Oil INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3639 of 3924

SC-30

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

BatteryINFOID:0000000001328260

StarterINFOID:0000000001328261

AlternatorINFOID:0000000001328262

Typ e11 0 D 2 6 L

Capacity V - AH 12 - 75

Cold cranking current (F or reference value) A 720

Applied model VK45DE VQ3 5DE (2WD) VQ35DE (AWD)

Ty p e M002T85075 S114-880A S114-881A

MITSUBISHI make HITACHI make Reduction gear type

System voltage V 12

No-load Te r m i n a l v o l t a g e V 11

Current A Less than 145 Less than 90

Revolution rpm More than 3,300 More than 2,880

Minimum diameter of commutator mm (in) 31.4 (1.236) 28.0 (1.102)

Minimum length of brush mm (in) 11.0 (0.433) 10.5 (0.413)

Brush spring tension N (kg, lb) 26.7 - 36.1

(2.72 - 3.68,

6.80 - 8.12) 16.2 (1.65, 3.6)

Clearance between bearing metal and armature shaft mm (in) Less than 0.2 (0.008)

Clearance between pinion front edge and pinion stopper mm (in) 0.5 - 2.0

(0.020 - 0.079) —

Movement in height of pinion assembly mm (in) — 0.3 - 2.5 (0.012 - 0.098)

Applied model VK45DE VQ35DE

Ty p e LR1110 - 716B A3TG0191

HITACHI make MITSUBISHI make

Nominal rating V - A 12 - 110

Ground polarity Negative

Minimum revolution under no-load (When 13.5 V is applied) rpm Less than 1,100 Less than 1,000

Hot output current (When 13.5 V is applied) A/rpm More than 70/1,800

More than 91/2,500

More than 110/5,000 More than 37/1,300

More than 92/2,500

More than 103/5,000

Regulated output voltage V 14.1 - 14.7

Minimum length of brush mm (in) More than 6.00 (0.236) More than 5.00 (0.197)

Brush spring pressure N (g, oz) 1.00 - 3.43

(102 - 350, 3.60 - 12.34) 4.8 - 6.0

(490 - 612, 17.28 - 21.60)

Slip ring minimum outer diameter mm (in) More than 26.0 (1.024) More than 22.1 (0.870)

Rotor (Field coil) resistance Ω2.31 1.7 - 2.1

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3643 of 3924

SE-4

< SERVICE INFORMATION >

PRECAUTIONS

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612906

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Service NoticeINFOID:0000000001328091

When removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

Handle trim, molding, instruments, grille, etc. carefull y during removing or installing. Be careful not to oil or

damage them.

Apply sealing compound where necessary when installing parts.

When applying sealing compound, be careful that the sealing compound does not protrude from parts.

When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust preven-

tion measures.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3772 of 3924

DRIVER AIR BAG MODULESRS-35

< SERVICE INFORMATION >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

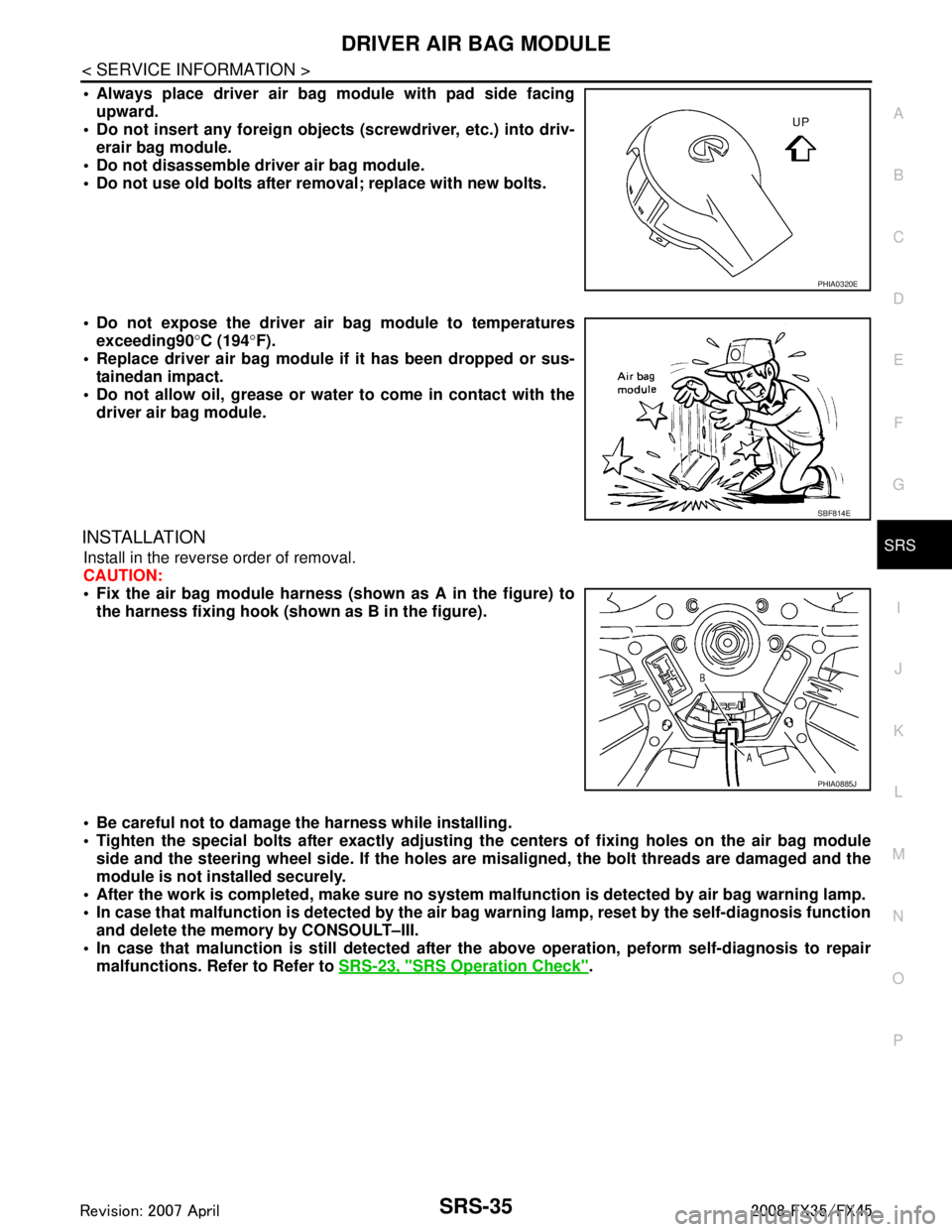

Always place driver air bag module with pad side facing upward.

Do not insert any foreign objects (screwdriver, etc.) into driv-

erair bag module.

Do not disassemble driver air bag module.

Do not use old bolts after removal; replace with new bolts.

Do not expose the driver air bag module to temperatures exceeding90 °C (194 °F).

Replace driver air bag module if it has been dropped or sus-

tainedan impact.

Do not allow oil, grease or water to come in contact with the

driver air bag module.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Fix the air bag module harness (shown as A in the figure) to

the harness fixing hook (s hown as B in the figure).

Be careful not to damage the harness while installing.

Tighten the special bolts after exactly adjusting the centers of fi xing holes on the air bag module

side and the steering wheel side. If the holes are misaligned, the bolt threads are damaged and the

module is not installed securely.

After the work is completed, make sure no system malfunction is detected by air bag warning lamp.

In case that malfunction is detected by the air ba g warning lamp, reset by the self-diagnosis function

and delete the memory by CONSOULT–III.

In case that malunction is still detected after th e above operation, peform self-diagnosis to repair

malfunctions. Refer to Refer to SRS-23, "

SRS Operation Check".

PHIA0320E

SBF814E

PHIA0885J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3776 of 3924

FRONT PASSENGER AIR BAG MODULESRS-39

< SERVICE INFORMATION >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

Replace front passenger air bag module if it has been dropped or sustained an impact.

Do not expose the front passenger air bag module to tempera-

tures exceeding 90 °C (194 °F).

Do not allow oil, grease or water to come in contact with the

front passenger air bag module.

After front passenger air bag module inflates, the instrument

panel assembly should be replaced.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Be careful not to damage the harness while installing.

After the work is completed, make sure no system malfunction is detected by air bag warning lamp.

In case that malfunction is detected by the air ba g warning lamp, reset by the self-diagnosis function

and delete the memory by CONSULT −III.

In case that malfunction is still detected after th e above operation, perform self-diagnosis to repair

malfunctions. Refer to Refer to SRS-23, "

SRS Operation Check".

SBF814E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3778 of 3924

SIDE CURTAIN AIR BAG MODULESRS-41

< SERVICE INFORMATION >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

Replace side curtain air bag modu le if it has been dropped or

sustained an impact.

Do not expose the air bag mo dule to temperatures exceeding

90 °C (194 °F).

Do not allow oil, grease or water to come in contact with the

side curtain air bag module.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Be careful not to damage the air bag harness.

After the work is completed, make sure no system malfunction is detected by air bag warning lamp.

In case that malfunction is detected by the air ba g warning lamp, reset by the self-diagnosis function

and delete the memory by CONSULT-III.

In case that malfunction is still detected after the avove operation, perform self-diagnosis to repair

malfunctions. Refer to Refer to SRS-23, "

SRS Operation Check".

SBF814E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3787 of 3924

TF-1

DRIVELINE/AXLE

CEF

G H

I

J

K L

M

SECTION TF

A

B

TF

N

O P

CONTENTS

TRANSFER

SERVICE INFORMATION .. ..........................3

DTC INDEX ..................................................... .....3

C1201-C1210, U1000 ......................................... ......3

PRECAUTIONS ...................................................4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution .................................................................4

Service Notice or Precaution .....................................5

PREPARATION ...................................................6

Special Service Tool ........................................... ......6

Commercial Service Tool ..........................................7

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

9

NVH Troubleshooting Chart ................................ ......9

TRANSFER FLUID .............................................10

Replacement ....................................................... ....10

Inspection ................................................................10

AWD SYSTEM ................................................ ....11

Power Transfer Diagram ..................................... ....11

System Description .................................................11

Schematic ...............................................................13

CAN Communication ...............................................13

TROUBLE DIAGNOSIS .....................................14

Fail-Safe Function ............................................... ....14

How to Perform Trouble Diagnosis .........................14

Location of Electrical Parts ......................................15

Circuit Diagram .......................................................16

Wiring Diagram - AWD - ..........................................17

Trouble Diagnosis Chart by Symptom ....................20

AWD Control Unit Input/Output Signal Reference

Value ................................................................... ....

20

CONSULT-III Function (ALL MODE AWD/4WD) ....21

TROUBLE DIAGNOSIS FOR SYSTEM .............24

DTC C1201 CONTROLLER FAILURE ................ ....24

DTC C1203 ABS SYSTEM ......................................24

DTC C1204 4WD SOLENOID ............................. ....25

DTC C1205 4WD ACTUATOR RLY ........................27

DTC C1210 ENGINE SIGNAL 1 ..............................28

DTC U1000 CAN COMM CIRCUIT .........................28

Power Supply Circuit for AWD Control Unit .............28

TROUBLE DIAGNOSIS FOR SYMPTOMS ......30

AWD Warning Lamp Does Not Turn ON When the

Ignition Switch Is Turned to ON ...............................

30

AWD Warning Lamp Does Not Turn OFF Several

Seconds after Engine Started ..................................

30

Heavy Tight-Corner Braking Symptom Occurs

When the Vehicle Is Driven and the Steering

Wheel Is Turned Fully to Either Side after the En-

gine Is Started .........................................................

32

Vehicle Does Not Enter AWD Mode Even Though

AWD Warning Lamp Turned to OFF .......................

33

While Driving, AWD Warning Lamp Flashes Rap-

idly (When Flashing in Approx. 1 Minute and Then

Turning OFF) ....................................................... ....

33

While Driving, AWD Warning Lamp Flashes Slow-

ly (When Continuing to Flash until Turning Ignition

Switch OFF) .............................................................

33

AWD CONTROL UNIT ......................................35

Removal and Installation .........................................35

FRONT OIL SEAL .............................................36

Removal and Installation .........................................36

REAR OIL SEAL ...............................................37

Removal and Installation .........................................37

AIR BREATHER HOSE ....................................39

Removal and Installation .........................................39

TRANSFER ASSEMBLY ..................................40

Removal and Installation .........................................40

Disassembly and Assembly .....................................40

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3792 of 3924

TF-6

< SERVICE INFORMATION >

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000001327426

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name Description

ST27862000

(—)

Drift

a: 62.5 mm (2.461 in) dia.

b: 42 mm (1.65 in) dia. Installing front oil seal

KV381054S0

(J-34286)

Puller Removing rear oil seal

ST30720000

(J-25405)

Drift

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia. Installing rear oil seal

Installing mainshaft oil seal

KV40104830

(—)

Drift

a: 70 mm (2.76 in) dia.

b: 63.5 mm (2.500 in) dia. Installing rear oil seal

KV38100300

(J-25523)

Drift

a: 54 mm (2.13 in) dia.

b: 46 mm (1.81 in) dia.

c: 32 mm (1.26 in) dia. Removing mainshaft bearing

ST33052000

(—)

Drift

a: 28 mm (1.10 in) dia.

b: 22 mm (0.87 in) dia. Removing mainshaft assembly

ZZA0194D

ZZA0601D

ZZA0811D

ZZA1003D

ZZA1046D

ZZA1000D

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3795 of 3924

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGTF-9

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

TF

N

O P

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

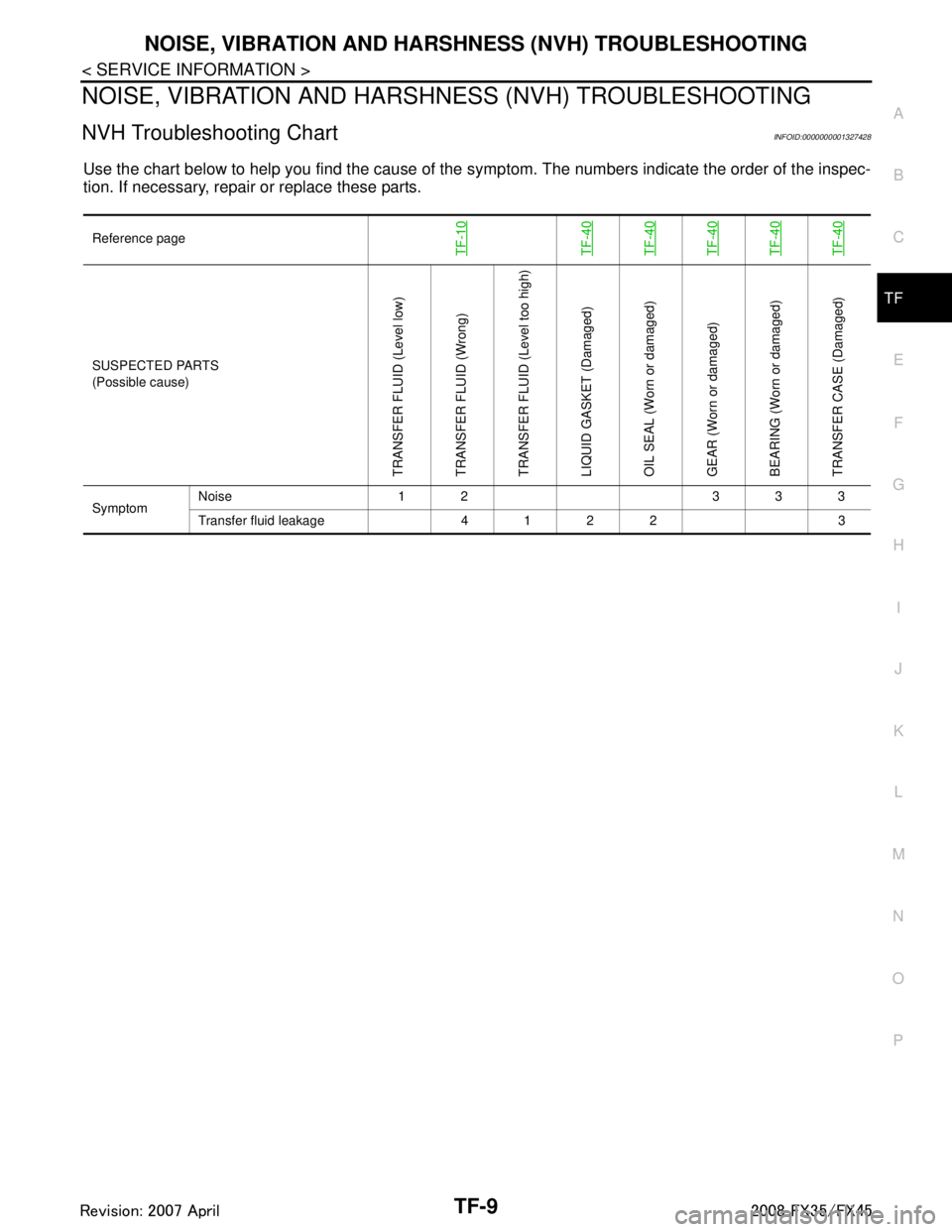

NVH Troubleshooting ChartINFOID:0000000001327428

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

Reference pageTF-10TF-40TF-40TF-40TF-40TF-40

SUSPECTED PARTS

(Possible cause)

TRANSFER FLUID (Level low)

TRANSFER FLUID (Wrong)

TRANSFER FLUID (Level too high)

LIQUID GASKET (Damaged)

OIL SEAL (Worn or damaged)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

TRANSFER CASE (Damaged)

Symptom Noise 1 2 3 3 3

Transfer fluid leakage 4 1 2 2 3

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3822 of 3924

TF-36

< SERVICE INFORMATION >

FRONT OIL SEAL

FRONT OIL SEAL

Removal and InstallationINFOID:0000000001327457

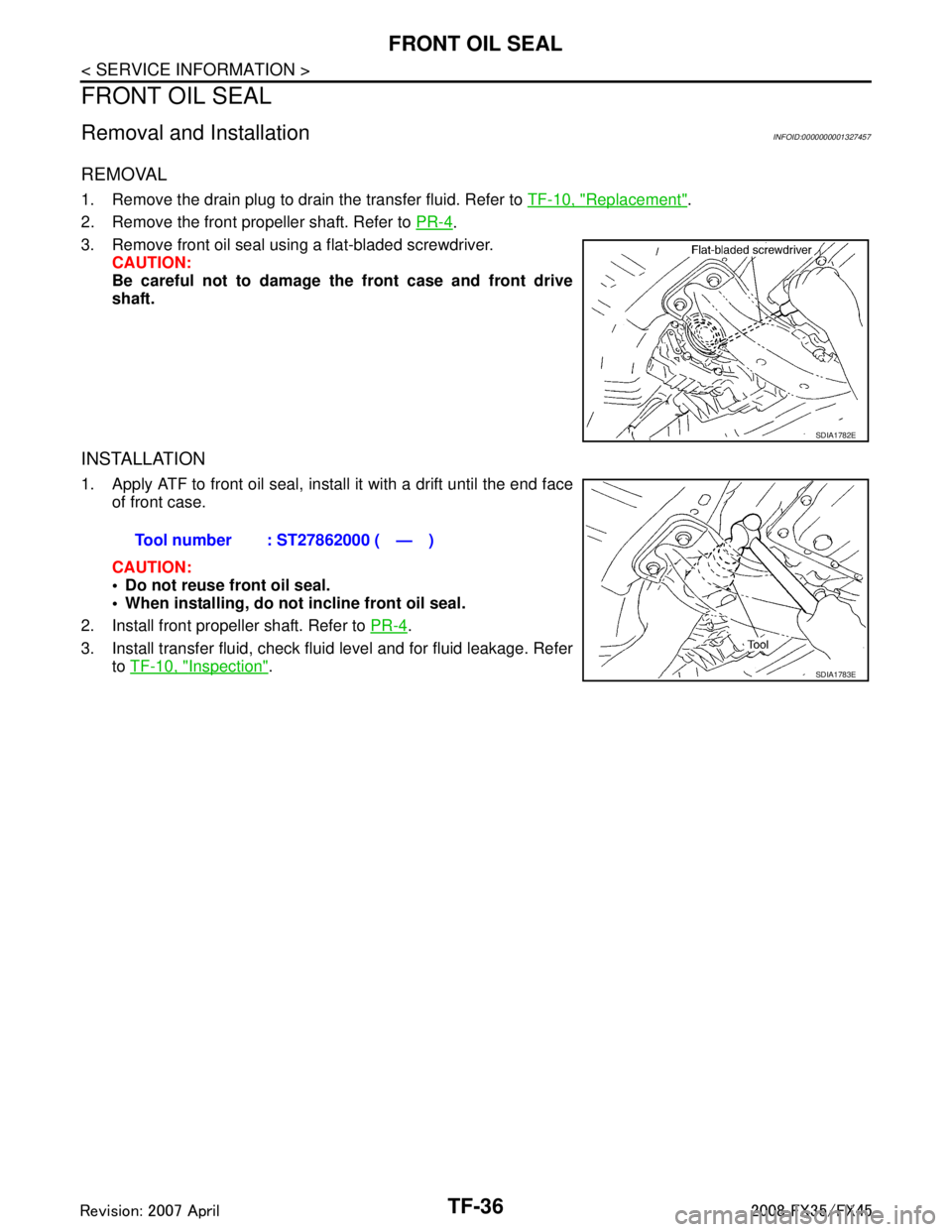

REMOVAL

1. Remove the drain plug to drain the transfer fluid. Refer to TF-10, "Replacement".

2. Remove the front propeller shaft. Refer to PR-4

.

3. Remove front oil seal using a flat-bladed screwdriver. CAUTION:

Be careful not to damage the front case and front drive

shaft.

INSTALLATION

1. Apply ATF to front oil seal, install it with a drift until the end faceof front case.

CAUTION:

Do not reuse front oil seal.

When installing, do no t incline front oil seal.

2. Install front propeller shaft. Refer to PR-4

.

3. Install transfer fluid, check fluid level and for fluid leakage. Refer to TF-10, "

Inspection".

SDIA1782E

Tool number : ST27862000 ( — )

SDIA1783E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3823 of 3924

REAR OIL SEALTF-37

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

TF

N

O P

REAR OIL SEAL

Removal and InstallationINFOID:0000000001327458

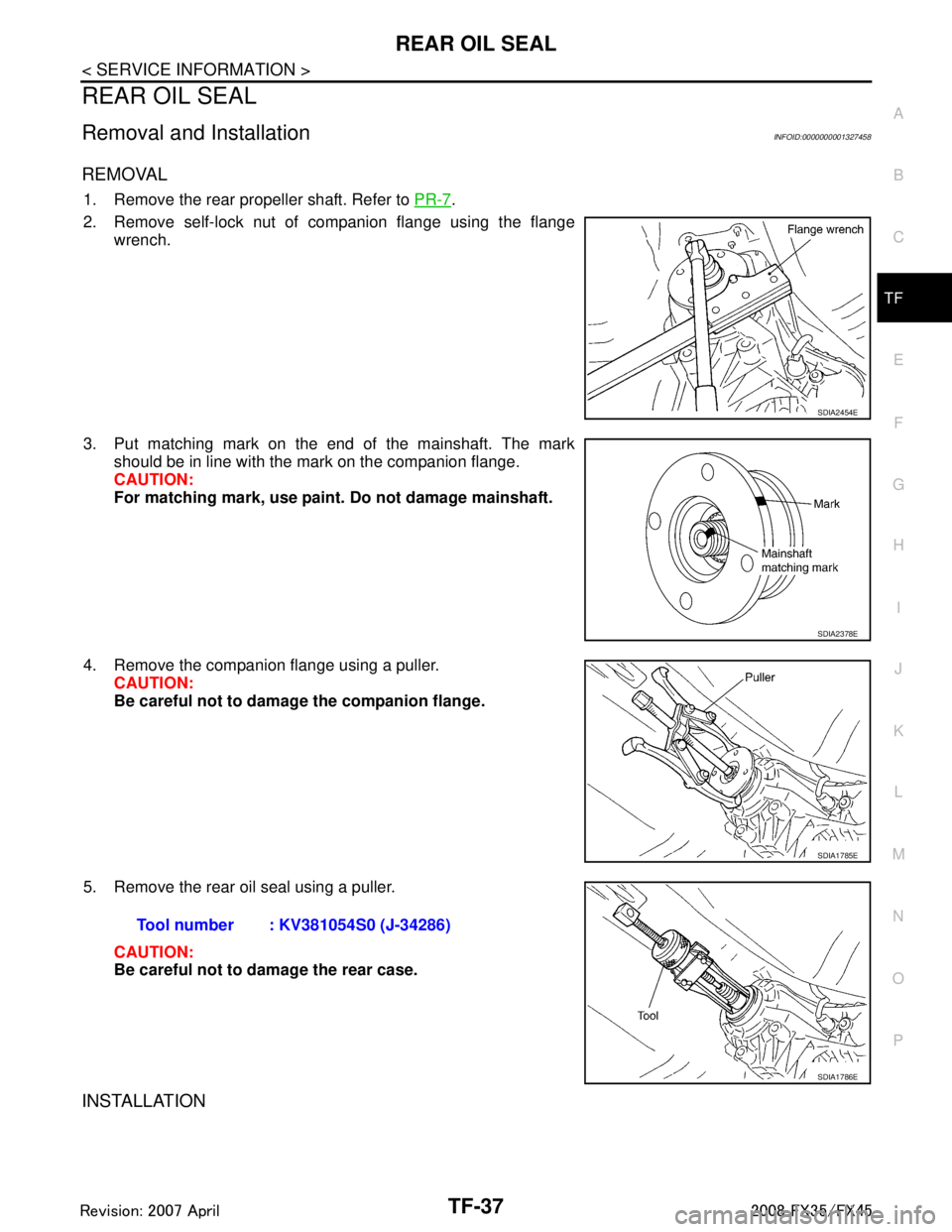

REMOVAL

1. Remove the rear propeller shaft. Refer to PR-7.

2. Remove self-lock nut of companion flange using the flange wrench.

3. Put matching mark on the end of the mainshaft. The mark should be in line with the mark on the companion flange.

CAUTION:

For matching mark, use paint. Do not damage mainshaft.

4. Remove the companion flange using a puller. CAUTION:

Be careful not to damage the companion flange.

5. Remove the rear oil seal using a puller. CAUTION:

Be careful not to damage the rear case.

INSTALLATION

SDIA2454E

SDIA2378E

SDIA1785E

Tool number : KV381054S0 (J-34286)

SDIA1786E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C