warning light INFINITI FX35 2008 Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3192 of 3924

LT-90

< SERVICE INFORMATION >

TURN SIGNAL AND HAZARD WARNING LAMPS

ACTIVE TEST

Display Item List

Turn Signal Lamp Does Not OperateINFOID:0000000001381753

1.CHECK BULB

Check bulb standard of each turn signal lamp is correct.

OK or NG

OK >> GO TO 2.

NG >> Replace turn signal lamp bulb.

2.CHECK COMBINATION SWITCH INPUT SIGNAL

CONSULT-III DATA MONITOR

1. Select “TURN SIGNAL R” and “TURN SIGNAL L” of BCM (FLASHER) data monitor item.

2. With operating the test item, check the monitor status.

CHECK THE COMBINATION SWITCH

Refer to LT-104, "

Combination Switch Inspection".

OK or NG

OK >> GO TO 3.

NG >> Check combination switch (lighting switch). Refer to LT-104, "

Combination Switch Inspection".

3.ACTIVE TEST

CONSULT-III ACTIVE TEST

1. Select “FLASHER” of BCM (FLASHER) active test item.

2. With operating the test item, check the turn signal lamp operation.

GO TO 4

OK or NG

OK >> Replace BCM. Refer to BCS-13, "Removal and Installation of BCM".

NG >> GO TO 4.

4.CHECK TURN SIGNAL LAMP CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector, front combination lamp (RH and LH) connectors, side turn signal lamp (RH and LH) connectors and rear combination lamp (RH and LH) connectors.

TURN SIGNAL L “ON/OFF” Displays “Turn left (ON)/Other (O FF)” status, determined from lighting switch signal.

BRAKE SW “ON/OFF” Displays “Stop lamp switch ON (ON)/Stop lamp switch OFF (OFF)” status, determined from stop lamp

switch signal.

Monitor item Contents

Test item Description

FLASHER Turn signal lamp (right or left) can be operated by any ON-OFF operations.

When lighting switch is

TURN RH position : TURN SIGNAL R ON

When lighting switch is

TURN LH position : TURN SIGNAL L ON

Turn signal lamp should operate.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3425 of 3924

HARNESSPG-61

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

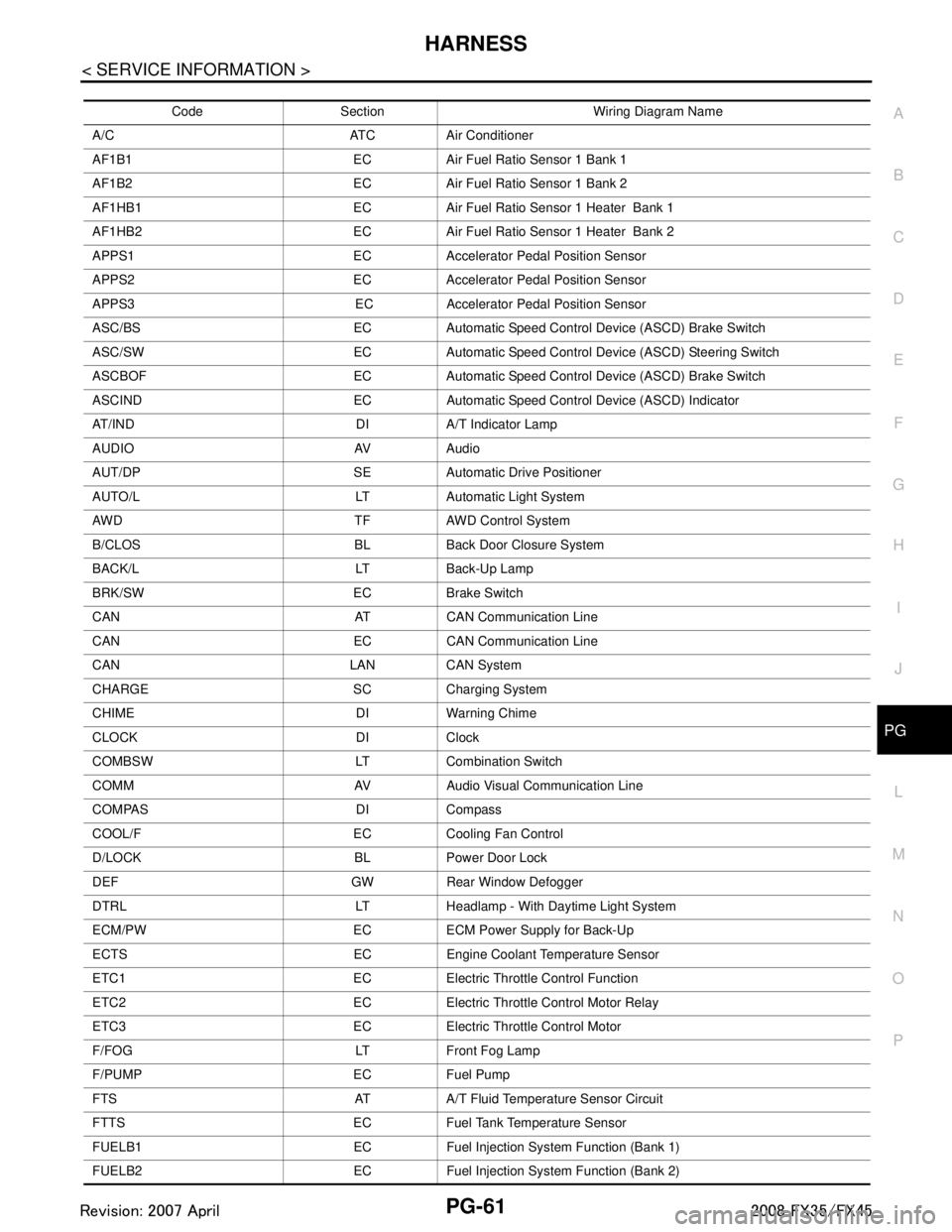

Code Section Wiring Diagram Name

A/C ATC Air Conditioner

AF1B1 EC Air Fuel Ratio Sensor 1 Bank 1

AF1B2 EC Air Fuel Ratio Sensor 1 Bank 2

AF1HB1 EC Air Fuel Ratio Sensor 1 Heater Bank 1

AF1HB2 EC Air Fuel Ratio Sensor 1 Heater Bank 2

APPS1 EC Accelerator Pedal Position Sensor

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC Automatic Speed Control Device (ASCD) Brake Switch

ASC/SW EC Automatic Speed Control Device (ASCD) Steering Switch

ASCBOF EC Automatic Speed Control Device (ASCD) Brake Switch

ASCIND EC Automatic Speed Contro l Device (ASCD) Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

AUT/DP SE Automatic Drive Positioner

AUTO/L LT Automatic Light System

AWD TF AWD Control System

B/CLOS BL Back Door Closure System

BACK/L LT Back-Up Lamp

BRK/SW EC Brake Switch

CAN AT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

CLOCK DI Clock

COMBSW LT Combination Switch

COMM AV Audio Visual Communication Line

COMPAS DI Compass

COOL/F EC Cooling Fan Control

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - With Daytime Light System

ECM/PW EC ECM Power Supply for Back-Up

ECTS EC Engine Coolant Temperature Sensor

ETC1 EC Electric Throttle Control Function

ETC2 EC Electric Throttle Control Motor Relay

ETC3 EC Electric Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FTS AT A/T Fluid Temperature Sensor Circuit

FTTS EC Fuel Tank Temperature Sensor

FUELB1 EC Fuel Injection System Function (Bank 1)

FUELB2 EC Fuel Injection System Function (Bank 2)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3632 of 3924

CHARGING SYSTEMSC-23

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

SC

N

O P

Check if battery terminals are clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair battery terminals connection.

2.CHECK FUSE AND FUSIBLE LINK

Check for blown alternator and combination meter fuses.

OK or NG

OK >> GO TO 3.

NG >> If fuse is blown, be sure eliminate cause of malfunction before installing new fuse.

3.CHECK “E” TERMINAL CONNECTION

Check if “E” terminal (alternator ground harness) is clean and tight.

OK or NG

OK >> GO TO 4.

NG >> Repair “E” terminal connection.

4.CHECK ALTERNATOR DRIVE BELT TENSION

Check alternator drive belt tension. Refer to EM-170, "

Checking Drive Belts" (VK45DE) or EM-14, "Checking

Drive Belts" (VQ35DE).

OK or NG

OK >> INSPECTION END

NG >> Repair as needed.

DIAGNOSTIC PROCEDURE 1

Check “L” Terminal Circuit (Open)

1.CHECK “L” TERMINAL CONNECTION

1. Turn ignition switch OFF.

2. Check if “L” terminal is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair “L” terminal connection. Confirm repa ir by performing complete Starting/Charging system

test. Refer to Technical Service Bulletin.

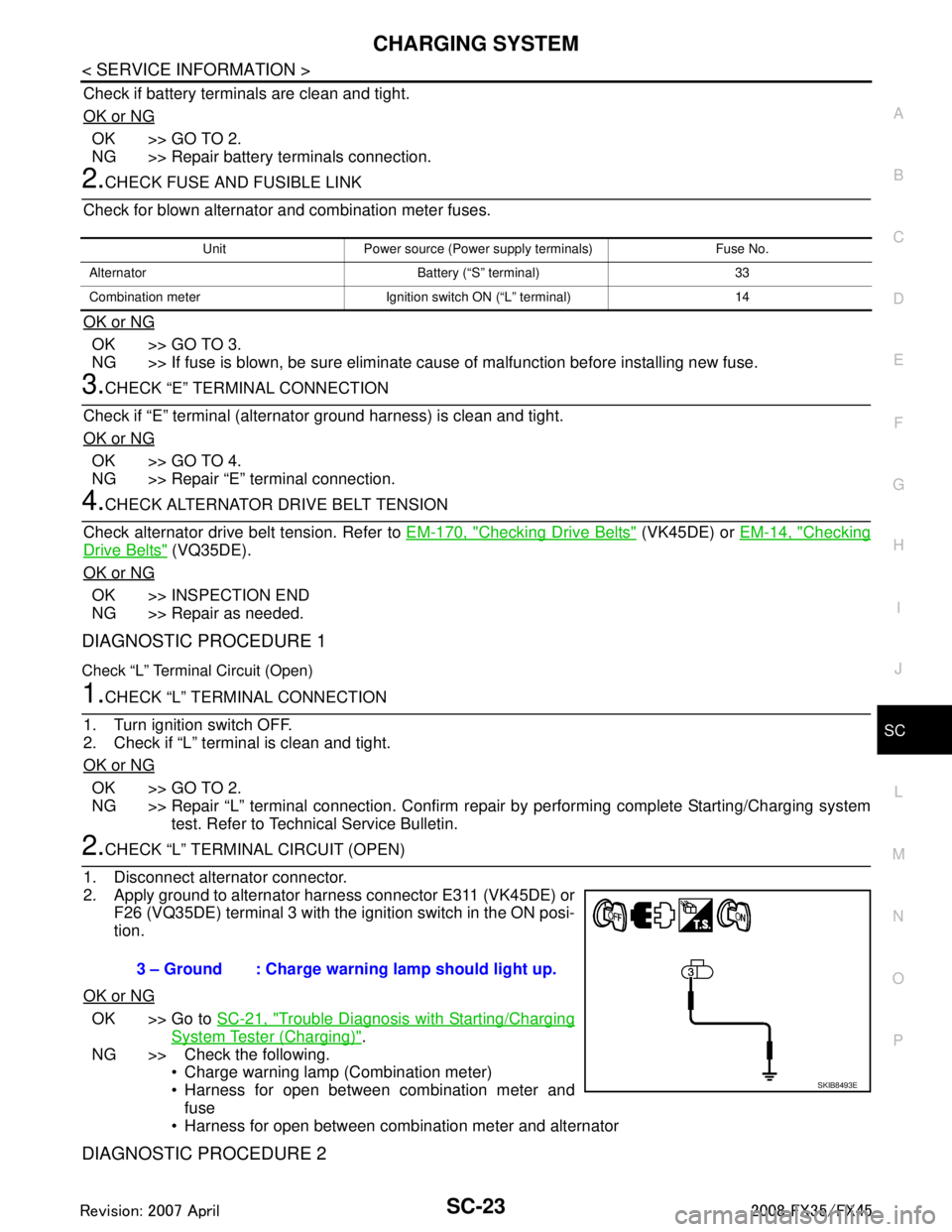

2.CHECK “L” TERMINAL CIRCUIT (OPEN)

1. Disconnect alternator connector.

2. Apply ground to alternator harness connector E311 (VK45DE) or F26 (VQ35DE) terminal 3 with the ignition switch in the ON posi-

tion.

OK or NG

OK >> Go to SC-21, "Trouble Diagnosis with Starting/Charging

System Tester (Charging)".

NG >> Check the following. Charge warning lamp (Combination meter)

Harness for open between combination meter and

fuse

Harness for open between combination meter and alternator

DIAGNOSTIC PROCEDURE 2

Unit Power source (Power supply terminals) Fuse No.

Alternator Battery (“S” terminal) 33

Combination meter Ignition switch ON (“L” terminal) 14

3 – Ground : Charge warning lamp should light up.

SKIB8493E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3633 of 3924

SC-24

< SERVICE INFORMATION >

CHARGING SYSTEM

Check “L” Terminal Circuit (Short)

1.CHECK “L” TERMINAL CIRCUIT (SHORT)

1. Turn ignition switch OFF.

2. Disconnect alternator connector.

3. Turn ignition switch ON.

Charge warning lamp should light up?

YES >> Check the following. Harness for short between combination meter and alternator

Charge warning lamp (Combination meter)

NO >> Go to SC-21, "

Trouble Diagnosis with Starting/Charging System Tester (Charging)".

DIAGNOSTIC PROCEDURE 3

Check “S” Terminal Circuit

1.CHECK “S” TERMINAL CONNECTION

1. Turn ignition switch OFF.

2. Check if “S” terminal is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair “S” terminal connection. Confirm repair by performing complete Starting/Charging system

test. Refer to Technical Service Bulletin.

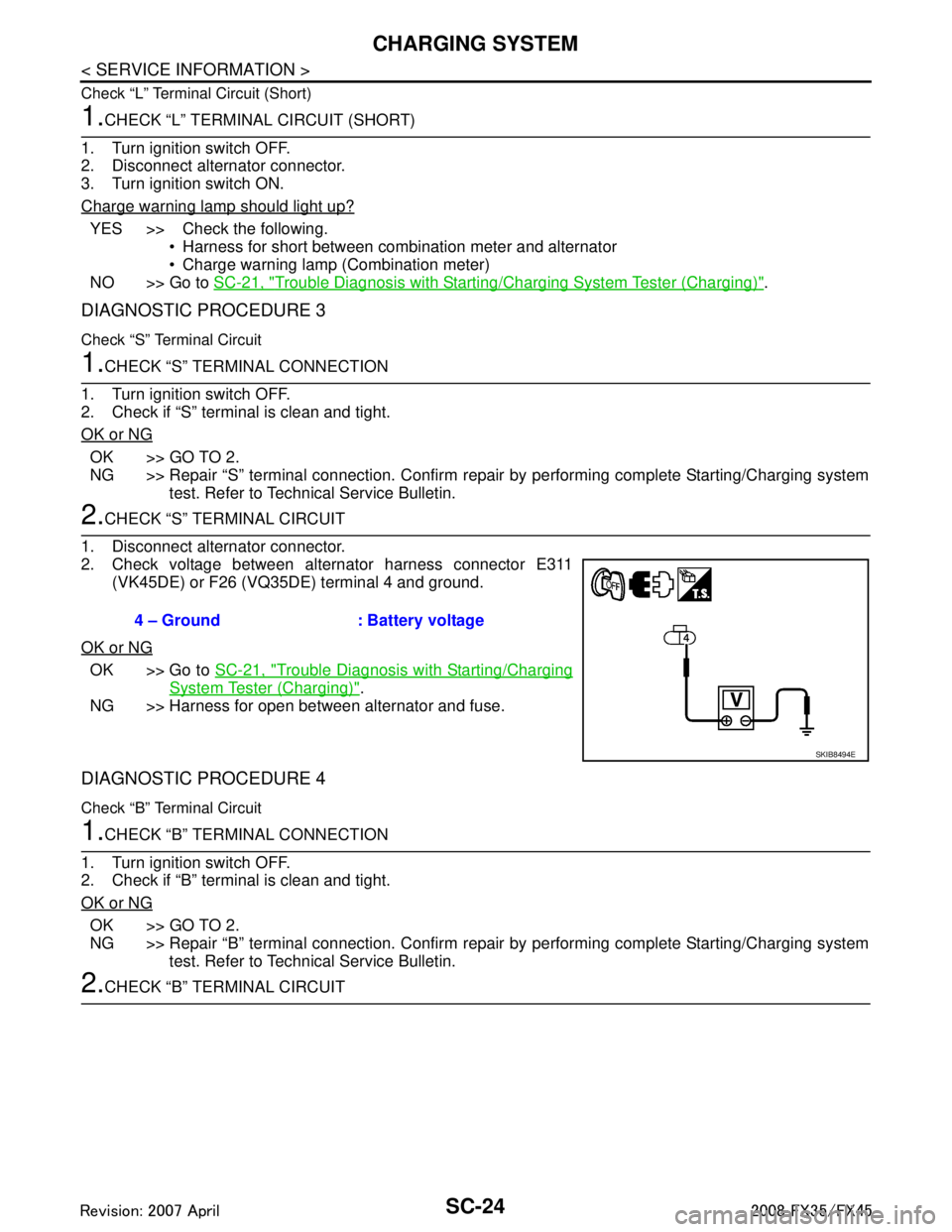

2.CHECK “S” TERMINAL CIRCUIT

1. Disconnect alternator connector.

2. Check voltage between alternator harness connector E311 (VK45DE) or F26 (VQ35DE) terminal 4 and ground.

OK or NG

OK >> Go to SC-21, "Trouble Diagnosis with Starting/Charging

System Tester (Charging)".

NG >> Harness for open between alternator and fuse.

DIAGNOSTIC PROCEDURE 4

Check “B” Terminal Circuit

1.CHECK “B” TERMINAL CONNECTION

1. Turn ignition switch OFF.

2. Check if “B” terminal is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair “B” terminal connection. Confirm repair by performing complete Starting/Charging system

test. Refer to Technical Service Bulletin.

2.CHECK “B” TERMINAL CIRCUIT 4 – Ground : Battery voltage

SKIB8494E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3766 of 3924

TROUBLE DIAGNOSISSRS-29

< SERVICE INFORMATION >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

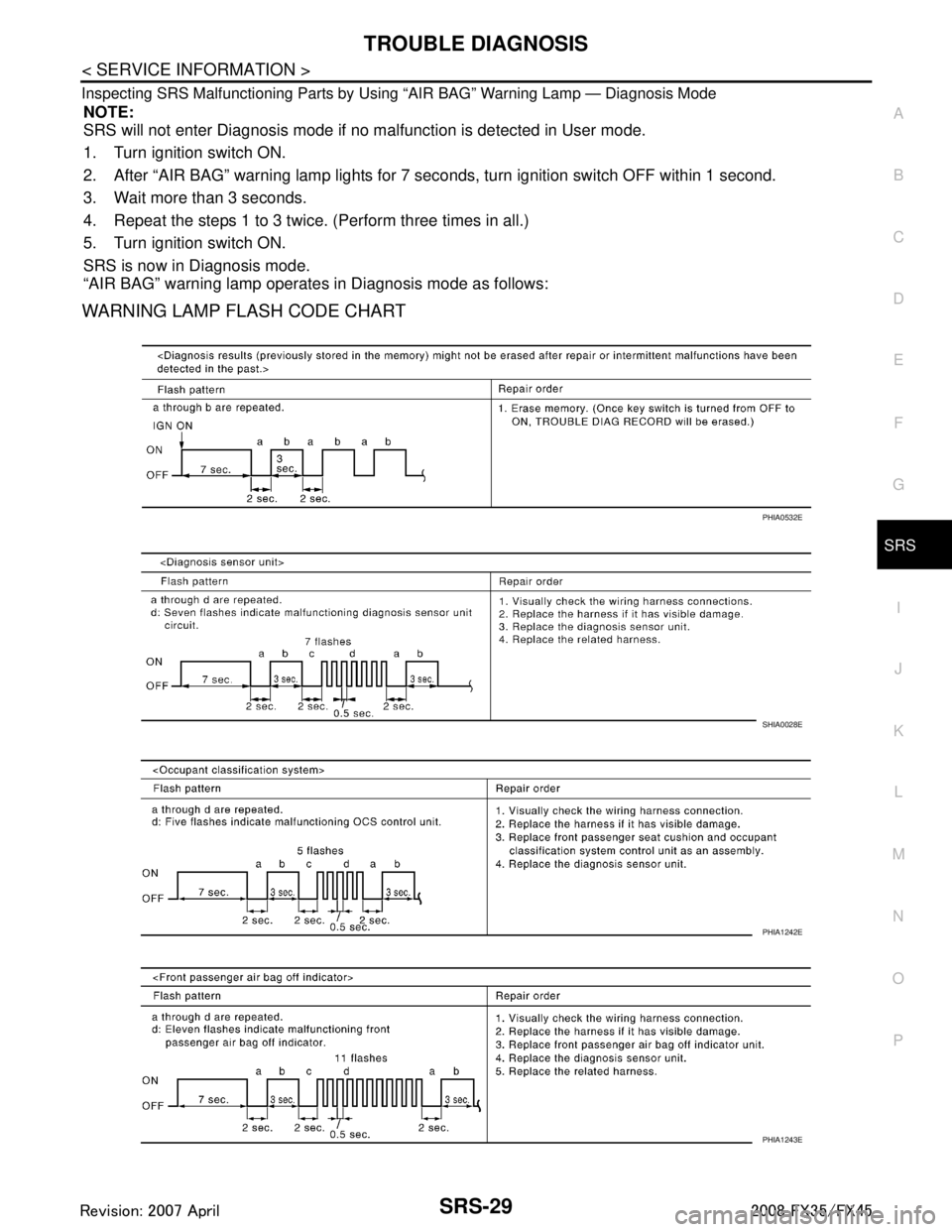

Inspecting SRS Malfunctioning Parts by Using “AIR BAG” Warning Lamp — Diagnosis Mode

NOTE:

SRS will not enter Diagnosis mode if no malfunction is detected in User mode.

1. Turn ignition switch ON.

2. After “AIR BAG” warning lamp lights for 7 seconds, turn ignition switch OFF within 1 second.

3. Wait more than 3 seconds.

4. Repeat the steps 1 to 3 twice. (Perform three times in all.)

5. Turn ignition switch ON.

SRS is now in Diagnosis mode.

“AIR BAG” warning lamp operates in Diagnosis mode as follows:

WARNING LAMP FLASH CODE CHART

PHIA0532E

SHIA0028E

PHIA1242E

PHIA1243E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3773 of 3924

SRS-36

< SERVICE INFORMATION >

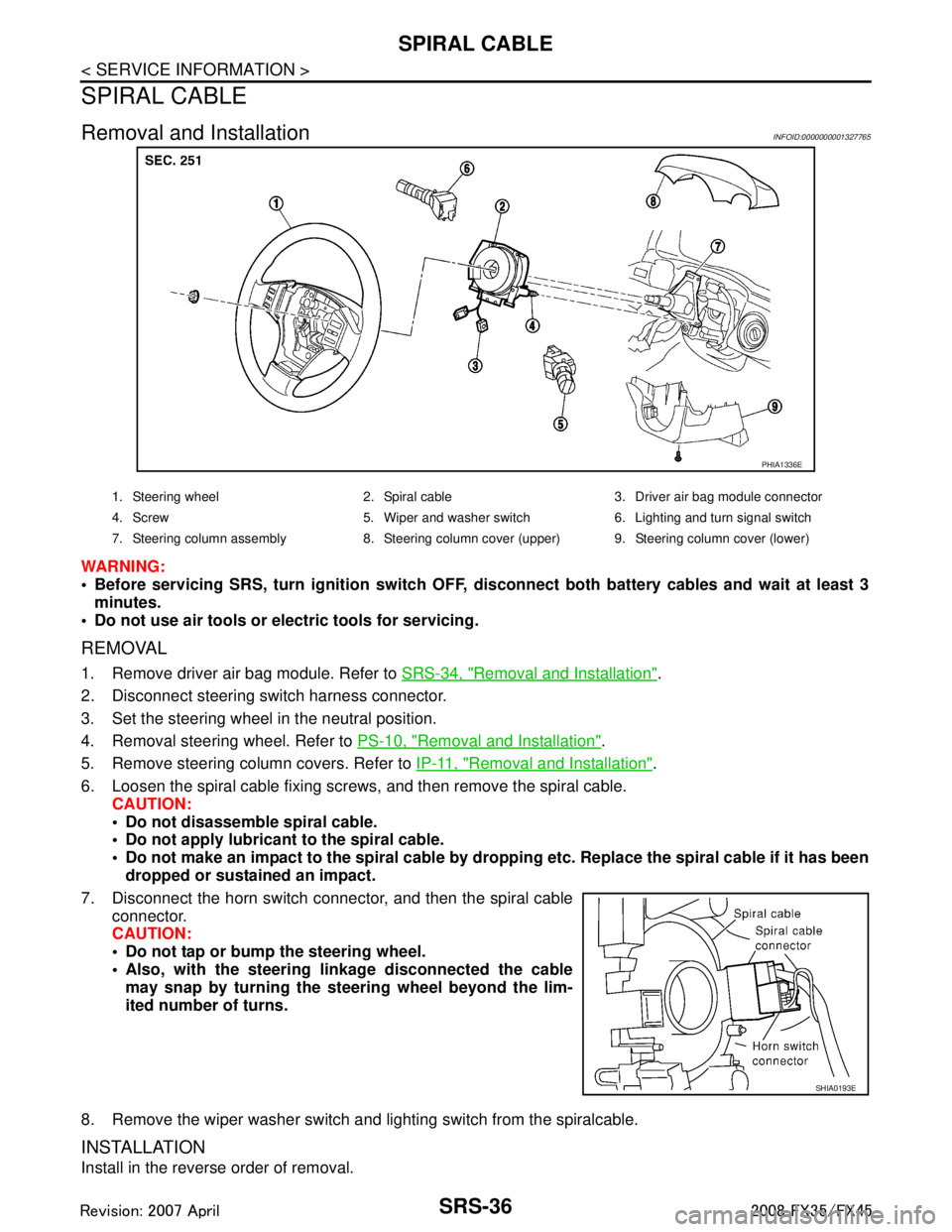

SPIRAL CABLE

SPIRAL CABLE

Removal and InstallationINFOID:0000000001327765

WARNING:

Before servicing SRS, turn ignition switch OFF, disconnect both ba ttery cables and wait at least 3

minutes.

Do not use air tools or el ectric tools for servicing.

REMOVAL

1. Remove driver air bag module. Refer to SRS-34, "Removal and Installation".

2. Disconnect steering switch harness connector.

3. Set the steering wheel in the neutral position.

4. Removal steering wheel. Refer to PS-10, "

Removal and Installation".

5. Remove steering column covers. Refer to IP-11, "

Removal and Installation".

6. Loosen the spiral cable fixing screws, and then remove the spiral cable. CAUTION:

Do not disassemble spiral cable.

Do not apply lubricant to the spiral cable.

Do not make an impact to the spiral cable by dro pping etc. Replace the spiral cable if it has been

dropped or sustained an impact.

7. Disconnect the horn switch connec tor, and then the spiral cable

connector.

CAUTION:

Do not tap or bump the steering wheel.

Also, with the steering li nkage disconnected the cable

may snap by turning the st eering wheel beyond the lim-

ited number of turns.

8. Remove the wiper washer switch and lighting switch from the spiralcable.

INSTALLATION

Install in the reverse order of removal.

PHIA1336E

1. Steering wheel 2. Spiral cable 3. Driver air bag module connector

4. Screw 5. Wiper and washer switch 6. Lighting and turn signal switch

7. Steering column assembly 8. Steering column cover (upper) 9. Steering column cover (lower)

SHIA0193E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3806 of 3924

TF-20

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart by Symptom

INFOID:0000000001327440

If AWD warning lamp turns ON, perform self-diagnosis. Refer to TF-21, "CONSULT-III Function (ALL MODE AWD/4WD)".

NOTE:

Light tight-corner braking symptom may occur depending on driving conditions. This is not malfunction.

AWD Control Unit Input/Output Signal Reference ValueINFOID:0000000001327441

AWD CONTROL UNIT INSPECTION TABLE

Specifications with CONSULT-III

Symptom Condition Check item Reference page

AWD warning lamp does not turn ON when

the ignition switch is turned to ON.

(AWD warning lamp check) Ignition switch: ONCAN communication line

TF-30

Unified meter and A/C amp.

Unified meter control unit

AWD warning lamp does not turn OFF sev-

eral seconds after engine started. Engine runningCAN communication line

TF-30

Power supply and ground for AWD con-

trol unit

Unified meter and A/C amp.

Unified meter control unit

AWD solenoid

AWD actuator relay (integrated in AWD

control unit)

Wheel sensor

Heavy tight-corner braking symptom occurs

when the vehicle is driven and the steering

wheel is turned fully to either side after the

engine is started. (See NOTE.) While driving

Steering wheel is

turned fully to either

sides CAN communication line

TF-32

Accelerator pedal position signal

AWD solenoid

Mechanical malfunction of electric con-

trolled coupling (clutch sticking etc.)

Vehicle does not enter AWD mode even

though AWD warning lamp turned to OFF. While drivingAWD solenoid

TF-33

Mechanical malfunction of electric con-

trolled coupling (Mechanical engage-

ment of clutch is not possible.)

While driving, AWD warning lamp flashes

rapidly. (When flashing in approx. 1 minute

and then turning OFF.)

Rapid flashing: 2 times/second While drivingProtection function is activated due to

heavy load to electric controlled cou-

pling. (AWD system is not malfunction-

ing. Also, optional distribution of torque

sometimes becomes rigid before lamp

flashes rapidly, but it is not malfunction.) TF-33

While driving, AWD warning lamp flashes

slowly. (When continuing to flash until turn-

ing ignition switch OFF)

Slow flashing: 1 time/2 seconds While driving

Vehicle speed: 20 km/h

(12 MPH) or more Tire size is different between front and

rear of vehicle.

TF-33

Monitored item [Unit] Content Condition Display value

FR RH SENSOR [km/h] or [mph] Wheel speed (Front wheel

right)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.

Approximately equal to

the indication on speed-

ometer (Inside of

±10%)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C