Brake System INFINITI FX35 2008 Manual PDF

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 165 of 3924

AT-92

< SERVICE INFORMATION >

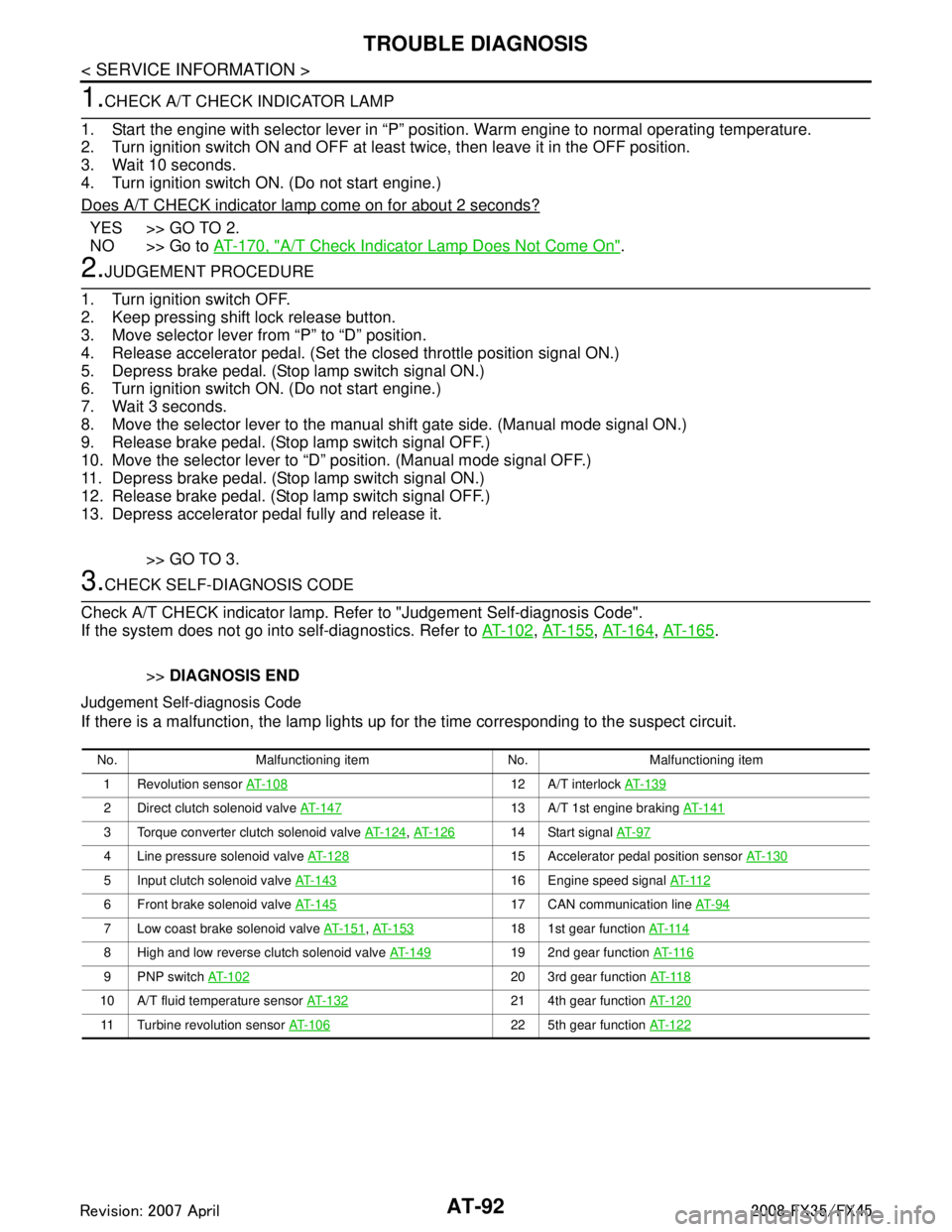

TROUBLE DIAGNOSIS

1.CHECK A/T CHECK INDICATOR LAMP

1. Start the engine with selector lever in “P” pos ition. Warm engine to normal operating temperature.

2. Turn ignition switch ON and OFF at least twice, then leave it in the OFF position.

3. Wait 10 seconds.

4. Turn ignition switch ON. (Do not start engine.)

Does A/T CHECK indicator lamp come on for about 2 seconds?

YES >> GO TO 2.

NO >> Go to AT-170, "

A/T Check Indicator Lamp Does Not Come On".

2.JUDGEMENT PROCEDURE

1. Turn ignition switch OFF.

2. Keep pressing shift lock release button.

3. Move selector lever from “P” to “D” position.

4. Release accelerator pedal. (Set the closed throttle position signal ON.)

5. Depress brake pedal. (Stop lamp switch signal ON.)

6. Turn ignition switch ON. (Do not start engine.)

7. Wait 3 seconds.

8. Move the selector lever to the manual shift gate side. (Manual mode signal ON.)

9. Release brake pedal. (Stop lamp switch signal OFF.)

10. Move the selector lever to “D” position. (Manual mode signal OFF.)

11. Depress brake pedal. (Stop lamp switch signal ON.)

12. Release brake pedal. (Stop lamp switch signal OFF.)

13. Depress accelerator pedal fully and release it.

>> GO TO 3.

3.CHECK SELF-DIAGNOSIS CODE

Check A/T CHECK indicator lamp. Refer to "Judgement Self-diagnosis Code".

If the system does not go into self-diagnostics. Refer to AT-102

, AT-155, AT-164, AT-165.

>> DIAGNOSIS END

Judgement Self-diagnosis Code

If there is a malfunction, the lamp lights up fo r the time corresponding to the suspect circuit.

No. Malfunctioning item No. Malfunctioning item

1 Revolution sensor AT- 1 0 8

12 A/T interlock AT- 1 3 9

2 Direct clutch solenoid valve AT- 1 4 713 A/T 1st engine braking AT-141

3 Torque converter clutch solenoid valve AT- 1 2 4, AT- 1 2 614 Start signal AT- 9 7

4 Line pressure solenoid valve AT- 1 2 815 Accelerator pedal position sensor AT- 1 3 0

5 Input clutch solenoid valve AT- 1 4 316 Engine speed signal AT- 11 2

6 Front brake solenoid valve AT- 1 4 517 CAN communication line AT- 9 4

7 Low coast brake solenoid valve AT- 1 5 1, AT- 1 5 318 1st gear function AT- 11 4

8 High and low reverse clutch solenoid valve AT- 1 4 919 2nd gear function AT- 11 6

9 PNP switch AT- 1 0 220 3rd gear function AT- 11 8

10 A/T fluid temperature sensor AT-13221 4th gear function AT- 1 2 0

11 Turbine revolution sensor AT- 1 0 622 5th gear function AT- 1 2 2

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 275 of 3924

AT-202

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

2. Check A/T fluid condition. Refer to AT-49, "Inspections Before

Trouble Diagnosis".

OK or NG

OK >> GO TO 6.

NG >> GO TO 9.

6.DETECT MALFUNCTIONING ITEM

Check the malfunction items. If any items are damaged, repair or replace damaged parts. Refer to AT-59,

"Symptom Chart" (Symptom No.50).

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK SYMPTOM

Check again. Refer to AT-53, "

Road Test".

OK or NG

OK >> INSPECTION END

NG >> GO TO 8.

8.CHECK TCM

1. Check TCM input/output signals. Refer to AT-83, "

TCM Input/Output Signal Reference Value".

2. If NG, recheck A/T assembly harness connector terminals for damage or loose connection with harness

connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

9.DETECT MALFUNCTIONING ITEM

Check the malfunction items. If any items are damaged, repair or replace damaged parts. Refer to AT-59,

"Symptom Chart" (Symptom No.50).

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

Vehicle Does Not Decele rate by Engine BrakeINFOID:0000000001327382

SYMPTOM:

No engine brake is applied when the gear is shifted from the 2nd to 1st gear.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

With CONSULT-III

Perform self-diagnosis.

Without CONSULT-III

Perform self-diagnosis. Refer to AT-91, "

Diagnosis Procedure without CONSULT-III".

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-84, "CONSULT-III Function (TRANSMISSION)",

AT-91, "

Diagnosis Procedure without CONSULT-III".

NO >> GO TO 2.

SCIA5199E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 278 of 3924

SHIFT CONTROL SYSTEMAT-205

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

SHIFT CONTROL SYSTEM

Control Device Remo val and InstallationINFOID:0000000001327383

REMOVAL

CAUTION:

Make sure that parking brake is a pplied before removal/installation.

1. Disconnect lower lever of control device and control rod.

1. Selector lever knob 2. Lock pin 3. Position indicator plate

4. A/T device harness connector 5. Snap pin 6. Conical washer

7. Plain washer 8. Busing 9. Collar

10. Control rod 11. Bracket 12. Dust cover

13. Dust cover plate 14. Shift lock solenoid and park position switch assembly15. Control device assembly

16. Position lamp

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

SCIA7753E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 280 of 3924

SHIFT CONTROL SYSTEMAT-207

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

1. Disconnect lower lever of control device and control rod.

2. Remove manual lever from A/T assembly.

3. Remove control rod from vehicle.

INSTALLATION

Install in reverse order of removal. Be careful of the following:

After installation is completed, adjust and check A/T position. Refer to AT-207, "

Adjustment of A/T Position"

and AT-207, "Checking of A/T Position".

Adjustment of A/T PositionINFOID:0000000001327385

1. Loosen nut of control rod.

2. Place PNP switch and selector lever in “P” position.

3. While pressing lower lever toward rear of vehicle (in “P” position

direction), tighten nut to the specified torque. Refer to AT-206,

"Control Rod Removal and Installation".

CAUTION:

Do not push the bracket.

Checking of A/T PositionINFOID:0000000001327386

1. Place selector lever in “P” posit ion, and turn ignition switch ON.

2. Check selector lever can be shifted to other than “P” position when brake pedal is depressed. Also check

selector lever can be shifted from “P” position only when brake pedal is depressed.

3. Move the selector lever and check for excessive effort, sticking, noise or rattle.

4. Check the selector lever stops at each position wit h the feel of engagement when it is moved through all

the positions. Check whether or not t he actual position the selector lever is in matches the position shown

by the shift position indicator and the transmission body.

5. The method of operating the lever to individual positions cor- rectly should be as shown in the figure.

6. When selector button is pressed in “P”, “R”, or “N” position with-

out applying forward/backward force to selector lever, check but-

ton operation for sticking.

7. Check the back-up lamps illuminate only when lever is placed in the “R” position. Check the back-up lamps does not illuminate

when selector lever is pushed against “R” position in the “P” or

“N” position.

8. Check the engine can only be started with the selector lever in the “P” and “N” positions. (With selector lever in the “P” position,

engine can be started even when selector lever is moved for-

ward and backward.)

9. Check transmission is locked completely in “P” position.

10. When selector lever is set to manual shift gate, check manual mode is displayed on combination meter. Shift selector lever to “+” and “-” sides, and check set shift position changes. (Only while a vehicle is oper-

ating.)

SCIA5736E

SCIA2119E

SCIA7465E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 281 of 3924

AT-208

< SERVICE INFORMATION >

A/T SHIFT LOCK SYSTEM

A/T SHIFT LOCK SYSTEM

DescriptionINFOID:0000000001327387

The mechanical key interlock mechanism also operates as a shift lock:With the ignition switch turned to ON, the selector le ver cannot be shifted from “P” position to any other posi-

tion unless the brake pedal is depressed.

With the key removed, the selector lever cannot be shifted from “P” position to any other position.

The key cannot be removed unless the selector lever is placed in “P” position.

The shift lock and key interlock mechanisms are contro lled by the ON-OFF operation of the shift lock sole-

noid and by the operation of the rotator and slider located inside the key cylinder.

Shift Lock System Electrical Parts LocationINFOID:0000000001327388

1. Stop lamp switch 2. Brake pedal 3. Key interlock cable

4. Shift lock solenoid

A. Center console assembly B. Shift lock release button C. Brake pedal, upper

D. Control device assembly E. Shift lock solenoid, reverse side F. Park position switch

SCIA8107E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 282 of 3924

A/T SHIFT LOCK SYSTEMAT-209

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

Wiring Diagram - AT - SHIFTINFOID:0000000001327389

Diagnosis ProcedureINFOID:0000000001327390

SYMPTOM 1:

Selector lever cannot be moved from “P” position with key in ON position and brake pedal applied.

Selector lever can be moved from “P” position with key in ON position and brake pedal released.

Selector lever can be moved from “P” posi tion when key is removed from key cylinder.

SYMPTOM 2:

TCWM0589E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 283 of 3924

AT-210

< SERVICE INFORMATION >

A/T SHIFT LOCK SYSTEM

Ignition key cannot be removed when sel ector lever is set to “P” position.

Ignition key can be removed when selector lever is set to any position except “P” position.

1.CHECK KEY INTERLOCK CABLE

Check the key interlock cable for damage.

OK or NG

OK >> GO TO 2.

NG >> Repair or replace key interlock cable. Refer to AT-212

.

2.CHECK SELECTOR LEVER POSITION

Check the selector lever position for damage. Refer to AT-207, "

Checking of A/T Position"

OK or NG

OK >> GO TO 3.

NG >> Adjust A/T position. Refer to AT-207, "

Adjustment of A/T Position".

3.CHECK SHIFT LOCK SOLENOID AND PARK POSITION SWITCH

1. Connect A/T device harness connector.

2. Turn ignition switch ON.

3. Selector lever is set in “P” position.

4. Check operation.

OK or NG

OK >> INSPECTION END

NG >> GO TO 4.

4.CHECK POWER SOURCE

1. Turn ignition switch ON.

2. Check the voltage between A/T device harness connector M67 terminal 1 and ground. Refer to AT-209, "

Wiring Diagram - AT -

SHIFT".

OK or NG

OK >> GO TO 7.

NG >> GO TO 5.

5.CHECK STOP LAMP SWITCH

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

Condition Brake pedal Operation

When ignition switch is turned to ON and selector lever is set in

“P” position. Depressed Yes

Released No

Condition Brake pedal Data (Approx.)

When ignition switch is turned to

ON. Depressed Battery voltage

Released 0 V

SCIA2122E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 284 of 3924

A/T SHIFT LOCK SYSTEMAT-211

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

3. Check continuity between stop lamp switch harness connector E210 terminals 3 and 4.

Check stop lamp switch after adjusting brake pedal — refer to

BR-5

.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.DETECT MALFUNCTIONING ITEM

Check the following items. If any items are damaged, repair or replace damaged parts.

Harness for short or open between ignition switch and stop lamp switch harness connector E210 terminal 3.

Harness for short or open between stop lamp switch harness connector E210 terminal 4 and A/T device har-

ness connector M67 terminal 1.

10 A fuse [No.12, located in the fuse block (J/B)].

Ignition switch, Refer to PG-3

.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

7.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness connector M67 terminal 2 and ground.

OK or NG

OK >> Replace shift lock solenoid and park position switch assembly.

NG >> Repair open circuit in harness or connectors.

Condition Continuity

When brake pedal is depressed Yes

When brake pedal is released No

SCIA2126E

Continuity should exist.

SCIA2125E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 834 of 3924

BL-100

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

19 SB Outside antenna LH (+) OutputLOCKDriver door request signal opera-

tion (Switch: ON)

20 G/Y Outside antenna LH (-) Output

25 W/R Door request switch

(passenger side)

Input —Door request switch operation:

Press (ON)

0

Other than the above (OFF) 5

26 P/L Stop lamp switch Input — Brake pedal depressed (ON) 5

Brake pedal not depressed

(OFF)

0

27 L/W Ignition knob switch Input — Press ignition knob. 12

Return ignition knob to LOCK po-

sition.

0

28 W/B Door unlock sensor Input — Door is locking → unlock 5 → 0

29 GY Door request switch

(back door)

Input —Back door request switch opera-

tion: Press (ON)

0

Other than the above (OFF) 5

31 Y/B Steering lock unit

ground —— — 0

32 R/B Steering lock unit com-

munication Output LOCKPress ignition knob with Intelli-

gent Key inside vehicle.

Other than the above 5

35 LG Inside key antenna (+)

signal

(Dashboard) Output

LOCKAny door open

→ Close (Door

switch: ON → OFF)

Ignition knob switch: ON (press

ignition knob.)

36 PU Inside key antenna (-)

signal

(Dashboard) Output

37 G Outside antenna RH (+) Output

LOCKPassenger door request switch

operation (Switch: ON)

38 G/W Outside antenna RH (-) Output

Te r -

minal Wire

color Item Signal

Input/

output Condition

Voltage (V)(Approx.)

Ignition

knob po-

sition Operation or conditions

SIIA1910J

SIIA1911J

SIIA1910J

SIIA1910J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 839 of 3924

INTELLIGENT KEY SYSTEMBL-105

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

ACTIVE TEST

List of Operation Related PartsINFOID:0000000001327850

Parts marked with × are the parts related to operation.

Monitor item [OPERATION] Description

PUSH SWITCH [ON/OFF] Displays status (Ignition knob switch ON/i

gnition knob switch OFF) as judged from

ignition knob switch signal.

KEY SW [ON/OFF] Displays status (Key inserted: ON/Key removed: OFF) as judged by key switch.

DR REQ SW [ON/OFF] Displays status (Operable: ON/Non-operable: OFF) as judged from door request

switch (driver

side) signal.

AS REQ SW [ON/OFF] Displays status (Operable: ON/Non-operable: OFF) as judged from door request

switch (passenger side) signal.

BD/TR REQ SW [ON/OFF] Displays status (Operable: ON/Non-operable: OFF) as judged from door request

switch (back door) signal.

IGN SW [ON/OFF] Displays status (Ignition knob ON position: ON/Ignition knob OFF position: OFF) as

judged from ignition switch signal.

ACC SW [ON/OFF] Displays status (Ignition switch ACC position: ON/Ignition switch OFF position:

OFF) as judged from ignition switch signal.

DOOR STAT SW [ON/OFF] Displays status from door unlock sensor ON/OFF condition.

STOP LAMP SW [ON/OFF] Displays status (Brake pedal depress: ON/brake pedal not depress: OFF) as

judged from stop lamp switch signal.

P RANGE SW [ON/OFF] Displays status from park/neutral position switch ON/OFF condition.

BD OPEN SW [ON/OFF] Displays status (Back door open: ON/Back door closed: OFF) as judged from back

door opener switch signal.

Monitor item Description

DOOR LOCK/UNLOCK This test is able to check all door lock actuators lock/unlock operation. These actu-

ators lock when “ON” on CONSULT-III screen is touched.

OUTSIDE BUZZER This test is able to check Intelligent Key warning buzzer operation. The buzzer will

be activated on when “ON” on CONSULT-III screen is touched.

INSIDE BUZZER This test is able to check buzzer (built-in combination meter) operation. The buzzer

will be activated on when “ON” on CONSULT-III screen is touched.

INDICATOR This test is able to check warning lamp operation. The lamp will be turned on when

“ON” on CONSULT-III screen is touched.

Will not operate if there is a malfunction in

the area where there is a ×.

Intelligent Key

Key switch

Ignition knob switch ACC switch

Ignition switch

Door unlock sensor

Door switch

Door request switch

Inside key antenna

Out side key antenna

Intelligent Key warning buzzer Intelligent Key unit

CAN communication system

BCM

Combination meter

Steering lock unit

Stop lamp switch Detention switch

Passenger side select unlock relay

Door lock/unlock operation using Intelligent

Key remote controller button operation ×××××××

Door lock/unlock operation using door re-

quest switch operation ×××××××××

Selective door unlock function using door

request switch operation ××××××× ×

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C