tires INFINITI FX35 2008 Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3841 of 3924

WT-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION WT

A

B

WT

N

O PCONTENTS

ROAD WHEELS & TIRES

SERVICE INFORMATION .. ..........................2

INDEX FOR DTC ............................................ .....2

DTC No. Index .................................................... ......2

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution .................................................................3

Service Notice or Precaution .....................................4

PREPARATION ...................................................5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

6

NVH Troubleshooting Chart ................................ ......6

ROAD WHEEL ....................................................7

Inspection ............................................................ ......7

ROAD WHEEL TIRE ASSEMBLY ......................8

Balancing Wheels (Bonding Weight Type) .......... ......8

Tire Rotation ..............................................................9

TIRE PRESSURE MONITORING SYSTEM .......10

System Component ............................................. ....10

System Description .................................................10

CAN COMMUNICATION ....................................13

System Description ............................................. ....13

TROUBLE DIAGNOSES ....................................14

Schematic ........................................................... ....14

Wiring Diagram- T/WARN - .....................................15

Control Unit Input/Output Signal Standard ..............17

ID Registration Procedure ................................... ....19

Transmitter Wake Up Operation ..............................20

Self-Diagnosis .........................................................20

CONSULT-III Function (BCM) .................................22

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

24

Preliminary Check ...................................................25

Malfunction Code/Symptom Chart ...........................26

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS .................................................

28

Transmitter or Control Unit (BCM) ...........................28

Transmitter - 1 .........................................................28

Transmitter - 2 .........................................................29

Vehicle Speed Signal ..............................................29

TROUBLE DIAGNOSIS FOR SYMPTOMS ......30

Low Tire Pressure Warning Lamp Does Not Come

On When Ignition Switch Is Turned On ...................

30

Low Tire Pressure Warning Lamp Stays On When

Ignition Switch Is Turned On ............................... ....

30

Low Tire Pressure Warning Lamp Blinks When Ig-

nition Switch Is Turned On ......................................

31

Run-Flat Tire Warning Lamp Stays On When Igni-

tion Switch Is Turned On .........................................

32

Turn Signal Lamp Blinks When Ignition Switch Is

Turned On ...............................................................

32

ID Registration Cannot Be Completed ....................32

REMOVAL AND INSTALLATION .....................33

Transmitter ..............................................................33

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

35

Road Wheel .............................................................35

Tire ..........................................................................35

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3847 of 3924

ROAD WHEELWT-7

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

ROAD WHEEL

InspectionINFOID:0000000001327573

ALUMINUM WHEEL

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheel runout.

a. Remove tire from aluminum wheel and mount on a tire balance machine.

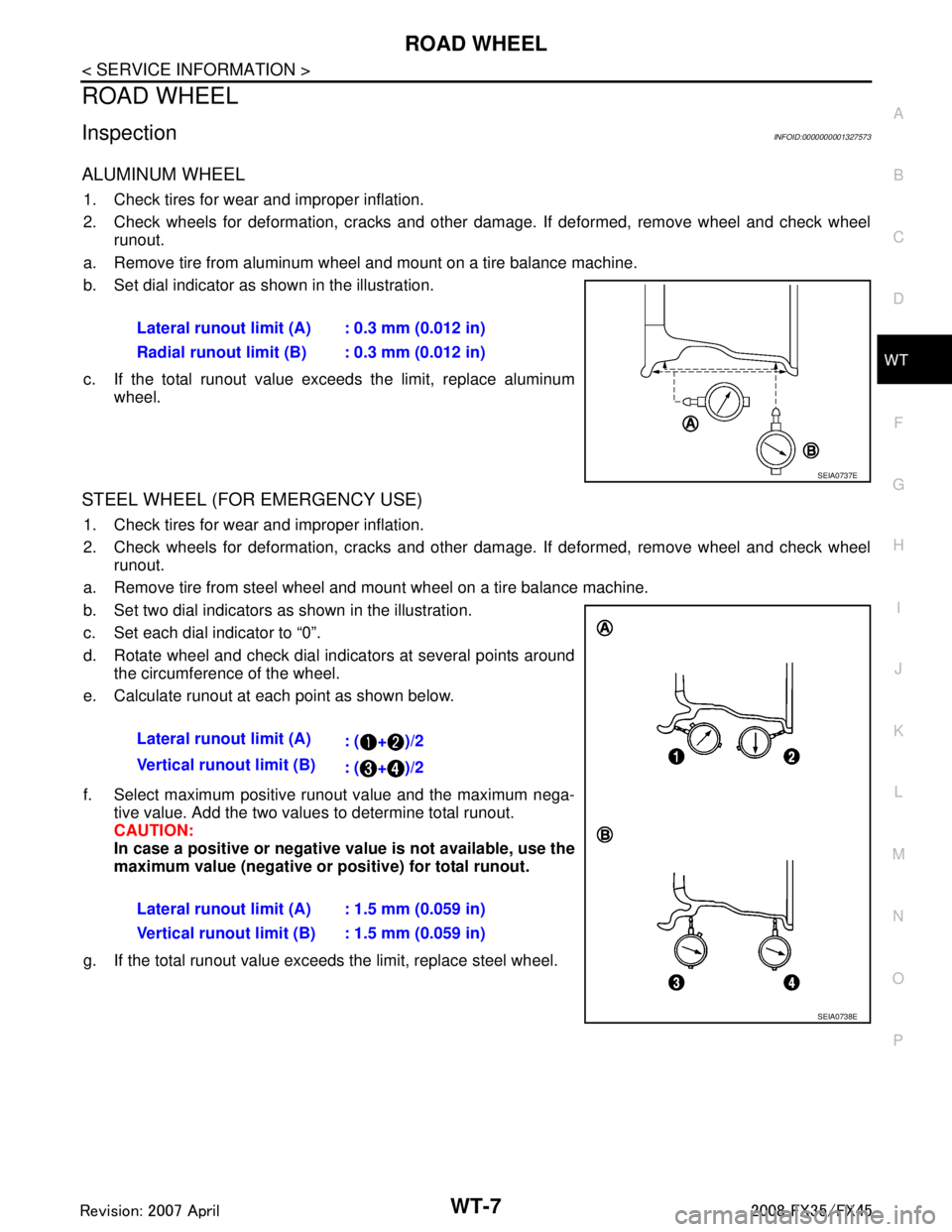

b. Set dial indicator as shown in the illustration.

c. If the total runout value exceeds the limit, replace aluminum wheel.

STEEL WHEEL (FOR EMERGENCY USE)

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheelrunout.

a. Remove tire from steel wheel and mount wheel on a tire balance machine.

b. Set two dial indicators as shown in the illustration.

c. Set each dial indicator to “0”.

d. Rotate wheel and check dial indicators at several points around the circumference of the wheel.

e. Calculate runout at each point as shown below.

f. Select maximum positive runout value and the maximum nega- tive value. Add the two values to determine total runout.

CAUTION:

In case a positive or negative val ue is not available, use the

maximum value (negative or positive) for total runout.

g. If the total runout value exceeds the limit, replace steel wheel.

Lateral runout limit (A) : 0.3 mm (0.012 in)

Radial runout limit (B) : 0.3 mm (0.012 in)

SEIA0737E

Lateral runout limit (A)

: ( + )/2

Vertical runout limit (B) : ( + )/2

Lateral runout limit (A) : 1.5 mm (0.059 in)

Vertical runout limit (B) : 1.5 mm (0.059 in)

SEIA0738E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3849 of 3924

ROAD WHEEL TIRE ASSEMBLYWT-9

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

d. If calculated balance weight value exceeds 50 g (1.76 oz), install two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Do not install one balance weig ht sheet on top of another.

3. Start tire balance machine again.

4. Install drive-in balance weight on inner side of road wheel in the tire balance machine indication position (angle).

CAUTION:

Do not install more than two balance weights.

5. Start tire balance machine. Make sure that inner and outer resid- ual unbalance values are 5 g (0.2 oz) each or below.

6. If either residual unbalance value exceeds 5 g (0.2 oz), repeat installation procedures.

Tire RotationINFOID:0000000001327575

1. Follow the maintenance schedule for tire rotation service intervals. Refer to MA-5, "Introduction of Peri-

odic Maintenance".

2. Do not include the spare tire when rotating the tires.

3. When installing the wheel, tighten wheel nuts to the specified torque.

CAUTION:

When installing wheels, tighten th em diagonally by dividing the work two to three times in order

to prevent the wheels from developing any distortion.

Be careful not to tighten wheel nut at torque exceeding the criteria for preventing strain of disc

rotor.

4. Perform the ID registration, after tire rotation. Refer to WT-19, "

ID Registration Procedure".

Wheel balance Dynamic (At rim flange) Static (At rim flange)

Maximum allowable un-

balance 5 g (0.2 oz) (one side) 20 g (0.7 oz)

SMA056D

Wheel nuts : 108 N·m (11 kg-m, 80 ft-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3860 of 3924

WT-20

< SERVICE INFORMATION >

TROUBLE DIAGNOSES

4. Inflate all tires to proper pressure. Refer to WT-35, "Tire".

Transmitter Wake Up OperationINFOID:0000000001327583

W I T H A C T I VAT I O N T O O L

1. With the transmitter activation tool (J-45295) pushed against the

front-left transmitter, press the button for 5 seconds.

When ignition switch ON, as the low tire pressure warninglamp blinks per the following diagram, the respective transmit-

ter then must be woken up.

2. Register the ID of wheel that low tire pressure warning lamp flashes. When wake up of registered wheel

has been completed, turn signal lamp flashes two times.

3. After completing wake up all transmitters, make sure low tire pressure warning lamp goes out.

Self-DiagnosisINFOID:0000000001327584

DESCRIPTION

During driving, the low tire pressure warning syste m receives the signal transmitted from the transmitter

installed in each wheel, and gives alarms when the tire pressure becomes low. The control unit (BCM) of this

system has pressure judgment and trouble diagnosis functions.

FUNCTION

When the low tire pressure warning system detects low inflation pressure or another unusual symptom, the

warning lamps in the combination meter comes on. To start the self-diagnostic results mode, ground terminal

of the tire pressure warning check connector. The malf unction location is indicated by the warning lamp flash-

ing and the buzzer sounds.

LOW TIRE PRESSURE WARNING LAMP DIAGNOSTIC CHART

Activation tire position CONSULT-III

Front LH “Red”↓

“Green”

Front RH

Rear RHRear LH

SEIA0460E

SEIA0794E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3869 of 3924

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

WT-29

< SERVICE INFORMATION >

C

D F

G H

I

J

K L

M A

B

WT

N

O P

YES >> GO TO 3.

NO >> Go to the inspection 1. Refer to WT-28, "

Transmitter or Control Unit (BCM)".

3.VEHICLE DRIVING

Drive at a speed of 40 km/h (25 MPH) or more for 3 minutes, and then drive the vehicle at any speed for 10

minutes. Then check all tire pressures with CO NSULT-III “DATA MONITOR ITEM” within 5 minutes.

Does

“DATA MONITOR ITEM” displayed tire pressure as normal without any warning lamp?

YES >> INSPECTION END.

NO >> Replace malfunctioning transmitter, and perform “Step 3” again.

Transmitter - 2INFOID:0000000001327591

MALFUNCTION CODE NO. 35, 36, 37 OR 38

1.CHECK ALL TIRE PRESSURES

Check all tire pressures. Refer to WT-35, "

Tire".

Are there any tires whose pressure is

“64 psi” or more?

YES >> Adjust tire pressure to specified value.

NO >> GO TO 2.

2.VEHICLE DRIVING

1. Perform ID registration of all transmitters.

2. Drive at a speed of 40 km/h (25 MPH) or more for several minutes without stopping.

Check all tire pressures with CONSULT-III “DATA MO NITOR ITEM” within 15 minutes after vehicle speed

become 17 km/h (11 MPH).

>> Replace transmitter with new one if “DATA MO NITOR ITEM” displayed 64 psi or more. Then GO

TO 3.

3.ID REGISTRATION AND VEHICLE DRIVING

1. Perform ID registration of all transmitters.

2. Drive at a speed of 40 km/h (25 MPH) or more fo r 3 minutes, and then drive the vehicle at any speed for

10 minutes. Then check all tire pressures with CONS ULT-III “DATA MONITOR ITEM” within 5 minutes.

Does

“DATA MONITOR ITEM” display tire pressure as normal without any warning lamp?

YES >> INSPECTION END

NO >> Go to the inspection applicable to DTC.

Vehicle Speed SignalINFOID:0000000001327592

MALFUNCTION CODE NO. 52

1.CHECK SELF-DIAGNOSIS RESULTS

1. Select “SELF-DIAG RESULTS” on “SELECT DIAG MODE” screen.

2. Check display contents in self-diagnostic results.

Is

“CAN COMM CIRCUIT” displayed in the self-diagnosis display items?

YES >> Malfunction in CAN communication system. Go to LAN-43, "CAN System Specification Chart".

NO >> No malfunction. Check combination meter refer to DI-5, "

System Description".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3872 of 3924

WT-32

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

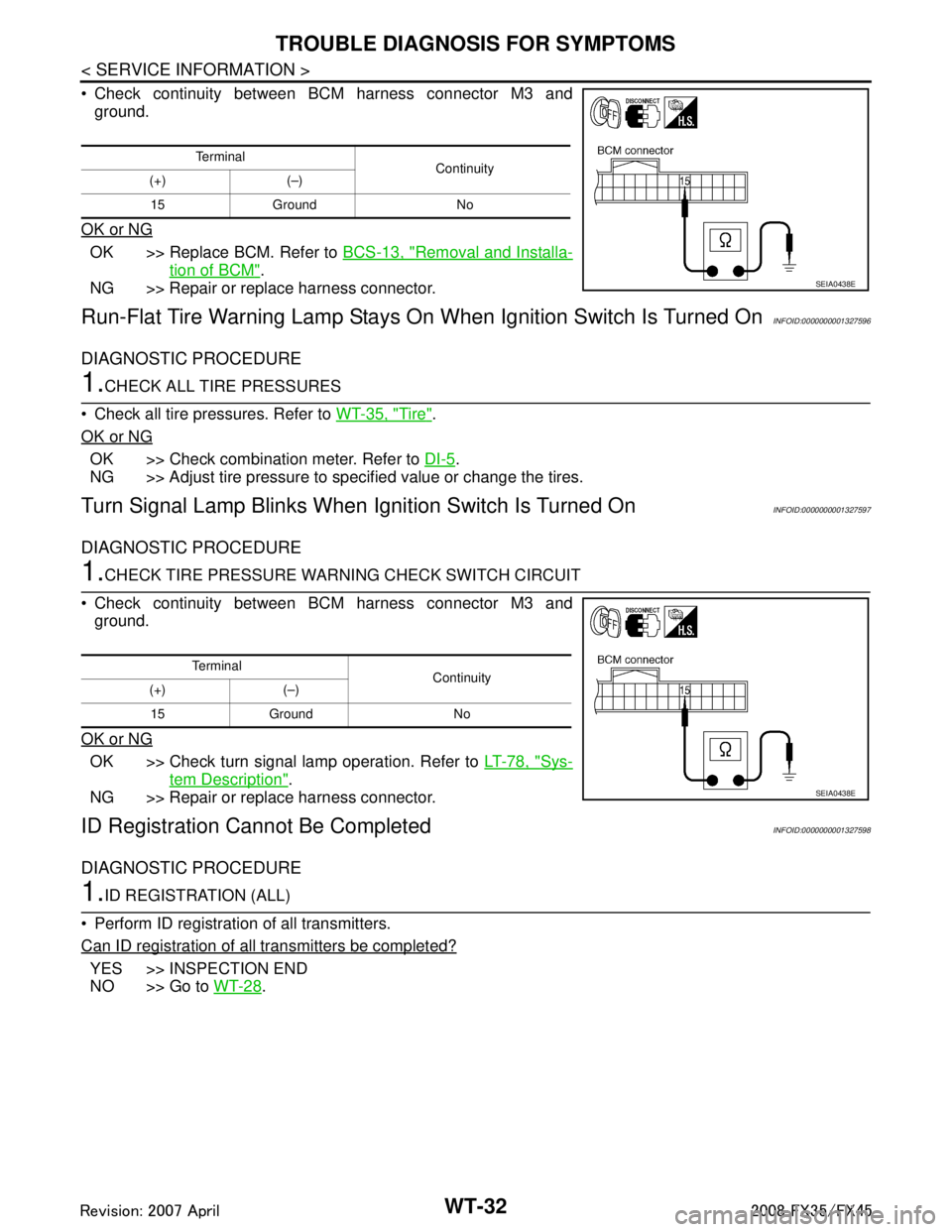

Check continuity between BCM harness connector M3 andground.

OK or NG

OK >> Replace BCM. Refer to BCS-13, "Removal and Installa-

tion of BCM".

NG >> Repair or replace harness connector.

Run-Flat Tire Warning Lamp Stays On When Ignition Switch Is Turned OnINFOID:0000000001327596

DIAGNOSTIC PROCEDURE

1.CHECK ALL TIRE PRESSURES

Check all tire pressures. Refer to WT-35, "

Tire".

OK or NG

OK >> Check combination meter. Refer to DI-5.

NG >> Adjust tire pressure to specified value or change the tires.

Turn Signal Lamp Blinks When Ignition Switch Is Turned OnINFOID:0000000001327597

DIAGNOSTIC PROCEDURE

1.CHECK TIRE PRESSURE WARNI NG CHECK SWITCH CIRCUIT

Check continuity between BCM harness connector M3 and ground.

OK or NG

OK >> Check turn signal lamp operation. Refer to LT-78, "Sys-

tem Description".

NG >> Repair or replace harness connector.

ID Registration Ca nnot Be CompletedINFOID:0000000001327598

DIAGNOSTIC PROCEDURE

1.ID REGISTRATION (ALL)

Perform ID registration of all transmitters.

Can ID registration of all transmitters be completed?

YES >> INSPECTION END

NO >> Go to WT-28

.

Te r m i n a l

Continuity

(+) (–)

15 Ground No

SEIA0438E

Te r m i n a l Continuity

(+) (–)

15 Ground No

SEIA0438E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C