no start INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3107 of 3924

HEADLAMP - XENON TYPE -LT-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

HEADLAMP - XENON TYPE -

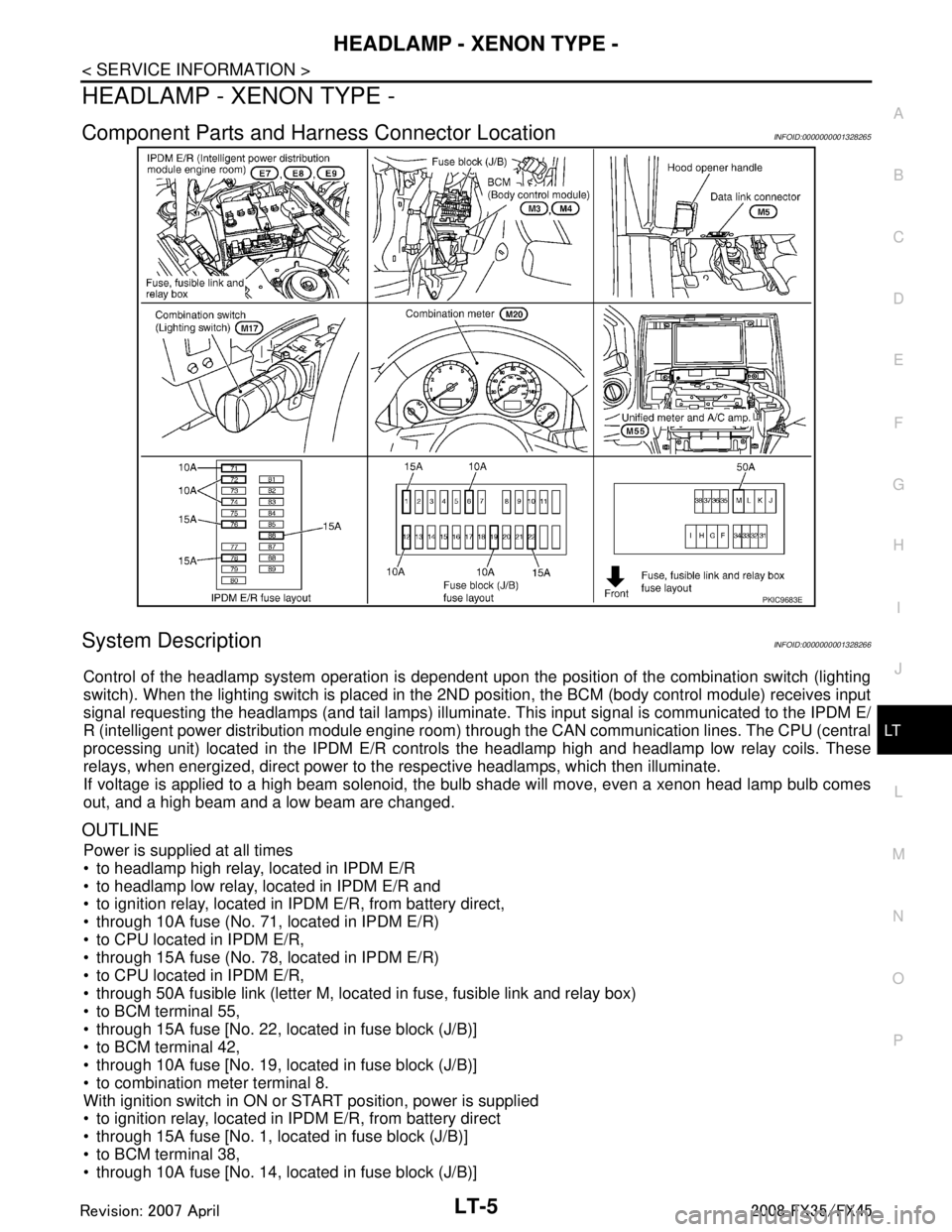

Component Parts and Har ness Connector LocationINFOID:0000000001328265

System DescriptionINFOID:0000000001328266

Control of the headlamp system operation is dependent upon t he position of the combination switch (lighting

switch). When the lighting switch is placed in the 2ND position, the BCM (body control module) receives input

signal requesting the headlamps (and tail lamps) illuminate. This input signal is communicated to the IPDM E/

R (intelligent power distribution module engine room) through the CAN communication lines. The CPU (central

processing unit) located in the IPDM E/R contro ls the headlamp high and headlamp low relay coils. These

relays, when energized, direct power to the respective headlamps, which then illuminate.

If voltage is applied to a high beam solenoid, the bulb shade will move, even a xenon head lamp bulb comes

out, and a high beam and a low beam are changed.

OUTLINE

Power is supplied at all times

to headlamp high relay, located in IPDM E/R

to headlamp low relay, located in IPDM E/R and

to ignition relay, located in IPDM E/R, from battery direct,

through 10A fuse (No. 71, located in IPDM E/R)

to CPU located in IPDM E/R,

through 15A fuse (No. 78, located in IPDM E/R)

to CPU located in IPDM E/R,

through 50A fusible link (letter M, located in fuse, fusible link and relay box)

to BCM terminal 55,

through 15A fuse [No. 22, located in fuse block (J/B)]

to BCM terminal 42,

through 10A fuse [No. 19, located in fuse block (J/B)]

to combination meter terminal 8.

With ignition switch in ON or START position, power is supplied

to ignition relay, located in IPDM E/R, from battery direct

through 15A fuse [No. 1, located in fuse block (J/B)]

to BCM terminal 38,

through 10A fuse [No. 14, located in fuse block (J/B)]

PKIC9683E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3117 of 3924

HEADLAMP - XENON TYPE -LT-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

2. Understand operation description and function description. Refer to LT- 5 , "System Description".

3. Perform Preliminary Check. Refer to LT-15, "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction.

5. Does headlamp operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. INSPECTION END

Preliminary CheckINFOID:0000000001328274

CHECK POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSES

Check for blown fuses.

Refer to LT- 9 , "

Wiring Diagram - H/LAMP -".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate caus e of malfunction before installing new fuse. Refer to PG-

3.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM harness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Unit Power source Fuse and fusible link No.

BCM Battery

M

22

Ignition switch ON or START position 1 Ignition switch ACC or ON position 6

IPDM E/R Battery 72

74

76

86

(+)

(-)Ignition switch position

BCM con- nector Terminal OFF ACC ON

M3 11

Ground Approx. 0 V

Battery volt-

age Battery volt-

age

38 Approx. 0 V Approx. 0 V Battery volt-

age

M4 42

Battery volt-

age Battery volt-

age Battery volt-

age

55 Battery volt-

age Battery volt-

age Battery volt-

age

PKIA5204E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3120 of 3924

LT-18

< SERVICE INFORMATION >

HEADLAMP - XENON TYPE -

NOTE:

Perform monitoring of IPDM E/R data with ignition switch ON. When ignition switch is at ACC, display may not

be correct.

ACTIVE TEST

Headlamp Does Not Change To High Beam (Both Sides)INFOID:0000000001381742

1.CHECK COMBINATION SWITCH INPUT SIGNAL

CONSULT-III DATA MONITOR

1. Select “HI BEAM SW” of BCM data monitor item.

2. With operating the lighting switch, check the monitor status.

CHECK THE COMBINATION SWITCH

Refer to LT-104, "

Combination Switch Inspection".

OK or NG

OK >> GO TO 2.

NG >> Check combination switch (lighting switch). Refer to LT-104, "

Combination Switch Inspection".

2.HEADLAMP ACTIVE TEST

CONSULT-III ACTIVE TEST

1. Select “LAMPS” of IPDM E/R active test item.

2. With operating the test item, check the headlamp high beam operation.

IPDM E/R AUTO ACTIVE TEST

1. Start auto active test. Refer to PG-20, "

Auto Active Test".

2. Check that the headlamp high beam operation.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

3.CHECK IPDM E/R

Item name CONSULT-III

screen display Display

or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Position lights request TAIL & CLR REQ ON/OFF ×× ×Signal status input from BCM

Headlamp low beam request HL LO REQ ON/OFF ×× ×Signal status input from BCM

Headlamp high beam request HL HI REQ ON/OFF ×× ×Signal status input from BCM

Front fog lights request FR FOG REQ ON/OFF ×× ×Signal status input from BCM

Te s t i t e mCONSULT-III

screen display Description

Headlamp relay (HI, LO) output

LAMPSAllows headlamp relay (HI, LO) to operate by switching operation (OFF, HI ON,

LO ON) at your option (Headlamp high beam repeats ON-OFF every 1 second).

Front fog lamp relay output Allows front fog lamp relay to operate by switching operation ON-OFF at your op-

tion.

Tail lamp relay output TAIL LAMP Allows tail lamp relay to operate by switching operation ON-OFF at your option.

When lighting switch is

HIGH BEAM : HI BEAM SW ON

Headlamp high beam should operate.

(Headlamp high beam repeats ON-OFF every 1 second).

Headlamp high beam should operate.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3121 of 3924

HEADLAMP - XENON TYPE -LT-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

CONSULT-III DATA MONITOR

1. Select “HL LO REQ” and “HL HI RE Q” of IPDM E/R data monitor item.

2. With operating the lighting switch, check the monitor status

OK or NG

OK >> Replace IPDM E/R. Refer to PG-24, "Removal and Installation of IPDM E/R".

NG >> Replace BCM. Refer to BCS-13, "

Removal and Installation of BCM".

4.CHECK HEADLAMP INPUT SIGNAL

CONSULT-III ACTIVE TEST

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH and LH connectors.

3. Select “LAMPS” of IPDM E/R active test item

4. With operating the test item, check voltage between front combi- nation lamp (RH and LH) harness connectors and ground.

NOTE:

Headlamp high beam repeats ON–OFF every 1 second.

IPDM E/R AUTO ACTIVE TEST

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH and LH connectors.

3. Start auto active test. Refer to PG-20, "

Auto Active Test".

4. With operating the test item, check voltage betw een front combination lamp (RH and LH) harness connec-

tors and ground.

NOTE:

Headlamp high beam repeats ON–OFF every 1 second.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.CHECK HEADLAMP CIRCUIT When lighting switch is

HIGH BEAM

: HL LO REQ ON

: HL HI REQ ON

Te r m i n a l s

Voltag e

(Approx.)

(+)

(-)

Front combination lamp

connector Te r m i n a l

RH E24 5 Ground Battery voltage

LH E44 5

Te r m i n a l s Voltag e

(Approx.)

(+)

(-)

Front combination lamp

connector Te r m i n a l

RH E24 5 Ground Battery voltage

LH E44 5

PKIA5205E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3123 of 3924

HEADLAMP - XENON TYPE -LT-21

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and front combination lamp RH or LH harness connector.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-24, "Removal and Installation of IPDM E/R".

NG >> Repair harness or connector.

3.CHECK HEADLAMP GROUND

Check continuity between front combination lamp RH or LH harness

connector and ground.

OK or NG

OK >> Check headlamp harness and connector.

NG >> Repair harness or connector.

Headlamp Low Beam Does No t Illuminate (Both Sides)INFOID:0000000001381744

1.CHECK COMBINATION SWITCH INPUT SIGNAL

CONSULT-III DATA MONITOR

1. Select “HEAD LAMP SW1” and “HEAD LA MP SW2” of BCM data monitor item.

2. With operating the lighting switch, check the monitor status.

CHECK THE COMBINATION SWITCH

Refer to LT-104, "

Combination Switch Inspection".

OK or NG

OK >> GO TO 2.

NG >> Check combination switch (lighting switch). Refer to LT-104, "

Combination Switch Inspection".

2.HEADLAMP ACTIVE TEST

CONSULT-III ACTIVE TEST

1. Select “LAMPS” of IPDM E/R active test item.

2. With operating the test item, check the headlamp low beam operation.

IPDM E/R AUTO ACTIVE TEST

1. Start auto active test. Refer to PG-20, "

Auto Active Test".

2. Check that the headlamp low beam operation.

OK or NG

Te r m i n a l s

Continuity

IPDM E/R Front combination lamp

Connector Terminal Connector Terminal

RH E7 27 E24 5

Ye s

LH 28 E44 5

PKIA5206E

Front combination lamp

connector Terminal

Ground Continuity

RH E24 7 Ye s

LH E44 7

PKIA5207E

When lighting switch is 2ND

position : HEAD LAMP SW1 ON

: HEAD LAMP SW2 ON

Headlamp low beam should operate.

Headlamp low beam should operate.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3124 of 3924

LT-22

< SERVICE INFORMATION >

HEADLAMP - XENON TYPE -

OK >> GO TO 3.

NG >> GO TO 4.

3.CHECK IPDM E/R

CONSULT-III DATA MONITOR

1. Select “HL LO REQ” of IPDM E/R data monitor item.

2. With operating the lighting switch, check the monitor status.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-24, "Removal and Installation of IPDM E/R".

NG >> Replace BCM. Refer to BCS-13, "

Removal and Installation of BCM".

4.CHECK HEADLAMP INPUT SIGNAL

CONSULT-III ACTIVE TEST

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH and LH connectors.

3. Select “LAMPS” of IPDM E/R active test item.

4. With operating the test item, check voltage between front combi- nation lamp (RH and LH) harness connectors and ground.

IPDM E/R AUTO ACTIVE TEST

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH and LH connectors.

3. Start auto active test. Refer to PG-20, "

Auto Active Test".

4. With operating the test item, check voltage betw een front combination lamp (RH and LH) harness connec-

tors and ground.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.CHECK HEADLAMP CIRCUIT When lighting switch is 2ND

position

: HL LO REQ ON

Te r m i n a l s

Vo l ta g e

(Approx.)

(+)

(-)

Front combination lamp

connector Te r m i n a l

RH E24 6 Ground Battery voltage

LH E44 6

Te r m i n a l s Vo l ta g e

(Approx.)

(+)

(-)

Front combination lamp

connector Te r m i n a l

RH E24 6 Ground Battery voltage

LH E44 6

PKIA5208E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3129 of 3924

HEADLAMP - XENON TYPE -LT-27

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

Xenon Headlamp Trouble DiagnosisINFOID:0000000001328286

1.CHECK 1: XENON HEADLAMP LIGHTING

Install normal xenon bulb to corresponding xenon bulb headlamp, and check if lamp lights up.

OK or NG

OK >> Replace xenon bulb.

NG >> GO TO 2.

2.CHECK 2: XENON HEADLAMP LIGHTING

Install normal HID control unit to corresponding xenon headlamp, and check if lamp lights up.

OK or NG

OK >> Replace HID control unit.

NG >> GO TO 3.

3.CHECK 3: XENON HEADLAMP LIGHTING

Install normal xenon lamp housing assembly to corresponding xenon headlamp, and check if lamp lights up.

OK or NG

OK >> Replace xenon headlamp housing assembly. [Malfunction in starter (boosting circuit) in xenon headlamp housing]

NG >> INSPECTION END

Aiming AdjustmentINFOID:0000000001328287

PREPARATION BEFORE ADJUSTING

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following.

1. Keep all tires inflated to correct pressures.

2. Place vehicle on level ground.

3. Set that there is no-load in vehicle other than the driv er (or equivalent weight placed in driver's position).

Coolant, engine oil filled up to correct level and full fuel tank.

LOW BEAM AND HIGH BEAM

PKIC9684E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3134 of 3924

LT-32

< SERVICE INFORMATION >

DAYTIME LIGHT SYSTEM

DAYTIME LIGHT SYSTEM

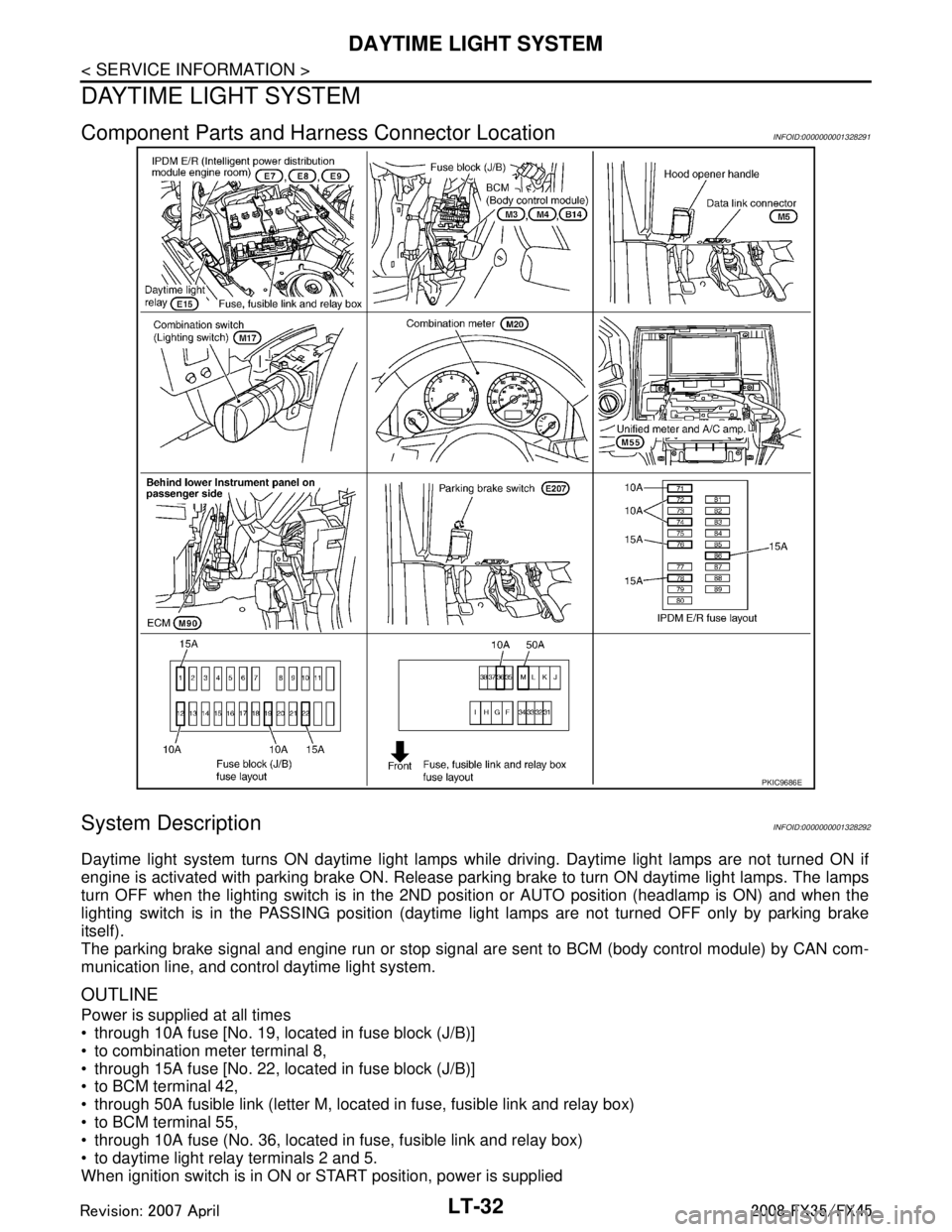

Component Parts and Harness Connector LocationINFOID:0000000001328291

System DescriptionINFOID:0000000001328292

Daytime light system turns ON daytime light lamps while driving. Daytime light lamps are not turned ON if

engine is activated with parking brake ON. Release parki ng brake to turn ON daytime light lamps. The lamps

turn OFF when the lighting switch is in the 2ND pos ition or AUTO position (headlamp is ON) and when the

lighting switch is in the PASSING position (daytime light lamps are not turned OFF only by parking brake

itself).

The parking brake signal and engine run or stop signal ar e sent to BCM (body control module) by CAN com-

munication line, and control daytime light system.

OUTLINE

Power is supplied at all times

through 10A fuse [No. 19, located in fuse block (J/B)]

to combination meter terminal 8,

through 15A fuse [No. 22, located in fuse block (J/B)]

to BCM terminal 42,

through 50A fusible link (letter M, located in fuse, fusible link and relay box)

to BCM terminal 55,

through 10A fuse (No. 36, located in fuse, fusible link and relay box)

to daytime light relay terminals 2 and 5.

When ignition switch is in ON or START position, power is supplied

PKIC9686E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3143 of 3924

DAYTIME LIGHT SYSTEMLT-41

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O PHow to Proceed with Trouble DiagnosisINFOID:0000000001328298

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer to LT-32, "

System Description".

3. Perform Preliminary Check. Refer to LT-41, "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction.

5. Does daytime light lamp operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. INSPECTION END

Preliminary CheckINFOID:0000000001328299

CHECK POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSES

Check for blown fuses.

Refer to LT-35, "

Wiring Diagram - DTRL -".

OK or NG

35 W/G Combination

switch output 2 ONLighting, turn, wip-

er switch

(Wiper intermittent

dial position 4) OFF

Approx. 7.2 V

Any of the conditions below

Lighting switch 2ND

Lighting switch PASSING (Operates only PASSING

switch)

Approx. 1.2 V

38 W/L Ignition switch

(ON)

ON — Battery voltage

39 L CAN − H— — —

40 P CAN − L— — —

42 L/R Battery power

supply

OFF — Battery voltage

49 B Ground ON — Approx. 0 V

52 B Ground ON — Approx. 0 V

55 G Battery power

supply OFF — Battery voltage

Te r m i -

nal No. Wire

color Signal name Measuring condition

Reference value

Ignition

switch Operation or condition

PKIB4960J

PKIB4958J

Unit Power source Fuse and fusible link No.

BCM Battery M

22

Ignition switch ON or START position 1

Daytime light relay Battery 36

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3150 of 3924

LT-48

< SERVICE INFORMATION >

AUTO LIGHT SYSTEM

The headlamps will then illuminate. For a description of headlamp operation, Refer to LT- 5 , "System Descrip-

tion".

COMBINATION SWITCH READING FUNCTION

Refer to BCS-4, "System Description".

DELAY TIMER FUNCTION

Delay timer function carries out a function that BCM ac tivates the timer and controls lights out of headlamps by

door switch signal and lightning switch signal when turn ing the Ignition switch OFF while it is ON and head-

lamps are ON by the auto light function.

Timer types are a 5 minute timer and a 45 second timer

When opening any door (door switch is ON), the 5 mi nute timer starts and then headlamps go out 5 minutes

later

When all the doors are closed (from door switch ON to OFF), the 45 second timer starts and then headlamps go out 45 seconds later. If any door is opened (door switch ON) while the 45 second timer is in operation, the

5 minute timer starts again

The timer stops when turning on the ignition switch or turning off the auto light switch under the above condi-

tions.

Delay timer control mode can be changed by the f unction setting of CONSULT-III or display.

CAN Communication System DescriptionINFOID:0000000001328308

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication s peed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CA N communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitINFOID:0000000001328309

Refer to LAN-43, "CAN System Specification Chart".

Major Component and FunctionsINFOID:0000000001328310

Components Functions

BCM Turns on/off circuits of tail light and headlamp according to signals from light sensor, lighting switch (AUTO),

driver door switch, passenger door switch, rear door switch, and ignition switch (ON, OFF).

Optical sensor Converts outside brightness (lux) to voltage, and sends it to BCM. (Detects brightness of 800 to 2,500 lux)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C