hood open INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 483 of 3924

ATC-78

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Test Reading

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to -operating Pressure Table

TROUBLE DIAGNOSIS FOR UNUSUAL PRESSURE

Whenever system’s high and/or low side pressure(s) is/are unusual, diagnose using a manifold gauge. The

marker above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the

standard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air tempera-

ture-to-operating pressure table).

Both High- and Low-pressure Sides are Too High

Hood Open

TEMP. Max. COLD

Mode switch (Ventilation) set

Intake switch (Recirculation) set

Fan (blower) speed Max. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet Discharge air temperature at center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 - 60 20 (68) 11.2 - 13.2 (52 - 56)

25 (77) 12.2 - 14.8 (54 - 59)

30 (86) 15.5 - 18.6 (60 - 65)

35 (95) 21.0 - 24.5 (70 - 76)

40 (104) 28.7 - 32.6 (84 - 91)

60 - 70 20 (68) 13.2 - 15.2 (56 - 59)

25 (77) 14.8 - 17.3 (59 - 63)

30 (86) 18.6 - 21.6 (65 - 71)

35 (95) 24.5 - 28.0 (76 - 82)

40 (104) 32.6 - 36.5 (91 - 98)

Ambient air High-pressure (Discharge side)

kPa (kg/cm

2, psi) Low-pressure (Suction side)

kPa (kg/cm2, psi)

Relative humidity

% Air temperature

°C ( °F)

50 - 70 20 (68)

961 - 1,167

(9.8 - 11.9, 139 - 169) 216 - 265

(2.2 - 2.7, 31 - 38)

25 (77) 1,108 - 1,353

(11.3 - 13.8, 161 - 196) 230 - 281

(2.3 - 2.9, 33 - 41)

30 (86) 1,275 - 1,549

(13.0 - 15.8, 185 - 225) 261 - 320

(2.7 - 3.3, 38 - 46)

35 (95) 1,549 - 1,893

(15.8 - 19.3, 225 - 274) 297 - 364

(3.0 - 3.7, 43 - 53)

40 (104) 1,814 - 2,216

(18.5 - 22.6, 263 - 321) 357 - 435

(3.6 - 4.4, 52 - 63)

Vehicle condition Indoors or in the shade (in a well-ventilated place)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 747 of 3924

HOODBL-13

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

HOOD

Fitting AdjustmentINFOID:0000000001327783

LONGITUDINAL AND LATERAL CLEARANCE ADJUSTMENT

1. Remove hood lock assembly, loosen the hood hinge nuts and close the hood.

2. Adjust the lateral and longitudinal clearance, and open the hood to tighten the hood hinge mounting bolts

to the specified torque.

3. Install the hood lock temporarily, and align the hood stri ker and lock so that the centers of striker and lock

become vertical viewed from the front , by moving the hood lock laterally.

4. Tighten hood lock mounting bolts to the specified torque.

CAUTION:

Adjust right/left clearance between hood an d headlamp to the following specification.

FRONT END HEIGHT ADJUSTMENT

1. Remove the hood lock and adjust the height by rota ting the bumper rubber until the hood becomes 1 to1.5

mm (0.04 to 0.059 in) lower than the fender.

2. Temporarily tighten the hood lock, and position it by engaging it with the hood striker. Check the lock and

striker for looseness, and tighten the hood lock mounting bolts to the specified torque.

SURFACE HEIGHT ADJUSTMENT

1. Remove hood lock, and adjust the surface height difference of hood, fender and headlamp according to

the fitting standard dimension, by rotating RH and LH bumper rubbers.

2. Install hood lock temporarily, and move hood lock laterally until the centers of striker and lock become ver- tical when viewed from the front.

1. Hood hinge 2. Nut 3. Hood stay

4. Hood lock 5. Bolt 6. Bumper rubber

PIIB1212E

Hood and headlamp (C–C) : Less than 2.0 mm (0.08 in)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 748 of 3924

BL-14

< SERVICE INFORMATION >

HOOD

3. Make sure that the hood lock secondary latch is properlyengaged with the secondary striker with hood's own weight.

4. Make sure that the hood lock primary latch is securely engaged with the hood striker with hood's own weight by dropping hood

from approx. 200 mm (7.87 in) height.

CAUTION:

Do not drop hood from a he ight of 300 mm (11.81 in) or

more.

5. Move hood lockup and down until striker smoothly engages the lock when the hood is closed.

6. When pulling the hood opener lever gently, make sure that front end of the hood rises by approximately 20 mm (0.79 in) and that

hood striker and hood lock primary latch is disengaged. Also make sure that hood opener returns to the

original position.

7. After adjustment, tighten lock bolts to the specified torque.

CAUTION:

Adjust evenness between hood and each part to the following specification.

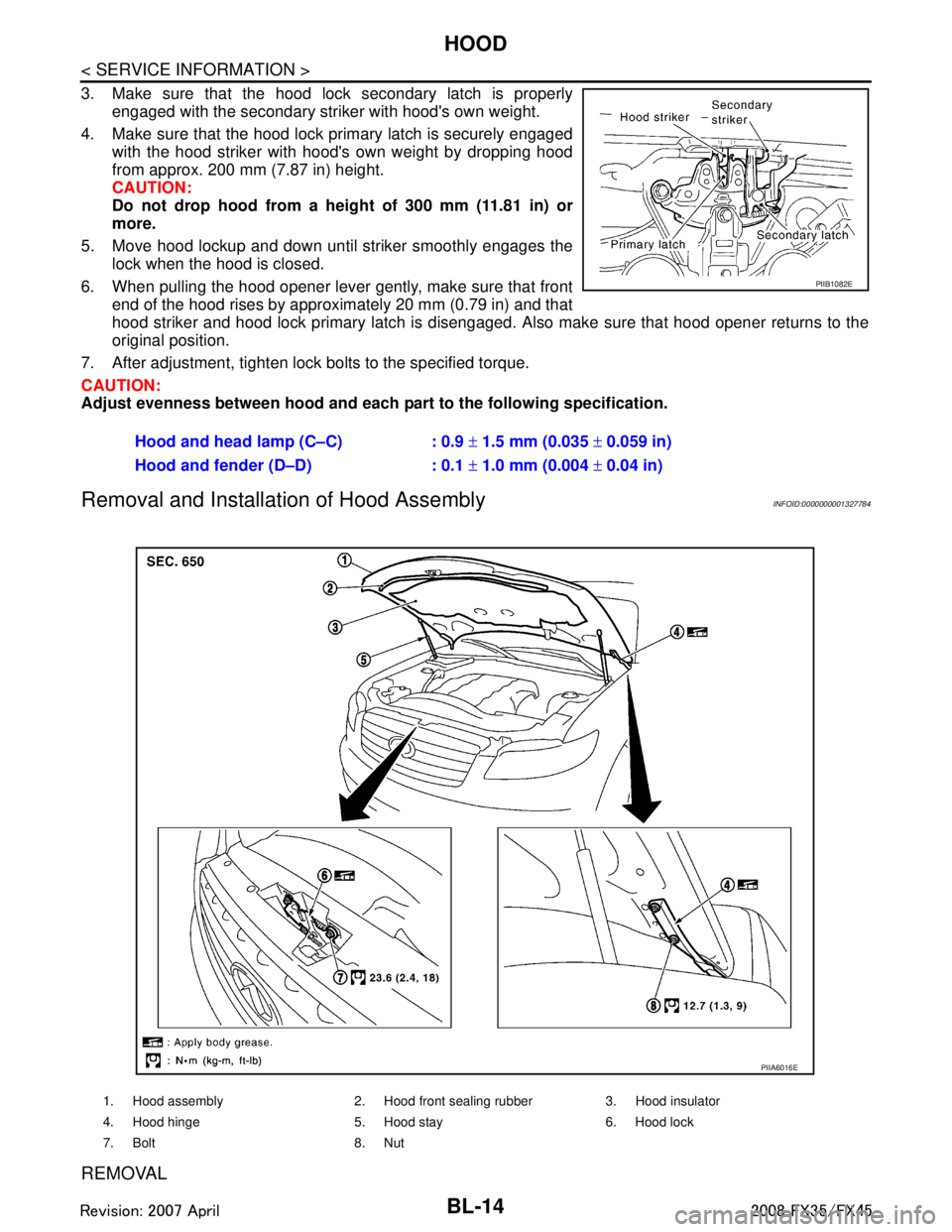

Removal and Installation of Hood AssemblyINFOID:0000000001327784

REMOVAL

Hood and head lamp (C–C) : 0.9 ± 1.5 mm (0.035 ± 0.059 in)

Hood and fender (D–D) : 0.1 ± 1.0 mm (0.004 ± 0.04 in)

PIIB1082E

1. Hood assembly 2. Hood front sealing rubber 3. Hood insulator

4. Hood hinge 5. Hood stay 6. Hood lock

7. Bolt 8. Nut

PIIA6016E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 749 of 3924

HOODBL-15

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

1. Support the hood striker with a proper material to prevent it from falling.

WARNING:

Body injury may occur if no supporting rod is holding the

hood open when removi ng the hood stay.

2. Remove the hood stays from the stud balls on the body side.

3. Remove the hinge mounting nuts on the hood to remove the hood assembly.

CAUTION:

Operate with two workers, because of its heavy weight.

INSTALLATION

Install in the reverse order of removal.

Removal and Installation of Hood Lock ControlINFOID:0000000001327785

REMOVAL

1. Remove the front grill. Refer to EI-22, "Component Parts Location".

2. Remove the front fender protector (LH). Refer to EI-24, "

Component Parts Location".

3. Disconnect the hood lock cable from the hood lock, and c lip it from the radiator core support upper and

hood ledge.

4. Remove instrument driver lower panel. Refer to IP-11, "

Removal and Installation".

5. After the bolt of the case with the air cleaner is disconnected, and it is moved, the cable is pulled.

PIIA6058E

1. Hood lock 2. Hood lock cable 3. Clip

4. Hood ledge upper front (LH) 5. Dash lower cross member reinforce (LH)

PIIA6017E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 750 of 3924

BL-16

< SERVICE INFORMATION >

HOOD

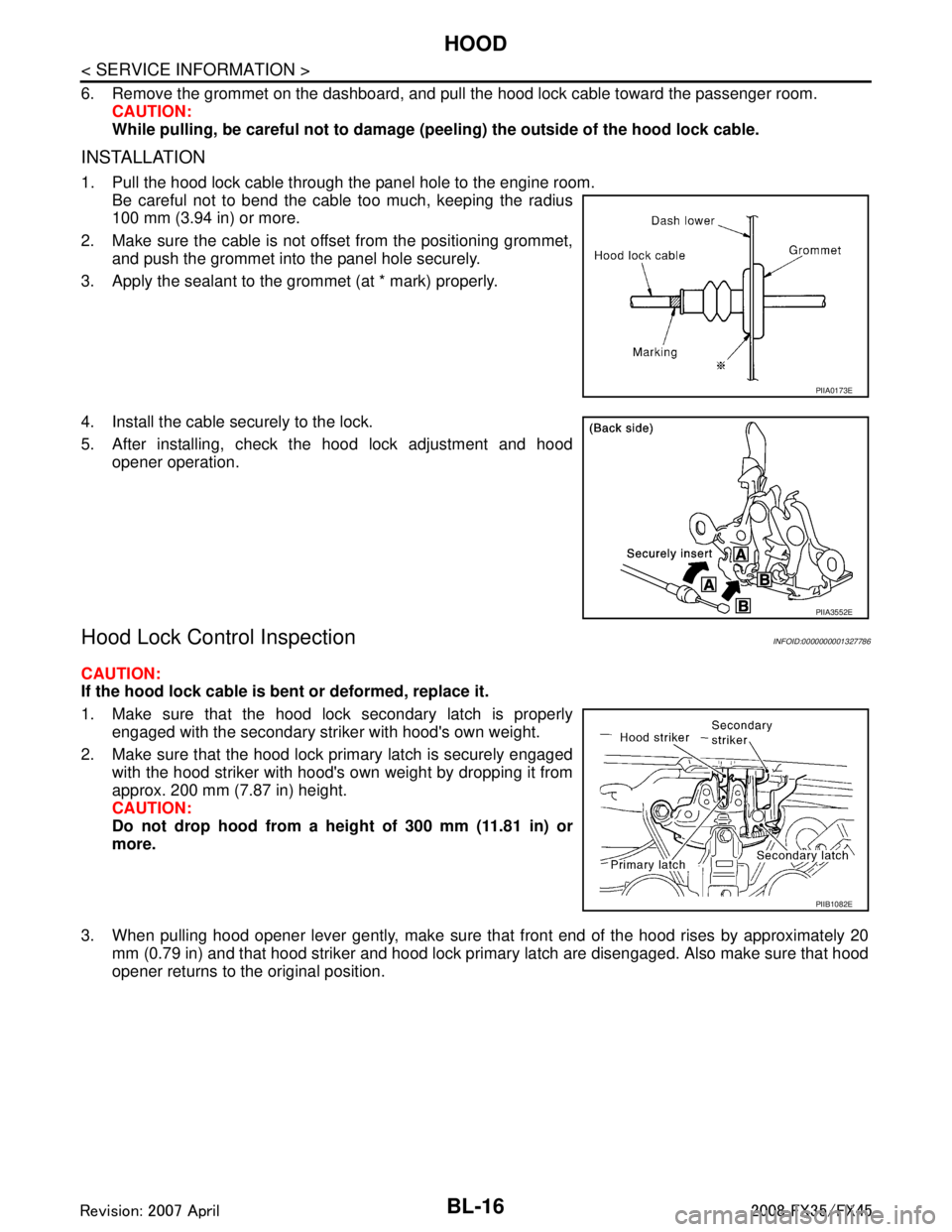

6. Remove the grommet on the dashboard, and pull the hood lock cable toward the passenger room.CAUTION:

While pulling, be careful not to damage (p eeling) the outside of the hood lock cable.

INSTALLATION

1. Pull the hood lock cable through the panel hole to the engine room.

Be careful not to bend the cable too much, keeping the radius

100 mm (3.94 in) or more.

2. Make sure the cable is not offset from the positioning grommet, and push the grommet into the panel hole securely.

3. Apply the sealant to the grommet (at * mark) properly.

4. Install the cable securely to the lock.

5. After installing, check the hood lock adjustment and hood opener operation.

Hood Lock Control InspectionINFOID:0000000001327786

CAUTION:

If the hood lock cable is bent or deformed, replace it.

1. Make sure that the hood lock secondary latch is properlyengaged with the secondary striker with hood's own weight.

2. Make sure that the hood lock primary latch is securely engaged with the hood striker with hood's own weight by dropping it from

approx. 200 mm (7.87 in) height.

CAUTION:

Do not drop hood from a he ight of 300 mm (11.81 in) or

more.

3. When pulling hood opener lever gently, make sure that front end of the hood rises by approximately 20 mm (0.79 in) and that hood striker and hood lock primary latch are disengaged. Also make sure that hood

opener returns to the original position.

PIIA0173E

PIIA3552E

PIIB1082E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 898 of 3924

BL-164

< SERVICE INFORMATION >

VEHICLE SECURITY (THEFT WARNING) SYSTEM

System Description

INFOID:0000000001327905

DESCRIPTION

Operation Flow

Setting the Vehicle Security System

Initial condition

Ignition switch is in OFF position.

Disarmed phase

When hood, doors or back door is open, the vehicle secu rity system is set in the disarmed phase on the

assumption that the owner is inside or near the vehicle.

When the vehicle security system is in the disarmed phase, the security indicator lamp blinks every 2.4 sec-

onds.

Pre-armed phase and armed phase

When the following operation 1 or 2 is performed, the vehicle security system turns into the “pre-armed”

phase. (The security indicator lamp illuminates.)

1. BCM receives LOCK signal from front door key cyli nder switch, key fob or Intelligent Key after hood, back

door and all doors are closed.

2. Hood, back door and all doors are closed after front doors are locked by key or door lock and unlock

switch.

The security indicator lamp illuminates for 30 sec onds. then, the system automatically shifts into the

“armed” phase.

Canceling the Set Vehicle Security System

When one of the following operations is performed, the armed phase is canceled.

1. Unlock the doors with the key, key fob or Intelligent Key.

2. Turn ignition switch “ON” or “ACC” position.

Canceling the Alarm Operation of the Vehicle Security System

When unlock the door with the key, key fob or Intelligent Key the alarm operation is canceled.

Activating the Alarm Operation of the Vehicle Security System

PIIB4075E

PIIB0176E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 899 of 3924

VEHICLE SECURITY (THEFT WARNING) SYSTEMBL-165

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Make sure the system is in the armed phase. (The security indicator lamp brinks every 2.4 seconds.)

When the following operation 1 or 2 is performed, t he system sounds the horns and flashes the headlamps for

about 50 seconds.

1. Hood, back door or any door is opened during armed phase.

2. Disconnecting and connecting the battery connector before canceling armed phase.

POWER SUPPLY

Power is supplied at all times

through 10A fuse [No.19, located in the fuse block (J/B)]

to security indicator lamp terminal 1.

through 50A fusible link (letter M, located in the fuse and fusible link box)

to BCM terminal 55.

through 15A fuse [No.22, located in the fuse block (J/B)]

to BCM terminal 42.

through 15A fuse [No.34, located in the fuse and fusible link box]

to horn relay terminal 2.

through 10A fuse [No.71, located in the IPDM E/R]

to IPDM E/R internal CPU.

through 15A fuse [No.78, located in the IPDM E/R]

to IPDM E/R internal CPU.

With the ignition switch in the ACC or ON position, power is supplied

through 10A fuse [No. 6, located in the fuse block (J/B)]

to BCM terminal 11.

INITIAL CONDITION TO ACTIVATE THE SYSTEM

The operation of the vehicle security system is controlled by the doors, hood and back door.

To activate the vehicle security system, BCM must receive signals indicating the doors, hood and back door

are closed and the doors are locked by key fob, Intelligent Key or ignition key.

When a door is open, BCM terminal 12 (passenger side door), 13 (rear RH door), 62 (driver side door), 63

(rear LH door) receives a ground signal from each door switch.

When front door LH is unlocked by power window main switch (door lock and unlock switch),

BCM terminal 22 receives a signal from terminal 14 of power window main switch with power window serial

link.

When front door RH is unlocked by front power window s witch (passenger side) (door lock and unlock switch),

BCM terminal 22 receives a signal from terminal 16 of front power window switch (passenger side) with power

window serial link.

When the hood is open, IPDM E/R receives a ground signal

to IPDM E/R terminal 56

through hood switch terminal 2

through hood switch terminal 1

through body grounds E21, E50 and E51.

The IPDM E/R then sends a signal to the BCM through the CAN SYSTEM.

When the back door is open,

to BCM terminal 58

through back door closure motor terminal 7

through back door closure motor terminal 8

through body grounds B15 and B45.

VEHICLE SECURITY SYSTEM ALARM OPERATION

The vehicle security system is triggered by

opening a door

opening the back door

opening the hood

detection of battery disconnect and connect.

The vehicle security system will be triggered once the system is in armed phase,

When BCM receives a ground signal at terminals 12 (p assenger side door), 13 (rear RH door), 58 (back door),

62 (driver side door), 63 (rear LH door), or rece ives a signal from the IPDM E/R (hood switch).

When the vehicle security system is triggered,

ground is supplied intermittently from IPDM E/R terminals 38 and 60.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 908 of 3924

BL-174

< SERVICE INFORMATION >

VEHICLE SECURITY (THEFT WARNING) SYSTEM

Terminal and Reference Value for IPDM E/R

INFOID:0000000001327911

CONSULT-III FunctionINFOID:0000000001327912

WORK SUPPORT

DATA MONITOR

62 W Front door switch

driver side signal Input ON (Open)

→ OFF (Closed) 0 → Battery voltage

63 P Rear door (LH) switch sig-

nal Input ON (Open)

→ OFF (Closed) 0 → Battery voltage

Terminal Wire color Item

Signal

Input/

output Condition

Voltage (V)

(Approx.)

Terminal Wire color Item Signal

Input/

output Condition

Voltage (V)

(Approx.)

20 LG Headlamp low (RH) Output Lighting switch 2ND position

ON

→ OFF Battery voltage

→ 0

27 BR Headlamp high (RH) Output Lighting switch HIGH or PASS

position

ON

→ OFF Battery voltage

→ 0

28 SB Headlamp high (LH) Output Lighting switch HIGH or PASS

position

ON

→ OFF Battery voltage

→ 0

30 GY Headlamp low (LH) Output Lighting switch 2ND position

ON

→ OFF Battery voltage

→ 0

38 B Ground (power) — — 0

48 L CAN-H Input/

Output ——

49 R CAN-L Input/

Output ——

51 SB Horn relay control signal Output Panic alarm is operating 0

Other than above Battery voltage

56 LG Hood switch signal Input ON (Open) → OFF (closed) 0 → Battery voltage

60 B Ground (signal) — — 0

BCM diagnosis test item Check item diagnosis test mode Content

Theft alm WORK SUPPORT Change setting of each function.

DATA MONITOR Displays the input data of BCM real time. ACTIVE TEST Gives a drive signal to a load to check the operation.

Test Item Description

SECURITY ALARM SET This mo de is able to confirm and change security alarm ON-OFF setting.

THEFT ALM TRG The switch which triggered vehicle security alarm is recorded. This mode is able to confirm and

erase the record of vehicle security alarm. The trigger data can be erased by touching “CLEAR” on

CONSULT-III screen.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 909 of 3924

![INFINITI FX35 2008 Service Manual

VEHICLE SECURITY (THEFT WARNING) SYSTEMBL-175

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O PACTIVE TEST

Monitored Item Description

IGN ON SW Indicates [ON/OFF] condition of ignition switch.

INFINITI FX35 2008 Service Manual

VEHICLE SECURITY (THEFT WARNING) SYSTEMBL-175

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O PACTIVE TEST

Monitored Item Description

IGN ON SW Indicates [ON/OFF] condition of ignition switch.](/img/42/57017/w960_57017-908.png)

VEHICLE SECURITY (THEFT WARNING) SYSTEMBL-175

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O PACTIVE TEST

Monitored Item Description

IGN ON SW Indicates [ON/OFF] condition of ignition switch.

ACC ON SW Indicates [ON/OFF] condition of ignition switch in ACC position.

KEY ON SW Indicates [ON/OFF] condition of key switch.

TRUNK OPNR SW This is displayed ev en when it is not equipped.

TRUNK CYL SW This is displayed ev en when it is not equipped.

TRUNK OPN MNTR This is displayed even when it is not equipped.

KEYLESS LOCK Indicates [ON/OFF] conditio n of lock signal from key fob.

KEYLESS UNLOCK Indicates [ON/O FF] condition of unlock signal from key fob.

KEYLESS TRUNK Indicates [ON/OFF] condition of trunk opener signal from key fob.

HOOD SW Indicates [ON/OFF] condition of hood switch.

DOOR SW-DR Indicates [ON/OFF] cond ition of front door switch LH.

DOOR SW-AS Indicates [ON/OFF] condition of front door switch RH.

DOOR SW-RR Indicates [ON/OFF] condition of rear door switch RH.

DOOR SW-RL Indicates [ON/OFF] condition of rear door switch LH.

BACK DOOR SW Indicates [ON/OFF] condition of back door switch.

KEY CYL LK SW Indicates [ON/OFF] condition of lock signal from key cylinder switch.

KEY CYL UN SW Indicates [ON/OFF] condition of unlock signal from key cylinder switch.

CDL LOCK SW Indicates [ON/OFF] condition of lock signal from door lock/unlock switch LH and RH.

CDL UNLOCK SW Indicates [ON/OFF] condition of unlock signal from door lock/unlock switch LH and RH.

Test Item Description

THEFT IND This test is able to check security indicator lamp operation. The lamp will be turned on when “ON”

on CONSULT-III screen is touched.

ANTI THEFT HORN This test is able to check vehicle security horn operation. The horns will be activated for 0.5 sec-

onds after “ON” on CONSULT-III screen is touched.

HEADLAMP(HI) This test is able to check vehicle security lamp operation. The headlamps will be activated for 0.5

seconds after “ON” on CONSULT-III screen is touched.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 912 of 3924

BL-178

< SERVICE INFORMATION >

VEHICLE SECURITY (THEFT WARNING) SYSTEM

*1: Make sure the system is in the armed phase.

Diagnosis Procedure 1INFOID:0000000001327916

1 – 1 CHECK DOOR SWITCH

First perform the “SELF-DIAG RESU LTS” in “BCM” with CONSULT-III, when pe rform the each trouble

diagnosis. Refer to BCS-13, "

U1000 CAN Communication Circuit".

1.CHECK DOOR SWITCH INPUT SIGNAL

With CONSULT-III

Check (“DOOR SW-DR”, “DOOR SW-AS”, “DOOR SW-RR” and “DOOR SW-RL”) in “DATA MONITOR” mode

with CONSULT-III.

Without CONSULT-III

Check voltage between BCM connector M3, B14 terminals and ground.

2 *1 Vehicle security

system does not

alarm when ···· Any door is opened.

Diagnostic Procedure 1 (Check door, hood and back door switch)

BL-178If the above systems are “OK”, replace BCM.BCS-13

3Vehicle security

alarm does not ac-

tivate. Horn alarm

Diagnostic Procedure 4 (Check vehicle security horn alarm)

BL-183

Check horn function. BL-72

If the above systems are “OK”, replace BCM.BCS-13

Head lamp alarmDiagnostic Procedure 5 (Check head lamp alarm)

BL-183If the above systems are “OK”, replace BCM.BCS-13

4Vehicle security

system cannot be

canceled by ···· Door outside key

Diagnostic Procedure 3 (Check door key cylinder switch)

BL-183

If the above systems are “OK”, check power window main switch. EI-36

Key fobCheck remote keyless entry function.

BL-50If the above systems are “OK”, replace BCM.BCS-13

Intelligent KeyCheck Intelligent Key

BL-78If the above systems are “OK”, replace BCM.BCS-13

Procedure

Diagnostic procedure Refer to page

Symptom

Monitor item Condition

DOOR SW-DR OPEN : ON

CLOSE : OFF

DOOR SW-AS OPEN : ON

CLOSE : OFF

DOOR SW-RR OPEN : ON

CLOSE : OFF

DOOR SW-RL OPEN : ON

CLOSE : OFF

Item Terminals (Wire color)

ConditionVoltage (V)

(Approx.)

(+) (–)

PIIA6223E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C