Oil INFINITI FX35 2008 Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 274 of 3924

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-201

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

NG >> Repair or replace damaged parts.

A/T Does Not Shift: 2nd Gear → 1st GearINFOID:0000000001327381

SYMPTOM:

When shifted from M2 to M1 position in manual mode, does not downshift from 2nd to 1st gear.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

With CONSULT-III

Perform self-diagnosis.

Without CONSULT-III

Perform self-diagnosis. Refer to AT-91, "

Diagnosis Procedure without CONSULT-III".

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfuncti oning system. Refer to AT-84, "CONSULT-III Function (TRANSMISSION)",

AT-91, "

Diagnosis Procedure without CONSULT-III".

NO >> GO TO 2.

2.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT- 11 , "

Checking A/T Fluid".

OK or NG

OK >> GO TO 3.

NG >> Refill ATF.

3.CHECK A/T POSITION

Check the A/T position. Refer to AT-207, "

Checking of A/T Position".

OK or NG

OK >> GO TO 4.

NG >> Adjust A/T position. Refer to AT-207, "

Adjustment of A/T

Position".

4.CHECK MANUAL MODE SWITCH

Check the manual mode switch. Refer to AT-155

.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-215, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

SAT638A

SCIA2119E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 276 of 3924

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-203

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

2.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT- 11 , "

Checking A/T Fluid".

OK or NG

OK >> GO TO 3.

NG >> Refill ATF.

3.CHECK A/T POSITION

Check the A/T position. Refer to AT-207, "

Checking of A/T Position".

OK or NG

OK >> GO TO 4.

NG >> Adjust A/T position. Refer to AT-207, "

Adjustment of A/T

Position".

4.CHECK MANUAL MODE SWITCH

Check the manual mode switch. Refer to AT-155

.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-215, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

2. Check A/T fluid condition. Refer to AT-49, "

Inspections Before

Trouble Diagnosis".

OK or NG

OK >> GO TO 6.

NG >> GO TO 9.

6.DETECT MALFUNCTIONING ITEM

Check the malfunction items. If any items are dam aged, repair or replace damaged parts. Refer to AT-59,

"Symptom Chart" (Symptom No.58).

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK SYMPTOM

Check again. Refer to AT-53, "

Road Test".

OK or NG

OK >> INSPECTION END

SAT638A

SCIA2119E

SCIA5199E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 288 of 3924

ON-VEHICLE SERVICEAT-215

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

ON-VEHICLE SERVICE

Control Valve with TCM and A/T Fluid Temperature Sensor 2INFOID:0000000001327393

COMPONENTS

CONTROL VALVE WITH TCM ASSEMB LY REMOVAL AND INSTALLATION

Removal

1. Disconnect the battery cable from the negative terminal.

2. Drain ATF through drain plug.

3. Remove front cross bar. Refer to FSU-6, "

Removal and Installation".

4. Disconnect heated oxygen sensor 2 harness connector.

5. Disconnect A/T assembly harness connector.

1. A/T 2. Snap ring 3. Sub-harness

4. Control valve with TCM 5. Bracket 6. A/T fluid temperature sensor 2

7. Oil pan gasket 8. Clip 9. Bracket (VK45DE)

10. Bracket (VK45DE) 11. Oil pan mounting bolt 12. Oil pan

13. Magnet 14. Drain plug 15. Drain plug gasket

16. Terminal cord assembly 17. O-ring

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

SCIA8045E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 289 of 3924

AT-216

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

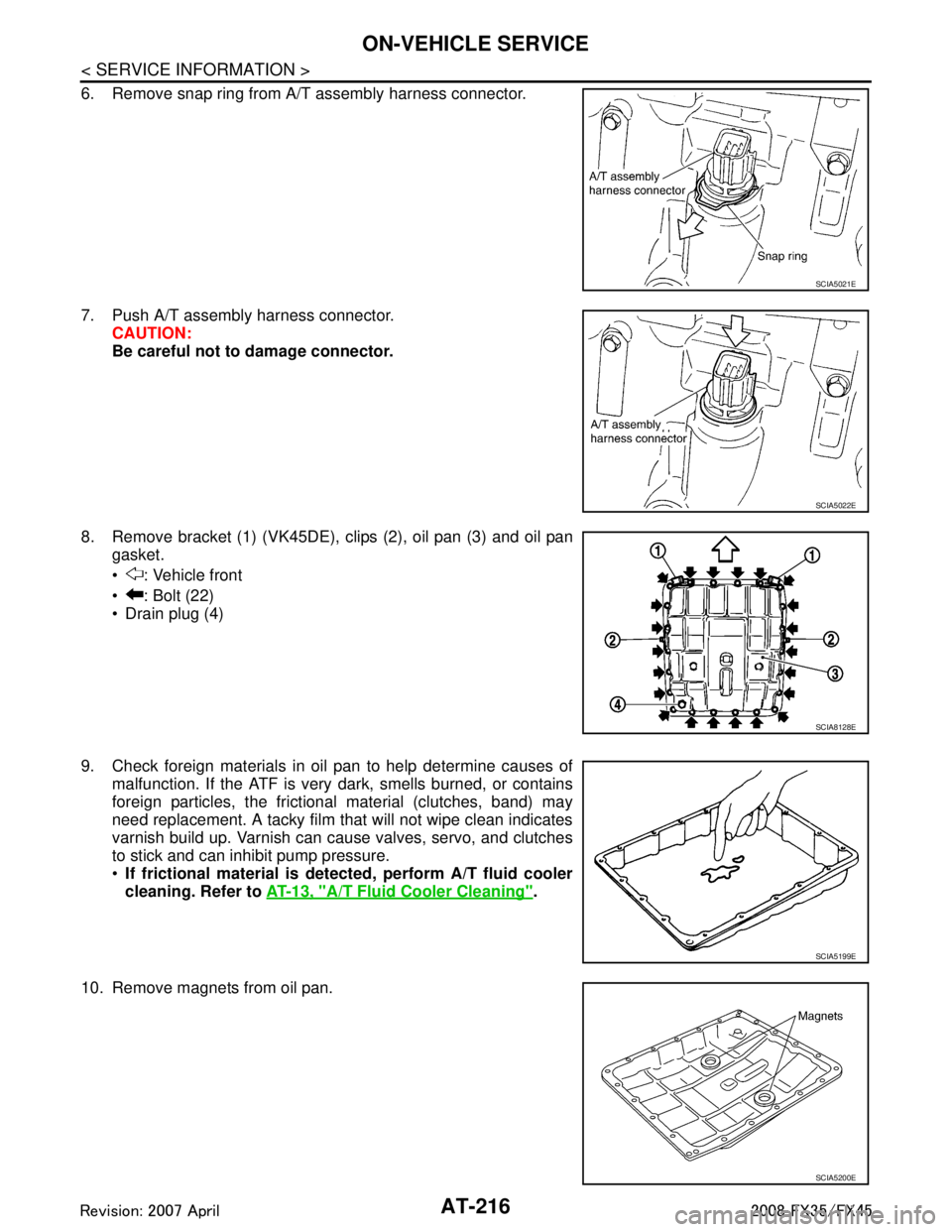

6. Remove snap ring from A/T assembly harness connector.

7. Push A/T assembly harness connector.CAUTION:

Be careful not to damage connector.

8. Remove bracket (1) (VK45DE), clips (2), oil pan (3) and oil pan gasket.

: Vehicle front

: Bolt (22)

Drain plug (4)

9. Check foreign materials in oil pan to help determine causes of malfunction. If the ATF is very dark, smells burned, or contains

foreign particles, the frictional material (clutches, band) may

need replacement. A tacky film that will not wipe clean indicates

varnish build up. Varnish can cause valves, servo, and clutches

to stick and can inhibit pump pressure.

If frictional material is de tected, perform A/T fluid cooler

cleaning. Refer to AT-13, "

A/T Fluid Cooler Cleaning".

10. Remove magnets from oil pan.

SCIA5021E

SCIA5022E

SCIA8128E

SCIA5199E

SCIA5200E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 295 of 3924

AT-222

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

12. Connect revolution sensor connector.

13. Securely fasten revolution sensor harness with terminal clip.

14. Install magnets in oil pan.

15. Install oil pan to transmission case.

a. Install oil pan gasket to oil pan.CAUTION:

Do not reuse oil pan gasket.

Install it in the direction to align hole positions.

Completely remove all moisture , oil and old gasket, etc. from oil pan gasket mounting surface.

b. Install oil pan (3) (with oil pan gasket), clips (2) and brackets (1) (VK45DE) to transmission case.

: Vehicle front

: Bolt (22)

CAUTION:

Install it so that drain plug (4) comes to the position as

shown in the figure.

Be careful not to pinch harnesses.

Completely remove all moisture, oil and old gasket, etc. from oil pan mounting surface.

SCIA7524E

SCIA7525E

SCIA5200E

SCIA8128E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 296 of 3924

ON-VEHICLE SERVICEAT-223

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

c. Tighten oil pan mounting bolts to the specified torque in numeri- cal order shown in the figure after temporarily tightening them.

Refer to "COMPONENTS".

CAUTION:

Do not reuse oil pan mounting bolts.

16. Install drain plug to oil pan, and then tighten drain plug to the specified torque. Refer to "COMPONENTS".

CAUTION:

Do not reuse drain plug gasket.

17. Pull up A/T assembly harness connector. CAUTION:

Be careful not to damage connector.

18. Install snap ring to A/T assembly harness connector.

19. Connect A/T assembly harness connector.

20. Connect heated oxygen sensor 2 harness connector.

21. Install front cross bar. Refer to FSU-6, "

Removal and Installa-

tion".

22. Pour ATF into A/T assembly. Refer to AT- 11 , "

Changing A/T

Fluid".

23. Connect the battery cable to the negative terminal.

A/T FLUID TEMPERATURE SENSOR 2 REMOVAL AND INSTALLATION

Removal

1. Disconnect the battery cabl e from the negative terminal.

2. Remove front cross bar. Refer to FSU-6, "

Removal and Installation".

3. Disconnect heated oxygen sensor 2 harness connector.

4. Drain ATF through drain plug.

5. Remove bracket (1) (VK45DE), clips (2), oil pan (3) and oil pan gasket.

: Vehicle front

: Bolt (22)

Drain plug (4)

SCIA4113E

SCIA5038E

SCIA5039E

SCIA8128E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 297 of 3924

AT-224

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

6. Check foreign materials in oil pan to help determine causes ofmalfunction. If the ATF is very dark, smells burned, or contains

foreign particles, the frictional material (clutches, band) may

need replacement. A tacky film that will not wipe clean indicates

varnish build up. Varnish can cause valves, servo, and clutches

to stick and can inhibit pump pressure.

If frictional material is de tected, perform A/T fluid cooler

cleaning. Refer to AT-13, "

A/T Fluid Cooler Cleaning".

7. Disconnect A/T fluid temperature sensor 2 connector (1). CAUTION:

Be careful not to damage connector.

8. Straighten terminal clip ( ) to free A/T fluid temperature sensor 2 harness.

9. Remove A/T fluid temperature sensor 2 with bracket from con- trol valve with TCM.

10. Remove bracket from A/T fluid temperature sensor 2.

Installation

CAUTION:

After completing installation, check A/T fluid leakage and A/F fluid level. Refer to AT- 11 , "

Checking A/T

Fluid".

SCIA5199E

SCIA8076E

SCIA5302E

SCIA5264E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 298 of 3924

ON-VEHICLE SERVICEAT-225

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

1. Install A/T fluid temperature sensor 2 to bracket.

2. Install A/T fluid temperature sens or 2 (with bracket) in control

valve with TCM, and then tighten A/T fluid temperature sensor 2

mounting bolt to the specified torque. Refer to "COMPO-

NENTS".

3. Connect A/T fluid temperature sensor 2 connector (1).

4. Securely fasten A/T fluid temperature sensor 2 harness with ter- minal clip ( ).

5. Install oil pan to transmission case.

a. Install oil pan gasket to oil pan. CAUTION:

Do not reuse oil pan gasket.

Install it in the direction to align hole positions.

Completely remove all moisture , oil and old gasket, etc. from oil pan mounting surface.

b. Install oil pan (3) (with oil pan gasket), clips (2) and brackets (1) (VK45DE) to transmission case.

: Vehicle front

: Bolt (22)

CAUTION:

Install it so that drain plug (4) comes to the position as

shown in the figure.

Be careful not to pinch harnesses.

Completely remove all moistu re, oil and old gasket, etc.

from oil pan mounting surface.

SCIA5264E

SCIA5302E

SCIA8076E

SCIA8128E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 299 of 3924

AT-226

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

c. Tighten oil pan mounting bolts to the specified torque in numeri-cal order shown in the figure after temporarily tightening them.

Refer to "COMPONENTS".

CAUTION:

Do not reuse oil pan mounting bolts.

6. Install drain plug to oil pan, and then tighten drain plug to the specified torque. Refer to "COMPONENTS".

CAUTION:

Do not reuse drain plug gasket.

7. Connect heated oxygen sensor 2 harness connector.

8. Install front cross bar. Refer to FSU-6, "

Removal and Installa-

tion".

9. Pour ATF into A/T assembly. Refer to AT- 11 , "

Changing A/T Fluid".

10. Connect the battery cable to the negative terminal.

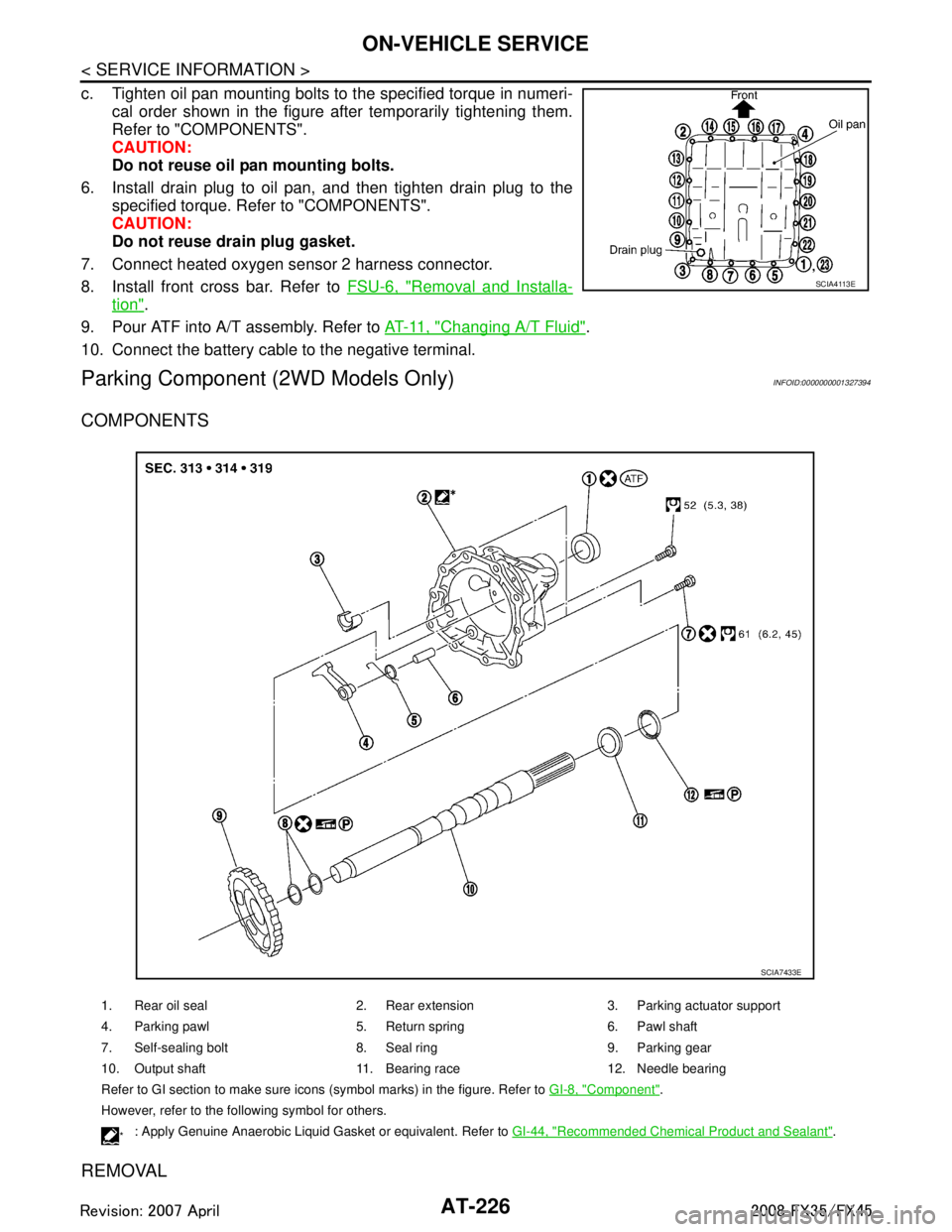

Parking Component (2WD Models Only)INFOID:0000000001327394

COMPONENTS

REMOVAL

SCIA4113E

1. Rear oil seal 2. Rear extension 3. Parking actuator support

4. Parking pawl 5. Return spring 6. Pawl shaft

7. Self-sealing bolt 8. Seal ring 9. Parking gear

10. Output shaft 11. Bearing race 12. Needle bearing

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

However, refer to the following symbol for others.

*: Apply Genuine Anaerobic Liquid Gasket or equivalent. Refer to GI-44, "Recommended Chemical Product and Sealant".

SCIA7433E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 302 of 3924

ON-VEHICLE SERVICEAT-229

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

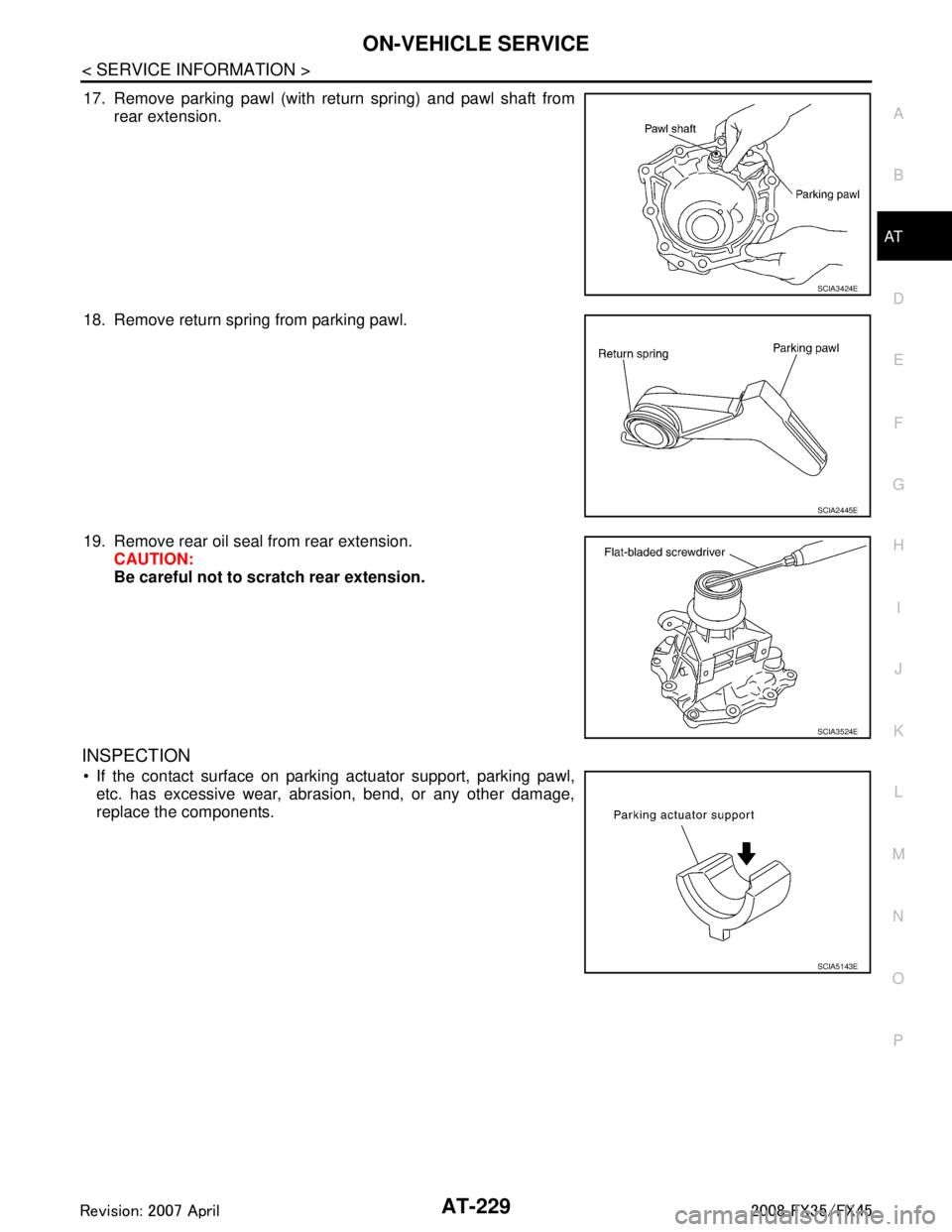

17. Remove parking pawl (with return spring) and pawl shaft from rear extension.

18. Remove return spring from parking pawl.

19. Remove rear oil seal from rear extension. CAUTION:

Be careful not to scratch rear extension.

INSPECTION

If the contact surface on parking actuator support, parking pawl,etc. has excessive wear, abrasion, bend, or any other damage,

replace the components.

SCIA3424E

SCIA2445E

SCIA3524E

SCIA5143E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C