeak and Rattle Troubleshooting ............8

Diagnostic Worksheet .............................................10

AUTOMATIC DRIVE POSITIONER ...................12

System Description ............................................. ....12

Component Parts and Harness Connector Loca-

tion ..........................................................................

16

CAN Communication System Description ...............17

CAN Communication Unit .......................................17

Schematic ...............................................................18

Wiring Diagram - AUT/DP - .....................................20

Terminal and Reference Value for BCM .................32

Terminal and Reference Value for Automatic

Drive Positioner Control Unit ...................................

32

Terminal and Reference Value for Driver Seat

Control Unit .............................................................

34

Work Flow ...............................................................37

Preliminary Check ...................................................37

CONSULT-III Function (AUTO DRIVE POS.) .........40

Check CAN Communication System ......................42

Symptom Chart .......................................................43

Check Sliding Motor Circuit .....................................44

Check Reclining Motor Circuit ............................. ....45

Check Front Lifting Motor Circuit .............................46

Check Rear Lifting Motor Circuit ..............................47

Check Telescopic Motor Circuit ...............................48

Check Tilt Motor Circuit ...........................................49

Check Driver Side Mirror Motor Circuit ....................50

Check Passenger Side Mirror Motor Circuit ............52

Check Sliding Sensor Circuit ...................................53

Check Reclining Sensor Circuit ...............................54

Check Front Lifting Sensor Circuit ...........................55

Check Rear Lifting Sensor Circuit ...........................56

Check Telescopic Sensor Circuit .............................57

Check Tilt Sensor Circuit .........................................58

Check Driver Side Mirror Sensor Circuit ..................59

Check Passenger Side Mirror Sensor Circuit ..........60

Check Steering and Door Mirror Sensor Power

Supply and Ground Circuit .................................. ....

61

Check Front Door Switch (Driver Side) Circuit ........62

Check Sliding Switch Circuit ....................................63

Check Reclining Switch Circuit ................................64

Check Front Lifting Switch Circuit ............................66

Check Rear Lifting Switch Circuit ............................67

Check Power Seat Switch Ground Circuit ...............68

Check Telescopic Switch Circuit .............................68

Check Tilt Switch Circuit ..........................................70

Check Door Mirror Remote Control Switch

(Changeover Switch) Circuit ................................ ....

71

Check Door Mirror Remote Control Switch (Mirror

Switch) Circuit ...................................................... ....

73

Check A/T Device (Park Position Switch) Circuit ....74

Check Key Switch Circuit (With Intelligent Key) ......76

Check Key Switch Circuit (Without Intelligent Key) ....77

Check Seat Memory Switch Circuit ..................... ....78

Check Seat Memory Indicator Lamp Circuit ............79

Check UART Communication Line Circuit ...............80

Check Lumbar Support Circuit ............................ ....82

POWER SEAT ...................................................84

Wiring Diagram - SEAT - .........................................84

HEATED SEAT .................................................86

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3643 of 3924

SE-4

< SERVICE INFORMATION >

PRECAUTIONS

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612906

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Service NoticeINFOID:0000000001328091

When removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

Handle trim, molding, instruments, grille, etc. carefull y during removing or installing. Be careful not to oil or

damage them.

Apply sealing compound where necessary when installing parts.

When applying sealing compound, be careful that the sealing compound does not protrude from parts.

When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust preven-

tion measures.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3646 of 3924

SQUEAK AND RATTLE TROUBLE DIAGNOSESSE-7

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half- clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, che ck ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool (Chassis Ear: J-39570,Engine Ear and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

removing the components in the area that you suspect the noise is coming from. Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

placing a piece of paper between components that you suspect are causing the noise.

looking for loose components and contact marks. Refer to SE-8, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane tape. A Nissan Squeak and Rattle Kit (J-43980) is av ailable through your authorized Nissan Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

The following materials are contained in the Niss an Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 × 135 mm (3.94 × 5.31 in)/76884-71L01: 60 × 85 mm (2.36 × 3.35 in)/76884-71L02:15 ×

25 mm (0.59 × 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 × 50 mm (1.97 × 1.97 in)/73982-50Y00: 10 mm (0.39 in) thick, 50

× 50 mm (1.97 × 1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 × 50 mm (1.18 × 1.97 in)

FELT CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 × 25 mm (0.59 × 0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll The following

materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW(TEFLON) TAPE

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3730 of 3924

FRONT SEATSE-91

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

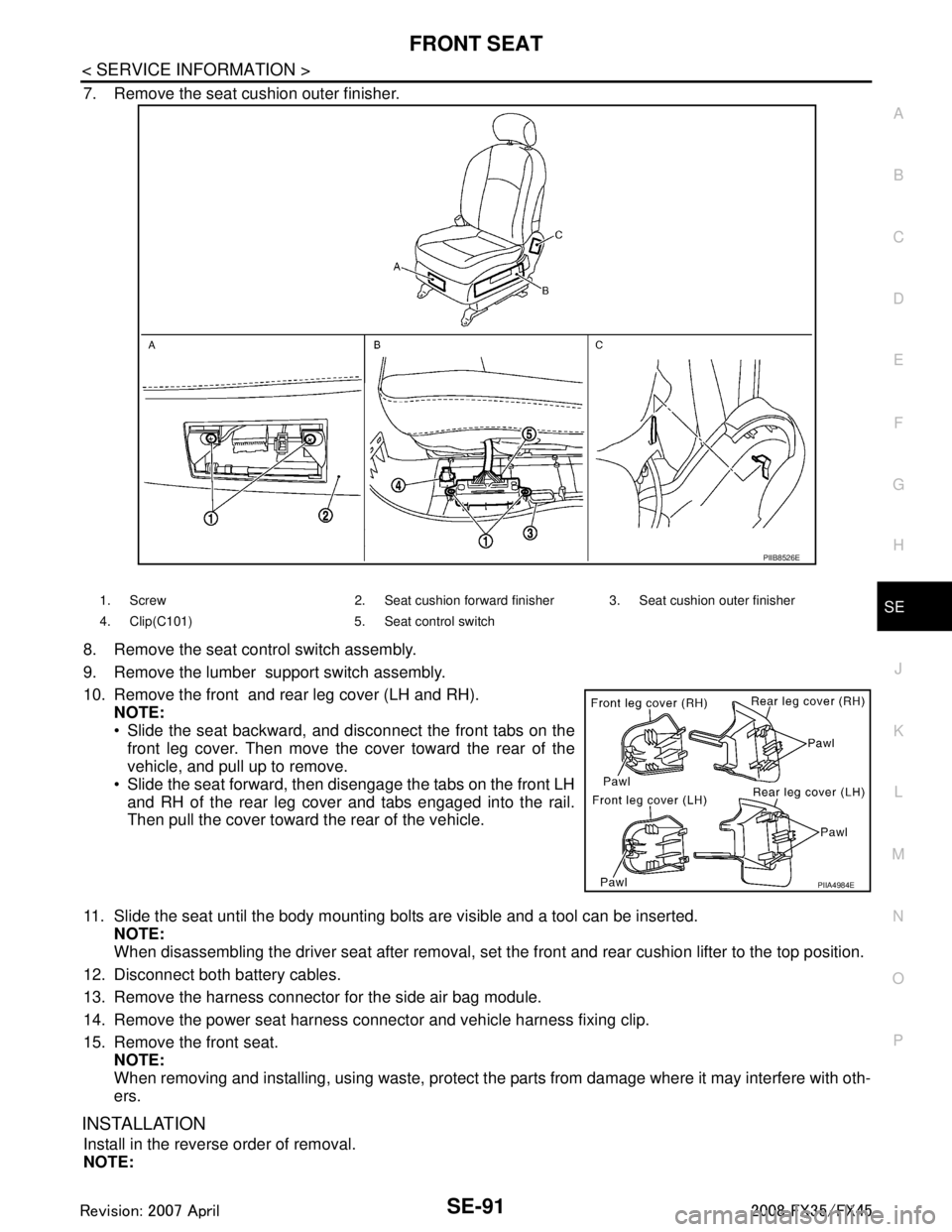

7. Remove the seat cushion outer finisher.

8. Remove the seat control switch assembly.

9. Remove the lumber support switch assembly.

10. Remove the front and rear leg cover (LH and RH). NOTE:

Slide the seat backward, and disconnect the front tabs on the

front leg cover. Then move the cover toward the rear of the

vehicle, and pull up to remove.

Slide the seat forward, then disengage the tabs on the front LH and RH of the rear leg cover and tabs engaged into the rail.

Then pull the cover toward the rear of the vehicle.

11. Slide the seat until the body mounting bolts are visible and a tool can be inserted. NOTE:

When disassembling the driver seat after removal, set the front and rear cushion lifter to the top position.

12. Disconnect both battery cables.

13. Remove the harness connector for the side air bag module.

14. Remove the power seat harness connector and vehicle harness fixing clip.

15. Remove the front seat. NOTE:

When removing and installing, using waste, protect t he parts from damage where it may interfere with oth-

ers.

INSTALLATION

Install in the reverse order of removal.

NOTE:

PIIB8526E

1. Screw 2. Seat cushion forward finisher 3. Seat cushion outer finisher

4. Clip(C101) 5. Seat control switch

PIIA4984E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3850 of 3924

WT-10

< SERVICE INFORMATION >

TIRE PRESSURE MONITORING SYSTEM

TIRE PRESSURE MONITORING SYSTEM

System ComponentINFOID:0000000001327576

System DescriptionINFOID:0000000001327577

TRANSMITTER

A sensor-transmitter integrated with a valve is installed on a wheel,

and transmits a detected air pressure signal in the form of a radio

wave.

REMOTE KEYLESS ENTRY RECEIVER

The remote keyless entry receiver receives the air pressure signal

transmitted by the transmitter in each wheel.

BCM (BODY CONTROL MODULE)

SEIA0599E

SEIA0521E

SEIA0431E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3879 of 3924

WW-4

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

FRONT WIPER AND WASHER SYSTEM

Component Parts and Harness Connector LocationINFOID:0000000001328542

System DescriptionINFOID:0000000001328543

All front wiper relays (HI, LO) are included in IPDM E/R (intelligent power distribution module engine room).

Wiper switch (combination switch) is composed of a combination of 5 output terminals and 5 input terminals.

Terminal combination status is read by BCM ( body control module) when switch is turned ON.

BCM controls front wiper LO, HI, and INT (intermittent) operation.

IPDM E/R operates wiper motor according to CAN communication signals from BCM.

OUT LINE

Power is supplied at all times

through 50 A fusible link (letter M, located in fuse, fusible link and relay box.)

to BCM terminal 55,

through 15 A fuse [No. 22, located in fuse block (J/B)]

to BCM terminal 42,

through 30 A fuse (No. 73, located in IPDM E/R)

to front wiper relay, located in IPDM E/R,

through 15 A fuse (No. 78, located in IPDM E/R) and

through 10 A fuse (No. 71, located in IPDM E/R)

to CPU located in IPDM E/R.

When the ignition switch is ON or START position, power is supplied

to ignition relay located in IPDM E/R, from battery direct,

through 15 A fuse [No. 1, located in fuse block (J/B)]

to BCM terminal 38,

through ignition relay, located in IPDM E/R

to front wiper relay, located in IPDM E/R

to front wiper high relay, located in IPDM E/R and

to CPU located in IPDM E/R,

through 10 A fuse (No. 84, located in IPDM E/R)

through IPDM E/R terminal 44

to combination switch terminal 14.

Ground is supplied

PKIC9701E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3905 of 3924

WW-30

< SERVICE INFORMATION >

REAR WIPER AND WASHER SYSTEM

REAR WIPER AND WASHER SYSTEM

Component Parts and Harness Connector LocationINFOID:0000000001328576

System DescriptionINFOID:0000000001328577

Wiper switch (combination switch) is composed of a combination of 5 output terminals and 5 input terminals.

Terminal combination status is read by BCM ( body control module) when switch is turned ON.

BCM controls rear wiper ON and INT (intermittent) operation.

Power supplied at all times

through 50 A fusible link (letter M, located in fuse, fusible link and relay box)

to BCM terminal 55,

through 15 A fuse [No. 22, located in fuse block (J/B)]

to BCM terminal 42.

When ignition switch ON or START position, power is supplied

through 15 A fuse [No.1, located in fuse block (J/B)]

to BCM terminal 38,

through 10 A fuse [No. 84, located in IPDM E/R (intelligent power distribution module engine room)]

to combination switch terminal 14.

Ground is supplied

to BCM terminals 49 and 52

through grounds M35, M45 and M85,

to combination switch terminal 12

through grounds M35, M45 and M85.

REAR WIPER OPERATION

When the wiper switch is in rear wiper ON position, BCM detects rear wiper ON signal by BCM wiper switch

reading function.

BCM operates rear wiper motor, power is supplied

through BCM terminal 70

to rear wiper motor 4.

Ground is supplied

to rear wiper motor terminal 2

through grounds B15 and B45.

With power and ground supplied, the rear wiper operates.

PKIC9708E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C