service INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 318 of 3924

TRANSMISSION ASSEMBLYAT-245

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

REMOVAL

CAUTION:

When removing the A/T assembly from engine, fi rst remove the crankshaft position sensor (POS)

from the A/T assembly.

Be careful not to damage sensor edge.

1. Disconnect the battery cabl e from the negative terminal.

2. Remove engine cover.

3. Remove A/T fluid level gauge.

4. Remove engine under cover with power tool.

5. Remove front cross bar. Refer to FSU-6, "

Removal and Installation".

6. Remove exhaust front tube and center muffler with power tool. Refer to EX-3, "

Component".

7. Remove three way catalyst. Refer to EM-179, "

Removal and Installation".

8. Remove front propeller shaft. Refer to PR-4, "

Removal and Installation".

9. Remove rear propeller shaft. Refer to PR-9, "

Removal and Installation".

10. Remove control rod. Refer to AT-206, "

Control Rod Removal and Installation".

1. A/T fluid charging pipe 2. O-ring 3. Engine mounting insulator (rear)

4. Rear engine mounting member 5. Copper washer 6. Bracket

7. Fluid cooler tube 8. Bracket 9. Bracket

10. Bracket 11. A/T assembly 12. A/T fluid level gauge

SCIA6426E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 319 of 3924

AT-246

< SERVICE INFORMATION >

TRANSMISSION ASSEMBLY

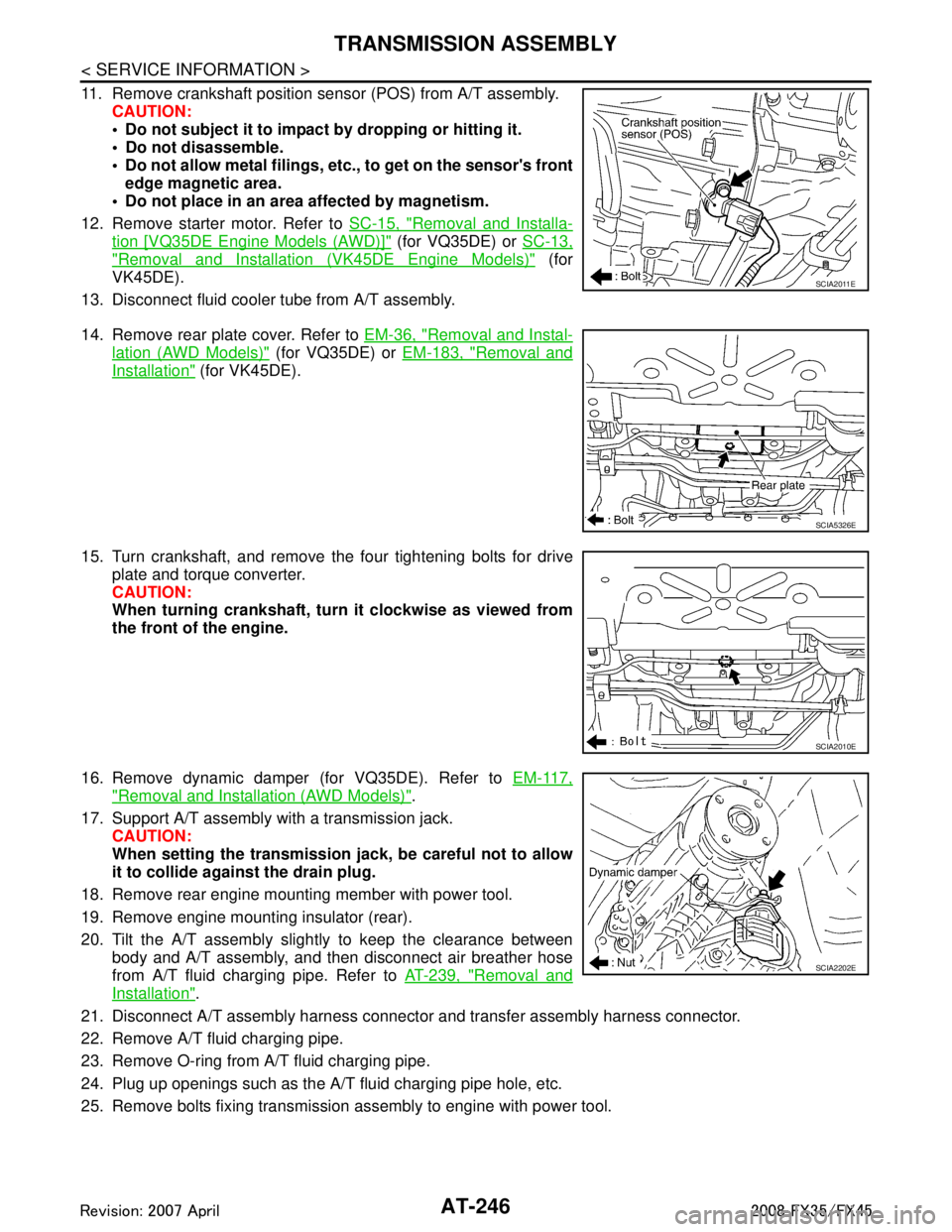

11. Remove crankshaft position sensor (POS) from A/T assembly.CAUTION:

Do not subject it to impact by dropping or hitting it.

Do not disassemble.

Do not allow metal filings, et c., to get on the sensor's front

edge magnetic area.

Do not place in an area affected by magnetism.

12. Remove starter motor. Refer to SC-15, "

Removal and Installa-

tion [VQ35DE Engine Models (AWD)]" (for VQ35DE) or SC-13,

"Removal and Installation (VK45DE Engine Models)" (for

VK45DE).

13. Disconnect fluid cooler tube from A/T assembly.

14. Remove rear plate cover. Refer to EM-36, "

Removal and Instal-

lation (AWD Models)" (for VQ35DE) or EM-183, "Removal and

Installation" (for VK45DE).

15. Turn crankshaft, and remove the four tightening bolts for drive plate and torque converter.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of the engine.

16. Remove dynamic damper (for VQ35DE). Refer to EM-117,

"Removal and Installation (AWD Models)".

17. Support A/T assembly with a transmission jack. CAUTION:

When setting the transmission j ack, be careful not to allow

it to collide agai nst the drain plug.

18. Remove rear engine mounting member with power tool.

19. Remove engine mounting insulator (rear).

20. Tilt the A/T assembly slightly to keep the clearance between body and A/T assembly, and then disconnect air breather hose

from A/T fluid charging pipe. Refer to AT-239, "

Removal and

Installation".

21. Disconnect A/T assembly harness connector and transfer assembly harness connector.

22. Remove A/T fluid charging pipe.

23. Remove O-ring from A/T fluid charging pipe.

24. Plug up openings such as the A/T fluid charging pipe hole, etc.

25. Remove bolts fixing transmission assembly to engine with power tool.

SCIA2011E

SCIA5326E

SCIA2010E

SCIA2202E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 320 of 3924

TRANSMISSION ASSEMBLYAT-247

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

26. Remove A/T assembly with transfer from vehicle. Secure torque converter to prevent it from dropping.

Secure A/T assembly to a jack.

27. Remove transfer from A/T assembly. Refer to TF-40, "

Removal

and Installation".

INSPECTION

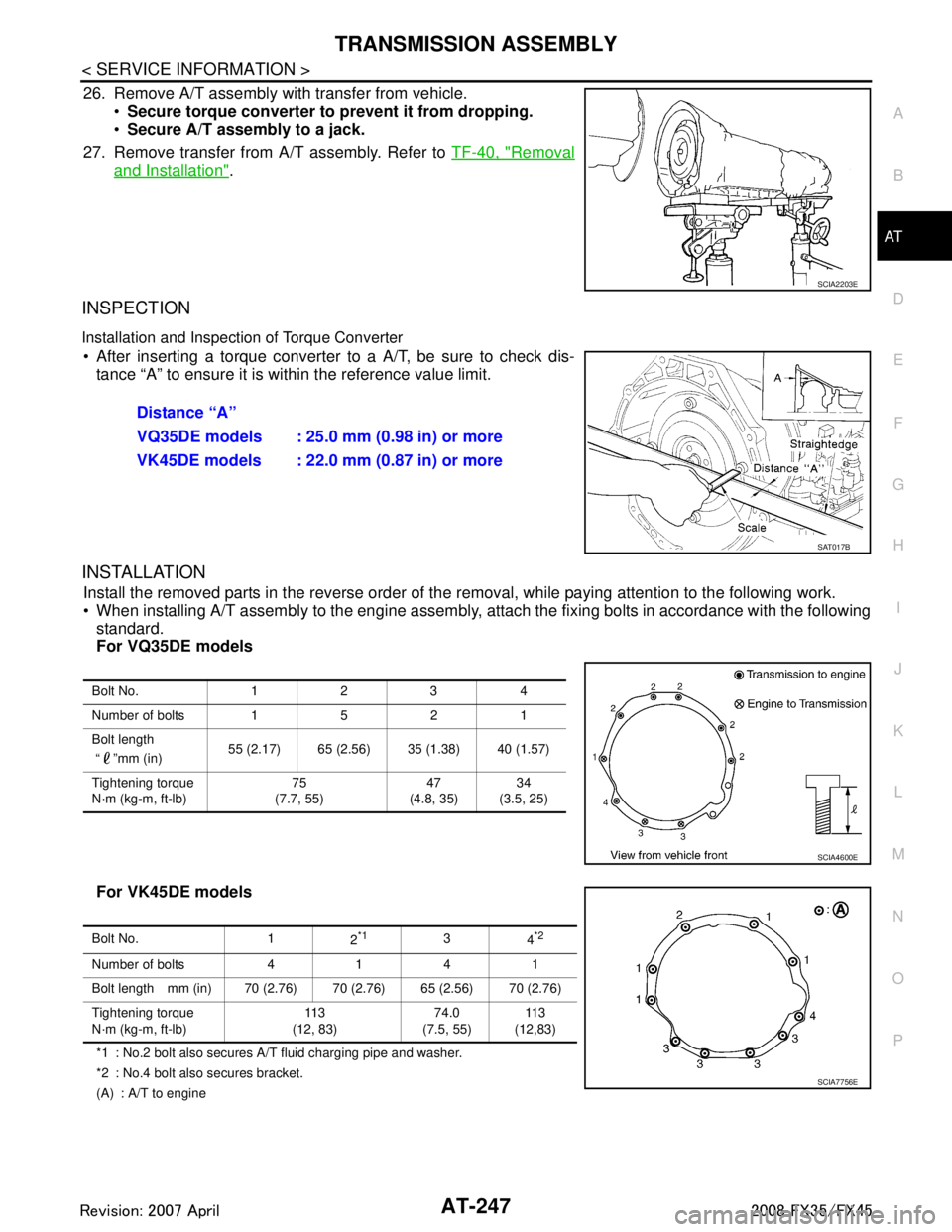

Installation and Inspection of Torque Converter

After inserting a torque converter to a A/T, be sure to check dis-

tance “A” to ensure it is within the reference value limit.

INSTALLATION

Install the removed parts in the reverse order of the removal, while paying attention to the following work.

When installing A/T assembly to the engine assembly, atta ch the fixing bolts in accordance with the following

standard.

For VQ35DE models

For VK45DE models

*1 : No.2 bolt also secures A/T fluid charging pipe and washer.

*2 : No.4 bolt also secures bracket.

(A) : A/T to engine

SCIA2203E

Distance “A”

VQ35DE models : 25.0 mm (0.98 in) or more

VK45DE models : 22.0 mm (0.87 in) or more

SAT017B

Bolt No. 1234

Number of bolts1521

Bolt length

“”mm (in) 55 (2.17) 65 (2.56) 35 (1.38) 40 (1.57)

Tightening torque

N·m (kg-m, ft-lb) 75

(7.7, 55) 47

(4.8, 35) 34

(3.5, 25)

SCIA4600E

Bolt No. 1 2*134*2

Number of bolts 4 1 4 1

Bolt length mm (in) 70 (2.76) 70 (2.76) 65 (2.56) 70 (2.76)

Tightening torque

N·m (kg-m, ft-lb) 11 3

(12, 83) 74.0

(7.5, 55) 11 3

(12,83)

SCIA7756E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 321 of 3924

AT-248

< SERVICE INFORMATION >

TRANSMISSION ASSEMBLY

Align the positions of tightening bolts for drive plate with those ofthe torque converter, and temporarily tighten the bolts. Then,

tighten the bolts with the specified torque. Refer to "COMPO-

NENTS (FOR VQ35DE)" or "COMPONENTS (FOR VK45DE)".

CAUTION:

Do not reuse O-ring and copper washers.

When turning crankshaft, turn it clockwise as viewed from the

front of the engine.

When tightening the tightening bolts for the torque converter

after fixing the crankshaft pulley bolts, be sure to confirm the

tightening torque of the crankshaft pulley mounting bolts.

Refer to EM-65, "

Removal and Installation" (for VQ35DE) or

EM-200, "

Removal and Installation" (for VK45DE)

After converter is installed to drive plate, rota te crankshaft several turns and check to be sure that

transmission rotates fr eely without binding.

Install crankshaft position sensor (POS). Refer to EM-35, "

Component (AWD Models)" (for VQ35DE) or EM-

183, "Component" (for VK45DE).

After completing installation, check A/T fluid leakage, A/T fluid level, and the positions of A/T. Refer to AT- 11 ,

"Checking A/T Fluid", AT-207, "Checking of A/T Position".

SCIA2010E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 322 of 3924

OVERHAULAT-249

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

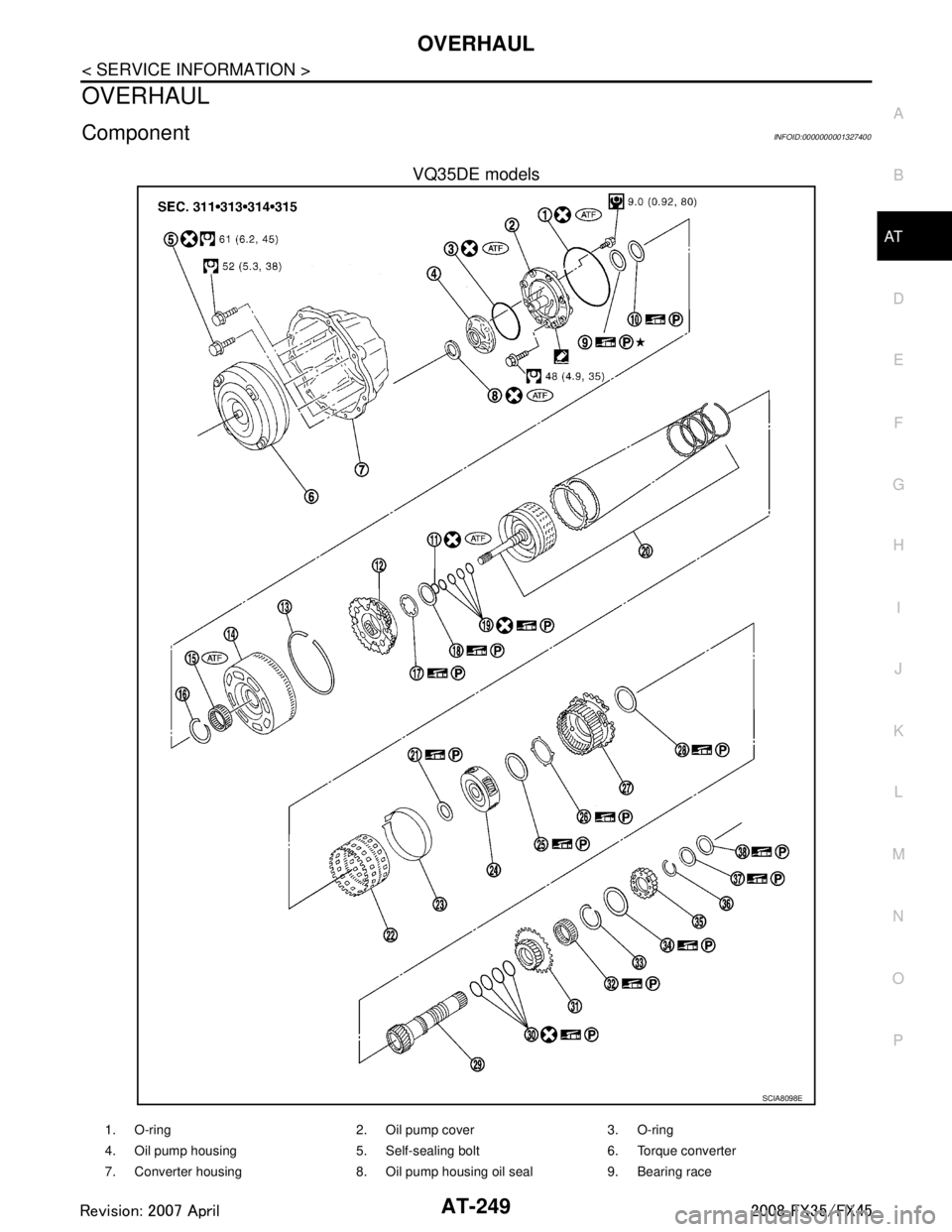

OVERHAUL

ComponentINFOID:0000000001327400

VQ35DE models

SCIA8098E

1. O-ring 2. Oil pump cover 3. O-ring

4. Oil pump housing 5. Self-sealing bolt 6. Torque converter

7. Converter housing 8. Oil pump housing oil seal 9. Bearing race

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 323 of 3924

AT-250

< SERVICE INFORMATION >

OVERHAUL

10. Needle bearing 11. O-ring 12. Front carrier assembly

13. Snap ring 14. Front sun gear 15. 3rd one-way clutch

16. Snap ring 17. Bearing race 18. Needle bearing

19. Seal ring 20. Input clutch assembly 21. Needle bearing

22. Rear internal gear 23. Brake band 24. Mid carrier assembly

25. Needle bearing 26. Bearing race 27. Rear carrier assembly

28. Needle bearing 29. Mid sun gear 30. Seal ring

31. Rear sun gear 32. 1st one-way clutch 33. Snap ring

34. Needle bearing 35. High and low reverse clutch hub 36. Snap ring

37. Bearing race 38. Needle bearing

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

However, refer to the following symbol for others.

: Apply Genuine RTV silicone sealant or equivalent. Refer to GI-44, "

Recommended Chemical Product and Sealant".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 324 of 3924

OVERHAULAT-251

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

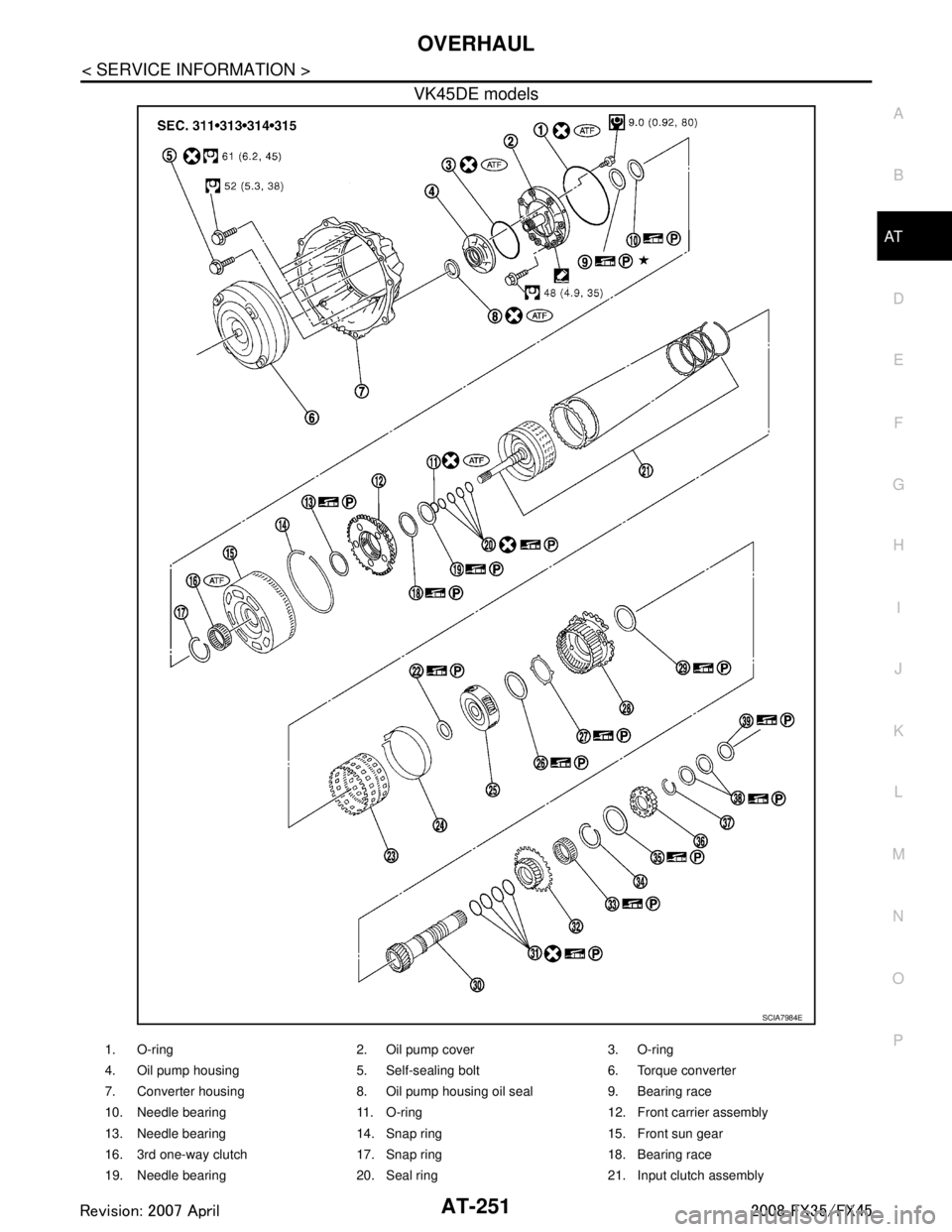

VK45DE models

SCIA7984E

1. O-ring 2. Oil pump cover 3. O-ring

4. Oil pump housing 5. Self-sealing bolt 6. Torque converter

7. Converter housing 8. Oil pump housing oil seal 9. Bearing race

10. Needle bearing 11. O-ring 12. Front carrier assembly

13. Needle bearing 14. Snap ring 15. Front sun gear

16. 3rd one-way clutch 17. Snap ring 18. Bearing race

19. Needle bearing 20. Seal ring 21. Input clutch assembly

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 325 of 3924

AT-252

< SERVICE INFORMATION >

OVERHAUL

22. Needle bearing 23. Rear internal gear 24. Brake band

25. Mid carrier assembly 26. Needle bearing 27. Bearing race

28. Rear carrier assembly 29. Needle bearing 30. Mid sun gear

31. Seal ring 32. Rear sun gear 33. 1st one-way clutch

34. Snap ring 35. Needle bearing 36. High and low reverse clutch hub

37. Snap ring 38. Bearing race 39. Needle bearing

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

However, refer to the following symbols for others. : Apply Genuine RTV silicone sealant or equivalent. Refer to GI-44, "

Recommended Chemical Product and Sealant".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 326 of 3924

OVERHAULAT-253

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

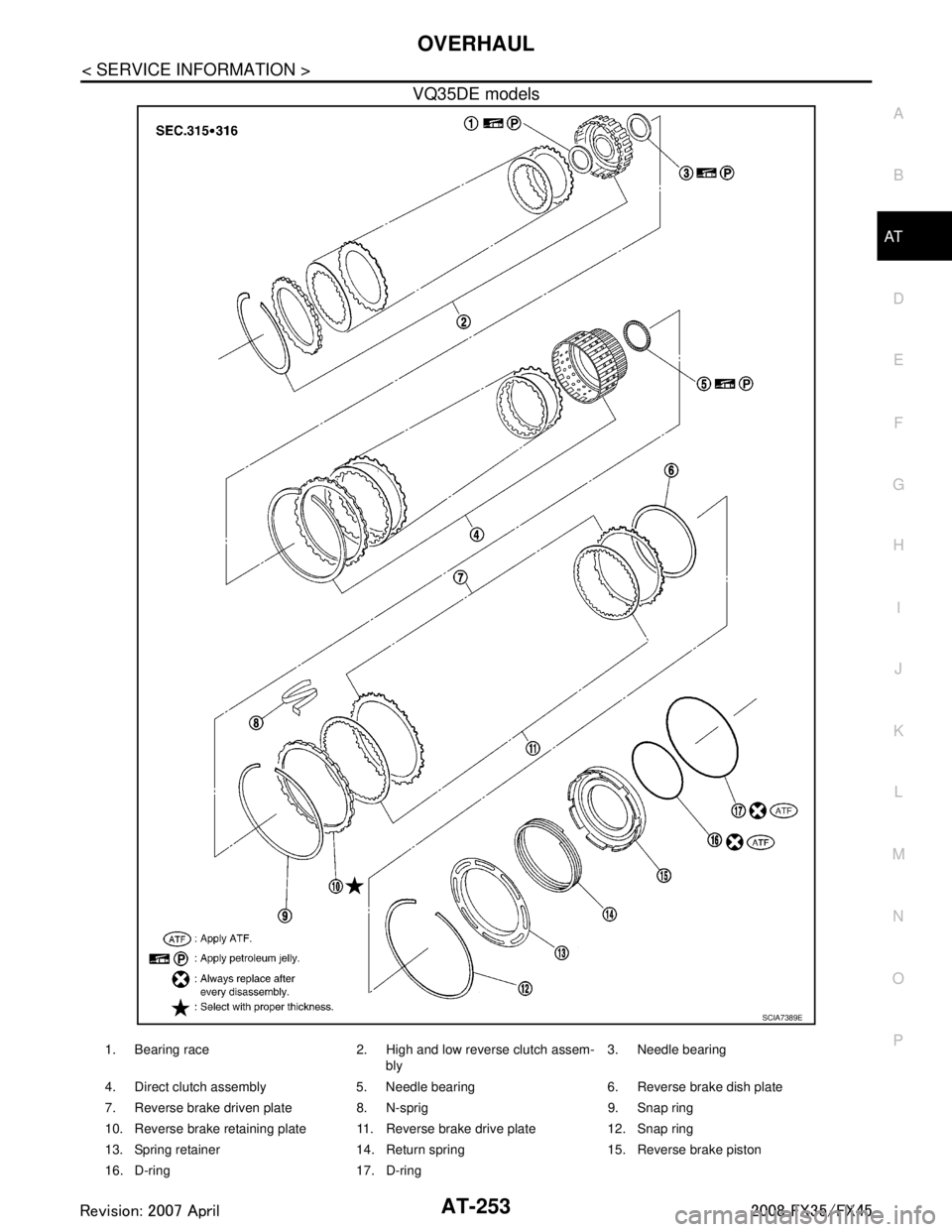

VQ35DE models

SCIA7389E

1. Bearing race 2. High and low reverse clutch assem- bly3. Needle bearing

4. Direct clutch assembly 5. Needle bearing 6. Reverse brake dish plate

7. Reverse brake driven plate 8. N-sprig 9. Snap ring

10. Reverse brake retaining plate 11. Reverse brake drive plate 12. Snap ring

13. Spring retainer 14. Return spring 15. Reverse brake piston

16. D-ring 17. D-ring

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 327 of 3924

AT-254

< SERVICE INFORMATION >

OVERHAUL

VK45DE models

SCIA6982E

1. Bearing race 2. High and low reverse clutch assembly 3. Needle bearing

4. Direct clutch assembly 5. Needle bearing 6. Reverse brake dish plate

7. Reverse brake dish plate 8. Reverse brake driven plate 9. N-spring

10. Snap ring 11. Reverse brake retaining plate 12. Reverse brake drive plate

13. Snap ring 14. Spring retainer 15. Return spring

16. Reverse brake piston 17. D-ring 18. D-ring

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C