power steering INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3308 of 5621

![INFINITI M35 2006 Factory Service Manual ENGINE ASSEMBLY

EM-245

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type li INFINITI M35 2006 Factory Service Manual ENGINE ASSEMBLY

EM-245

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type li](/img/42/57023/w960_57023-3307.png)

ENGINE ASSEMBLY

EM-245

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for

unavoidable reasons, support at the rear axle jacking point with transmission jack or similar tool

before starting work, in preparation for the backward shift of center of gravity.

For supporting points for lifting and jacking point at rear axle, refer to GI-42, "Garage Jack and

Safety Stand and 2-Pole Lift" .

REMOVAL

Outline

At first, remove engine, transmission assembly with front suspension member from vehicle downward. Then

separate engine from transmission.

Preparation

1. Release fuel pressure. Refer to EC-809, "FUEL PRESSURE RELEASE" .

2. Drain engine coolant from radiator. Refer to CO-40, "

Changing Engine Coolant" .

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belts.

3. Disconnect both battery cables. Refer to SC-4, "

BATTERY" .

4. Remove crankshaft position sensor (POS) from transmission.

CAUTION:

Handle carefully to avoid dropping and shocks.

Do not disassemble.

Do not allow metal powder to adhere to magnetic part at sensor tip.

Do not place sensors in a location where they are exposed to magnetism.

5. Remove the following parts:

Front and rear engine undercover (power tool)

Air duct (inlet), air duct and air cleaner case assembly; Refer to EM-177, "AIR CLEANER AND AIR

DUCT" .

Front road wheels and tires (power tool)

Engine Room LH

1. Disconnect heater hoses, and install plugs to avoid leakage of engine coolant.

2. Disconnect wire bonding from exhaust manifold cover to vehicle.

3. Disconnect vacuum hose between vehicle and engine and set it aside.

4. Discharge refrigerant from A/C circuit. Refer to ATC-151, "

REFRIGERANT LINES" .

5. Remove A/C piping from A/C compressor, and temporarily fasten it on vehicle with a rope. Refer to AT C -

151, "REFRIGERANT LINES" .

Engine Room RH

1. Disconnect fuel feed hose and EVAP hose. Refer to EM-193, "FUEL INJECTOR AND FUEL TUBE" .

CAUTION:

Fit plugs onto disconnected hose to prevent fuel leak.

2. Disconnect ground cable (between vehicle and right bank cylinder head).

3. Disconnect vacuum hose between vehicle and engine and set it aside.

4. Disconnect reservoir tank of power steering oil pump from engine, and move it aside for easier work.

CAUTION:

When temporarily securing, keep reservoir tank upright to avoid a fluid leak.

Ve h i c le i n s i d e

Follow procedure below to disconnect engine room harness connectors at passenger room side, and tempo-

rarily secure them on engine.

1. Remove passenger-side kicking plate, dash side finisher, and glove box. Refer to EI-37, "

BODY SIDE

TRIM" and IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Disconnect engine room harness connectors at unit sides TCM, ECM and other.

Page 3309 of 5621

![INFINITI M35 2006 Factory Service Manual EM-246

[VK45DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

3. Disengage intermediate fixing point. Pull out engine room harnesses to engine room side, and temporarily

secure them on engine.

CA INFINITI M35 2006 Factory Service Manual EM-246

[VK45DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

3. Disengage intermediate fixing point. Pull out engine room harnesses to engine room side, and temporarily

secure them on engine.

CA](/img/42/57023/w960_57023-3308.png)

EM-246

[VK45DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

3. Disengage intermediate fixing point. Pull out engine room harnesses to engine room side, and temporarily

secure them on engine.

CAUTION:

When pulling out harnesses, take care not to damage harnesses and connectors.

After temporarily securing, cover connectors with vinyl or similar material to protect against for-

eign material adhesion.

Vehicle Underbody

1. Remove A/T fluid cooler hoses and power steering oil pump oil cooler hoses.

Install plug to avoid leakage of A/T fluid and power steering fluid.

2. Disconnect heated oxygen sensor 2 harness. Refer to EX-3, "

EXHAUST SYSTEM" .

3. Remove exhaust front tube with power tool. Refer to EX-3, "

EXHAUST SYSTEM" .

4. Disconnect steering lower joint at power steering gear assembly side, and release steering lower shaft.

Refer to PS-13, "

STEERING COLUMN" .

5. Separate steering outer sockets from steering knuckle. Refer to PS-18, "

POWER STEERING GEAR" .

6. Remove A/T control rod at control device assembly side. Then temporarily secure it on transmission, so

that it does not sag. Refer to AT-222, "

SHIFT CONTROL SYSTEM" .

7. Remove rear plate cover from oil pan. Then remove bolts fixing drive plate to torque converter. Refer to

EM-187, "

OIL PAN AND OIL STRAINER" and AT-271, "TRANSMISSION ASSEMBLY" .

8. Remove transmission joint bolts which pierce at oil pan lower rear side. Refer to AT- 2 7 1 , "

TRANSMIS-

SION ASSEMBLY" .

9. Remove lower ends of left and right strut from transverse link. Refer to FSU-6, "

FRONT SUSPENSION

ASSEMBLY" .

10. Remove transverse link mounting bolts at knuckle side. Refer to FSU-14, "

TRANSVERSE LINK" .

11. Remove front stabilizer at transverse link side. Refer to FSU-6, "

FRONT SUSPENSION ASSEMBLY" .

12. Remove rear propeller shaft. Refer to PR-6, "

REAR PROPELLER SHAFT" .

Removal Work

1. Use manual lift table caddy (commercial service tool) or equiva-

lently rigid tool such as transmission jack. Securely support bot-

tom of suspension member and transmission assembly.

CAUTION:

Put a piece of wood or something similar as the supporting

surface, secure a completely stable condition.

2. Remove engine rear member mounting bolts.

3. Remove front suspension member mounting nuts and bolts with power tool. Refer to FSU-6, "

FRONT

SUSPENSION ASSEMBLY" .

4. Carefully lower jack, or raise lift to remove engine, transmission and front suspension member assembly.

When performing work, observe the following caution:

CAUTION:

Confirm there is no interference with vehicle.

Make sure that all connection points have been disconnected.

Keep in mind the center of vehicle gravity changes. If necessary, use jack(s) to support vehicle

at rear jacking point(s) to prevent it from falling it off the lift.

PBIC0804E

Page 3311 of 5621

![INFINITI M35 2006 Factory Service Manual EM-248

[VK45DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

Summary of the inspection items:

* Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc. Item Before starting eng INFINITI M35 2006 Factory Service Manual EM-248

[VK45DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

Summary of the inspection items:

* Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc. Item Before starting eng](/img/42/57023/w960_57023-3310.png)

EM-248

[VK45DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

Summary of the inspection items:

* Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc. Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 3364 of 5621

FRONT WHEEL HUB AND KNUCKLE

FAX-5

C

E

F

G

H

I

J

K

L

MA

B

FA X

Revision: 2006 January2006 M35/M45

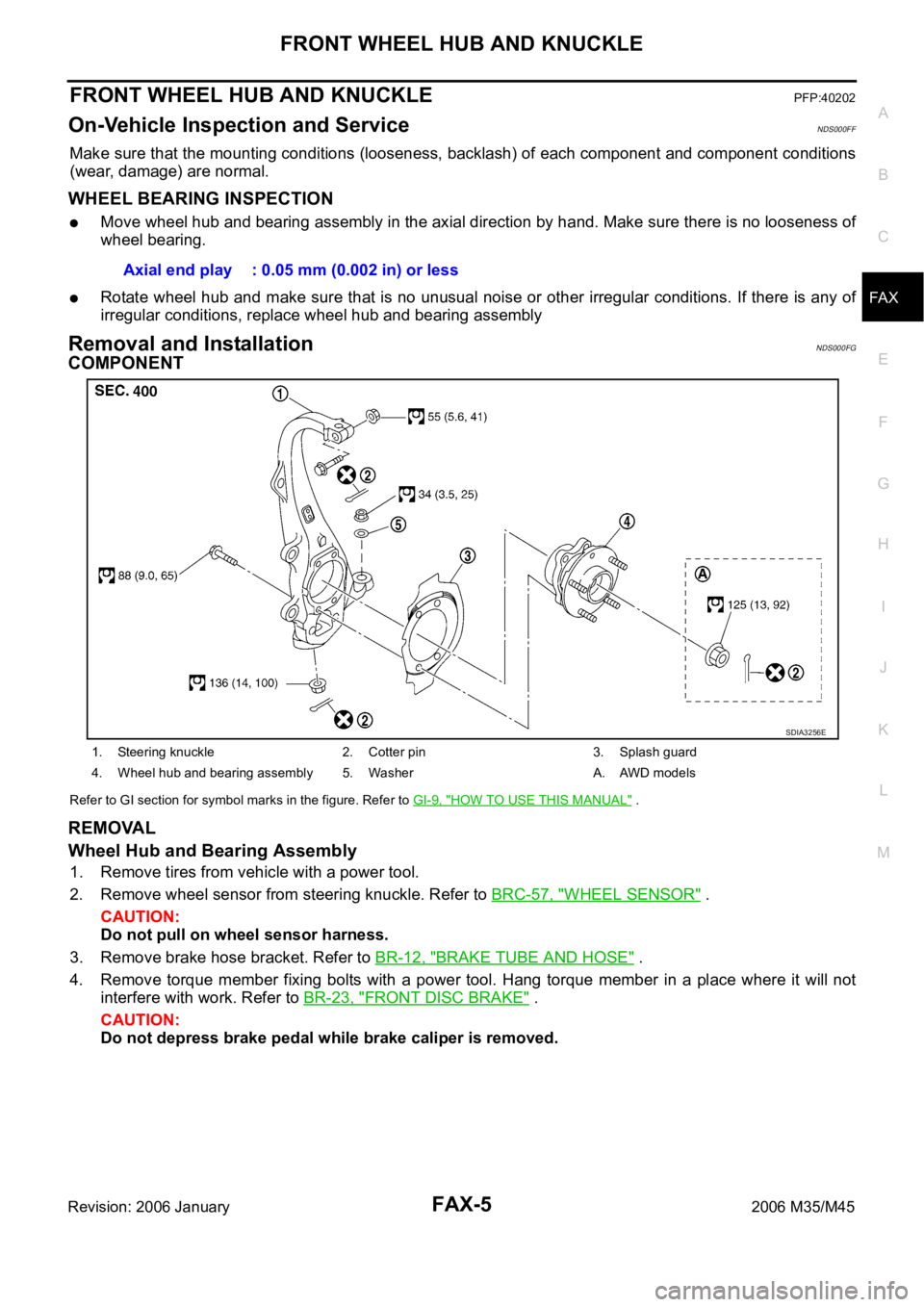

FRONT WHEEL HUB AND KNUCKLEPFP:40202

On-Vehicle Inspection and ServiceNDS000FF

Make sure that the mounting conditions (looseness, backlash) of each component and component conditions

(wear, damage) are normal.

WHEEL BEARING INSPECTION

Move wheel hub and bearing assembly in the axial direction by hand. Make sure there is no looseness of

wheel bearing.

Rotate wheel hub and make sure that is no unusual noise or other irregular conditions. If there is any of

irregular conditions, replace wheel hub and bearing assembly

Removal and InstallationNDS000FG

COMPONENT

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL" .

REMOVAL

Wheel Hub and Bearing Assembly

1. Remove tires from vehicle with a power tool.

2. Remove wheel sensor from steering knuckle. Refer to BRC-57, "

WHEEL SENSOR" .

CAUTION:

Do not pull on wheel sensor harness.

3. Remove brake hose bracket. Refer to BR-12, "

BRAKE TUBE AND HOSE" .

4. Remove torque member fixing bolts with a power tool. Hang torque member in a place where it will not

interfere with work. Refer to BR-23, "

FRONT DISC BRAKE" .

CAUTION:

Do not depress brake pedal while brake caliper is removed.Axial end play : 0.05 mm (0.002 in) or less

1. Steering knuckle 2. Cotter pin 3. Splash guard

4. Wheel hub and bearing assembly 5. Washer A. AWD models

SDIA3256E

Page 3365 of 5621

FAX-6

FRONT WHEEL HUB AND KNUCKLE

Revision: 2006 January2006 M35/M45

5. Put matching mark on disc rotor and wheel hub and bearing

assembly, then remove disc rotor.

6. Remove cotter pin, then loosen hub lock nut with a power tool.

(AWD)

7. Separate wheel hub and bearing assembly from drive shaft by

lightly tapping the end with a hammer (suitable tool) and a wood

block, and then remove hub lock nut. (AWD)

CAUTION:

Do not place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

Do not allow drive shaft to hang down without support for

housing (or joint sub-assembly), shaft and the other

parts.

NOTE:

Use a puller (suitable tool) if wheel hub and bearing assembly

and drive shaft cannot be separated even after performing the

above procedure.

8. Remove wheel hub and bearing assembly mounting bolts, and then remove splash guard and wheel hub

and bearing assembly from steering knuckle.

Steering knuckle

1. Refer to the procedure from 1 to 7 in “Wheel Hub and Bearing Assembly” FA X - 5 , "REMOVAL" .

2. Remove cotter pin (1), and then loosen the nut.

3. Remove steering outer socket (2) from steering knuckle (3) so

as not to damage ball joint boot (4) using the ball joint remover

(suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover (suitable tool) from

suddenly coming off.

4. Remove cotter pin of transverse link and steering knuckle, and

then loosen nut.

5. Remove transverse link from steering knuckle so as not to dam-

age ball joint boot using the ball joint remover (suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads and to prevent ball joint remover (suit-

able tool) from suddenly coming off.

6. Remove fixing nut and bolt with a power tool, and then remove steering knuckle from upper link. Refer to

FSU-8, "

Components" .

7. Remove wheel hub and bearing assembly mounting bolts, and then remove splash guard and wheel hub

and bearing assembly from steering knuckle.

INSPECTION AFTER REMOVAL

Check components for deformation, cracks, and other damage. Replace if there are.

Ball Joint Inspection

Check boots of transverse link and steering outer socket ball joint for breakage, axial play, and torque. Refer to

FSU-14, "

INSPECTION AFTER REMOVAL" , “TRANSVERSE LINK”, PS-22, "INSPECTION AFTER DISAS-

SEMBLY" , “POWER STEERING GEAR”.

SDIA2608E

SDIA1821E

SGIA1183E

Page 3367 of 5621

FAX-8

FRONT DRIVE SHAFT

Revision: 2006 January2006 M35/M45

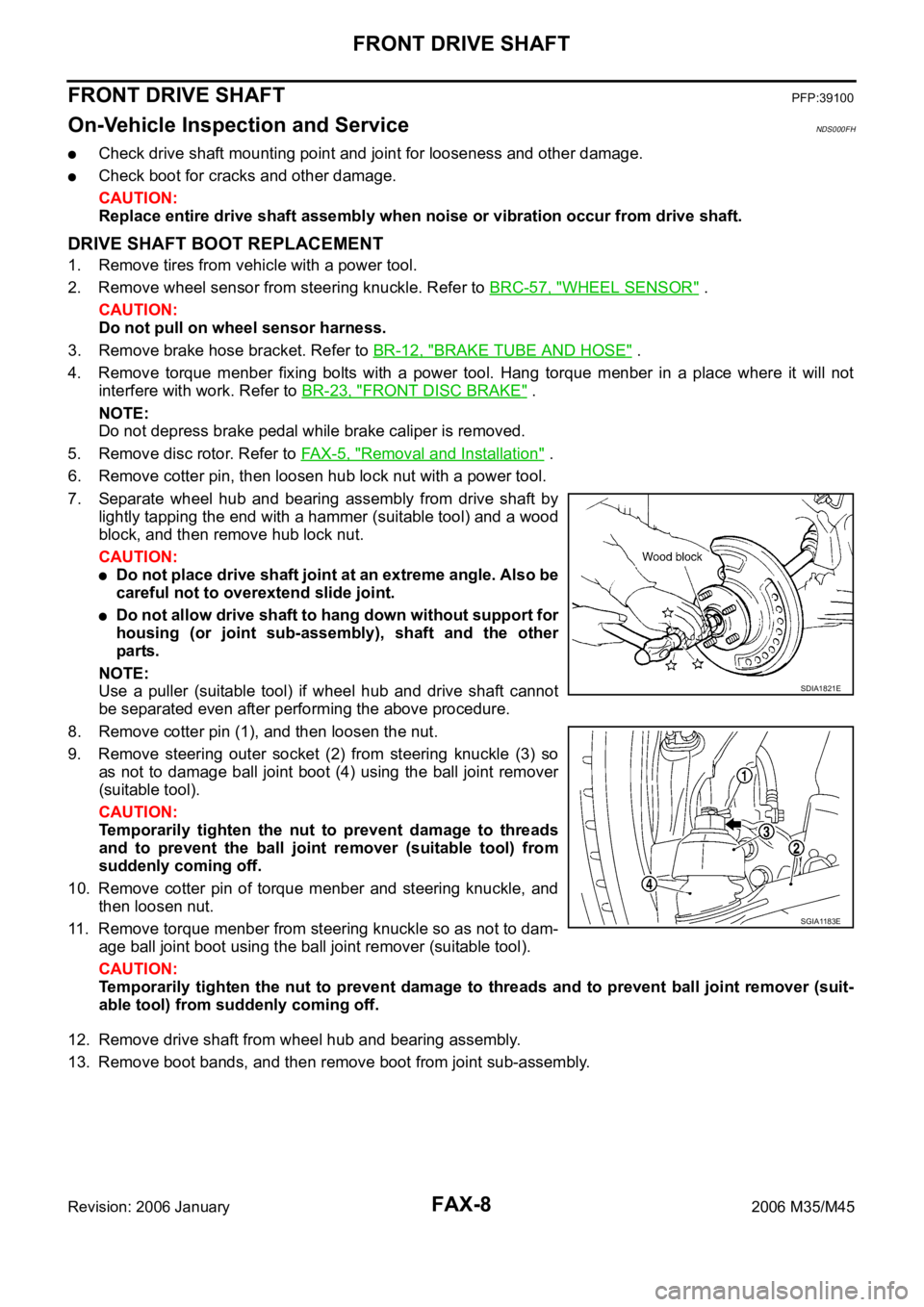

FRONT DRIVE SHAFTPFP:39100

On-Vehicle Inspection and ServiceNDS000FH

Check drive shaft mounting point and joint for looseness and other damage.

Check boot for cracks and other damage.

CAUTION:

Replace entire drive shaft assembly when noise or vibration occur from drive shaft.

DRIVE SHAFT BOOT REPLACEMENT

1. Remove tires from vehicle with a power tool.

2. Remove wheel sensor from steering knuckle. Refer to BRC-57, "

WHEEL SENSOR" .

CAUTION:

Do not pull on wheel sensor harness.

3. Remove brake hose bracket. Refer to BR-12, "

BRAKE TUBE AND HOSE" .

4. Remove torque menber fixing bolts with a power tool. Hang torque menber in a place where it will not

interfere with work. Refer to BR-23, "

FRONT DISC BRAKE" .

NOTE:

Do not depress brake pedal while brake caliper is removed.

5. Remove disc rotor. Refer to FA X - 5 , "

Removal and Installation" .

6. Remove cotter pin, then loosen hub lock nut with a power tool.

7. Separate wheel hub and bearing assembly from drive shaft by

lightly tapping the end with a hammer (suitable tool) and a wood

block, and then remove hub lock nut.

CAUTION:

Do not place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

Do not allow drive shaft to hang down without support for

housing (or joint sub-assembly), shaft and the other

parts.

NOTE:

Use a puller (suitable tool) if wheel hub and drive shaft cannot

be separated even after performing the above procedure.

8. Remove cotter pin (1), and then loosen the nut.

9. Remove steering outer socket (2) from steering knuckle (3) so

as not to damage ball joint boot (4) using the ball joint remover

(suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover (suitable tool) from

suddenly coming off.

10. Remove cotter pin of torque menber and steering knuckle, and

then loosen nut.

11. Remove torque menber from steering knuckle so as not to dam-

age ball joint boot using the ball joint remover (suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads and to prevent ball joint remover (suit-

able tool) from suddenly coming off.

12. Remove drive shaft from wheel hub and bearing assembly.

13. Remove boot bands, and then remove boot from joint sub-assembly.

SDIA1821E

SGIA1183E

Page 3370 of 5621

FRONT DRIVE SHAFT

FAX-11

C

E

F

G

H

I

J

K

L

MA

B

FA X

Revision: 2006 January2006 M35/M45

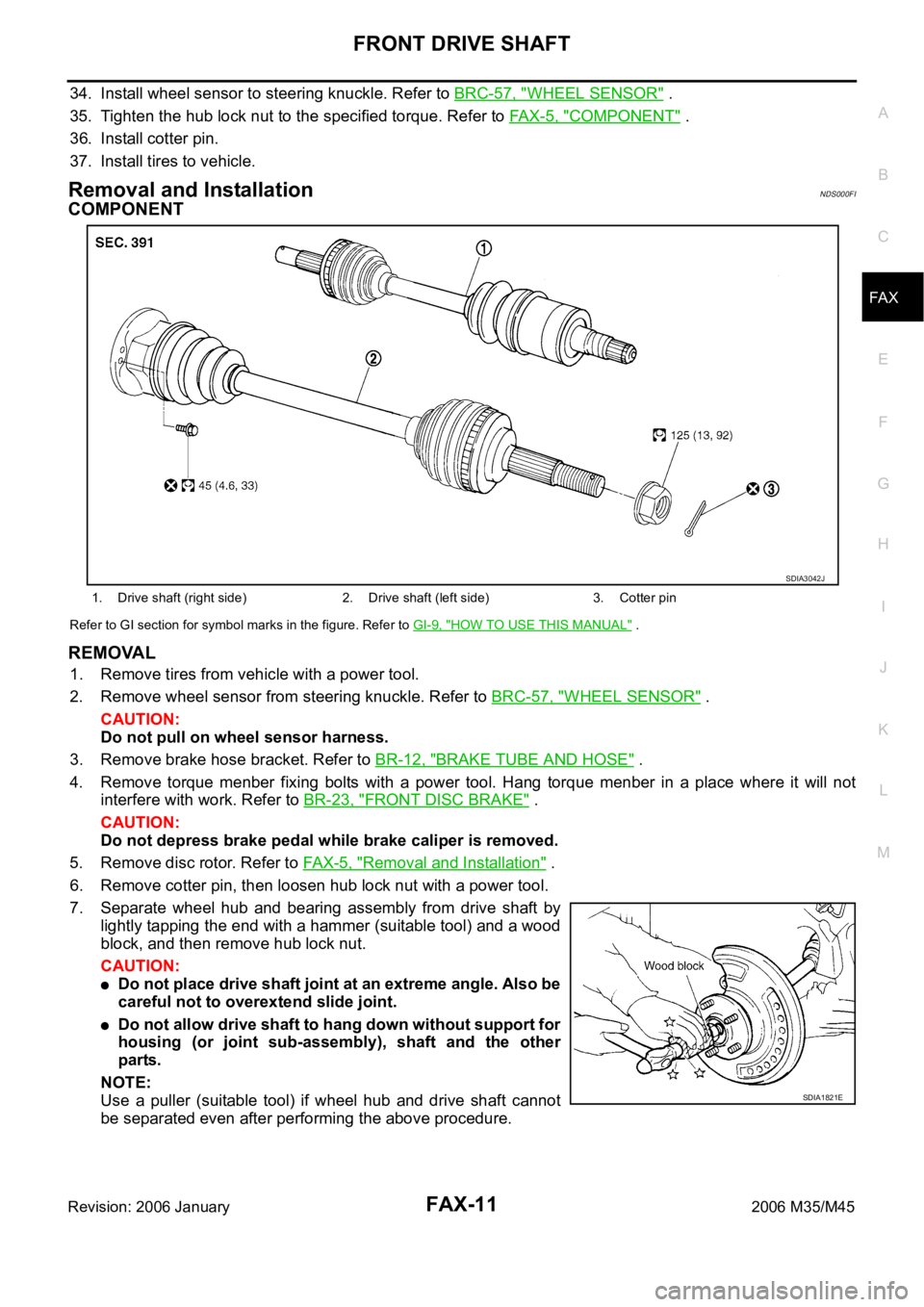

34. Install wheel sensor to steering knuckle. Refer to BRC-57, "WHEEL SENSOR" .

35. Tighten the hub lock nut to the specified torque. Refer to FA X - 5 , "

COMPONENT" .

36. Install cotter pin.

37. Install tires to vehicle.

Removal and InstallationNDS000FI

COMPONENT

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL" .

REMOVAL

1. Remove tires from vehicle with a power tool.

2. Remove wheel sensor from steering knuckle. Refer to BRC-57, "

WHEEL SENSOR" .

CAUTION:

Do not pull on wheel sensor harness.

3. Remove brake hose bracket. Refer to BR-12, "

BRAKE TUBE AND HOSE" .

4. Remove torque menber fixing bolts with a power tool. Hang torque menber in a place where it will not

interfere with work. Refer to BR-23, "

FRONT DISC BRAKE" .

CAUTION:

Do not depress brake pedal while brake caliper is removed.

5. Remove disc rotor. Refer to FAX-5, "

Removal and Installation" .

6. Remove cotter pin, then loosen hub lock nut with a power tool.

7. Separate wheel hub and bearing assembly from drive shaft by

lightly tapping the end with a hammer (suitable tool) and a wood

block, and then remove hub lock nut.

CAUTION:

Do not place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

Do not allow drive shaft to hang down without support for

housing (or joint sub-assembly), shaft and the other

parts.

NOTE:

Use a puller (suitable tool) if wheel hub and drive shaft cannot

be separated even after performing the above procedure.

1. Drive shaft (right side) 2. Drive shaft (left side) 3. Cotter pin

SDIA3042J

SDIA1821E

Page 3379 of 5621

FFD-2

PRECAUTIONS

Revision: 2006 January2006 M35/M45

PRECAUTIONSPFP:00001

Precautions Necessary for Steering Wheel Rotation after Battery DisconnectNDS000EK

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK

position, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Carry the Intelligent Key or insert it to the key slot and turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-II.

Service Notice or PrecautionsNDS000EL

Check for the correct installation status prior to removal or disassembly. If matching marks are required,

be certain they do not interfere with the function of the parts when applied.

Overhaul should be done in a clean work area, it is preferable to work in dustproof area.

Before disassembly, using steam or white gasoline, completely remove sand and mud from the exterior of

the unit, preventing them from entering into the unit during disassembly or assembly.

Check appearance of the disassembled parts for damage, deformation, and unusual wear. Replace them

with a new ones if necessary.

Gaskets, seals and O-rings should be replaced any time when the unit is disassembled.

In principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If

tightening sequence is specified, observe it.

Clean and flush the parts sufficiently and blow-dry them.

Be careful not to damage sliding surfaces and mating surfaces.

When applying sealant, remove the old sealant from the mounting surface; then remove any moisture, oil,

and foreign materials from the application and mounting surfaces.

Always use shop paper for cleaning the inside of components.

Avoid using cotton gloves or shop rags to prevent entering of lint.

During assembly, observe the specified tightening torque, and apply new gear oil, petroleum jelly, or multi-

purpose grease as specified for each vehicle, if necessary.

Page 3390 of 5621

FRONT FINAL DRIVE ASSEMBLY

FFD-13

C

E

F

G

H

I

J

K

L

MA

B

FFD

Revision: 2006 January2006 M35/M45

FRONT FINAL DRIVE ASSEMBLYPFP:38500

Removal and InstallationNDS000EU

COMPONENTS

REMOVAL

1. Remove front drive shaft both. Refer to FA X - 11 , "Removal and Installation" .

2. Remove front crossbar with power tool.

3. Separate steering outer socket and steering knuckle. Refer to PS-18, "

POWER STEERING GEAR" .

4. Remove side shaft.

5. Remove three way catalyst (right bank) with power tool. Refer to EX-3, "

EXHAUST SYSTEM" .

6. Remove front propeller shaft. Refer to PR-5, "

Removal and Installation" .

7. Separate EPS solenoid valve connector.

8. Separate power steering hydraulic line.

9. Remove stabilizer assembly with power tool. Refer to FSU-35, "

Removal and Installation" .

10. Separate steering lower joint and steering gear assembly. Refer to PS-18, "

POWER STEERING GEAR" .

11. Set a suitable jack to engine.

12. Remove front suspension member with power tool. Refer to FSU-26, "

Removal and Installation" .

13. Remove breather hose and tube.

14. Remove engine mounting bracket (RH) (Lower) and engine mounting insulator (RH) with power tool.

Refer to EM-118, "

Removal and Installation (AWD Models)" .

15. Remove front final drive assembly with power tool.

1. Front final drive assembly 2. Side shaft 3. Bushing

4. Front propeller shaft 5. Breather hose 6. Breather tube

7. Breather connector 8. Engine mounting bracket (RH)

(Lower)9. Engine mounting insulator (RH)

Refer to GI-11, "

Components" , for the symbols in the figure.

PDIA0789J

Page 3436 of 5621

![INFINITI M35 2006 Factory Service Manual FRONT SUSPENSION ASSEMBLY

FSU-9

[2WD]

C

D

F

G

H

I

J

K

L

MA

B

FSU

Revision: 2006 January2006 M35/M45

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL" INFINITI M35 2006 Factory Service Manual FRONT SUSPENSION ASSEMBLY

FSU-9

[2WD]

C

D

F

G

H

I

J

K

L

MA

B

FSU

Revision: 2006 January2006 M35/M45

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL"](/img/42/57023/w960_57023-3435.png)

FRONT SUSPENSION ASSEMBLY

FSU-9

[2WD]

C

D

F

G

H

I

J

K

L

MA

B

FSU

Revision: 2006 January2006 M35/M45

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL" .

Removal and Installation NES000ID

REMOVAL

1. For VK45DE engine models, disconnect related electric wires and hoses from engine assembly to remove

front suspension member with engine assembly. Refer to EM-244, "

ENGINE ASSEMBLY" .

2. Remove cowl top panel and hood. Refer to EI-18, "

COWL TOP" , EI-17, "HOOD" .

3. For VQ35DE engine models, install engine slinger, and then hoist engine. Refer to EM-113, "

Removal and

Installation (2WD Models)" .

4. Remove tires from vehicle with a power tool.

5. Remove wheel sensor from steering knuckle. Refer to BRC-57, "

WHEEL SENSOR" .

CAUTION:

Do not pull on wheel sensor harness.

6. Remove brake hose bracket. Refer to BR-12, "

BRAKE TUBE AND HOSE" .

7. Remove undercover with a power tool.

8. Remove cotter pin (1), and then loosen the nut.

9. Remove steering outer socket (2) from steering knuckle (3) so

as not to damage ball joint boot (4) using the ball joint remover

(suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover (suitable tool) from

suddenly coming off.

10. Remove the mounting nut on the upper side of stabilizer con-

necting rod with a power tool, and then remove stabilizer con-

necting rod from transverse link.

11. Separate steering gear assembly and lower joint. Refer to PS-13, "

STEERING COLUMN" .

12. Remove rack stay. Refer to FSU-8, "

Components" .

13. Remove steering hydraulic piping bracket from front suspension member. Refer to PS-38, "

HYDRAULIC

LINE" .

14. Remove the mounting nut and bolt on the lower side of shock absorber with a power tool, and then

remove shock absorber from transverse link.

15. Remove cotter pin of transverse link and steering knuckle, and then loosen nut.

16. Set jack under front suspension member.

17. Remove transverse link from steering knuckle so as not to damage ball joint boot using the ball joint

remover (suitable tool)

CAUTION:

Temporarily tighten the nut to prevent damage to threads and to prevent ball joint remover (suit-

able tool) from suddenly coming off.

18. Remove the mounting nuts of engine mounting insulator. Refer to EM-113, "

ENGINE ASSEMBLY" .

19. Remove the mounting bolts of member bracket, and then remove member bracket from front suspension

member with a power tool. Refer to FSU-8, "

Components" .

20. Remove the mounting nut and bolts of member stay, and then remove member stay from front suspension

member and vehicle with a power tool.

21. Remove the mounting nut of front suspension member with a power tool. Refer to FSU-8, "

Components" .

22. For VQ35DE engine models, gradually lower a jack to remove front suspension assembly from vehicle.

1. Shock absorber mounting bracket 2. Bound bumper 3. Rubber seat

4. Coil spring 5. Shock absorber 6. Upper link

7. Steering knuckle 8. Transverse link 9. Washer

10. Steering stopper bracket 11. Stabilizer connecting rod 12. Stabilizer bar

13. Stabilizer bushing 14. Stabilizer clamp 15. Front suspension member

16. Rack stay 17. Member stay 18. Member bracket

19. Clamp 20. Cotter pin 21. Stopper rubber

SGIA1183E