Oil INFINITI FX35 2008 Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 329 of 3924

AT-256

< SERVICE INFORMATION >

OVERHAUL

22. Spacer 23. Seal ring 24. Snap ring

25. Return spring 26. O-ring 27. Servo assembly

28. Snap ring 29. Sub-harness 30. Control valve with TCM

31. Bracket 32. A/T fluid temperature sensor 2 33. Clip

34. Oil pan mounting bolt 35. Oil pan 36. Magnet

37. Drain plug 38. Drain plug gasket 39. Oil pan gasket

40. Terminal cord assembly 41. O-ring 42. Retaining pin

43. Transmission case

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

However, refer to the following symbol for others.

*: Apply Genuine Anaerobic Liquid Gasket or equivalent. Refer to GI-44, "Recommended Chemical Product and Sealant".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 330 of 3924

OVERHAULAT-257

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

VQ35DE models for AWD

SCIA8100E

1. Rear oil seal 2. Bracket 3. Adapter case

4. Parking actuator support 5. Return spring 6. Parking pawl

7. Pawl shaft 8. Self-sealing bolt 9. Seal ring

10. Needle bearing 11. Gasket 12. Revolution sensor

13. Parking gear 14. Output shaft 15. Bearing race

16. Needle bearing 17. Manual plate 18. Parking rod

19. Manual shaft oil seal 20. Manual shaft 21. O-ring

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 331 of 3924

AT-258

< SERVICE INFORMATION >

OVERHAUL

22. Band servo anchor end pin 23. Detent spring 24. Spacer

25. Seal ring 26. Snap ring 27. Return spring

28. O-ring 29. Servo assembly 30. Snap ring

31. Sub-harness 32. Control valve with TCM 33. Bracket

34. A/T fluid temperature sensor 2 35. Clip 36. Oil pan mounting bolt

37. Oil pan 38. Magnet 39. Drain plug

40. Drain plug gasket 41. Oil pan gasket 42. Terminal cord assembly

43. O-ring 44. Retaining pin 45. Transmission case

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 332 of 3924

OVERHAULAT-259

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

VK45DE models for 4WD

SCIA8101E

1. Rear oil seal 2. Self-sealing bolt 3. Bracket

4. Adapter case 5. Parking actuator support 6. Parking pawl

7. Return spring 8. Pawl shaft 9. Seal ring

10. Needle bearing 11. Gasket 12. Revolution sensor

13. Parking gear 14. Output shaft 15. Bearing race

16. Needle bearing 17. Manual plate 18. Parking rod

19. Manual shaft oil seal 20. Manual shaft 21. O-ring

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 333 of 3924

AT-260

< SERVICE INFORMATION >

OVERHAUL

22. Band servo anchor end pin 23. Detent spring 24. Spacer

25. Seal ring 26. Snap ring 27. Return spring

28. O-ring 29. Servo assembly 30. Snap ring

31. Sub-harness 32. Control valve with TCM 33. Bracket

34. A/T fluid temperature sensor 2 35. Clip 36. Bracket

37. Bracket 38. Oil pan mounting bolt 39. Oil pan

40. Magnet 41. Drain plug 42. Drain plug gasket

43. Oil pan gasket 44. Terminal cord assembly 45. O-ring

46. Retaining pin 47. Transmission case

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 334 of 3924

OVERHAULAT-261

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

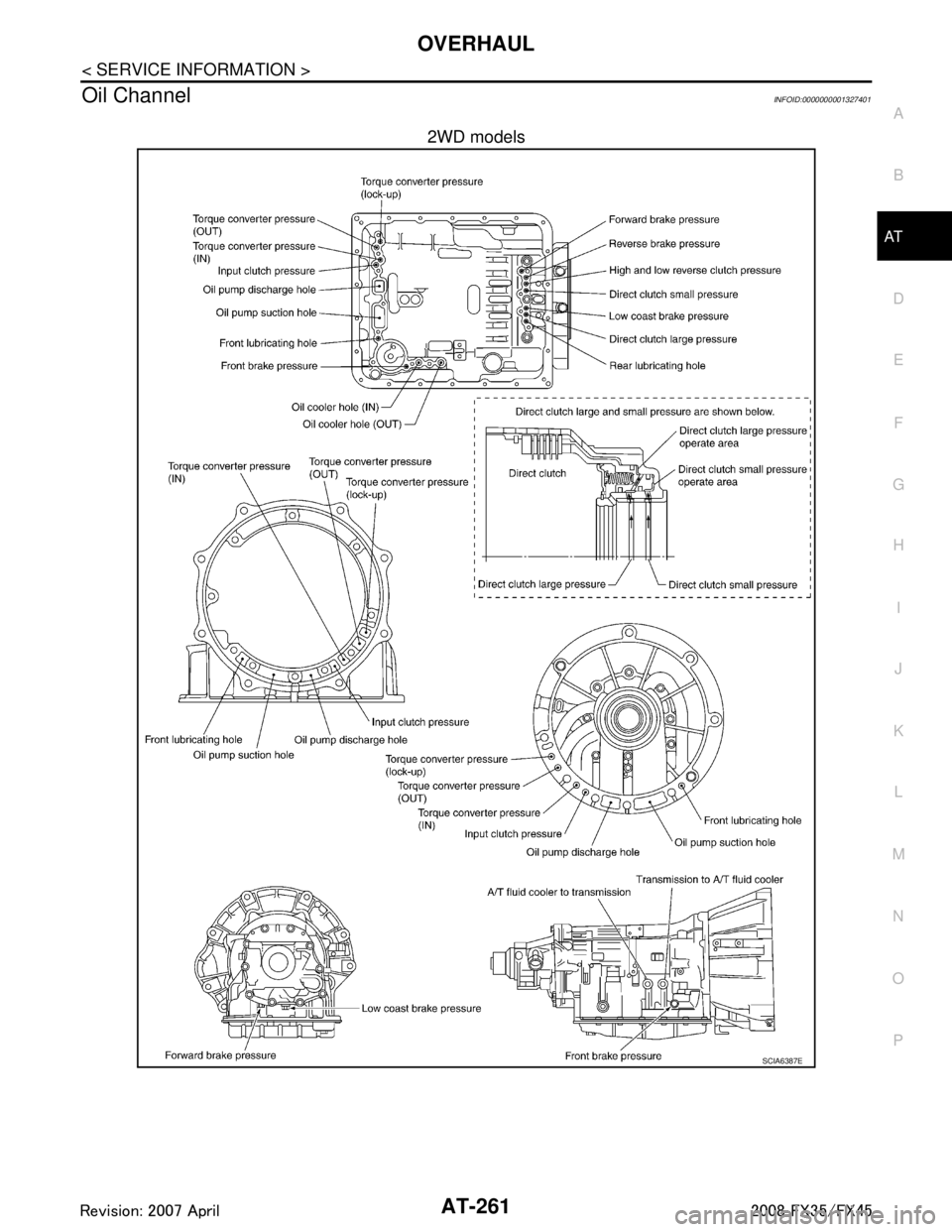

Oil ChannelINFOID:0000000001327401

2WD models

SCIA6387E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 341 of 3924

AT-268

< SERVICE INFORMATION >

DISASSEMBLY

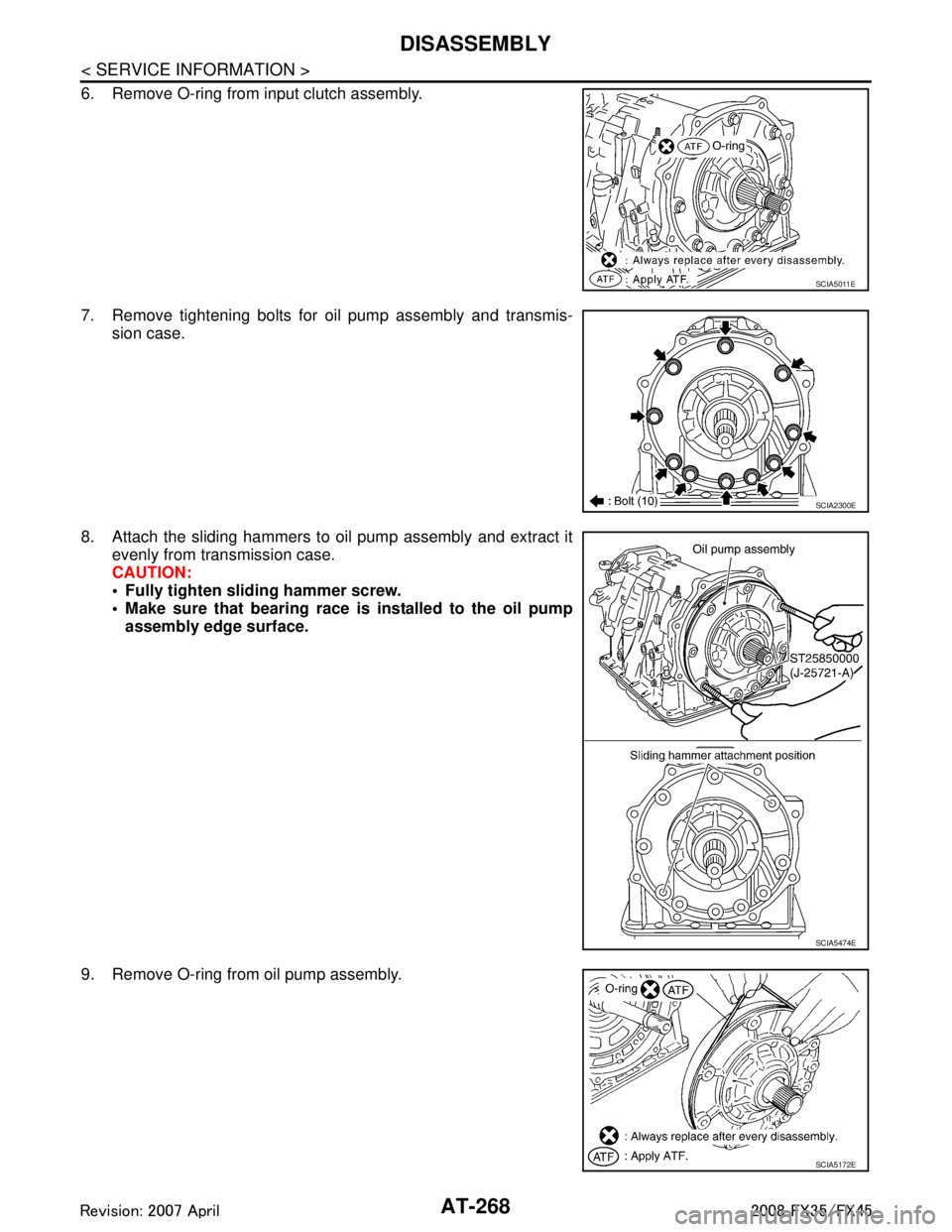

6. Remove O-ring from input clutch assembly.

7. Remove tightening bolts for oil pump assembly and transmis-sion case.

8. Attach the sliding hammers to oil pump assembly and extract it evenly from transmission case.

CAUTION:

Fully tighten sliding hammer screw.

Make sure that bearing race is installed to the oil pumpassembly edge surface.

9. Remove O-ring from oil pump assembly.

SCIA5011E

SCIA2300E

SCIA5474E

SCIA5172E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 342 of 3924

DISASSEMBLYAT-269

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

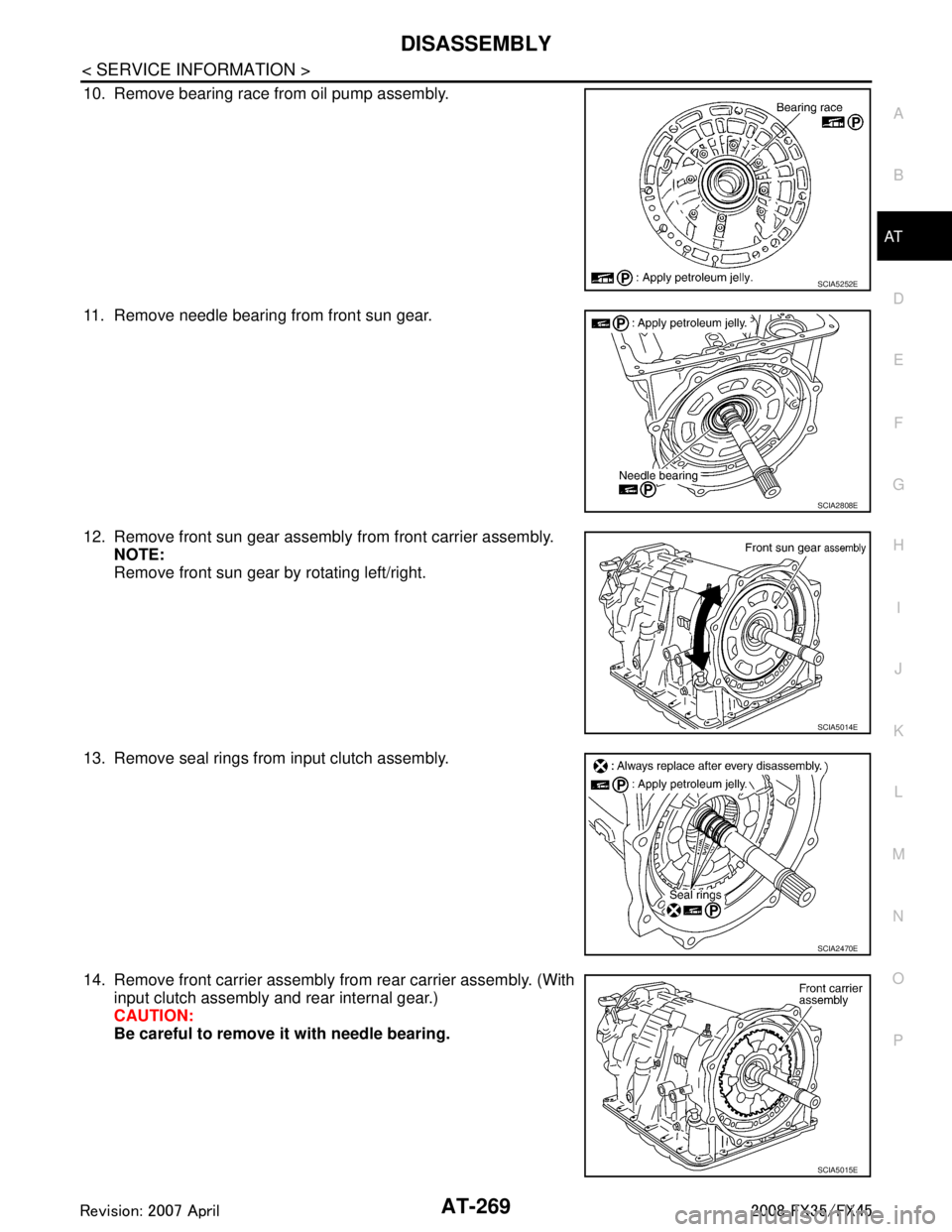

10. Remove bearing race from oil pump assembly.

11. Remove needle bearing from front sun gear.

12. Remove front sun gear assembly from front carrier assembly. NOTE:

Remove front sun gear by rotating left/right.

13. Remove seal rings from input clutch assembly.

14. Remove front carrier assembly from rear carrier assembly. (With input clutch assembly and rear internal gear.)

CAUTION:

Be careful to remove it with needle bearing.

SCIA5252E

SCIA2808E

SCIA5014E

SCIA2470E

SCIA5015E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 346 of 3924

DISASSEMBLYAT-273

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

29. Remove bracket (1) (VK45DE), clips (2), oil pan (3) and oil pan gasket.

: Vehicle front

: Bolt (22)

Drain plug (4)

30. Check foreign materials in oil pan to help determine causes of malfunction. If the ATF is very dark, smells burned, or contains

foreign particles, the frictional material (clutches, band) may

need replacement. A tacky film that will not wipe clean indicates

varnish build up. Varnish can c ause valves, servo, and clutches

to stick and can inhibit pump pressure.

If frictional material is detected, perform A/T fluid cooler

cleaning. Refer to AT-13, "

A/T Fluid Cooler Cleaning".

31. Remove magnets from oil pan.

32. Disconnect A/T fluid temperature sensor 2 connector (1). CAUTION:

Be careful not to damage connector.

33. Straighten terminal clips ( ) to free terminal cord assembly and A/T fluid temperature sensor 2 harness.

34. Disconnect revolution sensor connector. CAUTION:

Be careful not to damage connector.

SCIA8128E

SCIA5199E

SCIA5200E

SCIA8069E

SCIA7524E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 351 of 3924

AT-278

< SERVICE INFORMATION >

DISASSEMBLY

47. Remove parking gear from output shaft.

48. Remove seal rings from output shaft.

49. Remove needle bearing from transmission case.

50. Remove revolution sensor from transmission case.CAUTION:

Do not subject it to impact by dropping or hitting it.

Do not disassemble.

Do not allow metal filings, etc. to get on the sensor's front

edge magnetic area.

Do not place in an area affected by magnetism.

51. Remove reverse brake snap ring (fixing plate) using 2 flat- bladed screwdrivers.

NOTE:

Press out snap ring from the transmission case oil pan side gap

using a flat-bladed screwdriver, and remove it using another

screwdriver.

52. Remove reverse brake retaining plate from transmission case. Check facing for burns, cracks or damage. If necessary,

replace the plate.

SCIA5247E

SCIA5209E

SCIA5031E

SCIA2320E

SCIA5032E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C