transmission fluid INFINITI FX35 2008 Manual PDF

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2694 of 3924

![INFINITI FX35 2008 Manual PDF

EM-210

< SERVICE INFORMATION >[VK45DE]

TIMING CHAIN

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in guide may gen-

erate a pounding noise during and jus INFINITI FX35 2008 Manual PDF

EM-210

< SERVICE INFORMATION >[VK45DE]

TIMING CHAIN

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in guide may gen-

erate a pounding noise during and jus](/img/42/57017/w960_57017-2693.png)

EM-210

< SERVICE INFORMATION >[VK45DE]

TIMING CHAIN

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in guide may gen-

erate a pounding noise during and just after engine start. However, this does not indicate an unusualness.

Noise will stop after hydraulic pressure rises.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The followings are procedures for checking fluids leak, lubricates leak and exhaust gases leak. Before starting engine, check oil/fluid levels incl

uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-9, "

Fluids and Lubricants"

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

Warm up engine thoroughly to make sure there is no leak age of fuel, exhaust gases, or any oil/fluids includ-

ing engine oil and engine coolant.

Bleed air from lines and hoses of applic able lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid. power steering fluid, brake fluid, etc. Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2722 of 3924

![INFINITI FX35 2008 Manual PDF

EM-238

< SERVICE INFORMATION >[VK45DE]

ENGINE ASSEMBLY

1. Release fuel pressure. Refer to

EC-665, "Fuel Pressure Check".

2. Drain engine coolant from radiator. Refer to CO-37, "

Changing Engine Coo INFINITI FX35 2008 Manual PDF

EM-238

< SERVICE INFORMATION >[VK45DE]

ENGINE ASSEMBLY

1. Release fuel pressure. Refer to

EC-665, "Fuel Pressure Check".

2. Drain engine coolant from radiator. Refer to CO-37, "

Changing Engine Coo](/img/42/57017/w960_57017-2721.png)

EM-238

< SERVICE INFORMATION >[VK45DE]

ENGINE ASSEMBLY

1. Release fuel pressure. Refer to

EC-665, "Fuel Pressure Check".

2. Drain engine coolant from radiator. Refer to CO-37, "

Changing Engine Coolant".

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belts.

3. Disconnect both battery terminal. Refer to SC-4, "

How to Handle Battery".

4. Remove crankshaft position sensor (POS) from transmission. CAUTION:

Handle carefully to avoid dropping and shocks.

Do not disassemble.

Do not allow metal powder to adhere to magnetic part at sensor tip.

Do not place sensors in a location wh ere they are exposed to magnetism.

5. Remove the following parts: Hood assembly: Refer to BL-13, "

Fitting Adjustment".

Engine cover: Refer to EM-169

.

Front and rear engine undercover

Air duct (inlet), air duct and air cleaner case assembly: Refer to EM-173, "

Component".

Drive belts: Refer to EM-170, "

Component".

Radiator and radiator hoses (upper and lower): Refer to CO-40, "

Component".

Front road wheels and tires

Engine Room LH

1. Disconnect engine room harness from the engine side and set it aside for easier work.

2. Disconnect heater hoses, and install plugs to avoid leakage of engine coolant.

3. Disconnect ground cable from exhaust manifold cover to vehicle.

4. Disconnect vacuum hose between vehicle and engine and set it aside.

5. Discharge refrigerant from A/C circuit. Refer to ATC-120, "

HFC-134a (R-134a) Service Procedure".

6. Remove A/C piping from A/C compressor, and temporarily fasten it on vehicle with a rope. Refer to AT C -

121, "Component".

Engine Room RH

1. Disconnect fuel feed hose and EVAP hose. Refer to EM-190, "Component".

CAUTION:

Fit plugs onto disconnected hose to prevent fuel leak.

2. Disconnect engine room harness from the engine side and set it aside for easier work.

3. Disconnect ground cable from exhaust manifold cover to vehicle.

4. Disconnect vacuum hose between vehicle and engine and set it aside.

5. Disconnect reservoir tank of power steering oil pum p from engine, and move it aside for easier work.

CAUTION:

When temporarily securing, keep reservoir tank upright to avoid a fluid leak.

Vehicle Underbody

1. Remove front cross bar. Refer to FSU-5, "On-Vehicle Inspection and Service".

2. Disconnect power steering oil pump from engine. Move it from its location and secure with a rope for eas-

ier work. Refer to PS-29, "

Removal and Installation (VK45DE Models)".

3. Remove A/T fluid cooler tube. Refer to AT-241, "

Removal and Installation (2WD Models)".

4. Remove exhaust front tube and center muffler with power tool. Refer to EX-3, "

Checking Exhaust Sys-

tem".

5. Remove RH and LH transverse link mounting bolts and nuts. Refer to FSU-13, "

Removal and Installation".

6. Disconnect stabilizer connecting rod lower. Refer to FSU-5, "

On-Vehicle Inspection and Service".

7. Remove A/T control rod at control device assembly side. Then temporarily secure it on transmission, so

that it does not sag. Refer to AT-205, "

Control Device Removal and Installation".

8. Remove rear plate cover from oil pan. Then remove bolts fixing drive plate to torque converter. Refer to EM-183, "

Component" and AT-241, "Removal and Installation (2WD Models)".

9. Remove transmission joint bolts which pierce at oil pan lower rear side. Refer to AT-241, "

Removal and

Installation (2WD Models)".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2724 of 3924

![INFINITI FX35 2008 Manual PDF

EM-240

< SERVICE INFORMATION >[VK45DE]

ENGINE ASSEMBLY

Avoid damage to and oil/grease smearing or

spills onto engine mounting insulator.

4. Remove alternator. Refer to SC-19, "

System Description INFINITI FX35 2008 Manual PDF

EM-240

< SERVICE INFORMATION >[VK45DE]

ENGINE ASSEMBLY

Avoid damage to and oil/grease smearing or

spills onto engine mounting insulator.

4. Remove alternator. Refer to SC-19, "

System Description](/img/42/57017/w960_57017-2723.png)

EM-240

< SERVICE INFORMATION >[VK45DE]

ENGINE ASSEMBLY

Avoid damage to and oil/grease smearing or

spills onto engine mounting insulator.

4. Remove alternator. Refer to SC-19, "

System Description".

5. Remove starter motor. Refer to SC-8, "

System Description".

6. Separate engine from transmission assembly. Refer to AT-243, "

Removal and Installation (AWD Models)".

7. Remove front final drive from engine. Refer to FFD-14, "

Removal and Installation (VQ35DE Models)".

8. Remove engine mounting insulators (RH and LH) and brackets (RH and LH) from engine with power tool.

9. Remove engine rear member and engine mounting insulator (rear) from transmission.

INSTALLATION

Note the following, and install in the reverse order of removal.

Do not allow engine mounting insulator to be damage and careful no engine oil gets on it.

For a location with a positioning pin, insert it securely into hole of mating part.

For a part with a specified installation orientation, refer to component figure in "Removal and Installation".

When installing engine mounting brackets (RH and LH) on cylinder

block, tighten two upper bolts (show n as “A” in the figure) first.

Then tighten two lower bolts (shown as “B” in the figure).

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The followings are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-9, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

Warm up engine thoroughly to make sure there is no leak age of fuel, exhaust gases, or any oil/fluids includ-

ing engine oil and engine coolant.

Bleed air from lines and hoses of applic able lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid. power steering fluid, brake fluid, etc.

PBIC2365E

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2866 of 3924

GI-4

< SERVICE INFORMATION >

PRECAUTIONS

To prevent serious burns:Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

Dispose of or recycle drained oil or the solvent used for cleaning parts in an appropriate manner.

Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray

and possibly a fire.

Clean all disassembled parts in the designated liquid or solvent prior to inspection or assembly.

Replace oil seals, gaskets, packings, O-rings, locking washers, cotter pins, self-locking nuts, etc. with new ones.

Replace inner and outer races of tapered roller bearings and needle bearings as a set.

Arrange the disassembled parts in accordance with their assembled locations and sequence.

Do not touch the terminals of electrical com ponents which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

After disconnecting vacuum or air hoses, atta ch a tag to indicate the proper connection.

Use only the fluids and lubricants specified in this manual.

Use approved bonding agent, sealants or their equivalents when required.

Use hand tools, power tools (disassembly only) and recommended special tools where specified for safe and efficient service repairs.

When repairing the fuel, oil, water, vacuum or exhaust systems,

check all affected lines for leaks.

Before servicing the vehicle: Protect fenders, upholstery and carpeting with appropriate covers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic tro uble codes, do not carelessly disconnect the harness

connectors which are related to the engine cont rol system and TCM (transmission control module)

system. The connectors should be disconnected on ly when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precaution for Three Way CatalystINFOID:0000000001325655

If a large amount of unburned fuel flows into the catalyst , the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

When checking for ignition spark or measuring engine compression, make tests quickly and only when nec- essary.

Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to the

catalyst.

SGI233

PBIC0190E

SGI234

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2882 of 3924

GI-20

< SERVICE INFORMATION >

HOW TO USE THIS MANUAL

The Reference Area of the wiring diagram contains references to additional electrical reference pages at the

end of the manual. If connector numbers and titles are s hown in the Reference Area of the wiring diagram,

these connector symbols are not shown in the Connector Area.

AbbreviationsINFOID:0000000001325670

The following ABBREVIATIONS are used:

SGI092A

ABBREVIATION DESCRIPTION

A/C Air ConditionerA/T Automatic Transaxle/Transmission

ATF Automatic Transmission Fluid D

1Drive range 1st gear

D

2Drive range 2nd gear

D

3Drive range 3rd gear

D

4Drive range 4th gear

FR, RR Front, Rear

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3323 of 3924

MA-6

< SERVICE INFORMATION >

PERIODIC MAINTENANCE

NOTE:

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts if found

damaged or if the auto belt tensioner reading (only for VK45DE engine) reaches the maximum limit.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, refer to FL section.

(4) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(5) If valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by INFINITI for reliable vehicle operation. The owner need not perfo rm

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required.

CHASSIS AND BODY MAINTENANCE

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary.

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title

Perform at number of miles,

kilometers or months, which-

ever comes first. Miles x 1,000

(km x 1,000) Months 33.75

(54)27 37.5

(60) 30 41.25

(66)33 45

(72) 36 48.75

(78)39 52.5

(84) 42 56.25

(90)45 60

(96) 48

Drive belts NOTE (1) I* MA-11

,

MA-

19

Air cleaner filter NOTE (2) [R] MA-15,

MA-

22

EVAP vapor lines I*MA-18,

MA-

25

Fuel lines I*MA-15,

MA-

22

Fuel filter NOTE (3) -

Engine coolant NOTE (4) R* MA-12

,

MA-

19

Engine oil R R R R R R R R MA-15,

MA-

22

Engine oil filter (Use genuine

NISSAN engine oil filter or

equivalent.) R R RRRRRR

MA-16,

MA-

23

Spark plugs (PLATINUM-

TIPPED type) Replace every 105,000 miles (169,000 km).MA-17,

MA-

24

Intake & exhaust valve clear-

ance* NOTE (5) EM-91,

EM-

218

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section -

Page or - Con-

tent Title

Perform at number of miles,

kilometers or months,

whichever comes first. Miles x 1,000

(km x 1,000) Months 3.75

(6)3 7.50

(12) 6 11 . 2 5

(18) 9 15

(24) 12 18.75

(30)15 22.5

(36) 18 26.25

(42)21 30

(48) 24

Brake lines & cables IIMA-32

Brake pads & rotors

IIII MA-32

Automatic transmission &

transfer fluid & differential

gear oilNOTE (1) I I MA-26,

MA-28

,

MA-29

Steering gear, linkage &

transfer gear, axle & sus-

pension parts IIII

MA-33

,

MA-34

Tire rotation NOTE (2) MA-3,

MA-31

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3324 of 3924

PERIODIC MAINTENANCEMA-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

NOTE:

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) fl uid (A/T, trans-

fer)/oil at every 30,000 miles (48,000 km) or 24 months. Using automatic transmission fluid other than Genuine Nissan Matic J

ATF will cause deterioration in driveability and automatic transmission durability, and may damage the automatic transmis-

sion, which is not covered by the INFINITI new vehicle limited warranty.

(2) Refer to “Tire rotation” under the “GENERAL MAINTENANCE” heading earlier in this section.

Schedule 2INFOID:0000000001328896

EMISSION COMTROL SYSTEM MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or r eplace if necessary. [ ]: At the mileage intervals only

Drive shaft boots and pro-

peller shaft (AWD models) IIII

MA-34,

MA-29

Exhaust system IIII MA-26

In-cabin microfilter

RRAT C - 1 0 7

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section -

Page or - Con- tent Title

Perform at number of miles,

kilometers or months,

whichever comes first. Miles x 1,000

(km x 1,000)

Months 3.75

(6)

3 7.50

(12)

6 11 . 2 5

(18)

9 15

(24)

12 18.75

(30)

15 22.5

(36)

18 26.25

(42)

21 30

(48)

24

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section - Page

or - Content Title

Perform at number of miles,

kilometers or months,

whichever comes first. Miles x 1,000

(km x 1,000) Months 33.75

(54)27 37.5

(60) 30 41.25

(66)33 45

(72) 36 48.75

(78)39 52.5

(84) 42 56.25

(90)45 60

(96) 48

Brake lines & cables IIMA-32

Brake pads & rotors

IIII MA-32

Automatic transmission &

transfer fluid & differential

gear oilNOTE (1) I I

MA-26,

MA-28

,

MA-29

Steering gear, linkage &

transfer gear, axle & sus-

pension parts IIII

MA-33

, MA-34

Tire rotation NOTE (2) MA-3,

MA-31

Drive shaft boots and pro-

peller shaft (AWD models) IIII MA-34,

MA-29

Exhaust system IIII MA-26

In-cabin microfilter

RRAT C - 1 0 7

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Sec-

tion - Page or - Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000) Months 7.5

(12) 6 15

(24) 12 22.5

(36) 18 30

(48) 24 37.5

(60) 30 45

(72) 36 52.5

(84) 42 60

(96) 48

Drive belts NOTE (1) I* MA-11

, MA-19

Air cleaner filter [R] [R] MA-15, MA-22

EVAP vapor lines I* I* MA-18, MA-25

Fuel lines I* I* MA-15, MA-22

Fuel filter NOTE (2) -

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3325 of 3924

MA-8

< SERVICE INFORMATION >

PERIODIC MAINTENANCE

NOTE:

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts if found

damaged or if the auto belt tensioner reading (only for VK45DE engine) reaches the maximum limit.

(2) Maintenance-free item. For service procedures, refer to FL section.

(3) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(4) If valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by INFINITI for reliable vehicle operation. The owner need not perfo rm

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required

CHASSIS AND BODY MAINTENANCE

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary.

NOTE:

(1) Using automatic transmission fluid other than Genuine NISSAN Matic J ATF will cause deterioration in driveability and

automatic transmission durability, and may damage the automatic transmission, which is not covered by the INFINITI new

vehicle limited warranty.

(2) Refer to “Tire rotation” under the “GENERAL MAINTENANCE” heading earlier in this section.

Engine coolant NOTE (3) R*

MA-12

, MA-19

Engine oil R R R R R R R R MA-15, MA-22

Engine oil filter (Use genuine

NISSAN engine oil filter or equiv-

alent.) RRRR R RRR

MA-16

, MA-23

Spark plugs (PLATINUM-

TIPPED type) Replace every 105,000 miles (169,000 km).

MA-17, MA-24

Intake & exhaust valve clear-

ance* NOTE (4)

EM-91, EM-218

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Sec-

tion - Page or -

Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000)

Months 7.5

(12)

6 15

(24)

12 22.5

(36)

18 30

(48)

24 37.5

(60)

30 45

(72)

36 52.5

(84)

42 60

(96)

48

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Sec-

tion - Page or - Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000) Months 7.5

(12) 6 15

(24) 12 22.5

(36) 18 30

(48) 24 37.5

(60) 30 45

(72) 36 52.5

(84) 42 60

(96) 48

Brake lines & cables IIIIMA-32

Brake pads & rotors

IIIIMA-32

Automatic transmission & trans-

fer fluid & differential gear oilNOTE (1) IIII MA-26,

MA-28,

MA-29

Steering gear, linkage & transfer

gear, axle & suspension parts I I MA-33,

MA-34

Tire rotation NOTE (2) MA-3,

MA-31

Drive shaft boots and propeller

shaft (AWD models) IIII

MA-34, MA-29

Exhaust system

IIMA-26

In-cabin microfilter

RRRRAT C - 1 0 7

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3326 of 3924

RECOMMENDED FLUIDS AND LUBRICANTSMA-9

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and LubricantsINFOID:0000000001328897

*1: For further details, see “Engine Oil Recommendation”.

*2: Using automatic transmission fluid other than Genuine NISSAN Matic J ATF will cause deterioration in driveability and

automatic transmission durability, and may damage the automatic transmission, which is not covered by the INFINITI new

vehicle limited warranty.

*3: For hot climates, viscosity SAE 90 is suitable for ambient temperatures above 0 °C (32 °F).

*4: Canada NISSAN Au tomatic Transmission Fluid or DEXRON

TM VI type ATF may also be used.

*5: Available in mainland U.S.A. through your INFINITI dealer.

Engine Oil RecommendationINFOID:0000000001328898

NISSAN recommends the use of an energy conser ving oil in order to improve fuel economy.

Select only engine oils that meet the American Petroleum Institute (API) certification and International Lubri-

cant Standardization and Approval Committee (ILSAC) certification and SAE viscosity standard. These oils

have the API certification mark on the front of the c ontainer. Oils which do not have the specified quality label

should not be used as they could cause engine damage.

Capacity (Approximate)

Recommended Fluids/Lubricants

US measure Imp mea-

sure Liter

Engine oil

Drain and

refill With oil fil-

ter change

VK45DE 6-1/8 qt 5-1/8 qt 5.8

Engine oil with API Certification Mark*1

Viscosity SAE 5W-30

VQ35DE 5 qt 4 - 1/8 qt 4.7

Without oil

filter

change VK45DE 5-1/2 qt 4-5/8 qt 5.2

VQ35DE 4-5/8 qt 3-7/8 qt 4.4

Dry engine (Overhaul) VK45DE 7-3/8 qt 6-1/8 qt 7.0

VQ35DE 5-3/4 qt 4-3/4 qt 5.4

Cooling

system With res-

ervoir tank

VK45DE 10-5/8 qt 8-3/4 qt 10.0

Genuine NISSAN Long Life Antifreeze/ Coolant

or equivalent

VQ35DE 9-1/8 qt 7-5/8 qt 8.6

Reservoir

tank VK45DE 7/8 qt 3/4 qt 0.8

VQ35DE 7/8 qt 3/4 qt 0.8

Automatic transmission fluid 10-7/8 qt 9-1/8 qt 10.3 Genuine NISSAN Matic J ATF *2

Differential gear oil Front 1-3/8 pt 1-1/8 pt 0.65 Genuine NI

SSAN Differential Oil Hypoid Super

GL-5 80W-90 or API GL-5, Viscosity SAE 80W-

90 *3

Rear 3 pt 2-1/2 pt 1.40

Transfer fluid 2-5/8 pt 2-1/4 pt 1.25 Genuine NISSAN Matic D ATF (Continental U.S.

and Alaska) or Canada NISSAN Automatic

Transmission Fluid or equivalent (if available)

Power steering fluid (PSF) 1-1/8 qt 7/8 qt 1.0 Genuine NISSAN PSF or equivalent*4

Brake fluid — — — Genuine NISSAN Super He

avy Duty Brake Flu-

id*5 or equivalent

DOT 3 (US FMVSS No. 116)

Multi-purpose grease — — — NLGI No. 2 (Lithium soap base)

Windshield washer fluid — — — Genuine NISSAN Windshie

ld Washer Concen-

trate Cleaner & Antifreeze or equivalent

Fuel

recommendation VK45DE — — —

Refer to

GI-5, "

Precaution for Fuel (Unleaded

Premium Gasoline Required)"

VQ35DE——— Refer to

GI-5, "Precaution for Fuel (Unleaded

Premium Gasoline Recommended)"

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3344 of 3924

CHASSIS AND BODY MAINTENANCEMA-27

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

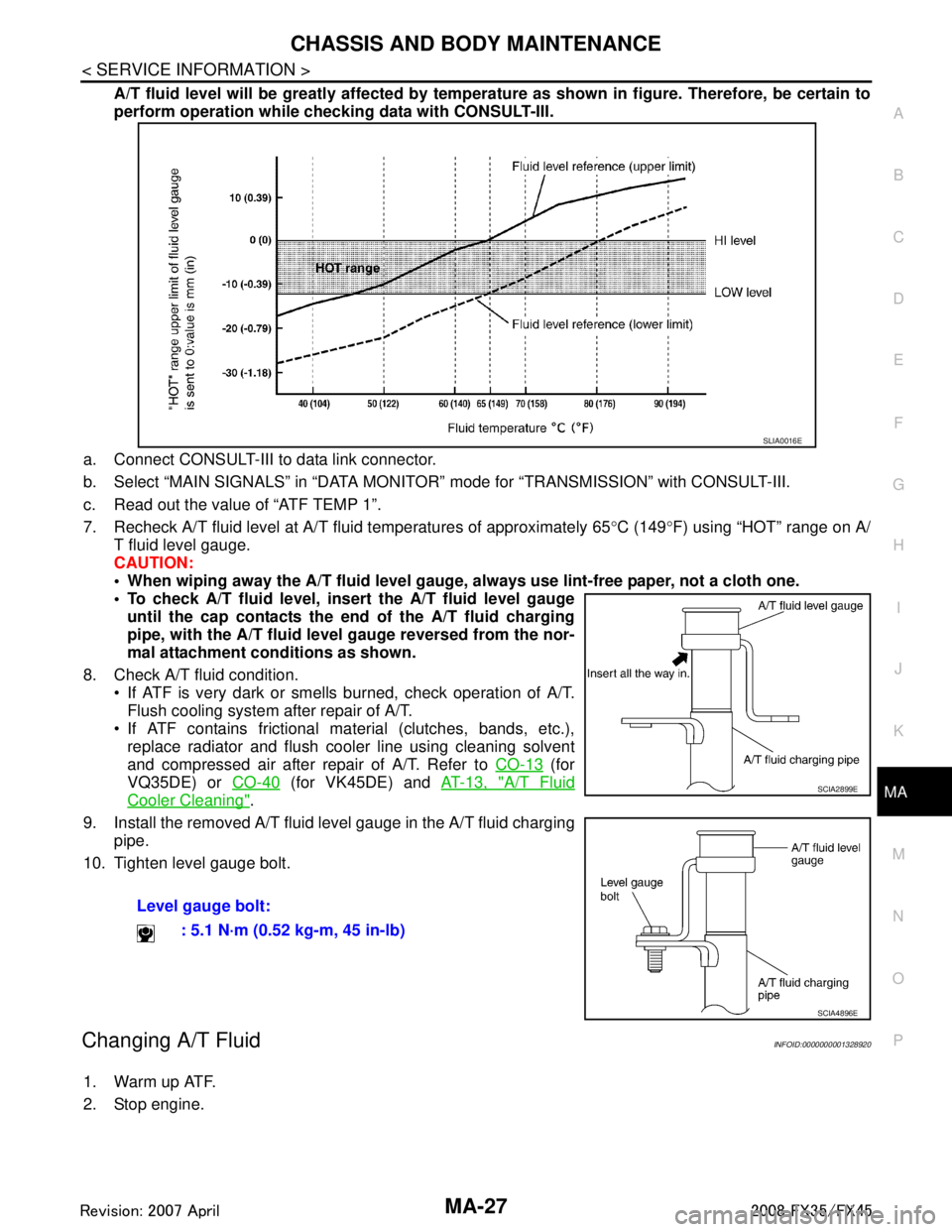

A/T fluid level will be greatly affected by temper ature as shown in figure. Therefore, be certain to

perform operation while checki ng data with CONSULT-III.

a. Connect CONSULT-III to data link connector.

b. Select “MAIN SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

c. Read out the value of “ATF TEMP 1”.

7. Recheck A/T fluid level at A/T fluid temperatures of approximately 65 °C (149 °F) using “HOT” range on A/

T fluid level gauge.

CAUTION:

When wiping away the A/T fluid level gauge, always use lint-free paper, not a cloth one.

To check A/T fluid level, inser t the A/T fluid level gauge

until the cap contacts the en d of the A/T fluid charging

pipe, with the A/T fluid level gauge reversed from the nor-

mal attachment conditions as shown.

8. Check A/T fluid condition. If ATF is very dark or smells burned, check operation of A/T.

Flush cooling system after repair of A/T.

If ATF contains frictional material (clutches, bands, etc.), replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer to CO-13

(for

VQ35DE) or CO-40

(for VK45DE) and AT-13, "A/T Fluid

Cooler Cleaning".

9. Install the removed A/T fluid level gauge in the A/T fluid charging pipe.

10. Tighten level gauge bolt.

Changing A/T FluidINFOID:0000000001328920

1. Warm up ATF.

2. Stop engine. Level gauge bolt:

: 5.1 N·m (0.52 kg-m, 45 in-lb)

SLIA0016E

SCIA2899E

SCIA4896E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C