fuel cap INFINITI FX35 2008 Manual PDF

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3332 of 3924

ENGINE MAINTENANCE (VQ35DE ENGINE)MA-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

4. Run the engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop the engine and wait until it cools down.

7. Drain water from the system. Refer to CO-10, "

Changing Engine Coolant".

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

Checking Fuel LineINFOID:0000000001328903

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections , chafing or deterioration.

If necessary, repair or replace damaged parts.

Changing Air Cleaner FilterINFOID:0000000001328904

VISCOUS PAPER TYPE

The viscous paper type filter does not need cleaning between

replacement intervals. Refer to MA-5

.

Changing Engine OilINFOID:0000000001328905

WARNING:

Be careful not to burn yoursel f, as engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thorough ly with soap or hand cleaner as

soon as possible.

1. Remove front engine undercover with power tool.

2. Warm up the engine, and check for engine oil leakage from engine components. Refer to LU-5, "

Inspec-

tion".

3. Stop the engine and wait for 10 minutes.

4. Loosen oil filler cap and then remove drain plug.

5. Drain engine oil.

6. Install drain plug with new washer. Refer to EM-30

.

CAUTION:

Be sure to clean drain plug and install with new washer.

7. Refill with new engine oil. Engine oil specificat ion and viscosity:

Refer to MA-9

.

SMA803A

SBIA0463E

Oil pan drain plug:

: 34.3 N·m (3.5 kg-m, 25 ft-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3335 of 3924

MA-18

< SERVICE INFORMATION >

ENGINE MAINTENANCE (VQ35DE ENGINE)

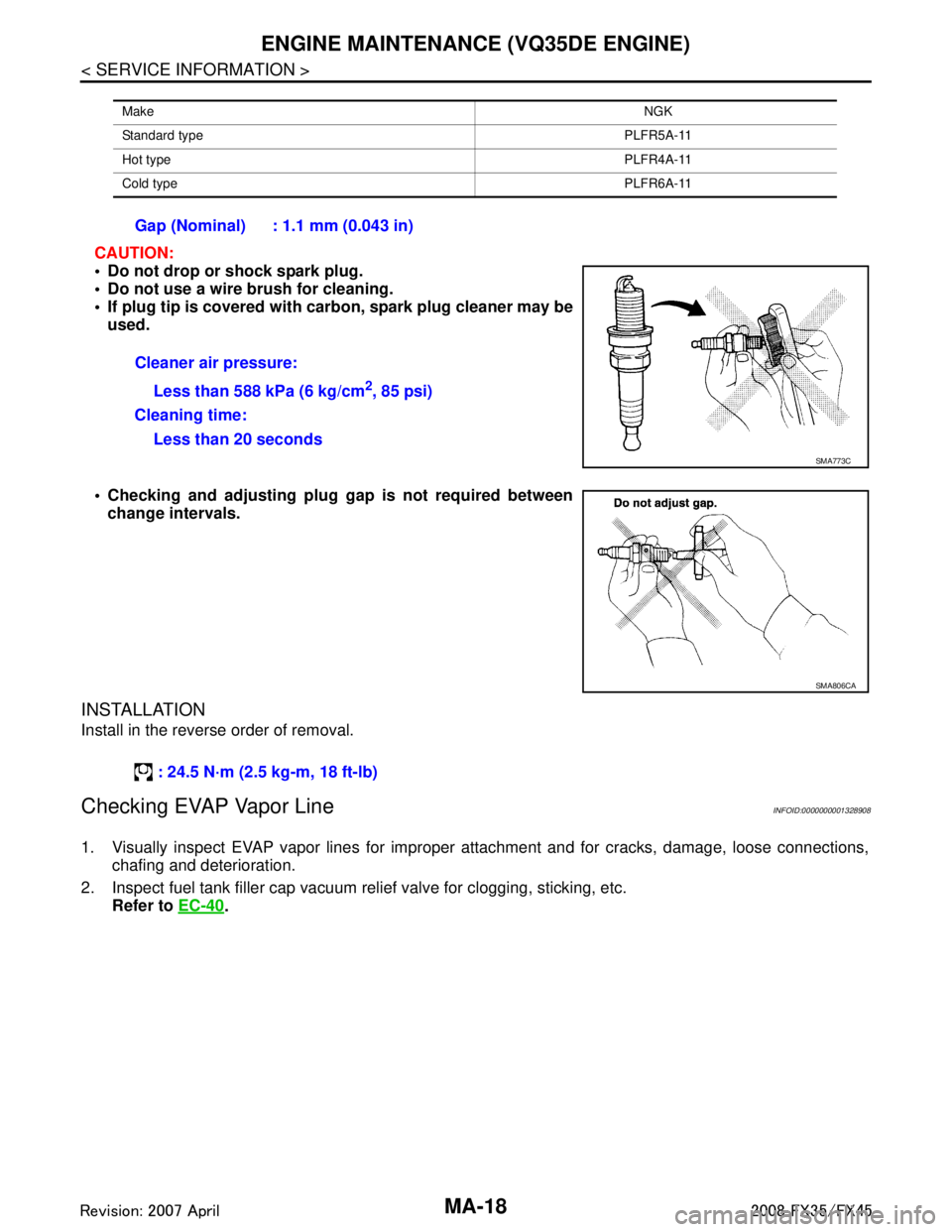

CAUTION:

Do not drop or shock spark plug.

Do not use a wire brush for cleaning.

If plug tip is covered with carbon, spark plug cleaner may be

used.

Checking and adjusting plug gap is not required between

change intervals.

INSTALLATION

Install in the reverse order of removal.

Checking EVAP Vapor LineINFOID:0000000001328908

1. Visually inspect EVAP vapor lines for improper attachment and for cracks, damage, loose connections,

chafing and deterioration.

2. Inspect fuel tank filler cap vacuum relief valve for clogging, sticking, etc.

Refer to EC-40

.

Make NGK

Standard type PLFR5A-11

Hot type PLFR4A-11

Cold type PLFR6A-11

Gap (Nominal) : 1.1 mm (0.043 in)

Cleaner air pressure:

Less than 588 kPa (6 kg/cm

2, 85 psi)

Cleaning time: Less than 20 seconds

SMA773C

SMA806CA

: 24.5 N·m (2.5 kg-m, 18 ft-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3339 of 3924

MA-22

< SERVICE INFORMATION >

ENGINE MAINTENANCE (VK45DE ENGINE)

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the system. Refer to "DRAINING ENGINE COOLANT".

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

Checking Fuel LineINFOID:0000000001328912

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

Changing Air Cleaner FilterINFOID:0000000001328913

VISCOUS PAPER TYPE

The viscous paper type filter does not need cleaning between replacement intervals. Refer to MA-5.

1. Remove air duct (inlet), air cleaner case and mass air flow sensor assembly. Refer to EM-173

.

2. Remove air cleaner filter from air cleaner case.

Changing Engine OilINFOID:0000000001328914

WARNING:

Be careful not to burn yoursel f, as engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause ski n cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1. Remove front engine undercover with power tool.

2. Warm up engine, put vehicle horizontally and check for engine oil leakage from engine components. Refer

to LU-23, "

Inspection".

3. Stop engine and wait for 15 minutes.

4. Loosen oil filler cap, and then remove drain plug.

5. Drain engine oil.

6. Install drain plug with new washer. Refer to EM-183

.

CAUTION:

Be sure to clean drain plug and install with new washer.

7. Refill with new engine oil. Engine oil specification and viscosity:

Refer to MA-9

.

Engine oil capacity (Approximate):

Unit: (US qt, Imp qt)

CAUTION:

SMA803A

Oil pan drain plug:

: 34.3 N·m (3.5 kg-m, 25 ft-lb)

PBIC0993E

Drain and refill With oil filter change 5.8 (6-1/8, 5-1/8)

Without oil filter change 5.2 (5-1/2, 4-5/8)

Dry engine (engine overhaul) 7.0 (7-3/8, 6-1/8)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3342 of 3924

ENGINE MAINTENANCE (VK45DE ENGINE)MA-25

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

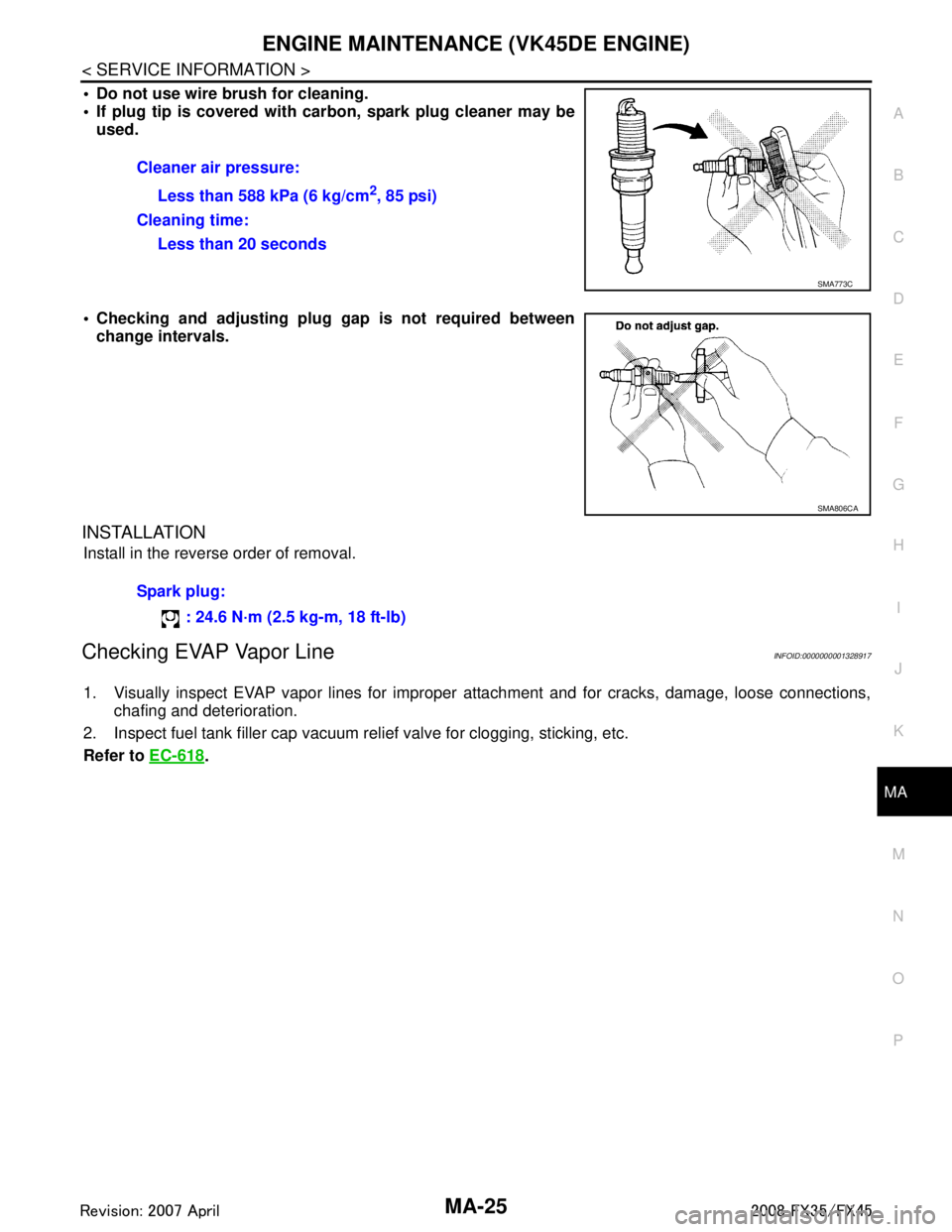

Do not use wire brush for cleaning.

If plug tip is covered with car bon, spark plug cleaner may be

used.

Checking and adjusting plug gap is not required between

change intervals.

INSTALLATION

Install in the reverse order of removal.

Checking EVAP Vapor LineINFOID:0000000001328917

1. Visually inspect EVAP vapor lines for improper attachment and for cracks, damage, loose connections,

chafing and deterioration.

2. Inspect fuel tank filler cap vacuum relief valve for clogging, sticking, etc.

Refer to EC-618

.

Cleaner air pressure:

Less than 588 kPa (6 kg/cm

2, 85 psi)

Cleaning time: Less than 20 seconds

SMA773C

SMA806CA

Spark plug:

: 24.6 N·m (2.5 kg-m, 18 ft-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3586 of 3924

REAR SUSPENSION ASSEMBLYRSU-5

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

REAR SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000001327552

Make sure the mounting conditions (looseness, ba ck lash) of each component and component status (wear,

damage) are normal.

INSPECTION OF BALL JOINT END PLAY

Measure axial end play by installing and moving up/down with an

iron pry bar or something similar between suspension arm and axle.

CAUTION:

Be careful not to damage ball joint boot.

SHOCK ABSORBER INSPECTION

Check shock absorber for oil leakage, damage and replace if necessary.

Wheel AlignmentInspectionINFOID:0000000001327553

DESCRIPTION

Measure wheel alignment under unladen conditions. “U nladen conditions” means that fuel, engine coolant,

and lubricant are full. Spare tire, jack, hand tools and mats in designated positions.

PRELIMINARY INSPECTION

Check tires for improper air pressure and wear.

Check road wheels for runout.

Check wheel bearing axial end play.

Check ball joint axial end play of suspension arm.

Check shock absorber operation.

Check each mounting point of axle and suspension for looseness and deformation.

Check each link, arm and member for cracks, deformation, and other damage.

Check vehicle posture.

GENERAL INFORMATION AND RECOMMENDATIONS

A four-wheel thrust alignment should be performed.

- This type of alignment is recomm ended for any NISSAN/INFINITI vehicle.

- The four-wheel “thrust” process helps ensure that t he vehicle is properly aligned and the steering wheel is

centered.

- The alignment rack itself should be capable of accepting any NISSAN/INFINITI vehicle.

- The rack should be checked to ensure that it is level.

Make sure the machine is properly calibrated.

- Your alignment equipment should be regularly ca librated in order to give correct information.

- Check with the manufacturer of your specific equi pment for their recommended Service/Calibration Sched-

ule.

THE ALIGNMENT PROCESS

IMPORTANT:

Use only the alignment specificati ons listed in this Service Manual.

When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

- The alignment specifications programmed into your machine that operate these indicators may not be cor-

rect.

- This may result in an ERROR.

Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). DO NOT use this “Rolling Compensation”

method. Standard value

Axial end play : 0 mm (0 in)

SEIA0245J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C