display INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3814 of 3924

TF-28

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYSTEM

OK or NG

OK >>INSPECTION END

NG >> Replace AWD control unit.

DTC C1210 ENGINE SIGNAL 1INFOID:0000000001327448

DIAGNOSTIC PROCEDURE

Check the following if “ECM SIGNAL 1 [C1210]” is di splayed in self-diagnostic results of CONSULT-III.

1.CHECK DTC WITH ECM

Perform self-diagnosis with ECM. Refer to EC-55, "

Emission-Related Diagnostic Information" (VQ engine

models) or EC-633, "

Emission-related Diagnostic Information" (VK engine models).

Is any malfunction detec ted by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 2.

2.CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to TF-20, "

AWD Control Unit Input/Output Signal Reference

Va l u e".

OK or NG

OK >> GO TO 3.

NG >> Check AWD control unit pin terminals for dam age or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

3.CHECK DTC

Perform the self-diagnosis, after driving a vehicle for a while.

OK or NG

OK >> INSPECTION END

NG >> Perform self-diagnosis with ECM again. Refer to EC-55, "

Emission-Related Diagnostic Informa-

tion" (VQ engine models) or EC-633, "Emission-related Diagnostic Information" (VK engine mod-

els).

DTC U1000 CAN COMM CIRCUITINFOID:0000000001327449

DIAGNOSTIC PROCEDURE

Check the following if “CAN COMM CIRCUIT [U1000]” is detected in self-diagnostic results of CONSULT-III.

1.CHECK CAN COMMUNICATION CIRCUIT

With CONSULT-III

1. Turn ignition switch “ON” and start engine.

2. Select “SELF-DIAG RESULTS” mode for “ALL MODE AWD/4WD” with in CONSULT-III.

3. Perform the self-diagnosis.

Is the

“CAN COMM CIRCUIT [U1000]” displayed?

YES >> Print out CONSULT-III screen and go to LAN-43, "CAN System Specification Chart".

NO >> INSPECTION END

Power Supply Circuit for AWD Control UnitINFOID:0000000001327443

CONSULT-III REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

DIAGNOSTIC PROCEDURE

1.CHECK POWER SUPPLY

1. Turn ignition switch “OFF”.

Monitored item [Unit] Condition Display value (Approx.)

BATTERY VOLT [V] Ignition switch: ON Battery voltage

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3816 of 3924

TF-30

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

TROUBLE DIAGNOSIS FOR SYMPTOMS

AWD Warning Lamp Does Not Turn ON When the Ignition Switch Is Turned to ON

INFOID:0000000001327450

DIAGNOSTIC PROCEDURE

1.CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to TF-21, "

CONSULT-III Function (ALL MODE AWD/4WD)".

Is the

“CAN COMM CIRCUIT [U1000]” displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer to TF-28, "DTC U1000 CAN COMM

CIRCUIT".

NO >> GO TO 2.

2.CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to TF-20, "

AWD Control Unit Input/Output Signal Reference

Va l u e".

OK or NG

OK >> GO TO 3.

NG >> Check AWD control unit pin terminals for dam age or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

3.CHECK OUTPUT SIGNAL WITH UNIFIED METER AND A/C AMP.

With CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “METER A/C AMP” with CONSULT-III.

3. Start the engine, and then make sure that “4WD W/L” display turns from “ON” to “OFF” after several sec-

onds.

OK or NG

OK >> GO TO 4.

NG >> Perform trouble diagnosis for combination meter. Refer to DI-15, "

Trouble Diagnosis".

4.SYMPTOM CHECK

Check again.

OK or NG

OK >> INSPECTION END

NG >> Replace unified meter control unit assembly. Refer to DI-23, "

Disassembly and Assembly of Com-

bination Meter".

AWD Warning Lamp Does Not Turn OFF Several Seconds after Engine Started

INFOID:0000000001327451

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to TF-21, "

CONSULT-III Function (ALL MODE AWD/4WD)".

Is any malfunction detec ted by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 2.

2.CHECK AWD CONTROL UNIT POWER SUPPLY CIRCUIT

1. Turn ignition switch “OFF”.

Monitor item Condition Display value

4WD W/L Ignition switch ON ON

Start engine (after several seconds) OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3818 of 3924

TF-32

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

3. Start the engine, and then make sure that “4WD W/L” display turns from “ON” to “OFF” after several sec-

onds.

OK or NG

OK >> GO TO 6.

NG >> Perform trouble diagnosis for combination meter. Refer to DI-15, "

Trouble Diagnosis".

6.SYMPTOM CHECK

Check again.

OK or NG

OK >> INSPECTION END

NG >> Replace unified meter control unit assembly. Refer to DI-23, "

Disassembly and Assembly of Com-

bination Meter".

Heavy Tight-Corner Braking Symptom Occurs When the Vehicle Is Driven and the

Steering Wheel Is Turned Fu lly to Either Side after the Engine Is Started

INFOID:0000000001327452

NOTE:

Light tight-corner braking symptom may occur depending on driving conditions. This is not malfunc-

tion.

DIAGNOSTIC PROCEDURE

1.CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to TF-21, "

CONSULT-III Function (ALL MODE AWD/4WD)".

Is the

“CAN COMM CIRCUIT [U1000]” displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer to TF-28, "DTC U1000 CAN COMM

CIRCUIT".

NO >> GO TO 2.

2.CHECK ACCELERATOR PEDAL POSITION SIGNAL CIRCUIT

Perform self-diagnosis for ECM. Refer to EC-55, "

Emission-Related Diagnostic Information" (VQ35DE mod-

els) or EC-633, "

Emission-related Diagnostic Information" (VK45DE models).

Is any malfunction detec ted by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 3.

3.CHECK SYSTEM FOR AWD SOLENOID

Perform trouble diagnosis for AWD solenoid system. Refer to TF-25, "

DTC C1204 4WD SOLENOID".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK ELECTRIC CONTROLLED COUPLING

1. Turn ignition switch “OFF”.

2. Set the selector lever to “N” (neutral) position and disengage the parking brake.

3. Lift up the vehicle.

4. Rotate the rear propeller shaft by hand.

5. Hold front propeller shaft lightly.

Does front propeller shaft rotate?

YES >> Replace electric controlled coupling for mec hanical malfunction (clutch sticking etc.). Refer to TF-

40, "Disassembly and Assembly".

NO >> GO TO 5.

Monitor item Condition Display value

4WD W/L Ignition switch ON ON

Start engine (after several seconds) OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3820 of 3924

TF-34

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

DIAGNOSTIC PROCEDURE

1.CHECK TIRE

Check the following.

Tire pressure

Wear condition

Longitudinal tire size (There is no difference between longitudinal tires.)

OK or NG

OK >> GO TO 2.

NG >> Drive at vehicle speed of 20 km/h (12 MPH) or more for 5 seconds or more after repairing or replacing damaged parts. (Initialize improper size tire information.)

2.CHECK INPUT SIGNAL OF TIRE DIAMETER

With CONSULT-III

1. Start engine.

2. Drive at 20 km/h (12 MPH) or more for approx. 200 seconds.

3. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-III.

4. Check monitor “DIS-TIRE MONI”.

Display of

“DIS-TIRE MONI”

“0-4mm”>> INSPECTION END

Except for “0-4mm”>>GO TO 3.

3.CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to TF-20, "

AWD Control Unit Input/Output Signal Reference

Va l u e".

OK or NG

OK >> GO TO 4.

NG >> Check AWD control unit pin terminals for dam age or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

4.SYMPTOM CHECK

Check again.

OK or NG

OK >> INSPECTION END

NG >> Replace AWD control unit.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3852 of 3924

WT-12

< SERVICE INFORMATION >

TIRE PRESSURE MONITORING SYSTEM

Note 1: Standard air pressure is for 220 kpa (2.2 kg/cm2, 32 psi) vehicles.

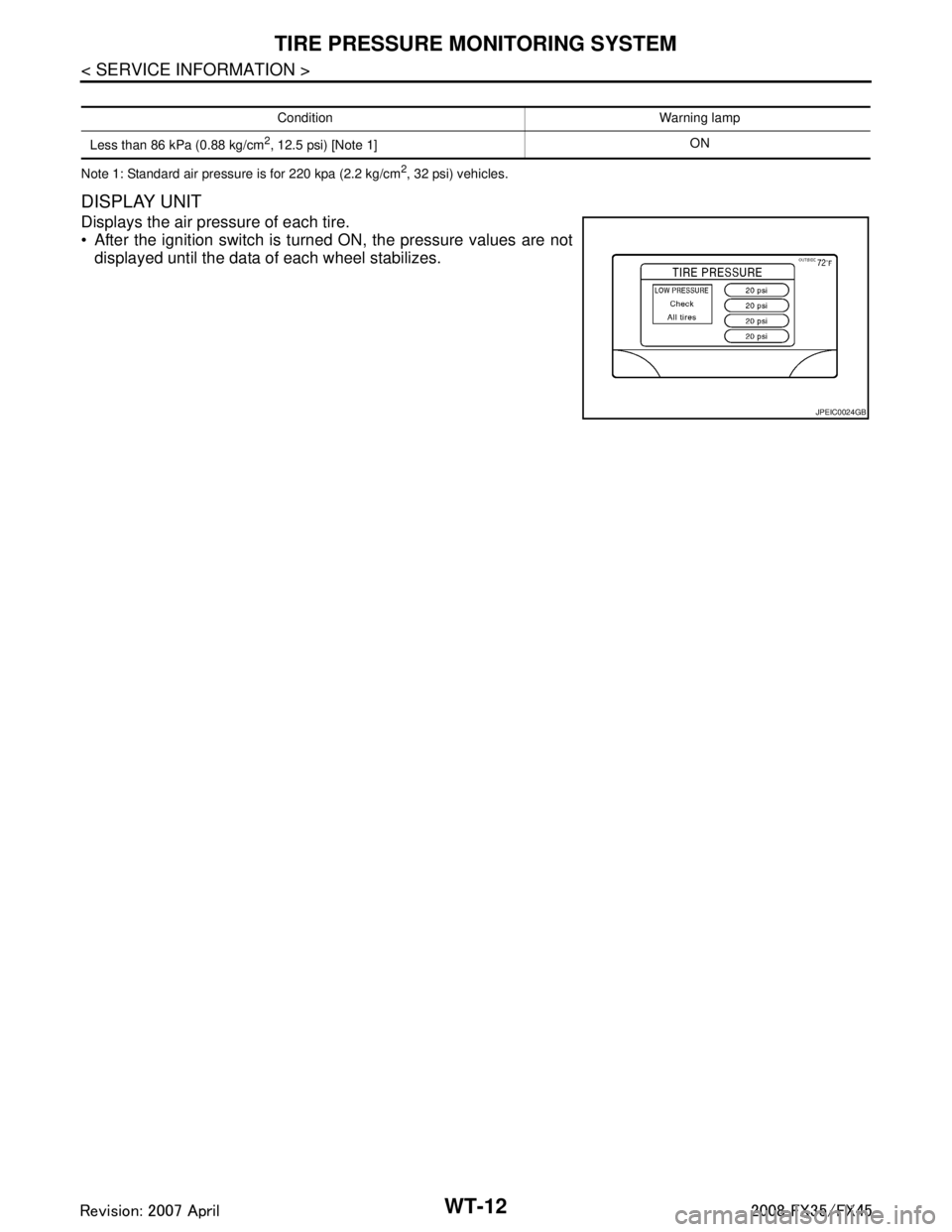

DISPLAY UNIT

Displays the air pressure of each tire.

After the ignition switch is turned ON, the pressure values are notdisplayed until the data of each wheel stabilizes.

Condition Warning lamp

Less than 86 kPa (0.88 kg/cm

2, 12.5 psi) [Note 1] ON

JPEIC0024GB

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3862 of 3924

WT-22

< SERVICE INFORMATION >

TROUBLE DIAGNOSES

NOTE:

If more than one wheel transmitter is NOT activated, the warning lamp blinking patterns for those wheels will combine. (Example: one

blink/OFF/three blinks = Rear LH and Rear RH transmitters are not activated.)

RUN-FLAT TIRE WARNING LAMP DIAGNOSTIC CHART

CONSULT-III Function (BCM)INFOID:0000000001327585

FUNCTION

CONSULT-III can display each self-diagnostic item using the diagnostic test modes shown following.

Low tire pres-

sure warning

lampWarning lamp blinks

4 times

Rear LH wheel trans-

mitter is not activat-

ed.Activate rear LH wheel

transmitter. Refer to WT-20,

"Transmitter Wake Up Oper-

ation".

Warning lamp comes

on and does not turn

off The fuse for combi-

nation meter from

battery is pulled out.

Check the fuse for combina-

tion meter from battery. In-

stall or replace (if needed).

BCM connector

pulled out. Check BCM connector. Re-

connect if needed.

Low tire pressure or

tire pressure moni-

toring system mal-

function. Perform CONSULT-III Self

Diagnosis. Refer to "Self-

Diagnosis".

- Perform ID Registration if needed. Refer to WT-19,

"ID Registration Proce-

dure".

Turn signal

lamp Turn signal lamp

does not flash 2 times

or horn does not

sound after transmit-

ter activation. 1. Tool J-45295

(special ser-

vice tool) bat-

tery low.

2. Ignition OFF

during activa-

tion.

3. Tool J-45295

(special ser-

vice tool) not

positioned cor-

rectly.

4. Transmitters al- ready activated. 1. Install new battery.

2. Make sure ignition is

ON during activation.

3. Position tool correctly during activation.

4. None

Diagnosis

Item Symptom

(Ignition switch ON) Low tire pressure wa

rning lamp Cause Action

SEIA0597E

SEIA0598E

Diagnosis

Item Symptom

(Ignition Switch ON) Run-flat tire warning lamp Cause Action

Run-flat tire

warning lamp Warning lamp comes

on and does not turn

off Tire pressure drop to

86 kPa (0.88 kg/cm

2,

12.5 psi) or less. 1. Check air pressure of

tire.

2. Repair or change the

tire (if needed)

3. Perform CONSULT-III Self Diagnosis. Refer

to WT-22, "

CONSULT-

III Function (BCM)".SEIA0793E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3863 of 3924

TROUBLE DIAGNOSESWT-23

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

WORK SUPPORT MODE

Test Item

ID Read

ID Regist

ID Read

The registered ID number is displayed.

ID Regist

Refer to WT-19, "ID Registration Procedure".

SELF-DIAGNOSTIC RESULTS MODE

NOTE:

Before performing the self-diagnosis, be sure to register the ID, or else the actual malfunction location may be different from that dis-

played on CONSULT-III.

DATA MONITOR MODE

Display item List

Diagnostic test mode Function

WORK SUPPORT This mode enables a technician to adjust some devices faster and more accurately by following

the indications on CONSULT-III.

SELF-DIAGNOSTIC RESULTS Self-diagnostic results can be read and erased quickly.

DATA MONITOR Input/Output data in the control unit can be read.

ACTIVE TEST Diagnostic Test Mode in with CONSULT-III drives some actuators apart from the control unit

(BCM) and also shifts some pa

rameters in a specified range.

Diagnostic item Diagnostic item is detected when ···

[C1704]

[C1705]

[C1706]

[C1707] LOW PRESSURE FL

LOW PRESSURE FR

LOW PRESSURE RR

LOW PRESSURE RL Front-left tire pressure drops to 173 kPa (1.8 kg/cm

2, 25 psi) or less.

Front-right tire pressure drops to 173 kPa (1.8 kg/cm2, 25 psi) or less.

Rear-right tire pressure dr ops to 173 kPa (1.8 kg/cm2, 25 psi) or less.

Rear-left tire pressure drops to 173 kPa (1.8 kg/cm2, 25 psi) or less.

[C1708]

[C1709]

[C1710]

[C1711] [NO DATA] FL

[NO DATA] FR

[NO DATA] RR

[NO DATA] RL Data from front-left transmitter can not be received.

Data from front-right transmitter can not be received.

Data from rear-right transm

itter can not be received.

Data from rear-left transmitter can not be received.

[C1712]

[C1713]

[C1714]

[C1715] [CHECKSUM ERR] FL

[CHECKSUM ERR] FR

[CHECKSUM ERR] RR

[CHECKSUM ERR] RL Checksum data from front-left transmitter is malfunctioning.

Checksum data from front-right transmitter is malfunctioning.

Checksum data from

rear-right transmitter is malfunctioning.

Checksum data from rear-left transmitter is malfunctioning.

[C1716]

[C1717]

[C1718]

[C1719] [PRESS DATA ERR] FL

[PRESS DATA ERR] FR

[PRESS DATA ERR] RR

[PRESS DATA ERR] RL Air pressure data from front-left transmitter is malfunctioning.

Air pressure data from front-right transmitter is malfunctioning.

Air pressure data from

rear-right transmitter is malfunctioning.

Air pressure data from rear-left transmitter is malfunctioning.

[C1720]

[C1721]

[C1722]

[C1723] [CODE ERR] FL

[CODE ERR] FR

[CODE ERR] RR

[CODE ERR] RL Function code data from front-left transmitter is malfunctioning.

Function code data from front-right transmitter is malfunctioning.

Function code data from rear-righ

t transmitter is malfunctioning.

Function code data from rear-left transmitter is malfunctioning.

[C1724]

[C1725]

[C1726]

[C1727] [BATT VOLT LOW] FL

[BATT VOLT LOW] FR

[BATT VOLT LOW] RR

[BATT VOLT LOW] RL Battery voltage of front-left transmitter drops.

Battery voltage of front-right transmitter drops.

Battery voltage of rea

r-right transmitter drops.

Battery voltage of rear-left transmitter drops.

[C1729] VHCL SPEED SIG ERR Veh icle speed signal is error.

[C1730]

[C1731]

[C1732]

[C1733] FLAT TIRE FL

FLAT TIRE FR

FLAT TIRE RR

FLAT TIRE RL Front-left tire pressure drops to 86 kPa (0.88 kg/cm

2, 12.5 psi) or less.

Front-right tire pressure drops to 86 kPa (0.88 kg/cm2, 12.5 psi) or less.

Rear-right tire pressure dr ops to 86 kPa (0.88 kg/cm2, 12.5 psi) or less.

Rear-left tire pressure drops to 86 kPa (0.88 kg/cm2, 12.5 psi) or less.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3868 of 3924

WT-28

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Transmitter or Control Unit (BCM)INFOID:0000000001327589

MALFUNCTION CODE NO. 21, 22, 23 OR 24

1.CHECK CONTROL UNIT

Drive for several minutes. Check all tire pr essures with CONSULT-III “DATA MONITOR ITEM”.

Are all tire pressures displayed 0 kPa?

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK REMOTE KEYLESS EN TRY RECEIVER CONNECTOR

1. Disconnect remote keyless entry receiver harness connector M98.

2. Check terminals for damage or loose connection.

3. Reconnect harness connector.

OK or NG

OK >> Replace BCM refer to BCS-13, "Removal and Installation of BCM", then GO TO 3.

NG >> Repair or replace remote keyless entry receiver harness connector.

3.ID REGISTRATION

Perform ID registration of all transmitters.

Is there any tire that ID can not be registered to?

YES >> Replace transmitter of the tire, then GO TO 5.

NO >> GO TO 4.

4.VEHICLE DRIVING

Drive at a speed of 40 km/h (25 MPH) or more for several minutes without stopping. Check all tire pressures with CONSULT-III “DATA MONITOR ITEM” within 15 minutes after vehicle speed

becomes 17 km/h (11 MPH).

Does

“DATA MONITOR ITEM” display tire pressure as normal without any warning lamp?

YES >> INSPECTION END

NO >> GO TO 5.

5.ID REGISTRATION AND VEHICLE DRIVING

1. Perform ID registration of all transmitters.

2. Drive at a speed of 40 km/h (25 MPH) or more fo r 3 minutes, and then drive the vehicle at any speed for

10 minutes. Then check all tire pressures with CO NSULT-III “DATA MONITOR ITEM” within 5 minutes.

Does

“DATA MONITOR ITEM” display tire pressure as normal without any warning lamp?

YES >> INSPECTION END

NO >> Go to the inspection applicable to DTC.

Transmitter - 1INFOID:0000000001327590

MALFUNCTION CODE NO. 31, 32, 33, 34, 41, 42, 43, 44, 45, 46, 47 OR 48

1.ID REGISTRATION (CORRECTION OF TRANSMITTER LOCATION)

1. Perform ID registration of all transmitters.

2. Drive at a speed of 40 km/h (25 MPH) or more fo r 3 minutes, and then drive the vehicle at any speed for

10 minutes.

>> GO TO 2.

2.REPLACE TRANSMITTER

1. Check low tire pressure warning condition again, replace malfunctioning transmitter.

2. Perform ID registration of all transmitters.

Can ID registration of all transmitters be completed?

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3869 of 3924

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

WT-29

< SERVICE INFORMATION >

C

D F

G H

I

J

K L

M A

B

WT

N

O P

YES >> GO TO 3.

NO >> Go to the inspection 1. Refer to WT-28, "

Transmitter or Control Unit (BCM)".

3.VEHICLE DRIVING

Drive at a speed of 40 km/h (25 MPH) or more for 3 minutes, and then drive the vehicle at any speed for 10

minutes. Then check all tire pressures with CO NSULT-III “DATA MONITOR ITEM” within 5 minutes.

Does

“DATA MONITOR ITEM” displayed tire pressure as normal without any warning lamp?

YES >> INSPECTION END.

NO >> Replace malfunctioning transmitter, and perform “Step 3” again.

Transmitter - 2INFOID:0000000001327591

MALFUNCTION CODE NO. 35, 36, 37 OR 38

1.CHECK ALL TIRE PRESSURES

Check all tire pressures. Refer to WT-35, "

Tire".

Are there any tires whose pressure is

“64 psi” or more?

YES >> Adjust tire pressure to specified value.

NO >> GO TO 2.

2.VEHICLE DRIVING

1. Perform ID registration of all transmitters.

2. Drive at a speed of 40 km/h (25 MPH) or more for several minutes without stopping.

Check all tire pressures with CONSULT-III “DATA MO NITOR ITEM” within 15 minutes after vehicle speed

become 17 km/h (11 MPH).

>> Replace transmitter with new one if “DATA MO NITOR ITEM” displayed 64 psi or more. Then GO

TO 3.

3.ID REGISTRATION AND VEHICLE DRIVING

1. Perform ID registration of all transmitters.

2. Drive at a speed of 40 km/h (25 MPH) or more fo r 3 minutes, and then drive the vehicle at any speed for

10 minutes. Then check all tire pressures with CONS ULT-III “DATA MONITOR ITEM” within 5 minutes.

Does

“DATA MONITOR ITEM” display tire pressure as normal without any warning lamp?

YES >> INSPECTION END

NO >> Go to the inspection applicable to DTC.

Vehicle Speed SignalINFOID:0000000001327592

MALFUNCTION CODE NO. 52

1.CHECK SELF-DIAGNOSIS RESULTS

1. Select “SELF-DIAG RESULTS” on “SELECT DIAG MODE” screen.

2. Check display contents in self-diagnostic results.

Is

“CAN COMM CIRCUIT” displayed in the self-diagnosis display items?

YES >> Malfunction in CAN communication system. Go to LAN-43, "CAN System Specification Chart".

NO >> No malfunction. Check combination meter refer to DI-5, "

System Description".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3870 of 3924

WT-30

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

TROUBLE DIAGNOSIS FOR SYMPTOMS

Low Tire Pressure Warning Lamp Does Not Come On When Ignition Switch Is Turned

On

INFOID:0000000001327593

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSIS RESULTS

1. Select “SELF-DIAG RESULTS” on “SELECT DIAG MODE” screen.

2. Check display contents in self-diagnostic results.

Is

“CAN COMM CIRCUIT” displayed in the self-diagnosis display items?

YES >> Malfunction in CAN communication system. Go to LAN-43, "CAN System Specification Chart".

NO >> No malfunction. GO TO 2.

2.CHECK COMBINATION METER

Check combination meter function.

OK or NG

OK >> GO TO 3.

NG >> Check combination meter. Refer to DI-5, "

System Description".

3.CHECK LOW TIRE PRESSURE WARNING LAMP

Disconnect BCM harness connectors M3 and M4.

Does the warning lamp activate?

YES >> Replace BCM. Refer to BCS-13, "Removal and Installation of BCM".

NO >> Check combination meter and repair or replace.

Low Tire Pressure Warning Lamp Stays On When Ignition Switch Is Turned On

INFOID:0000000001327594

DIAGNOSTIC PROCEDURE

1.CHECK CONNECTOR

1. Disconnect BCM harness connectors M3 and M4.

2. Check terminals for damage or loose connections.

OK or NG

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

2.CHECK POWER SUPPLY CIRCUIT (BATTERY)

Make sure voltage between BCM harness connector M4 and

ground.

OK or NG

OK >> GO TO 3.

NG >> Check BCM power supply circuit for open or short.

3.CHECK POWER SUPPLY CIRCUIT (IGN)

1. Turn ignition switch ON.

Te r m i n a l Vol tag e

(+) (–)

42, 55 Ground 12V

SEIA0435E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C