wheel INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3026 of 5621

FENDER PROTECTOR

EI-21

C

D

E

F

G

H

J

K

L

MA

B

EI

Revision: 2006 January2006 M35/M45

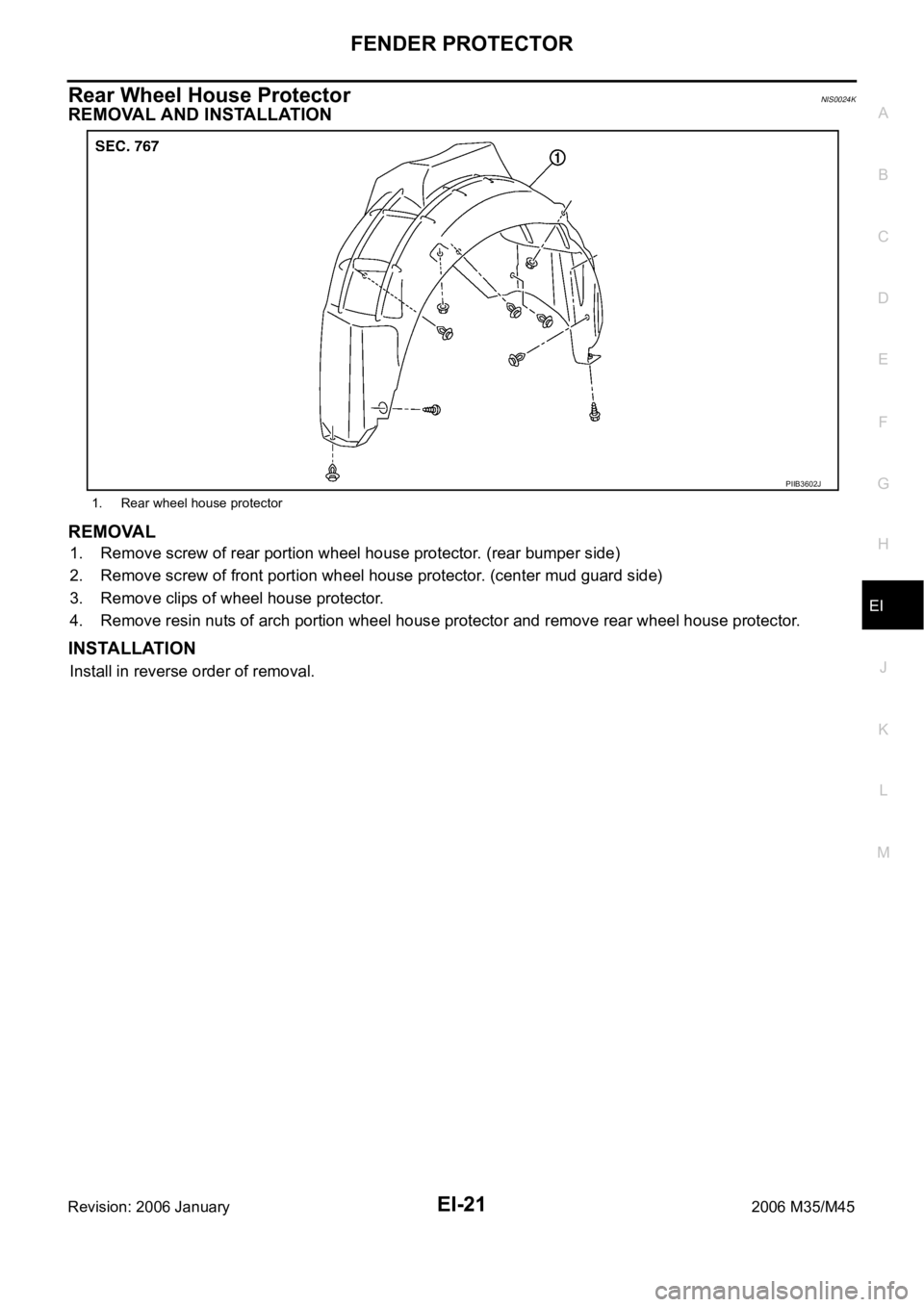

Rear Wheel House ProtectorNIS0024K

REMOVAL AND INSTALLATION

REMOVAL

1. Remove screw of rear portion wheel house protector. (rear bumper side)

2. Remove screw of front portion wheel house protector. (center mud guard side)

3. Remove clips of wheel house protector.

4. Remove resin nuts of arch portion wheel house protector and remove rear wheel house protector.

INSTALLATION

Install in reverse order of removal.

1. Rear wheel house protector

PIIB3602J

Page 3042 of 5621

BODY SIDE TRIM

EI-37

C

D

E

F

G

H

J

K

L

MA

B

EI

Revision: 2006 January2006 M35/M45

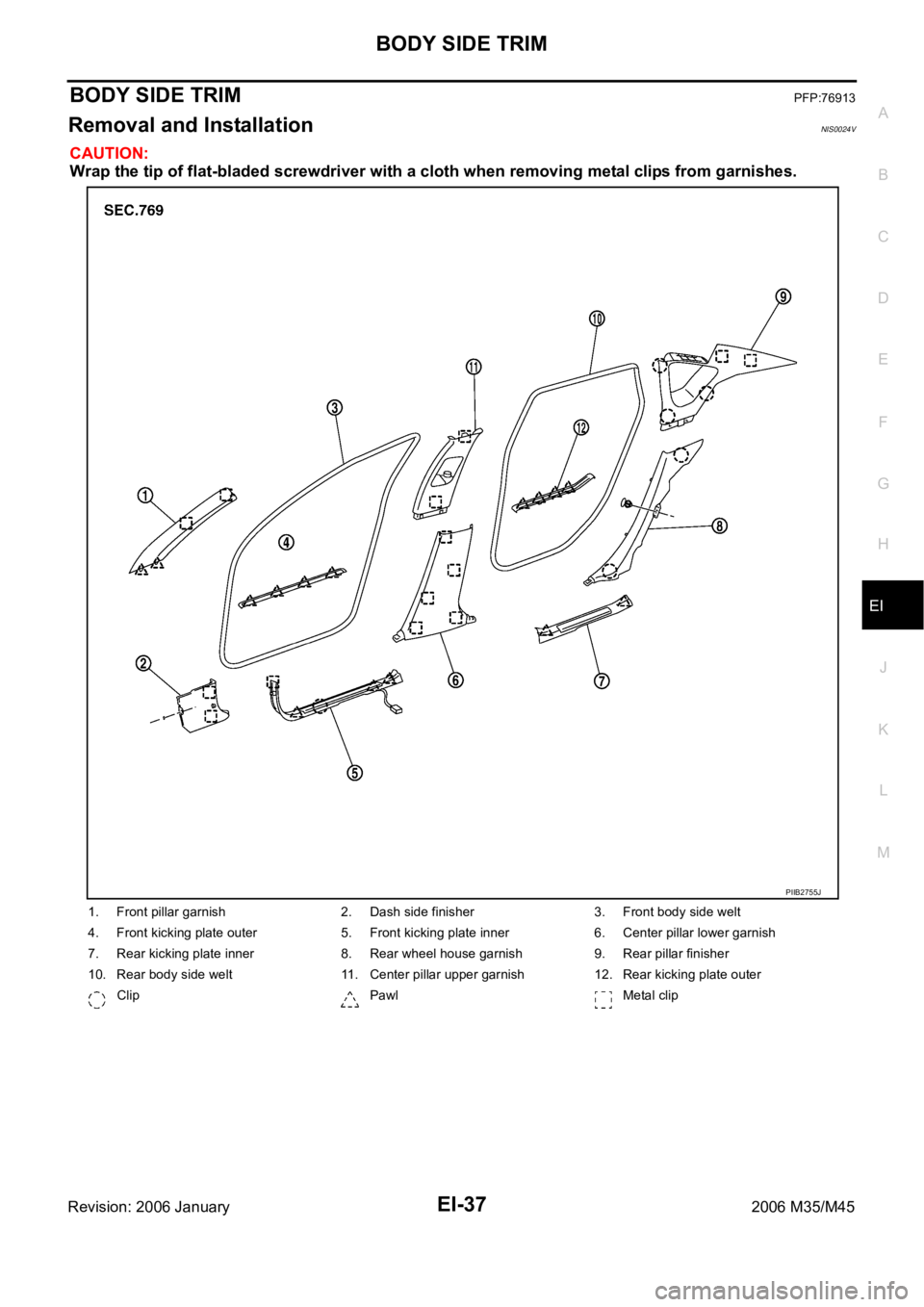

BODY SIDE TRIMPFP:76913

Removal and InstallationNIS0024V

CAUTION:

Wrap the tip of flat-bladed screwdriver with a cloth when removing metal clips from garnishes.

1. Front pillar garnish 2. Dash side finisher 3. Front body side welt

4. Front kicking plate outer 5. Front kicking plate inner 6. Center pillar lower garnish

7. Rear kicking plate inner 8. Rear wheel house garnish 9. Rear pillar finisher

10. Rear body side welt 11. Center pillar upper garnish 12. Rear kicking plate outer

Clip Pawl Metal clip

PIIB2755J

Page 3046 of 5621

BODY SIDE TRIM

EI-41

C

D

E

F

G

H

J

K

L

MA

B

EI

Revision: 2006 January2006 M35/M45

REAR WHEEL HOUSE GARNISH

Removal

1. Remove rear seat cushion and rear seatback. Refer to SE-176, "Removal and Installation" .

2. Remove rear body side welt.

3. Remove clip of rear wheel house garnish.

4. Remove rear wheel house garnish.

Installation

Install in the reverse order of removal.

NOTE:

To install, check if all clips are matched over holes of panel on vehicle, then push on.

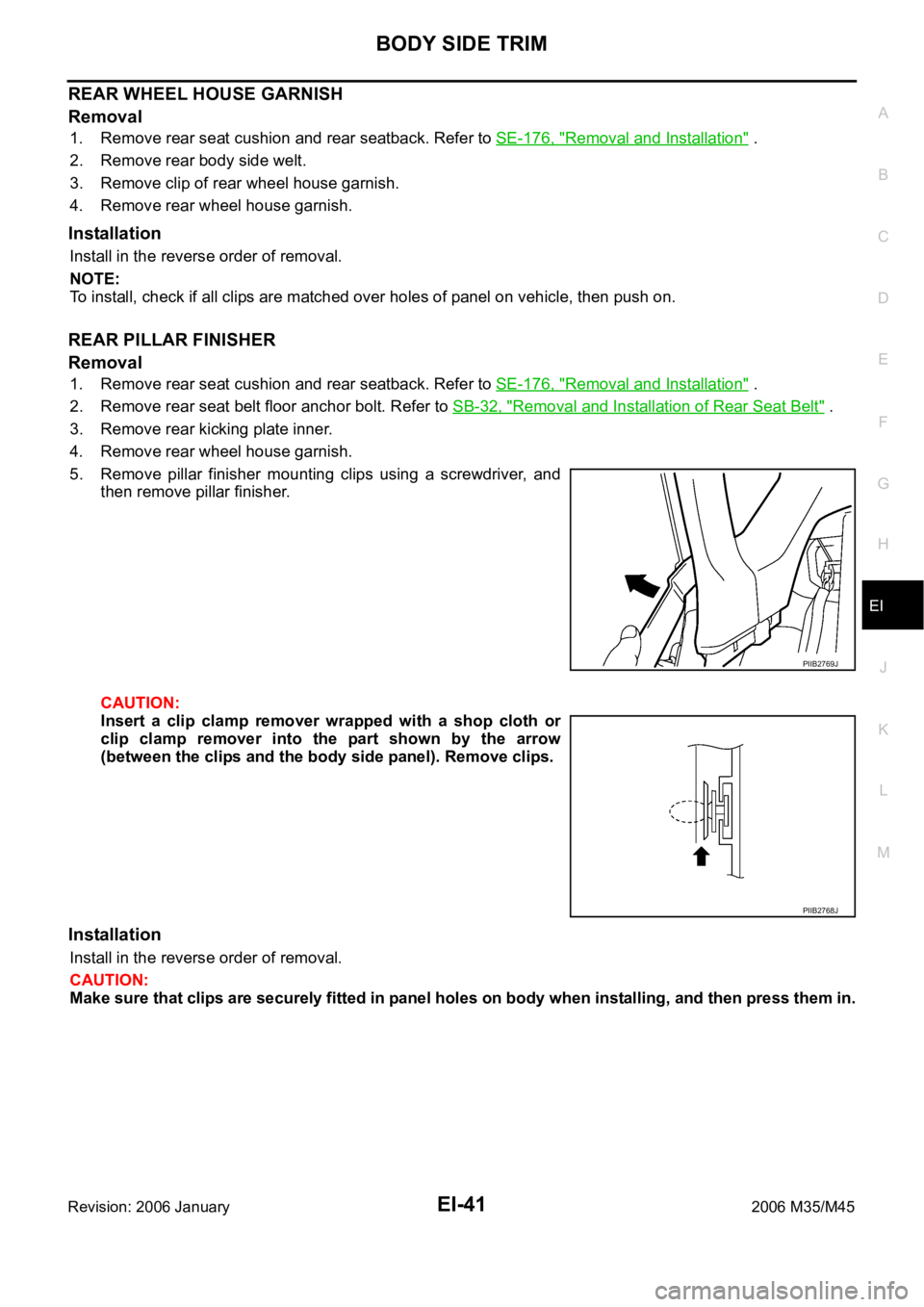

REAR PILLAR FINISHER

Removal

1. Remove rear seat cushion and rear seatback. Refer to SE-176, "Removal and Installation" .

2. Remove rear seat belt floor anchor bolt. Refer to SB-32, "

Removal and Installation of Rear Seat Belt" .

3. Remove rear kicking plate inner.

4. Remove rear wheel house garnish.

5. Remove pillar finisher mounting clips using a screwdriver, and

then remove pillar finisher.

CAUTION:

Insert a clip clamp remover wrapped with a shop cloth or

clip clamp remover into the part shown by the arrow

(between the clips and the body side panel). Remove clips.

Installation

Install in the reverse order of removal.

CAUTION:

Make sure that clips are securely fitted in panel holes on body when installing, and then press them in.

PIIB2769J

PIIB2768J

Page 3047 of 5621

EI-42

REAR PARCEL SHELF FINISHER

Revision: 2006 January2006 M35/M45

REAR PARCEL SHELF FINISHERPFP:79910

Removal and InstallationNIS0024W

REMOVAL

1. Remove rear seatback and rear seat cushion. Refer to SE-176, "Removal and Installation" .

2. Remove rear seat belt floor anchor bolt and rear seat belt shoulder anchor bolt. Refer to SB-32, "

Removal

and Installation of Rear Seat Belt" .

3. Disengage child anchor cover front pawls, and then pull out child anchor cover (LH/RH center) toward

front of vehicle. (Models with rear window sunshade)

4. Remove rear kicking plate inner, rear wheelhouse garnish, rear pillar finisher. Refer to EI-37, "

BODY SIDE

TRIM" .

1. Rear parcel shelf lid 2. High-mounted stop lamp 3. Child anchor cover

4. Rear parcel shelf finisher 5. Rear seat belt shoulder anchor cover 6. Rear window sunshade

PIIB4590E

Page 3055 of 5621

EI-50

FLOOR TRIM

Revision: 2006 January2006 M35/M45

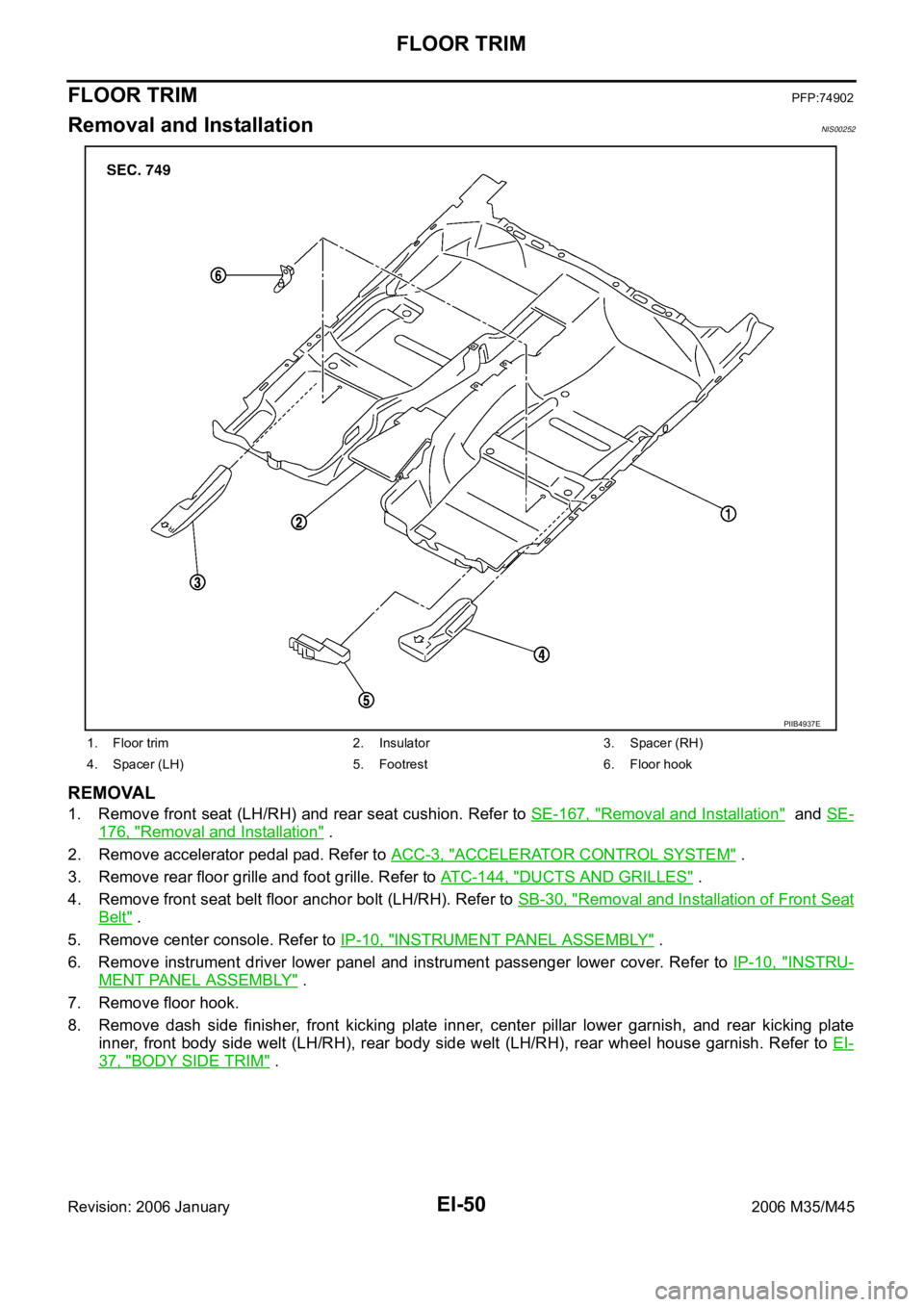

FLOOR TRIMPFP:74902

Removal and InstallationNIS00252

REMOVAL

1. Remove front seat (LH/RH) and rear seat cushion. Refer to SE-167, "Removal and Installation" and SE-

176, "Removal and Installation" .

2. Remove accelerator pedal pad. Refer to ACC-3, "

ACCELERATOR CONTROL SYSTEM" .

3. Remove rear floor grille and foot grille. Refer to ATC-144, "

DUCTS AND GRILLES" .

4. Remove front seat belt floor anchor bolt (LH/RH). Refer to SB-30, "

Removal and Installation of Front Seat

Belt" .

5. Remove center console. Refer to IP-10, "

INSTRUMENT PANEL ASSEMBLY" .

6. Remove instrument driver lower panel and instrument passenger lower cover. Refer to IP-10, "

INSTRU-

MENT PANEL ASSEMBLY" .

7. Remove floor hook.

8. Remove dash side finisher, front kicking plate inner, center pillar lower garnish, and rear kicking plate

inner, front body side welt (LH/RH), rear body side welt (LH/RH), rear wheel house garnish. Refer to EI-

37, "BODY SIDE TRIM" .

1. Floor trim 2. Insulator 3. Spacer (RH)

4. Spacer (LH) 5. Footrest 6. Floor hook

PIIB4937E

Page 3058 of 5621

HEADLINING

EI-53

C

D

E

F

G

H

J

K

L

MA

B

EI

Revision: 2006 January2006 M35/M45

REMOVAL

1. Remove front pillar garnish (LH/RH). Refer to EI-37, "BODY SIDE TRIM" .

2. Remove roof harness and antenna feeder securing clip using a clip clamp remover after removing front

pillar garnish (LH/RH), and then disconnect roof harness and antenna feeder connectors.

3. Remove rear seat cushion and seatback. Refer to SE-172, "

REAR SEAT" .

4. Remove front kicking plate inner, center pillar lower garnish, center pillar upper garnish, front body side

welt, rear kicking plate inner, rear wheelhouse garnish, rear pillar finisher, rear body side welt. Refer to EI-

37, "BODY SIDE TRIM" .

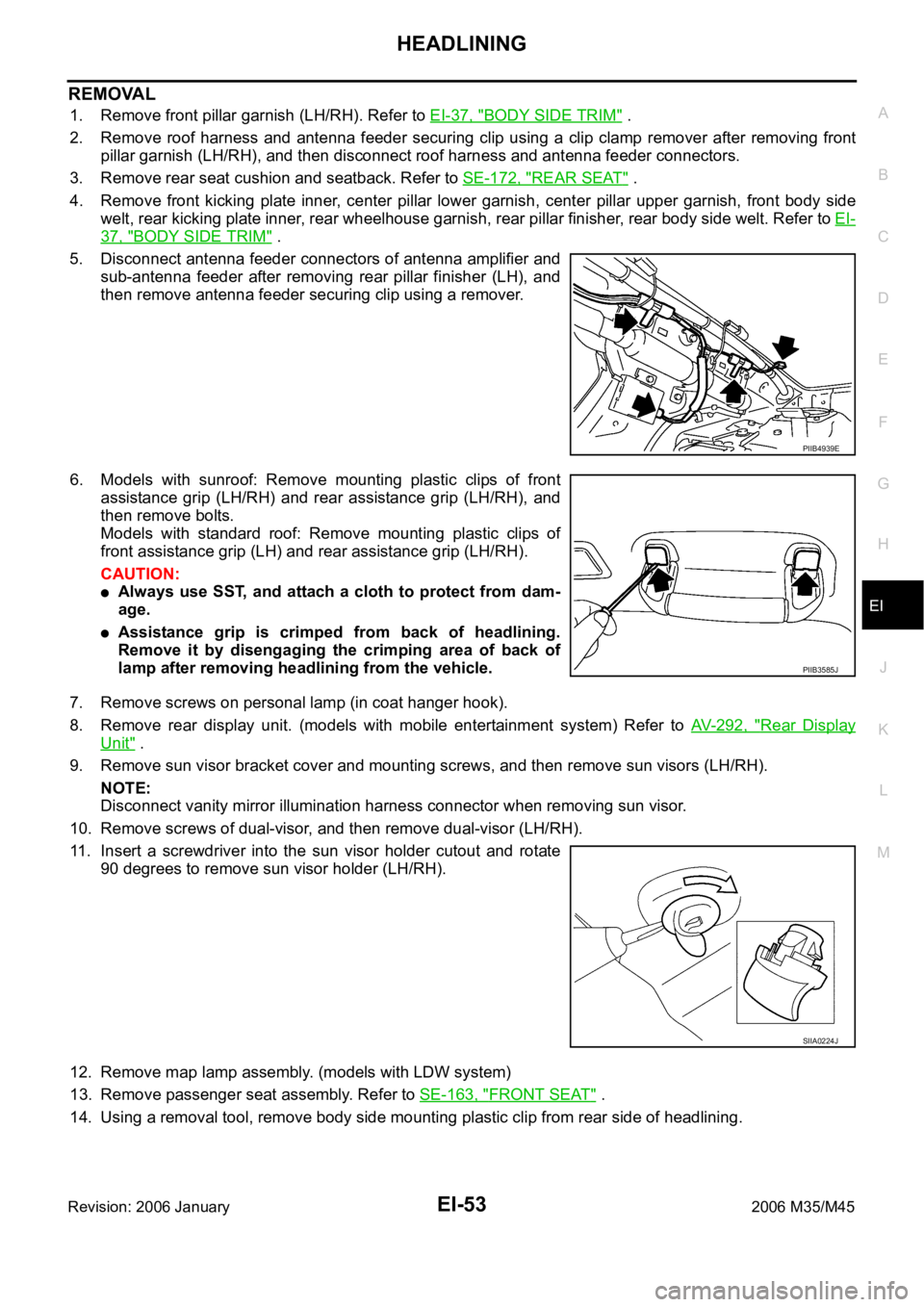

5. Disconnect antenna feeder connectors of antenna amplifier and

sub-antenna feeder after removing rear pillar finisher (LH), and

then remove antenna feeder securing clip using a remover.

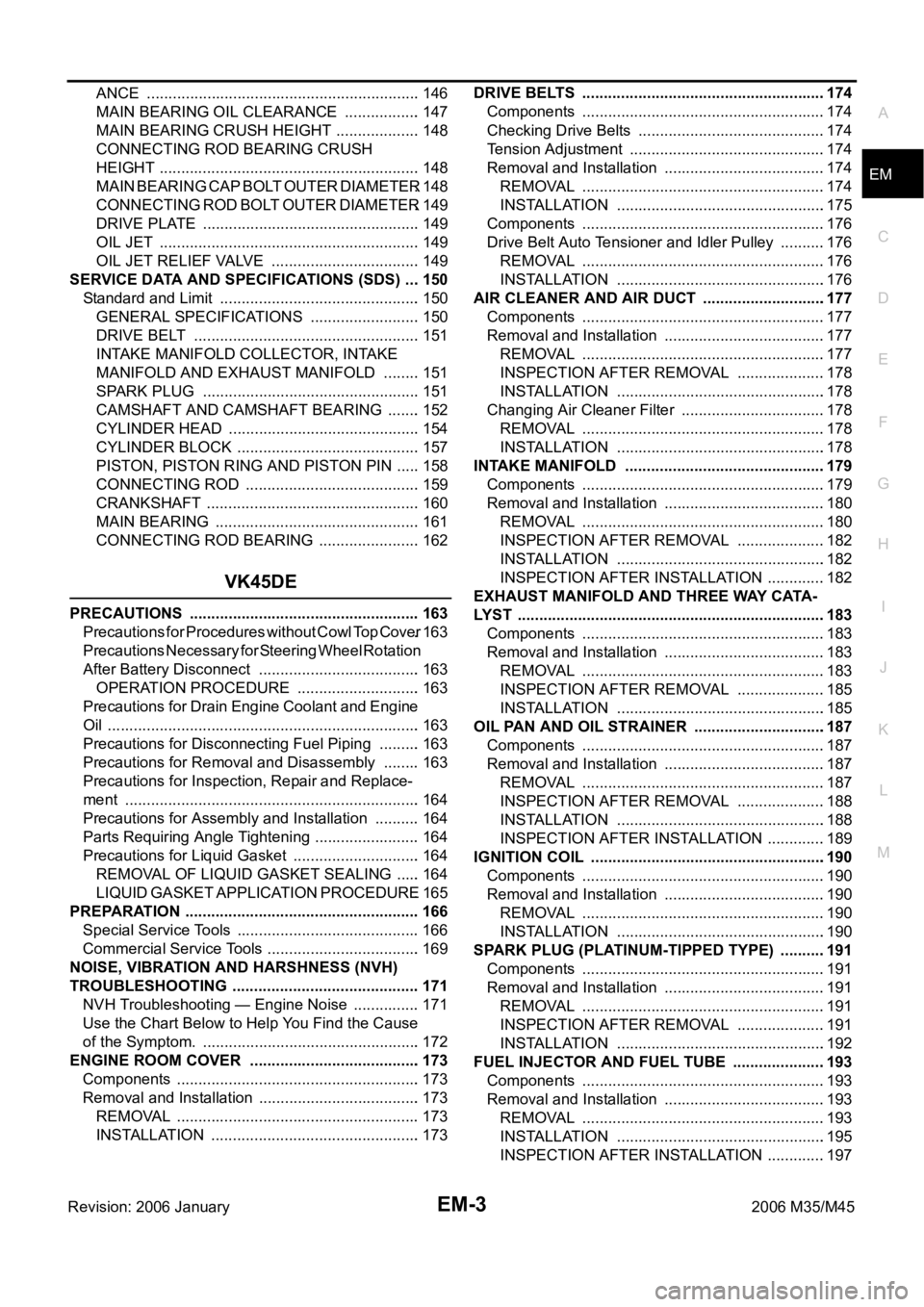

6. Models with sunroof: Remove mounting plastic clips of front

assistance grip (LH/RH) and rear assistance grip (LH/RH), and

then remove bolts.

Models with standard roof: Remove mounting plastic clips of

front assistance grip (LH) and rear assistance grip (LH/RH).

CAUTION:

Always use SST, and attach a cloth to protect from dam-

age.

Assistance grip is crimped from back of headlining.

Remove it by disengaging the crimping area of back of

lamp after removing headlining from the vehicle.

7. Remove screws on personal lamp (in coat hanger hook).

8. Remove rear display unit. (models with mobile entertainment system) Refer to AV- 2 9 2 , "

Rear Display

Unit" .

9. Remove sun visor bracket cover and mounting screws, and then remove sun visors (LH/RH).

NOTE:

Disconnect vanity mirror illumination harness connector when removing sun visor.

10. Remove screws of dual-visor, and then remove dual-visor (LH/RH).

11. Insert a screwdriver into the sun visor holder cutout and rotate

90 degrees to remove sun visor holder (LH/RH).

12. Remove map lamp assembly. (models with LDW system)

13. Remove passenger seat assembly. Refer to SE-163, "

FRONT SEAT" .

14. Using a removal tool, remove body side mounting plastic clip from rear side of headlining.

PIIB4939E

PIIB3585J

SIIA0224J

Page 3064 of 5621

EM-1

ENGINE MECHANICAL

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION EM

A

EM

Revision: 2006 January2006 M35/M45

ENGINE MECHANICAL

VQ35DE

PRECAUTIONS .......................................................... 5

Precautions for Procedures without Cowl Top Cover ..... 5

Precautions Necessary for Steering Wheel Rotation

After Battery Disconnect .......................................... 5

OPERATION PROCEDURE ................................. 5

Precautions for Drain Engine Coolant and Engine

Oil ............................................................................. 5

Precautions for Disconnecting Fuel Piping .............. 5

Precautions for Removal and Disassembly ............. 5

Precautions for Inspection, Repair and Replace-

ment ......................................................................... 6

Precautions for Assembly and Installation ............... 6

Precautions for Angle Tightening ............................. 6

Precautions for Liquid Gasket .................................. 6

REMOVAL OF LIQUID GASKET SEALING .......... 6

LIQUID GASKET APPLICATION PROCEDURE ..... 7

PREPARATION ........................................................... 8

Special Service Tools ............................................... 8

Commercial Service Tools ...................................... 10

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .............................................. 12

NVH Troubleshooting — Engine Noise .................. 12

Use the Chart Below to Help You Find the Cause

of the Symptom. ..................................................... 13

ENGINE ROOM COVER .......................................... 14

Components ........................................................... 14

Removal and Installation ........................................ 14

REMOVAL ........................................................

... 14

INSTALLATION ................................................... 14

DRIVE BELTS ........................................................... 15

Checking Drive Belts .............................................. 15

Tension Adjustment ................................................ 15

ALTERNATOR AND POWER STEERING OIL

PUMP BELT ........................................................ 16

A/C COMPRESSOR BELT ................................. 16

Removal and Installation ........................................ 16

REMOVAL ........................................................

... 16

INSTALLATION ................................................... 16AIR CLEANER AND AIR DUCT ............................... 17

Components ........................................................... 17

Removal and Installation ........................................ 17

REMOVAL ........................................................

... 17

INSTALLATION ................................................... 17

Changing Air Cleaner Filter .................................... 18

REMOVAL ........................................................

... 18

INSTALLATION ................................................... 18

INTAKE MANIFOLD COLLECTOR .......................... 19

Components ........................................................... 19

Removal and Installation ........................................ 19

REMOVAL ........................................................

... 19

INSPECTION AFTER REMOVAL ....................... 21

INSTALLATION ................................................... 22

INTAKE MANIFOLD ................................................. 24

Components ........................................................... 24

Removal and Installation ........................................ 24

REMOVAL ........................................................

... 24

INSPECTION AFTER REMOVAL ....................... 25

INSTALLATION ................................................... 25

EXHAUST MANIFOLD ............................................. 26

Components ........................................................... 26

Removal and Installation ........................................ 26

REMOVAL ........................................................

... 26

INSPECTION AFTER REMOVAL ....................... 27

INSTALLATION ................................................... 27

OIL PAN AND OIL STRAINER ................................. 29

Components (2WD Models) ................................... 29

Removal and Installation (2WD Models) ................ 29

REMOVAL ........................................................

... 29

INSPECTION AFTER REMOVAL ....................... 31

INSTALLATION ................................................... 31

INSPECTION AFTER INSTALLATION ................ 34

Components (AWD Models) ................................... 35

Removal and Installation (AWD Models) ................ 36

REMOVAL ........................................................

... 36

INSPECTION AFTER REMOVAL ....................... 38

INSTALLATION ................................................... 38

INSPECTION AFTER INSTALLATION ................ 41

Page 3066 of 5621

EM-3

C

D

E

F

G

H

I

J

K

L

M

EMA

Revision: 2006 January2006 M35/M45 ANCE ................................................................146

MAIN BEARING OIL CLEARANCE ..................147

MAIN BEARING CRUSH HEIGHT ....................148

CONNECTING ROD BEARING CRUSH

HEIGHT .............................................................148

MAIN BEARING CAP BOLT OUTER DIAMETER .148

CONNECTING ROD BOLT OUTER DIAMETER .149

DRIVE PLATE ...................................................149

OIL JET .............................................................149

OIL JET RELIEF VALVE ...................................149

SERVICE DATA AND SPECIFICATIONS (SDS) ....150

Standard and Limit ...............................................150

GENERAL SPECIFICATIONS ..........................150

DRIVE BELT .....................................................151

INTAKE MANIFOLD COLLECTOR, INTAKE

MANIFOLD AND EXHAUST MANIFOLD .........151

SPARK PLUG ...................................................151

CAMSHAFT AND CAMSHAFT BEARING ........152

CYLINDER HEAD .............................................154

CYLINDER BLOCK ...........................................157

PISTON, PISTON RING AND PISTON PIN ......158

CONNECTING ROD .........................................159

CRANKSHAFT ..................................................160

MAIN BEARING ................................................161

CONNECTING ROD BEARING ........................162

VK45DE

PRECAUTIONS ......................................................163

Precautions for Procedures without Cowl Top Cover .163

Precautions Necessary for Steering Wheel Rotation

After Battery Disconnect ......................................163

OPERATION PROCEDURE .............................163

Precautions for Drain Engine Coolant and Engine

Oil .........................................................................163

Precautions for Disconnecting Fuel Piping ..........163

Precautions for Removal and Disassembly .........163

Precautions for Inspection, Repair and Replace-

ment .....................................................................164

Precautions for Assembly and Installation ...........164

Parts Requiring Angle Tightening .........................164

Precautions for Liquid Gasket ..............................164

REMOVAL OF LIQUID GASKET SEALING ......164

LIQUID GASKET APPLICATION PROCEDURE .165

PREPARATION .......................................................166

Special Service Tools ...........................................166

Commercial Service Tools ....................................169

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ............................................171

NVH Troubleshooting — Engine Noise ................171

Use the Chart Below to Help You Find the Cause

of the Symptom. ...................................................172

ENGINE ROOM COVER ........................................173

Components .........................................................173

Removal and Installation ......................................173

REMOVAL ........................................................

.173

INSTALLATION .................................................173DRIVE BELTS .........................................................174

Components .........................................................174

Checking Drive Belts ............................................174

Tension Adjustment .............................................

.174

Removal and Installation ......................................174

REMOVAL ........................................................

.174

INSTALLATION .................................................175

Components .........................................................176

Drive Belt Auto Tensioner and Idler Pulley ...........176

REMOVAL ........................................................

.176

INSTALLATION .................................................176

AIR CLEANER AND AIR DUCT .............................177

Components .........................................................177

Removal and Installation ......................................177

REMOVAL ........................................................

.177

INSPECTION AFTER REMOVAL .....................178

INSTALLATION .................................................178

Changing Air Cleaner Filter ..................................178

REMOVAL ........................................................

.178

INSTALLATION .................................................178

INTAKE MANIFOLD ..............................................

.179

Components .........................................................179

Removal and Installation ......................................180

REMOVAL ........................................................

.180

INSPECTION AFTER REMOVAL .....................182

INSTALLATION .................................................182

INSPECTION AFTER INSTALLATION ..............182

EXHAUST MANIFOLD AND THREE WAY CATA-

LYST ........................................................................183

Components .........................................................183

Removal and Installation ......................................183

REMOVAL ........................................................

.183

INSPECTION AFTER REMOVAL .....................185

INSTALLATION .................................................185

OIL PAN AND OIL STRAINER ...............................187

Components .........................................................187

Removal and Installation ......................................187

REMOVAL ........................................................

.187

INSPECTION AFTER REMOVAL .....................188

INSTALLATION .................................................188

INSPECTION AFTER INSTALLATION ..............189

IGNITION COIL .......................................................190

Components .........................................................190

Removal and Installation ......................................190

REMOVAL ........................................................

.190

INSTALLATION .................................................190

SPARK PLUG (PLATINUM-TIPPED TYPE) ...........191

Components .........................................................191

Removal and Installation ......................................191

REMOVAL ........................................................

.191

INSPECTION AFTER REMOVAL .....................191

INSTALLATION .................................................192

FUEL INJECTOR AND FUEL TUBE ......................193

Components .........................................................193

Removal and Installation ......................................193

REMOVAL ........................................................

.193

INSTALLATION .................................................195

INSPECTION AFTER INSTALLATION ..............197

Page 3068 of 5621

![INFINITI M35 2006 Factory Service Manual PRECAUTIONS

EM-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004MF

When performing the proced INFINITI M35 2006 Factory Service Manual PRECAUTIONS

EM-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004MF

When performing the proced](/img/42/57023/w960_57023-3067.png)

PRECAUTIONS

EM-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004MF

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions Necessary for Steering Wheel Rotation After Battery DisconnectNBS005RR

NOTE:

This Procedure is applied only to models with Intelligent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

LOCK position.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the

ACC position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the

LOCK position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Precautions for Drain Engine Coolant and Engine OilNBS004MH

Drain engine coolant and engine oil when the engine is cooled.

Precautions for Disconnecting Fuel PipingNBS004MI

Before starting work, make sure no fire or spark producing items are in the work area.

Release fuel pressure before disconnecting and disassembly.

After disconnecting pipes, plug openings to stop fuel leakage.

Precautions for Removal and DisassemblyNBS004MJ

When instructed to use SST, use specified tools. Always be careful to work safely, avoid forceful or unin-

structed operations.

Exercise maximum care to avoid damage to mating or sliding surfaces.

PIIB3706J

Page 3176 of 5621

![INFINITI M35 2006 Factory Service Manual ENGINE ASSEMBLY

EM-113

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

ENGINE ASSEMBLYPFP:10001

Components (2WD Models)NBS004NW

Removal and Installation (2WD Models)NBS004NX

WAR INFINITI M35 2006 Factory Service Manual ENGINE ASSEMBLY

EM-113

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

ENGINE ASSEMBLYPFP:10001

Components (2WD Models)NBS004NW

Removal and Installation (2WD Models)NBS004NX

WAR](/img/42/57023/w960_57023-3175.png)

ENGINE ASSEMBLY

EM-113

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

ENGINE ASSEMBLYPFP:10001

Components (2WD Models)NBS004NW

Removal and Installation (2WD Models)NBS004NX

WAR NING :

Situate the vehicle on a flat and solid surface.

Place chocks at front and back of rear wheels.

For engines not equipped with engine slingers, attach proper slingers and bolts described in

PARTS CATALOG.

CAUTION:

Always be careful to work safely, avoid forceful or uninstructed operations.

Do not start working until exhaust system and engine coolant are cool enough.

If items or work required are not covered by the engine section, refer to the applicable sections.

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for

unavoidable reasons, support at rear axle jacking point with transmission jack or similar tool

before starting work, in preparation for the backward shift of center of gravity.

For supporting points for lifting and jacking point at rear axle, refer to GI-42, "Garage Jack and

Safety Stand and 2-Pole Lift" .

1. Engine mounting bracket (RH) 2. Heat insulator (RH) 3. Engine mounting insulator (RH)

4. Engine mounting bracket (LH) 5. Heat insulator (LH) 6. Engine mounting insulator (LH)

7. Rear engine mounting member 8. Dynamic damper 9. Engine mounting insulator (rear)

10. Dynamic damper

A. Front mark

PBIC3363E