check engine INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3320 of 3924

GENERAL MAINTENANCEMA-3

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

GENERAL MAINTENANCE

Explanation of Gene ral MaintenanceINFOID:0000000001328893

General maintenance includes those items which shoul d be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or have their INFINITI dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge, including the spare, at least once a month

and always prior to a long distance trips. Adjust to the specified pressure if nec-

essary. Check carefully for damage, cuts or excessive wear. —

Wheel nuts When checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary. —

Windshield Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. —

Tire rotation Tires should be rotated every 12,000 km (7,500 miles). MA-31

Transmitter compo-

nents in tire pressure

monitoring system

(TPMS)Replace grommet seal, valve core and cap of the transmitter in TPMS every tire

replacement by reaching wear limit of tire.

WT-10

Wheel alignment and

balanceIf the vehicle pulls to either side while driving on a straight and level road, or if

you detect uneven or abnormal tire wear, there may be a need for wheel align-

ment. If the steering wheel or seat vibrates at normal highway speeds, wheel

balancing may be needed. MA-30

,

FSU-5

Windshield wiper

blades Check for cracks or wear if they do not wipe properly. —

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the trunk

lid and back hatch. Also make sure that all latches lock securely. Lubricate if

necessary. Make sure that the secondary latch keeps the hood from opening

when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently. MA-35

Lamps

Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head-

lamp aim. Clean the headlamps on a regular basis. —

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly. —

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak.

—

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner. —

Steering wheel Check that it has the specified play. Be sure to check for changes in the steering

condition, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) —

Seats Check seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restrains move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seatbacks. —

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage. MA-35

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3321 of 3924

MA-4

< SERVICE INFORMATION >

GENERAL MAINTENANCE

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

Accelerator pedalCheck the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. —

Brakes Check that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to

keep the floor mats away from the pedal. BR-5

,

BR-14

Parking brake Check that the pedal has the proper travel and make sure that the vehicle is

held securely on a fairly steep hill when only the parking brake is applied. PB-3

Automatic transmis-

sion "Park" mecha-

nismCheck that the lock release button on the selector lever operates properly and

smoothly. On a fairly steep hill check that the vehicle is held securely with the

selector lever in the P (Park) position without applying any brakes.

—

Item

Reference page

Item Reference page

Windshield washer

fluid Check that there is adequate fluid in the tank. —

Engine coolant level Check the coolant level when the engine is cold. MA-12

, MA-19

Radiator and hoses Check the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the hoses have no cracks, deformation, de-

terioration or loose connections. —

Brake fluid level Make sure that the brake fluid level is between the “MAX” and “MIN” lines on the

reservoir. MA-32

Battery Check the fluid level in each cell. It should be between the “MAX” and “MIN”

lines. Vehicles operated in high temperatures or under severe conditions re-

quire frequent checks of the battery fluid level. SC-4

Engine drive belts

Make sure that no belt is frayed, worn, cracked or oily. MA-11, MA-19

Engine oil level Check the level on the oil level gauge after parking the vehicle on a level spot

and turning off the engine. MA-15,

MA-22

Power steering fluid

level and lines Check the level on the dipstick with the engine off. Check the lines for improper

attachment, leaks, cracks, etc.

MA-33

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate

the trouble and correct it. MA-26

Underbody

The underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these sub-

stances, otherwise rust will form on the floor pan, frame, fuel lines and around

the exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately. —

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3328 of 3924

ENGINE MAINTENANCE (VQ35DE ENGINE)MA-11

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

ENGINE MAINTENANCE (VQ35DE ENGINE)

Checking Drive BeltsINFOID:0000000001328900

WARNING:

Be sure to perform when engine is stopped.

1. Inspect belts for cracks, fraying, wear and oil. If necessary, replace.

2. Inspect drive belt deflection or tension at a point on belt midway

between pulleys.

Inspection should be done only when engine is cold, or over 30 minutes after engine is stopped.

Measure the belt tension with belt tension gauge (Commercial service tool: BT3373-F or equivalent) (A) at points marked

shown in the figure.

When measuring the deflection, apply 98 N (10 kg, 22 lb) at

the marked point.

Adjust if the belt deflection exceeds the limit or if the belt ten- sion is not within specifications.

CAUTION:

• When checking the belt deflect ion or the tension immedi-

ately after installation, first ad just it to the specified value.

Then, after turning crankshaft two turns or more, re-adjust

to the specified value to avo id variation in deflection

between pulleys.

Tighten idler pulley lock nut by hand and measure the deflection or the tension without loose-

ness.

Belt Deflection and Tension

*: If belt tension gauge cannot be installed at check points shown, check drive belt tension at different location on belt.

Drive Belts Tension AdjustmentINFOID:0000000001328901

CAUTION:

1 : Power steering oil pump

2 : Alternator

3 : Idler pulley

4 : Crankshaft pulley

5 : A/C compressor

JPBIA0421ZZ

JPBIA0422ZZ

Items Deflection adjustment Unit: mm (in) Tension adjustment* Unit: N (kg, lb)

Used belt New beltUsed belt

New belt

Limit After adjustment Limit After adjustment

Alternator and

power steering

oil pump belt 12 (0.47)

7 - 8

(0.28 - 0.31) 6 - 7

(0.24 - 0.28) 294 (30, 66) 730 - 818

(74.5 - 83.5, 164 - 184) 838 - 926

(85.5 - 94.5, 188 - 208)

A/C compressor

belt 12 (0.47)9 - 10

(0.35 - 0.39) 8 - 9

(0.31 - 0.35) 196 (20, 44) 348 - 436

(35.5 - 44.5, 78 - 98) 470 - 559

(48 - 57,

106 - 126)

Applied pushing

force 98 N (10 kg, 22 lb) —

Portion

Belt tightening method for adjustment

Alternator and power steering oil pump belt Adjusting bolt on idler pulley

A/C compressor belt Adjusting bolt on idler pulley

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3329 of 3924

MA-12

< SERVICE INFORMATION >

ENGINE MAINTENANCE (VQ35DE ENGINE)

When belt is replaced with a new one, adjust it to value for “New belt” to accommodate for insuffi-

cient adaptability with pulley grooves.

When deflection or tension of belt being used exceeds “Limit”, adjust it to value for “After adjust-

ment”.

When checking belt deflection or te nsion immediately after installation, first adjust it to the specified

value. Then, after turning crankshaft two turns or mo re, re-adjust to the specified value to avoid vari-

ation in deflection between pulleys.

When installing belt, make sure that it is correctly engaged with pulley grooves.

Keep engine oil, working fluid and engine coolant away from belt and pulley grooves.

Do not twist or bend belt excessively.

ALTERNATOR AND POWER STEERING OIL PUMP BELT

1. Remove front engine undercover with power tool.

2. Loosen idler pulley lock nut (A) and adjust tension by turning adjusting bolt (B).

For the specified belt tension, refer to EM-14, "

Checking Drive

Belts".

3. Tighten nut (A).

A/C COMPRESSOR BELT

1. Remove front engine undercover with power tool.

2. Loosen idler pulley lock nut (C) and adjust tension by turning adjusting bolt (D). For the specified belt tension, refer to EM-14, "

Checking Drive Belts".

3. Tighten nut (C).

Changing Engine CoolantINFOID:0000000001328902

WARNING:

To avoid being scalded, do not change en gine coolant when the engine is hot.

Wrap a thick cloth around radiator cap and carefully remove radiator cap. First, turn radiator cap a

quarter of a turn to release built-up pressu re. Then turn radiator cap all the way.

Be careful not to allow engine coolant to contact drive belts.

DRAINING ENGINE COOLANT

1. Remove front engine undercover with power tool.

1 : Alternator and power steering oil pump belt

2: A/C compressor belt

3 : Power steering oil pump

4 : Idler pulley

5 : Alternator

6 : Crankshaft pulley

7: A/C compressor

: 34.8 N·m (3.5 kg-m, 26 ft-lb)

JPBIA0423ZZ

: 34.8 N·m (3.5 kg-m, 26 ft-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3330 of 3924

ENGINE MAINTENANCE (VQ35DE ENGINE)MA-13

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

2. Open radiator drain plug at the bottom of radiator, and then

remove radiator cap.

When draining all of engine coolant in the system , open water drain plugs on cylinder block. Refer

to EM-123, "

Disassembly and Assembly".

3. Remove reservoir tank as necessary, drain engine coolant and clean reservoir tank before installing.

4. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system. Refer to CO-10, "

Changing Engine Coolant".

REFILLING ENGINE COOLANT

1. Install reservoir tank if removed, and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-123, "

Dis-

assembly and Assembly".

2. Make sure that each hose clamp has been firmly tightened.

3. Remove air relief plug on heater hose.

4. Fill radiator, and reservoir tank if removed, to specified level. Pour engine coolant through engine coolant filler neck

slowly of less than 2 (2-1/8 US qt, 1-3/4 lmp qt) a minute

to allow air in system to escape.

Use Genuine NISSAN Long Li fe Antifreeze/Coolant or

equivalent mixed with water (dis tilled or demineralized).

Refer to MA-9

.

SBIA0444E

Radiator drain plug:

: 1.18 N·m (0.12 kg-m, 10 in-lb)

SBIA0445E

Engine coolant capacity

(With reservoir tank at “MAX” level): Approximately 8.6 (9-1/8 US qt, 7-5/8 lmp qt)

SMA182B

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3331 of 3924

MA-14

< SERVICE INFORMATION >

ENGINE MAINTENANCE (VQ35DE ENGINE)

When engine coolant overflows air relief hole on heater hose,install air relief plug with new O-ring.

5. Install radiator cap.

6. Warm up until opening thermostat. Standard for warming- up time is approximately 10 minutes at 3,000

rpm.

Make sure thermostat opening condition by touching radiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat engine.

7. Stop the engine and cool down to less than approximately 50 °C (122 °F).

Cool down using fan to reduce the time.

If necessary, refill radiator up to filler neck with engine coolant.

8. Refill reservoir tank to “MAX” level line with engine coolant.

9. Repeat steps 4 through 7 two or more times with radiator cap installed until engine coolant level no longer drops.

10. Check cooling system for leaks with engine running.

11. Warm up the engine, and check for sound of engine coolant flow while running engine from idle up to 3,000 rpm with heater temperature controller set at several position between “COOL” and “WARM”.

Sound may be noticeable at heater unit.

12. Repeat step 11 three times.

13. If sound is heard, bleed air from cooling system by repeating step 4 through 7 until engine coolant level no

longer drops.

FLUSHING COOLING SYSTEM

1. Install reservoir tank, and radiator drain plug.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-123, "

Dis-

assembly and Assembly".

2. Remove air relief plug on heater hose.

3. Fill radiator with water until water spills from the ai r relief hole, then close air relief plug. Fill radiator and

reservoir tank with water and reinstall radiator cap. Reservoir tank engine coolant capacity

(At “MAX” level)

: 0.8 (7/8 US qt, 3/4 lmp qt)

Air relief plug: : 1.19 N·m (0.12 kg-m, 11 in-lb)

SMA412B

Radiator drain plug:

: 1.18 N·m (0.12 kg-m, 10 in-lb)

SBIA0445E

Air relief plug: : 1.19 N·m (0.12 kg-m, 11 in-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3332 of 3924

ENGINE MAINTENANCE (VQ35DE ENGINE)MA-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

4. Run the engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop the engine and wait until it cools down.

7. Drain water from the system. Refer to CO-10, "

Changing Engine Coolant".

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

Checking Fuel LineINFOID:0000000001328903

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections , chafing or deterioration.

If necessary, repair or replace damaged parts.

Changing Air Cleaner FilterINFOID:0000000001328904

VISCOUS PAPER TYPE

The viscous paper type filter does not need cleaning between

replacement intervals. Refer to MA-5

.

Changing Engine OilINFOID:0000000001328905

WARNING:

Be careful not to burn yoursel f, as engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thorough ly with soap or hand cleaner as

soon as possible.

1. Remove front engine undercover with power tool.

2. Warm up the engine, and check for engine oil leakage from engine components. Refer to LU-5, "

Inspec-

tion".

3. Stop the engine and wait for 10 minutes.

4. Loosen oil filler cap and then remove drain plug.

5. Drain engine oil.

6. Install drain plug with new washer. Refer to EM-30

.

CAUTION:

Be sure to clean drain plug and install with new washer.

7. Refill with new engine oil. Engine oil specificat ion and viscosity:

Refer to MA-9

.

SMA803A

SBIA0463E

Oil pan drain plug:

: 34.3 N·m (3.5 kg-m, 25 ft-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3333 of 3924

MA-16

< SERVICE INFORMATION >

ENGINE MAINTENANCE (VQ35DE ENGINE)

Engine oil capacity (Approximate):Unit: (US qt, lmp qt)

CAUTION:

When filling engine oil, do not pull out oil level gauge.

The refill capacity depends on the engine oi l temperature and drain time. Use these specifica-

tions for reference only.

Always use oil level gauge to determine the proper amount of engine oil in engine.

8. Warm up the engine and check area around drain plug and oil filter for engine oil leakage.

9. Stop the engine and wait for 10 minutes.

10. Check the engine oil level.

Changing Oil FilterINFOID:0000000001328906

REMOVAL

WARNING:

Be careful not to get burned when the engine and engine oil may be hot.

1. Remove front engine undercover with power tool.

2. Using oil filter wrench (SST), remove oil filter. CAUTION:

Oil filter is provided with relief valve. Use genuine NISSAN

oil filter or equivalent.

When removing, prepare a sh op cloth to absorb any

engine oil leakage or spillage.

Do not allow engine oil to adhere to drive belts.

Completely wipe off any engine oil that adheres to engine and vehicle.

INSTALLATION

1. Remove foreign materials adhering to oil filter installation surface.

Drain and refill With oil filter change 4.7 (5, 4-1/8)

Without oil filter change 4.4 (4-5/8, 3-7/8)

Dry engine (Overhaul) 5.4 (5-3/4, 4-3/4)

PBIC3101E

SBIA0454E

SBIA0455E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3334 of 3924

ENGINE MAINTENANCE (VQ35DE ENGINE)MA-17

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

2. Apply engine oil to the oil seal contact surface of new oil filter.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to the specification.

INSPECTION AFTER INSTALLATION

1. Start the engine, and check there is no leak of engine oil.

2. Stop the engine and wait for 10 minutes.

3. Check the engine oil level, and adjust the level. Refer to MA-15, "

Changing Engine Oil".

Changing Spark Plugs (Platinum-Tipped Type)INFOID:0000000001328907

REMOVAL

1. Remove engine cover with power tool. Refer to EM-19.

2. Remove ignition coil. Refer to EM-42

.

3. Remove spark plug with a spark plug wrench (commercial ser- vice tool).

INSPECTION AFTER REMOVAL

Use the standard type spark plug for normal condition.

The hot type spark plug is suitable when fouling occurs with the standard type spark plug under conditions

such as:

Frequent engine starts

Low ambient temperatures

The cold type spark plug is suitable when spark knock occurs with the standard type spark plug under condi-

tions such as:

Extended highway driving

Frequent high engine revolution

SMA010

Oil filter:

: 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

SEM294A

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3335 of 3924

MA-18

< SERVICE INFORMATION >

ENGINE MAINTENANCE (VQ35DE ENGINE)

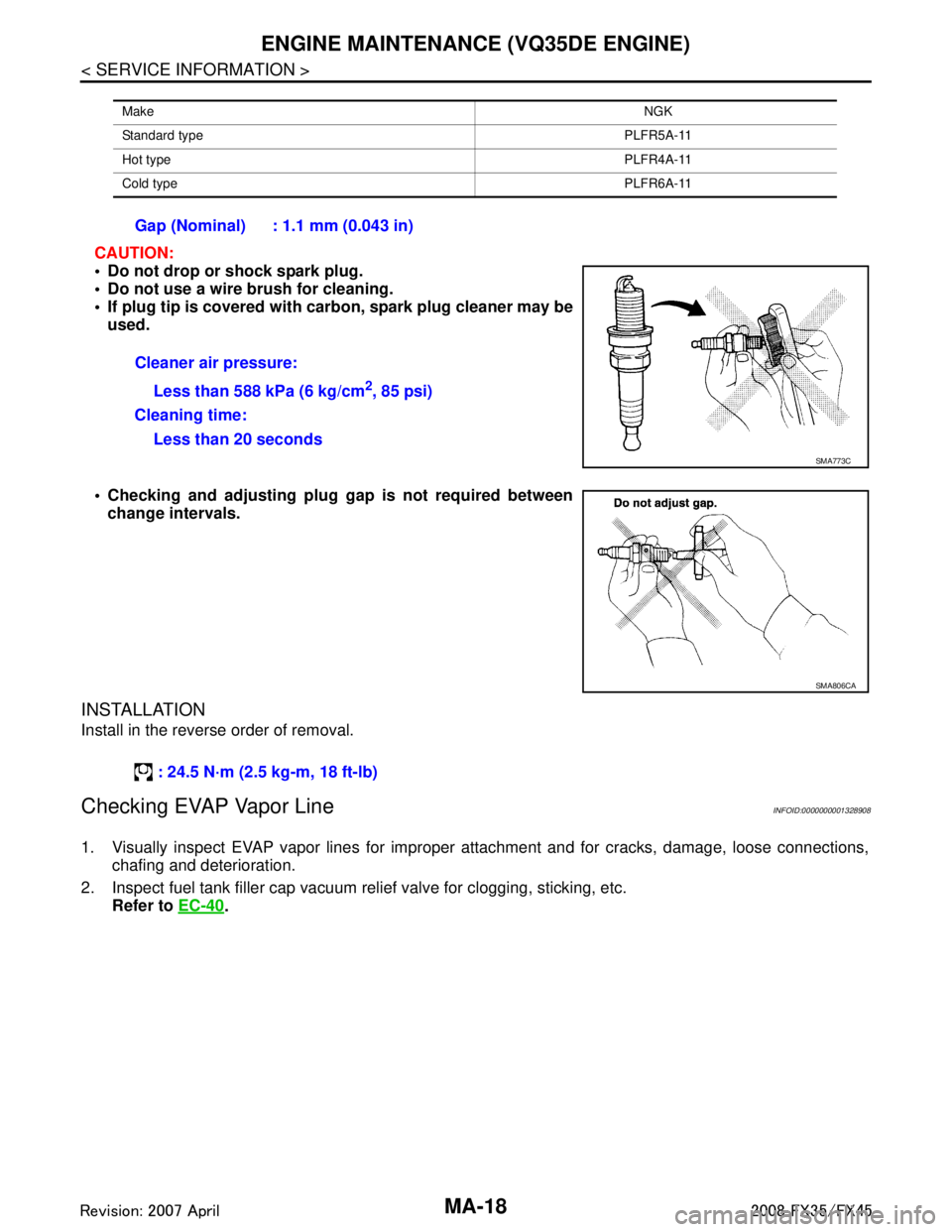

CAUTION:

Do not drop or shock spark plug.

Do not use a wire brush for cleaning.

If plug tip is covered with carbon, spark plug cleaner may be

used.

Checking and adjusting plug gap is not required between

change intervals.

INSTALLATION

Install in the reverse order of removal.

Checking EVAP Vapor LineINFOID:0000000001328908

1. Visually inspect EVAP vapor lines for improper attachment and for cracks, damage, loose connections,

chafing and deterioration.

2. Inspect fuel tank filler cap vacuum relief valve for clogging, sticking, etc.

Refer to EC-40

.

Make NGK

Standard type PLFR5A-11

Hot type PLFR4A-11

Cold type PLFR6A-11

Gap (Nominal) : 1.1 mm (0.043 in)

Cleaner air pressure:

Less than 588 kPa (6 kg/cm

2, 85 psi)

Cleaning time: Less than 20 seconds

SMA773C

SMA806CA

: 24.5 N·m (2.5 kg-m, 18 ft-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C