ignition INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1234 of 3924

DI-108

< SERVICE INFORMATION >

REAR VIEW MONITOR

6. Select “SAVE”, and confirm the guide line.

7. Select “End”.

8. Select “ADJ GUIDELINE POSITION”.

9. Adjust the guide line selecting “X UP”, “X DOWN”, “Y UP” or “Y DOWN” so that the corrected line can fit

the guide line.

10. Touch “SAVE”, and confirm the guide line.

11. Touch “End” to finish correcting.

Power Supply and Ground Circuit InspectionINFOID:0000000001328536

1.CHECK FUSE

Make sure the fuses for rear view camera control unit is blown.

OK or NG

OK >> GO TO 2.

NG >> Be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-3

.

2.CHECK POWER SUPPLY CIRCUIT

Check voltage between rear view camera control unit harness con-

nector M48 terminals 1, 2 and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness between rear view camera control unit and fuse.

3.CHECK REAR VIEW CAMERA CONTROL UNIT GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear view camera control unit connector.

3. Check continuity between rear view camera control unit harness connector M48 terminal 3 and ground.

OK or NG

OK >> INSPECTION END

NG >> Repair harness or connector.

Rear View Is Not Displayed with the A/T Selector Lever in R-PositionINFOID:0000000001328537

1.BACK-UP LAMP INSPECTION

1. Turn ignition switch ON.

2. Shift A/T selector lever to R position.

Does back-up lamp illuminate?

Power source Fuse No.

Battery power supply 19 ACC power supply 6

Te r m i n a l s OFF ACC

(+)

(–)

Connector Terminal

M48 1 Ground Battery voltage Battery voltage

2 Ground 0 V Battery voltage

PKIB3580E

3 – Ground : Continuity should exist.

SKIA5081E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1235 of 3924

REAR VIEW MONITORDI-109

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

YES >> GO TO 2.

NO >> Check back-up lamp system. Refer to LT-116, "

Wiring Diagram - BACK/L -" in LT section.

2.CHECK REVERSE POSITION INPUT SIGNAL

With CONSULT-III

1. Select “Data Monitor” of “REARVIEW CAMERA”.

2. Operate ignition switch with “R POSI SIG” of “Data Monitor” and check operate status.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Disconnect rear view camera control unit connector.

3. Turn ignition switch ON.

4. Shift A/T selector lever to R position.

5. Check voltage between rear view camera control unit harness

connector M48 terminal 4 and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness between rear view camera control unit and back-up lamp relay.

3.CHECK DISPLAY CONTROL UNIT OUTPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear view camera control unit connector.

3. Turn ignition switch ON.

4. Check voltage between rear view camera control unit harness connector M48 terminal 5 and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK DISPLAY CO NTROL UNIT CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect display control unit connector.

3. Check continuity between rear view camera control unit harness connector M48 terminal 5 and display control unit harness con-

nector M75 terminal 8.

4. Check continuity between rear view camera control unit harness connector M48 terminal 5 and ground.

OK or NG

OK >> Replace display control unit.

NG >> Repair harness or connector.

5.CHECK CONTROL 1 SIGNAL

1. Turn ignition switch OFF.

2. Connect rear view camera control unit connector. 4 – Ground : Battery voltage

SKIA5086E

5 – Ground : Approx. 5 V

SKIA7148E

5 – 8 : Continuity should exist.

5 – Ground : Continuity should not exist.

SKIA7149E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1236 of 3924

DI-110

< SERVICE INFORMATION >

REAR VIEW MONITOR

3. Turn ignition switch ON.

4. Shift A/T selector lever to R position.

5. Check voltage between rear view camera control unit harnessconnector M48 terminal 5 and ground.

OK or NG

OK >> GO TO 6.

NG >> Replace rear view camera control unit.

6.CHECK REAR VIEW CAMERA OPEN CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear view camera connector.

3. Check continuity between rear view camera control unit harness connector M48 terminal 8 and rear view camera harness con-

nector D108 terminal 1.

4. Check continuity between rear view camera control unit harness connector M48 terminal 9 and rear view camera harness con-

nector D108 terminal 4.

5. Check continuity between rear view camera control unit harness connector M48 terminal 10 and rear view ca mera harness connector D108 terminal 3.

OK or NG

OK >> GO TO 7.

NG >> Repair harness or connector.

7.CHECK REAR VIEW CAMERA SHORT CIRCUIT

1. Check continuity between rear view camera control unit harness connector M48 terminal 8 and ground.

2. Check continuity between rear view camera control unit harness connector M48 terminal 9 and ground.

3. Check continuity between rear view camera control unit harness connector M48 terminal 10 and ground.

OK or NG

OK >> GO TO 8.

NG >> Repair harness on connector.

8.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check power supply and ground circuit. Refer to DI-108, "

Power Supply and Ground Circuit Inspection".

OK or NG

OK >> GO TO 9. 5 – Ground : Approx. 0 V

SKIA7150E

8 – 1 : Continuity should exist.

9 – 4 : Continuity should exist.

10 – 3 : Continuity should exist.

SKIA5095E

8 – Ground : Continuity should not exist.

9 – Ground : Continuity should not exist.

10 – Ground : Continuity should not exist.

SKIA5098E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1237 of 3924

REAR VIEW MONITORDI-111

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

NG >> Repair or replace power supply and ground circuit.

9.CHECK REAR VIEW CAMERA CONTROL UNIT OUTPUT SIGNAL

1. Turn ignition switch OFF.

2. Connect rear view camera control unit connector.

3. Turn ignition switch ON.

4. Shift A/T selector lever to R position.

5. Check voltage between rear view camera control unit harness connector M48 terminal 8 and ground.

OK or NG

OK >> GO TO 10.

NG >> Replace rear view camera control unit.

10.CHECK REAR VIEW CAMERA SIGNAL

1. Turn ignition switch OFF.

2. Connect rear view camera connector.

3. Turn ignition switch ON.

4. Shift A/T selector lever to R position.

5. Check voltage signal between rear view camera control unit har- ness connector M48 terminal 10 and ground.

OK or NG

OK >> GO TO 11.

NG >> Replace rear view camera.

11 .CHECK COMPOSITE SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear view camera control unit connector and display connector.

3. Check continuity between rear view camera control unit harness connector M48 terminal 12 and display harness connector M63

terminal 15.

4. Check continuity between rear view camera control unit harness connector M48 terminal 12 and ground.

OK or NG

OK >> GO TO 12.

NG >> Repair harness or connector.

12.CHECK COMPOSITE SI GNAL GROUND CIRCUIT

8 – Ground : Approx. 6 V

PKIB3581E

10 – Ground:

PKIB3582ESKIA4894E

12 – 15 : Continuity should exist.

12 – Ground : Continuity should not exist.

SKIB0482E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1238 of 3924

DI-112

< SERVICE INFORMATION >

REAR VIEW MONITOR

1. Check continuity between rear view camera control unit harnessconnector M48 terminal 11 and display harness connector M63

terminal 4.

2. Check continuity between rear view camera control unit harness connector M48 terminal 11 and ground.

OK or NG

OK >> GO TO 13.

NG >> Repair harness or connector.

13.CHECK COMPOSITE SIGNAL

1. Connect rear view camera control unit connector and display connector.

2. Turn ignition switch ON.

3. Shift A/T selector lever to R position.

4. Check voltage signal between rear view camera control unit har- ness connector M48 terminal 12 and ground.

OK or NG

OK >> Replace display.

NG >> Replace rear view camera control unit.

The Rear View Image Is DistortedINFOID:0000000001328538

1.CHECK SYNCHRO SIGNAL OPEN OR SHORT CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear view camera control unit connector and display connector.

3. Check continuity between rear view camera control unit harness connector M48 terminal 14 and display harness connector M63

terminal 16.

4. Check continuity between rear view camera control unit harness connector M48 terminal 14 and ground.

OK or NG

OK >> GO TO 2.

NG >> Repair harness or connector.

2.CHECK COMPOSITE SI GNAL GROUND CIRCUIT

11 – 4 : Continuity should exist.

11 – Ground : Continuity should not exist.

SKIA5102E

12 – Ground:

PKIB3583ESKIA4896E

14 – 16 : Continuity should exist.

14 – Ground : Continuity should not exist.

SKIA5101E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1239 of 3924

REAR VIEW MONITORDI-113

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

1. Check continuity between rear view camera control unit harness connector M48 terminal 11 and display harness connector M63

terminal 4.

2. Check continuity between rear view camera control unit harness connector M48 terminal 11 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK REAR VIEW CONTROL UNIT SYNCHRO SIGNAL

1. Connect rear view camera control unit connector and display connector.

2. Turn ignition switch ON.

3. Shift A/T selector lever to R position.

4. Check voltage signal between rear view camera control unit har- ness connector M48 terminal 14 and ground.

OK or NG

OK >> Replace rear view camera control unit.

NG >> Replace display.

Removal and Installation of R ear View Camera Control UnitINFOID:0000000001328539

REMOVAL

1. Remove instrument clock finisher and A/T console finisher.

Refer to IP-10, "

Component Parts Location".

2. Remove screws (2), and remove rear view camera control unit.

INSTALLATION

Installation is the reverse order of removal.

Removal and Installation of Rear View CameraINFOID:0000000001328540

REMOVAL

1. Remove back door trim. Refer to EI-47, "Component Parts Location".

2. Remove back door outside finisher upper. Refer to EI-35, "

Component Parts Location".

11 – 4 : Continuity should exist.

11 – Ground : Continuity should not exist.

SKIA5102E

14 – Ground:

PKIB3584ESKIA5896E

SKIA5797E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1241 of 3924

EC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

VQ35DE

SERVICE INFORMATION .. .........................

17

INDEX FOR DTC ............................................ ....17

DTC No. Index .................................................... ....17

Alphabetical Index ...................................................20

PRECAUTIONS ..................................................25

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

25

Precaution for Procedure without Cowl Top Cover ....25

On Board Diagnosis (OBD) System of Engine and

A/T ...........................................................................

25

Precaution ...............................................................26

PREPARATION ..................................................29

Special Service Tool ........................................... ....29

Commercial Service Tool ........................................30

ENGINE CONTROL SYSTEM ............................31

Schematic ........................................................... ....31

Multiport Fuel Injection (MFI) System .....................31

Electronic Ignition (EI) System ................................34

Fuel Cut Control (at No Load and High Engine

Speed) .....................................................................

34

AIR CONDITIONING CUT CONTROL ...............36

Input/Output Signal Chart .................................... ....36

System Description .................................................36

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ...............................................................

37

System Description ............................................. ....37

Component Description ...........................................38

CAN COMMUNICATION ....................................39

System Description ............................................. ....39

EVAPORATIVE EMISSION SYSTEM ................40

Description .......................................................... ....40

Component Inspection ......................................... ....42

Removal and Installation .........................................44

How to Detect Fuel Vapor Leakage .........................44

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ......................................................

46

System Description ..................................................46

Diagnosis Procedure ...............................................46

Component Inspection .............................................48

POSITIVE CRANKCASE VENTILATION .........51

Description ...............................................................51

Component Inspection .............................................51

IVIS (INFINITI VEHICLE IMMOBILIZER SYS-

TEM-NATS) .......................................................

53

Description ...............................................................53

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....54

Introduction ..............................................................54

Two Trip Detection Logic .........................................54

Emission-Related Diagnostic Information ................55

Malfunction Indicator Lamp (MIL) ............................71

OBD System Operation Chart .................................74

BASIC SERVICE PROCEDURE .......................80

Basic Inspection ......................................................80

Idle Speed and Ignition Timing Check .....................84

Procedure After Replacing ECM .............................84

VIN Registration ......................................................84

Accelerator Pedal Released Position Learning .......85

Throttle Valve Closed Position Learning .................85

Idle Air Volume Learning .........................................85

Fuel Pressure Check ...............................................87

TROUBLE DIAGNOSIS ....................................89

Trouble Diagnosis Introduction ................................89

DTC Inspection Priority Chart ..................................93

Fail-Safe Chart ........................................................95

Symptom Matrix Chart .............................................96

Engine Control Component Parts Location ...........100

Vacuum Hose Drawing ..........................................106

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1248 of 3924

EC-8

Component Inspection ...........................................545

ASCD INDICATOR ..........................................547

Component Description ....................................... ..547

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

547

Wiring Diagram ......................................................548

Diagnosis Procedure .............................................548

ELECTRICAL LOAD SIGNAL .........................550

Description ........................................................... ..550

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

550

Diagnosis Procedure .............................................550

FUEL INJECTOR .............................................552

Component Description ....................................... ..552

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

552

Wiring Diagram ......................................................553

Diagnosis Procedure .............................................554

Component Inspection ...........................................557

Removal and Installation .......................................557

FUEL PUMP .....................................................558

Description ........................................................... ..558

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

558

Wiring Diagram ......................................................559

Diagnosis Procedure .............................................560

Component Inspection ...........................................562

Removal and Installation .......................................562

ICC BRAKE SWITCH ......................................563

Component Description ....................................... ..563

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

563

Wiring Diagram ......................................................564

Diagnosis Procedure .............................................565

Component Inspection ...........................................567

IGNITION SIGNAL ...........................................569

Component Description ....................................... ..569

Wiring Diagram ......................................................570

Diagnosis Procedure .............................................575

Component Inspection ...........................................578

Removal and Installation .......................................580

REFRIGERANT PRESSURE SENSOR ..........581

Component Description ....................................... ..581

Wiring Diagram ......................................................582

Diagnosis Procedure .............................................583

Removal and Installation .......................................585

SNOW MODE SWITCH ...................................586

Description ........................................................... ..586

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

586

Wiring Diagram ......................................................587

Diagnosis Procedure .............................................587

Component Inspection ...........................................589

MIL AND DATA LINK CONNECTOR ...............591

Wiring Diagram .................................................... .591

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

593

Fuel Pressure ....................................................... .593

Idle Speed and Ignition Timing .............................593

Calculated Load Value ..........................................593

Mass Air Flow Sensor ...........................................593

Intake Air Temperature Sensor .............................593

Engine Coolant Temperature Sensor ...................593

Air Fuel Ratio (A/F) Sensor 1 Heater ....................593

Heated Oxygen sensor 2 Heater ..........................593

Crankshaft Position Sensor (POS) .......................594

Camshaft Position Sensor (PHASE) .....................594

Throttle Control Motor .......................................... .594

Fuel Injector ..........................................................594

Fuel Pump .............................................................594

VK45DE

SERVICE INFORMATION .. .......................

595

INDEX FOR DTC ............................................ ..595

DTC No. Index ..................................................... .595

Alphabetical Index .................................................598

PRECAUTIONS .............................................. ..603

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

603

Precaution for Procedure without Cowl Top Cover .603

On Board Diagnosis (OBD) System of Engine and

A/T ........................................................................

603

Precaution .............................................................604

PREPARATION ................................................607

Special Service Tool ............................................ .607

Commercial Service Tool ......................................608

ENGINE CONTROL SYSTEM ..........................609

Schematic ............................................................ .609

Multiport Fuel Injection (MFI) System ...................609

Electronic Ignition (EI) System ..............................612

Fuel Cut Control (at No Load and High Engine

Speed) ..................................................................

612

AIR CONDITIONING CUT CONTROL .............614

Input/Output Signal Chart .................................... .614

System Description ...............................................614

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ..............................................................

615

System Description .............................................. .615

Component Description ........................................616

CAN COMMUNICATION ..................................617

System Description .............................................. .617

EVAPORATIVE EMISSION SYSTEM ..............618

Description ........................................................... .618

Component Inspection ..........................................620

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1249 of 3924

EC-9

C

DE

F

G H

I

J

K L

M

EC A

N

O P

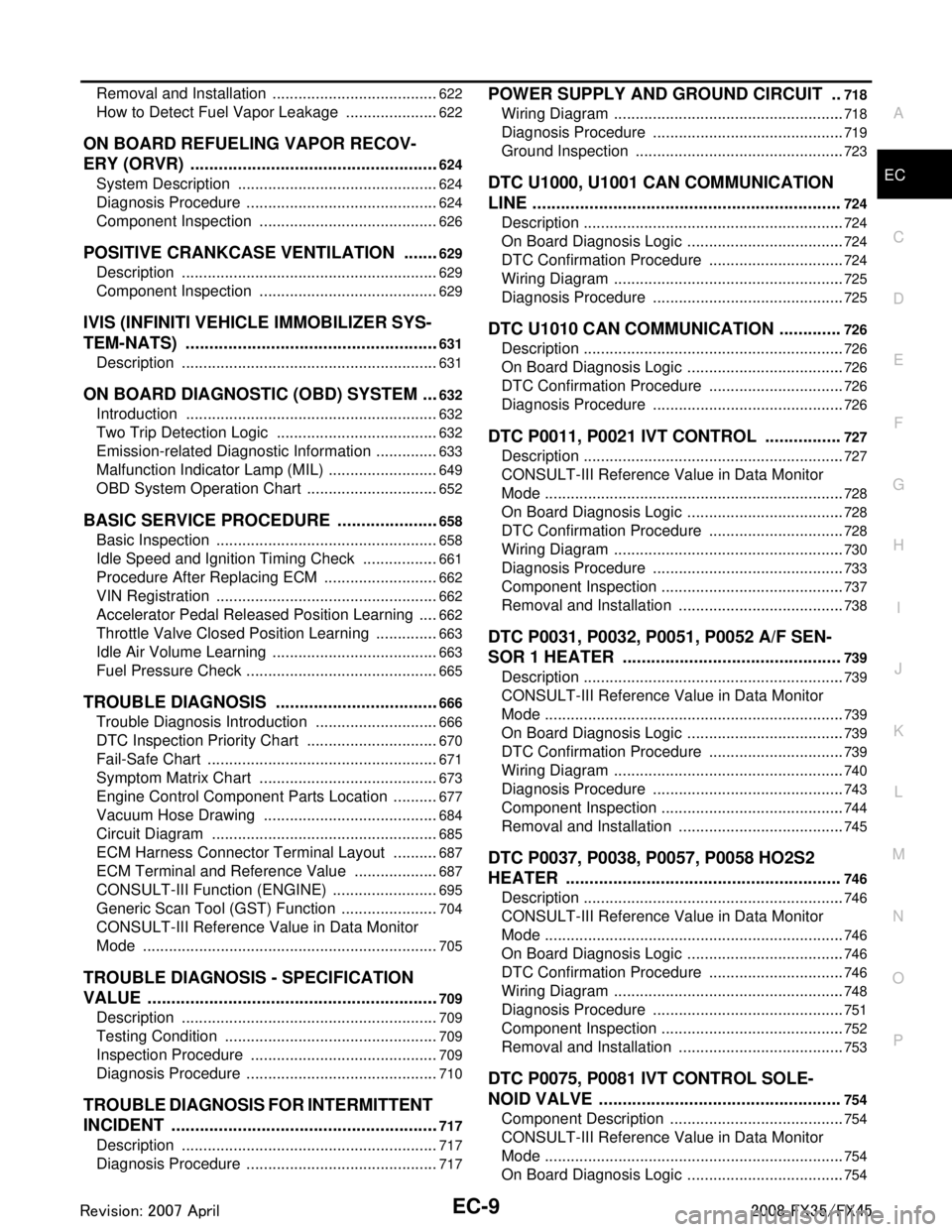

Removal and Installation .....................................

..

622

How to Detect Fuel Vapor Leakage ......................622

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) .....................................................

624

System Description ............................................. ..624

Diagnosis Procedure .............................................624

Component Inspection ..........................................626

POSITIVE CRANKCASE VENTILATION ........629

Description .......................................................... ..629

Component Inspection ..........................................629

IVIS (INFINITI VEHICLE IMMOBILIZER SYS-

TEM-NATS) ......................................................

631

Description .......................................................... ..631

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....632

Introduction ......................................................... ..632

Two Trip Detection Logic ......................................632

Emission-related Diagnostic Information ...............633

Malfunction Indicator Lamp (MIL) ..........................649

OBD System Operation Chart ...............................652

BASIC SERVICE PROCEDURE ......................658

Basic Inspection .................................................. ..658

Idle Speed and Ignition Timing Check ..................661

Procedure After Replacing ECM ...........................662

VIN Registration ....................................................662

Accelerator Pedal Released Position Learning .....662

Throttle Valve Closed Position Learning ...............663

Idle Air Volume Learning .......................................663

Fuel Pressure Check .............................................665

TROUBLE DIAGNOSIS ...................................666

Trouble Diagnosis Introduction ........................... ..666

DTC Inspection Priority Chart ...............................670

Fail-Safe Chart ......................................................671

Symptom Matrix Chart ..........................................673

Engine Control Component Parts Location ...........677

Vacuum Hose Drawing .........................................684

Circuit Diagram .....................................................685

ECM Harness Connector Terminal Layout ...........687

ECM Terminal and Reference Value ....................687

CONSULT-III Function (ENGINE) .........................695

Generic Scan Tool (GST) Function .......................704

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

705

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE ..............................................................

709

Description .......................................................... ..709

Testing Condition ..................................................709

Inspection Procedure ............................................709

Diagnosis Procedure .............................................710

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT .........................................................

717

Description .......................................................... ..717

Diagnosis Procedure .............................................717

POWER SUPPLY AND GROUND CIRCUIT ..718

Wiring Diagram .................................................... ..718

Diagnosis Procedure .............................................719

Ground Inspection .................................................723

DTC U1000, U1001 CAN COMMUNICATION

LINE .................................................................

724

Description .............................................................724

On Board Diagnosis Logic .....................................724

DTC Confirmation Procedure ................................724

Wiring Diagram ......................................................725

Diagnosis Procedure .............................................725

DTC U1010 CAN COMMUNICATION .............726

Description .............................................................726

On Board Diagnosis Logic .....................................726

DTC Confirmation Procedure ................................726

Diagnosis Procedure .............................................726

DTC P0011, P0021 IVT CONTROL ................727

Description .............................................................727

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

728

On Board Diagnosis Logic .....................................728

DTC Confirmation Procedure ................................728

Wiring Diagram ......................................................730

Diagnosis Procedure .............................................733

Component Inspection ...........................................737

Removal and Installation .......................................738

DTC P0031, P0032, P0051, P0052 A/F SEN-

SOR 1 HEATER ..............................................

739

Description .............................................................739

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

739

On Board Diagnosis Logic .....................................739

DTC Confirmation Procedure ................................739

Wiring Diagram ......................................................740

Diagnosis Procedure .............................................743

Component Inspection ...........................................744

Removal and Installation .......................................745

DTC P0037, P0038, P0057, P0058 HO2S2

HEATER ..........................................................

746

Description .............................................................746

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

746

On Board Diagnosis Logic .....................................746

DTC Confirmation Procedure ................................746

Wiring Diagram ......................................................748

Diagnosis Procedure .............................................751

Component Inspection ...........................................752

Removal and Installation .......................................753

DTC P0075, P0081 IVT CONTROL SOLE-

NOID VALVE ...................................................

754

Component Description .........................................754

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

754

On Board Diagnosis Logic .....................................754

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1255 of 3924

EC-15

C

DE

F

G H

I

J

K L

M

EC A

N

O P

DTC P2119 ELECTRIC THROTTLE CON-

TROL ACTUATOR .........................................

1102

Component Description .......................................1102

On Board Diagnosis Logic ..................................1102

DTC Confirmation Procedure ..............................1102

Diagnosis Procedure ...........................................1103

DTC P2122, P2123 APP SENSOR ................1104

Component Description .......................................1104

CONSULT-III Refe rence Value in Data Monitor

Mode ...................................................................

1104

On Board Diagnosis Logic ..................................1104

DTC Confirmation Procedure ..............................1105

Wiring Diagram ...................................................1106

Diagnosis Procedure ...........................................1107

Component Inspection ........................................1109

Removal and Installation .....................................1109

DTC P2127, P2128 APP SENSOR ................1110

Component Description .......................................1110

CONSULT-III Refe rence Value in Data Monitor

Mode ...................................................................

1110

On Board Diagnosis Logic ..................................1110

DTC Confirmation Procedure ..............................1110

Wiring Diagram ...................................................1111

Diagnosis Procedure ...........................................1112

Component Inspection ........................................1115

Removal and Installation .....................................1115

DTC P2135 TP SENSOR ...............................1116

Component Description .......................................1116

CONSULT-III Refe rence Value in Data Monitor

Mode ...................................................................

1116

On Board Diagnosis Logic ..................................1116

DTC Confirmation Procedure ..............................1116

Wiring Diagram ...................................................1117

Diagnosis Procedure ...........................................1118

Component Inspection ........................................1120

Removal and Installation .....................................1121

DTC P2138 APP SENSOR .............................1122

Component Description .......................................1122

CONSULT-III Refe rence Value in Data Monitor

Mode ...................................................................

1122

On Board Diagnosis Logic ..................................1122

DTC Confirmation Procedure ..............................1123

Wiring Diagram ...................................................1124

Diagnosis Procedure ...........................................1125

Component Inspection ........................................1128

Removal and Installation .....................................1128

DTC P2A00, P2A03 A/F SENSOR 1 ..............1129

Component Description .......................................1129

CONSULT-III Refe rence Value in Data Monitor

Mode ...................................................................

1129

On Board Diagnosis Logic ..................................1129

DTC Confirmation Procedure ..............................1129

Wiring Diagram ...................................................1131

Diagnosis Procedure ...........................................1134

Removal and Installation .....................................1138

ASCD BRAKE SWITCH .................................1139

Component Description .......................................1139

CONSULT-III Reference Value in Data Monitor

Mode ....................................................................

1139

Wiring Diagram ....................................................1140

Diagnosis Procedure ...........................................1141

Component Inspection .........................................1142

ASCD INDICATOR .........................................1144

Component Description .......................................1144

CONSULT-III Reference Value in Data Monitor

Mode ....................................................................

1144

Wiring Diagram ....................................................1145

Diagnosis Procedure ...........................................1145

ELECTRICAL LOAD SIGNAL .......................1147

Description ...........................................................1147

CONSULT-III Reference Value in Data Monitor

Mode ....................................................................

1147

Diagnosis Procedure ...........................................1147

FUEL INJECTOR ...........................................1149

Component Description .......................................1149

CONSULT-III Reference Value in Data Monitor

Mode ....................................................................

1149

Wiring Diagram ....................................................1150

Diagnosis Procedure ...........................................1151

Component Inspection .........................................1154

Removal and Installation .....................................1154

FUEL PUMP ...................................................1155

Description ...........................................................1155

CONSULT-III Reference Value in Data Monitor

Mode ....................................................................

1155

Wiring Diagram ....................................................1156

Diagnosis Procedure ...........................................1157

Component Inspection .........................................1159

Removal and Installation .....................................1159

ICC BRAKE SWITCH .....................................1160

Component Description .......................................1160

CONSULT-III Reference Value in Data Monitor

Mode ....................................................................

1160

Wiring Diagram ....................................................1161

Diagnosis Procedure ...........................................1162

Component Inspection .........................................1164

IGNITION SIGNAL .........................................1166

Component Description .......................................1166

Wiring Diagram ....................................................1167

Diagnosis Procedure ...........................................1172

Component Inspection .........................................1175

Removal and Installation .....................................1176

REFRIGERANT PRESSURE SENSOR .........1177

Component Description .......................................1177

Wiring Diagram ....................................................1178

Diagnosis Procedure ...........................................1179

Removal and Installation .....................................1181

SNOW MODE SWITCH ..................................1182

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C