battery INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1245 of 5621

BL-306

BODY REPAIR

Revision: 2006 January2006 M35/M45

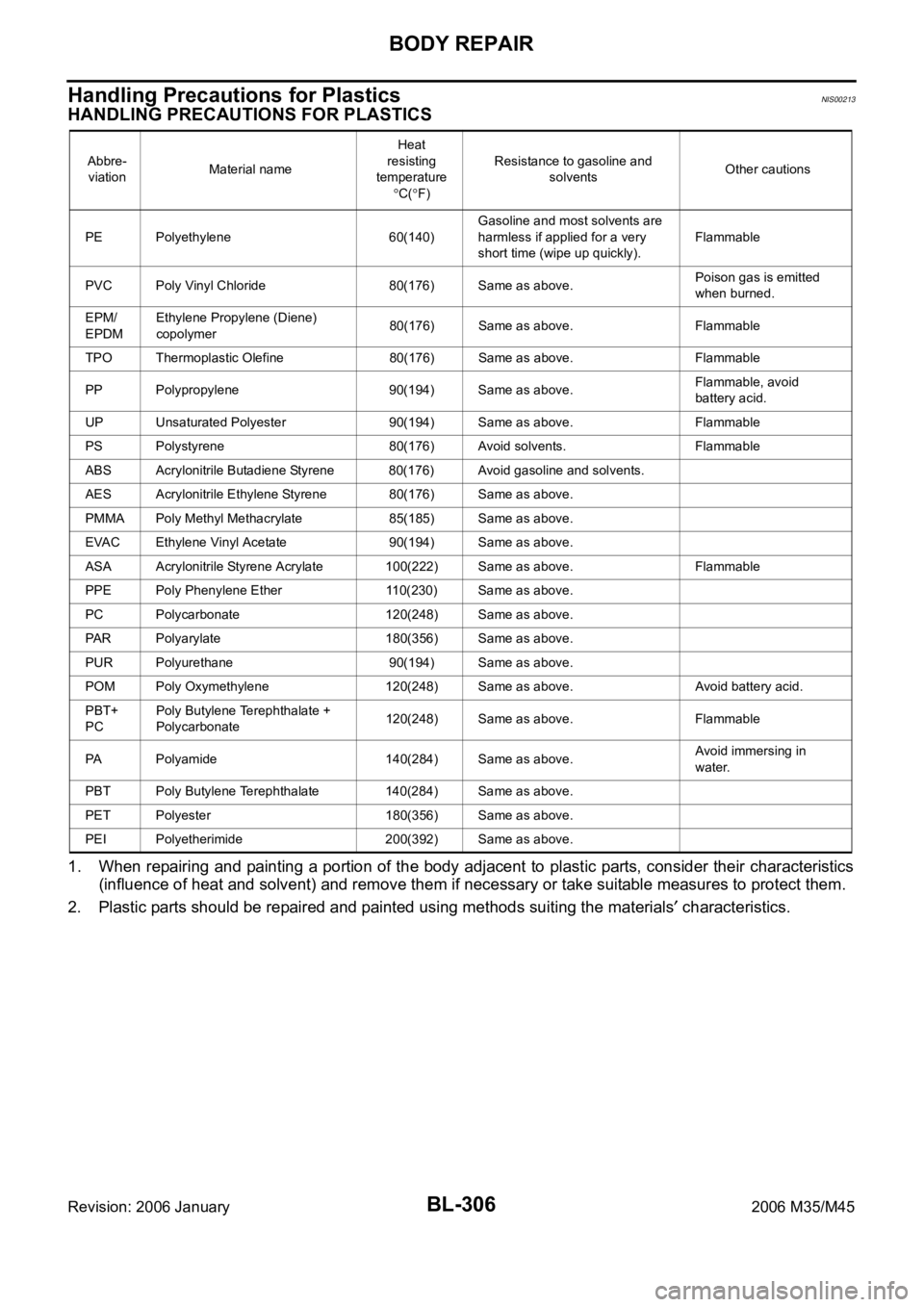

Handling Precautions for PlasticsNIS00213

HANDLING PRECAUTIONS FOR PLASTICS

1. When repairing and painting a portion of the body adjacent to plastic parts, consider their characteristics

(influence of heat and solvent) and remove them if necessary or take suitable measures to protect them.

2. Plastic parts should be repaired and painted using methods suiting the materials

characteristics.

Abbre-

viationMaterial nameHeat

resisting

temperature

C(F)Resistance to gasoline and

solventsOther cautions

PE Polyethylene 60(140)Gasoline and most solvents are

harmless if applied for a very

short time (wipe up quickly).Flammable

PVC Poly Vinyl Chloride 80(176) Same as above.Poison gas is emitted

when burned.

EPM/

EPDMEthylene Propylene (Diene)

copolymer80(176) Same as above. Flammable

TPO Thermoplastic Olefine 80(176) Same as above. Flammable

PP Polypropylene 90(194) Same as above.Flammable, avoid

battery acid.

UP Unsaturated Polyester 90(194) Same as above. Flammable

PS Polystyrene 80(176) Avoid solvents. Flammable

ABS Acrylonitrile Butadiene Styrene 80(176) Avoid gasoline and solvents.

AES Acrylonitrile Ethylene Styrene 80(176) Same as above.

PMMA Poly Methyl Methacrylate 85(185) Same as above.

EVAC Ethylene Vinyl Acetate 90(194) Same as above.

ASA Acrylonitrile Styrene Acrylate 100(222) Same as above. Flammable

PPE Poly Phenylene Ether 110(230) Same as above.

PC Polycarbonate 120(248) Same as above.

PAR Polyarylate 180(356) Same as above.

PUR Polyurethane 90(194) Same as above.

POM Poly Oxymethylene 120(248) Same as above. Avoid battery acid.

PBT+

PCPoly Butylene Terephthalate +

Polycarbonate120(248) Same as above. Flammable

PA Polyamide 140(284) Same as above.Avoid immersing in

water.

PBT Poly Butylene Terephthalate 140(284) Same as above.

PET Polyester 180(356) Same as above.

PEI Polyetherimide 200(392) Same as above.

Page 1278 of 5621

PRECAUTIONS

BR-3

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

NFS000ON

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WAR NING :

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

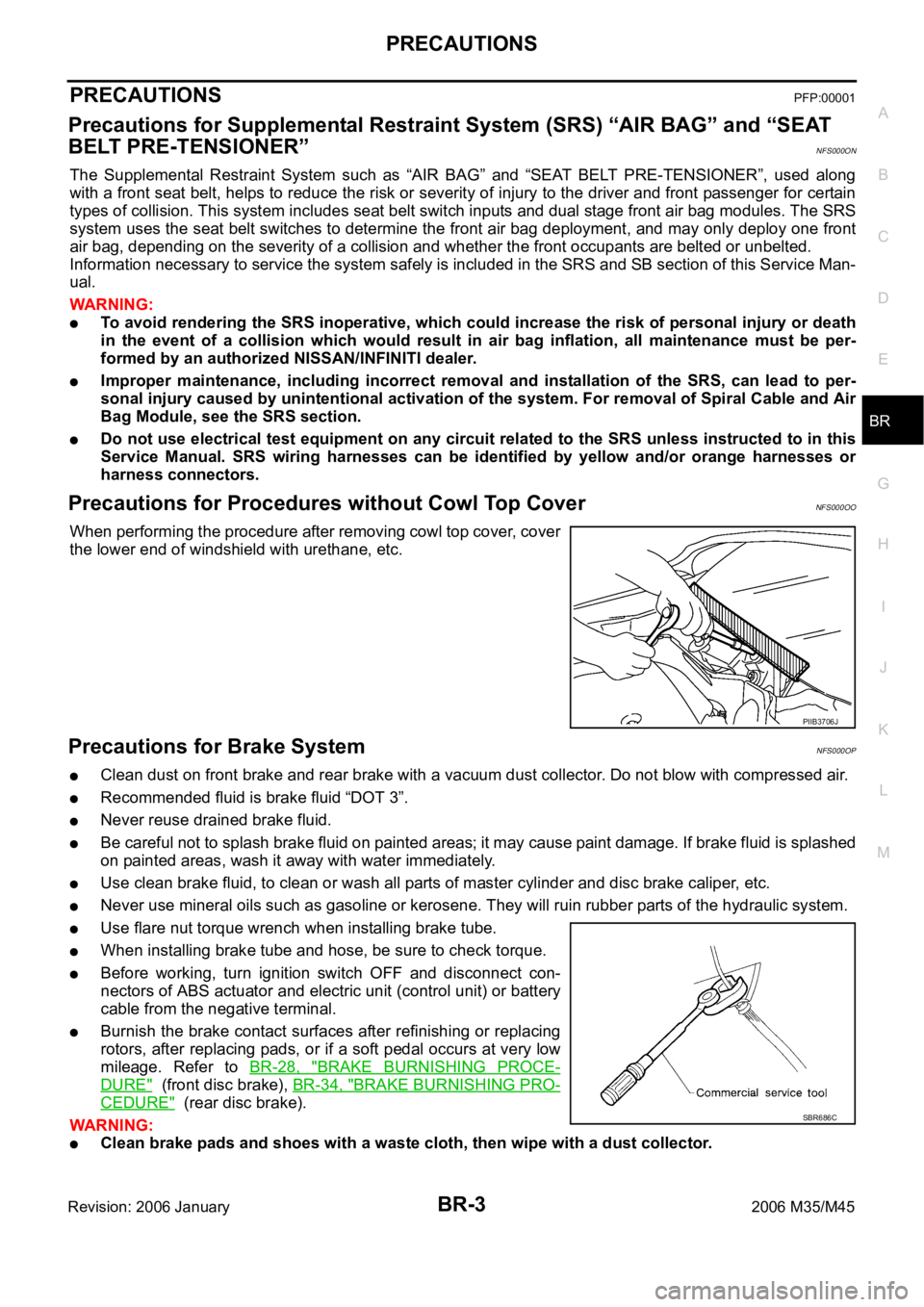

Precautions for Procedures without Cowl Top CoverNFS000OO

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions for Brake SystemNFS000OP

Clean dust on front brake and rear brake with a vacuum dust collector. Do not blow with compressed air.

Recommended fluid is brake fluid “DOT 3”.

Never reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed

on painted areas, wash it away with water immediately.

Use clean brake fluid, to clean or wash all parts of master cylinder and disc brake caliper, etc.

Never use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

Use flare nut torque wrench when installing brake tube.

When installing brake tube and hose, be sure to check torque.

Before working, turn ignition switch OFF and disconnect con-

nectors of ABS actuator and electric unit (control unit) or battery

cable from the negative terminal.

Burnish the brake contact surfaces after refinishing or replacing

rotors, after replacing pads, or if a soft pedal occurs at very low

mileage. Refer to BR-28, "

BRAKE BURNISHING PROCE-

DURE" (front disc brake), BR-34, "BRAKE BURNISHING PRO-

CEDURE" (rear disc brake).

WAR NING :

Clean brake pads and shoes with a waste cloth, then wipe with a dust collector.

PIIB3706J

SBR686C

Page 1285 of 5621

BR-10

BRAKE FLUID

Revision: 2006 January2006 M35/M45

BRAKE FLUIDPFP:KN100

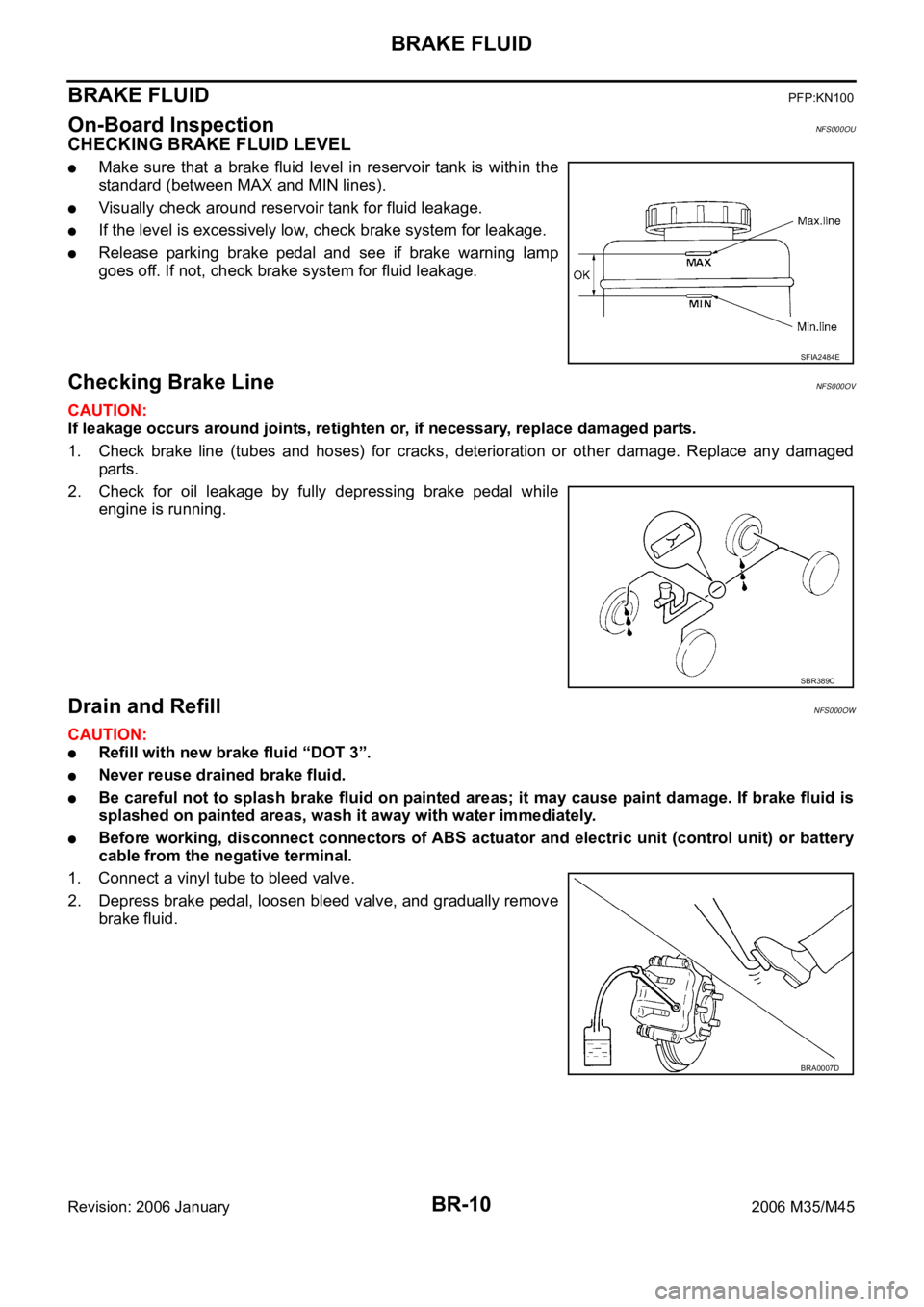

On-Board Inspection NFS000OU

CHECKING BRAKE FLUID LEVEL

Make sure that a brake fluid level in reservoir tank is within the

standard (between MAX and MIN lines).

Visually check around reservoir tank for fluid leakage.

If the level is excessively low, check brake system for leakage.

Release parking brake pedal and see if brake warning lamp

goes off. If not, check brake system for fluid leakage.

Checking Brake LineNFS000OV

CAUTION:

If leakage occurs around joints, retighten or, if necessary, replace damaged parts.

1. Check brake line (tubes and hoses) for cracks, deterioration or other damage. Replace any damaged

parts.

2. Check for oil leakage by fully depressing brake pedal while

engine is running.

Drain and RefillNFS000OW

CAUTION:

Refill with new brake fluid “DOT 3”.

Never reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

Before working, disconnect connectors of ABS actuator and electric unit (control unit) or battery

cable from the negative terminal.

1. Connect a vinyl tube to bleed valve.

2. Depress brake pedal, loosen bleed valve, and gradually remove

brake fluid.

SFIA2484E

SBR389C

BRA0007D

Page 1286 of 5621

BRAKE FLUID

BR-11

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

3. Make sure there is no foreign material in the reservoir tank, and

refill with new brake fluid.

4. Loosen bleed valve, depress brake pedal slowly to full stroke

and then release it. Repeat the procedure every 2 or 3 seconds

until the new brake fluid comes out, then close the bleed valve

while depressing the pedal. Repeat the same work for each

wheel.

5. Bleed air. Refer to BR-11, "

Bleeding Brake System" .

Bleeding Brake System NFS000OX

CAUTION:

While bleeding, pay attention to master cylinder fluid level.

Before working, disconnect connectors of ABS actuator and electric unit (control unit) or battery

cable from the negative terminal.

1. Connect a vinyl tube to rear right brake caliper bleed valve.

2. Fully depress brake pedal 4 or 5 times.

3. With brake pedal depressed, loosen bleed valve to bleed air in brake line, and then tighten it immediately.

4. Repeat steps 2 and 3 until all of the air is out of the brake line.

5. Tighten the bleed valve to the specified torque. Refer to front disc brake: BR-23, "

Components" , rear disc

brake: BR-29, "

Components" .

6. From step 1 to 5, with master cylinder reservoir tank filled at least half way, bleed air from brake hydraulic

line bleed valves in the following order:

Rear right brake

Front left brakeRear left brakeFront right brake

PFIA0403J

Page 1312 of 5621

BRC-1

BRAKE CONTROL SYSTEM

F BRAKES

CONTENTS

C

D

E

G

H

I

J

K

L

M

SECTION BRC

A

B

BRC

Revision: 2006 January2006 M35/M45

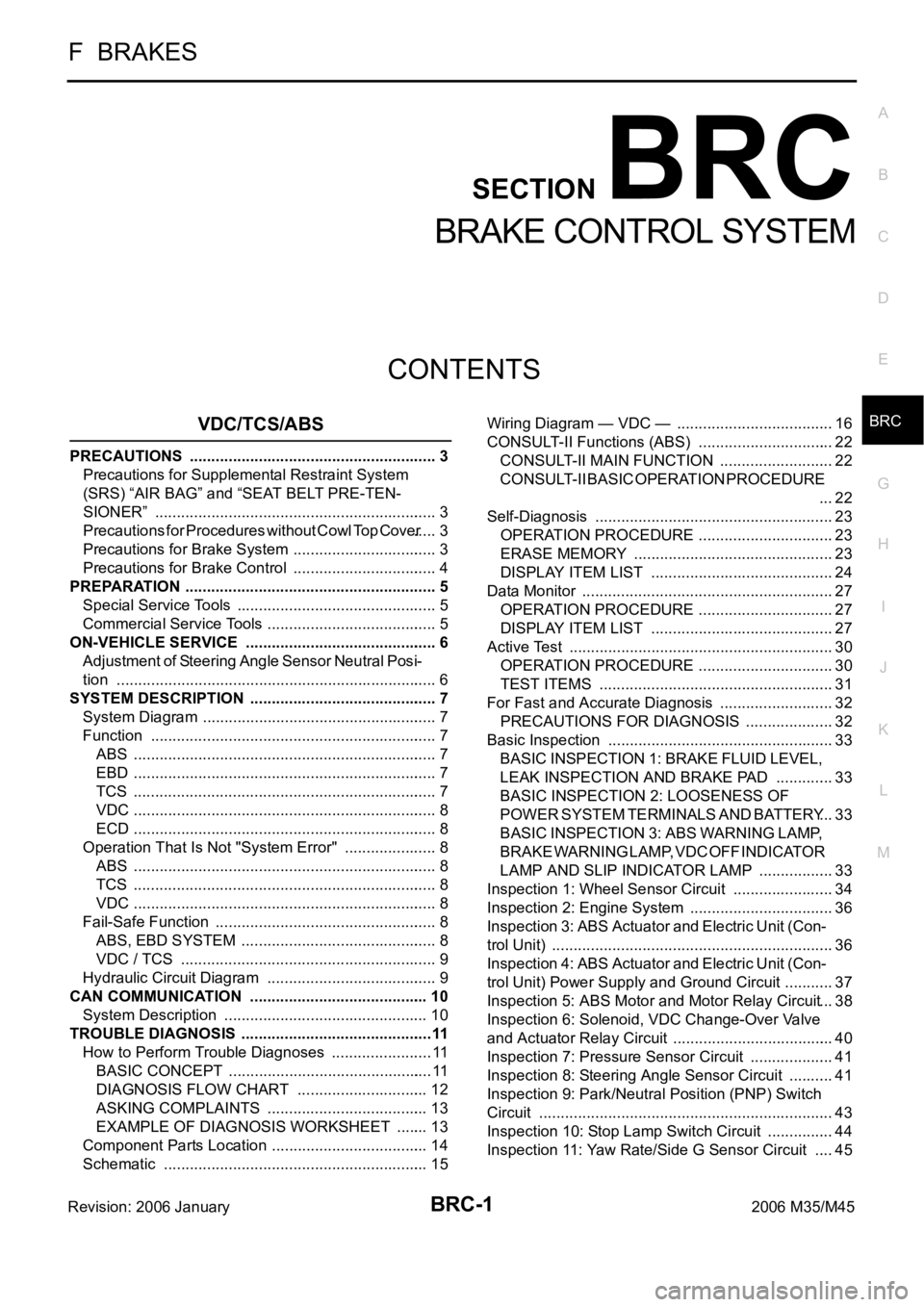

BRAKE CONTROL SYSTEM

VDC/TCS/ABS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for Procedures without Cowl Top Cover ..... 3

Precautions for Brake System .................................. 3

Precautions for Brake Control .................................. 4

PREPARATION ........................................................... 5

Special Service Tools ............................................... 5

Commercial Service Tools ........................................ 5

ON-VEHICLE SERVICE ............................................. 6

Adjustment of Steering Angle Sensor Neutral Posi-

tion ........................................................................... 6

SYSTEM DESCRIPTION ............................................ 7

System Diagram ....................................................... 7

Function ................................................................... 7

ABS ....................................................................... 7

EBD ....................................................................... 7

TCS ....................................................................... 7

VDC ....................................................................... 8

ECD ....................................................................... 8

Operation That Is Not "System Error" ...................... 8

ABS ....................................................................... 8

TCS ....................................................................... 8

VDC ....................................................................... 8

Fail-Safe Function .................................................... 8

ABS, EBD SYSTEM .............................................. 8

VDC / TCS ............................................................ 9

Hydraulic Circuit Diagram ........................................ 9

CAN COMMUNICATION .......................................... 10

System Description ................................................ 10

TROUBLE DIAGNOSIS .............................................11

How to Perform Trouble Diagnoses ........................ 11

BASIC CONCEPT ................................................ 11

DIAGNOSIS FLOW CHART ............................... 12

ASKING COMPLAINTS ...................................... 13

EXAMPLE OF DIAGNOSIS WORKSHEET ........ 13

Component Parts Location ..................................... 14

Schematic .............................................................. 15Wiring Diagram — VDC — ..................................... 16

CONSULT-II Functions (ABS) ................................ 22

CONSULT-II MAIN FUNCTION ........................... 22

CONSULT-II BASIC OPERATION PROCEDURE

... 22

Self-Diagnosis .....................................................

... 23

OPERATION PROCEDURE ................................ 23

ERASE MEMORY ............................................... 23

DISPLAY ITEM LIST ........................................... 24

Data Monitor ........................................................... 27

OPERATION PROCEDURE ................................ 27

DISPLAY ITEM LIST ........................................... 27

Active Test .............................................................. 30

OPERATION PROCEDURE ................................ 30

TEST ITEMS ....................................................... 31

For Fast and Accurate Diagnosis ........................... 32

PRECAUTIONS FOR DIAGNOSIS ..................... 32

Basic Inspection ..................................................... 33

BASIC INSPECTION 1: BRAKE FLUID LEVEL,

LEAK INSPECTION AND BRAKE PAD .............. 33

BASIC INSPECTION 2: LOOSENESS OF

POWER SYSTEM TERMINALS AND BATTERY ... 33

BASIC INSPECTION 3: ABS WARNING LAMP,

BRAKE WARNING LAMP, VDC OFF INDICATOR

LAMP AND SLIP INDICATOR LAMP .................. 33

Inspection 1: Wheel Sensor Circuit ........................ 34

Inspection 2: Engine System .................................. 36

Inspection 3: ABS Actuator and Electric Unit (Con-

trol Unit) .................................................................. 36

Inspection 4: ABS Actuator and Electric Unit (Con-

trol Unit) Power Supply and Ground Circuit ............ 37

Inspection 5: ABS Motor and Motor Relay Circuit ... 38

Inspection 6: Solenoid, VDC Change-Over Valve

and Actuator Relay Circuit ...................................... 40

Inspection 7: Pressure Sensor Circuit .................... 41

Inspection 8: Steering Angle Sensor Circuit ........... 41

Inspection 9: Park/Neutral Position (PNP) Switch

Circuit ..................................................................... 43

Inspection 10: Stop Lamp Switch Circuit ................ 44

Inspection 11: Yaw Rate/Side G Sensor Circuit ..... 45

Page 1335 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-24

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DISPLAY ITEM LIST

Code Display item Malfunction detecting condition Check item

C1101 RR RH SENSOR-1Circuit of rear RH wheel se INFINITI M35 2006 Factory Service Manual BRC-24

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DISPLAY ITEM LIST

Code Display item Malfunction detecting condition Check item

C1101 RR RH SENSOR-1Circuit of rear RH wheel se](/img/42/57023/w960_57023-1334.png)

BRC-24

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DISPLAY ITEM LIST

Code Display item Malfunction detecting condition Check item

C1101 RR RH SENSOR-1Circuit of rear RH wheel sensor is open. Or when the sensor

power voltage is outside the standard.

BRC-34,

"Inspection 1:

Wheel Sensor

Circuit"

(Note 1) C1102 RR LH SENSOR-1Circuit of rear LH wheel sensor is open. Or when the sensor

power voltage is outside the standard.

C1103 FR RH SENSOR-1Circuit of front RH wheel sensor is open. Or when the sensor

power voltage is outside the standard.

C1104 FR LH SENSOR-1Circuit of front LH wheel sensor is open. Or when the sensor

power voltage is outside the standard.

C1105 RR RH SENSOR-2When the circuit in the rear RH wheel sensor is short-circuited.

Or when the distance between the wheel sensor and sensor rotor

is too large and the sensor pulse cannot be recognized by the

control unit.

C1106 RR LH SENSOR-2When the circuit in the rear LH wheel sensor is short-circuited. Or

when the distance between the wheel sensor and sensor rotor is

too large and the sensor pulse cannot be recognized by the con-

trol unit.

C1107 FR RH SENSOR-2When the circuit in the front RH wheel sensor is short-circuited.

Or when the distance between the wheel sensor and sensor rotor

is too large and the sensor pulse cannot be recognized by the

control unit.

C1108 FR LH SENSOR- 2When the circuit in the front LH wheel sensor is short-circuited.

Or when the distance between the wheel sensor and sensor rotor

is too large and the sensor pulse cannot be recognized by the

control unit.

C1109BATTERY VOLTAGE

[ABNORMAL]When the ABS actuator and electric unit (control unit) power sup-

ply voltage is lower than normal.BRC-37,

"Inspection 4:

ABS Actuator

and Electric Unit

(Control Unit)

Power Supply

and Ground Cir-

cuit"

C1110 CONTROLLER FAILUREWhen there is an internal malfunction in the ABS actuator and

electric unit (control unit).BRC-36,

"Inspection 3:

ABS Actuator

and Electric Unit

(Control Unit)"

C 1111 P U M P M O T O RDuring the actuator motor operating with ON, when the actuator

motor turns OFF, or when the control line for actuator motor relay

is open.BRC-38,

"Inspection 5:

ABS Motor and

Motor Relay Cir-

cuit"

During the actuator motor operating with OFF, when the actuator

motor turns ON, or when the control line for relay is shorted to

ground.

C1114 MAIN RELAYDuring the actuator relay operating with OFF, when the actuator

relay turns ON. Or when the control line for the relay is shorted to

the ground.BRC-40,

"Inspection 6:

Solenoid, VDC

Change-Over

Valve and Actua-

tor Relay Circuit"

During the actuator relay operating with ON, when the actuator

relay turns OFF, or when the control line for the relay is open.

C 111 5ABS SENSOR

[ABNORMAL SIGNAL]When wheel sensor input signal is malfunctioning.BRC-34,

"Inspection 1:

Wheel Sensor

Circuit"

(Note 1)

Page 1338 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-27

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

Data MonitorNFS000QH

OPERATION PROCEDURE

1. Touch “START (NISSAN BASED VHCL)”, “ABS”, “DA INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-27

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

Data MonitorNFS000QH

OPERATION PROCEDURE

1. Touch “START (NISSAN BASED VHCL)”, “ABS”, “DA](/img/42/57023/w960_57023-1337.png)

TROUBLE DIAGNOSIS

BRC-27

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

Data MonitorNFS000QH

OPERATION PROCEDURE

1. Touch “START (NISSAN BASED VHCL)”, “ABS”, “DATA MONITOR” in order on CONSULT-II screen.

CAUTION:

When “START (NISSAN BASED VHCL)” is touched immediately after starting engine or turning on

the ignition switch, “ABS” might not be displayed in the system selection screen. In this case,

repeat the operation from step 1.

2. At the monitor item selection screen, touch one of the items “ECU INPUT SIGNALS”, “MAIN SIGNALS” or

“SELECTION FROM MENU”.

3. Touch “START” to proceed to the data monitor screen.

DISPLAY ITEM LIST

CAUTION:

The display shows the control unit calculation data, so a normal value might be displayed even in the

event the output circuit (harness) is open or short - circuited.

E: ECU INPUT SIGNALS M: MAIN SIGNALS S: SELECTION FROM MENU

SELECT

MONITOR

ITEM Monitor item Display contentData monitor

ConditionReference value in

normal operation

E, M, SFR LH SENSOR

FR RH SENSOR

RR LH SENSOR

RR RH SENSORWheel speed0 [km/h] Vehicle stopped

Nearly matches the speed

meter display (

10 % or

less)Vehicle running

(Note 1)

E, M, S STOP LAMP SW Brake pedal operationWhen brake pedal is

depressedON

When brake pedal is not

depressedOFF

E, M, S BATTERY VOLTBattery voltage supplied to the ABS

actuator and electric unit (control

unit)Ignition switch ON 10 – 16 V

E, M, S GEAR Gear position determined by TCM1st gear

2nd gear

3rd gear

4th gear

5th gear1

2

3

4

5

E, M, S SLCT LVR POSI A/T shift positionP position

R position

N position

D positionP

R

N

D

E, M, S OFF SW VDC OFF switch ON/OFFVDC OFF switch ON

(When VDC OFF indicator

lamp is ON)ON

VDC OFF switch OFF

(When VDC OFF indicator

lamp is OFF)OFF

E, M, S YAW RATE SENYaw rate detected by yaw rate/side

G sensorWhen vehicle stop Approx. 0 d/s

When vehicle turning (-75 to 75 d/s)

E, M, S4WD MODE MON

(Note 2)AWD activated Engine running AUTO

E, S ACCEL POS SIG Throttle actuator opening/closing is

displayed (linked with accelerator

pedal)Accelerator pedal not

depressed (ignition switch

is ON)0 %

Depress accelerator pedal

(ignition switch is ON)0 - 100 %

Page 1344 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-33

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

Basic InspectionNFS000QK

BASIC INSPECTION 1: BRAKE FLUID LEVEL, LEAK INSPECTION AND BRAKE PAD

1. C INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-33

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

Basic InspectionNFS000QK

BASIC INSPECTION 1: BRAKE FLUID LEVEL, LEAK INSPECTION AND BRAKE PAD

1. C](/img/42/57023/w960_57023-1343.png)

TROUBLE DIAGNOSIS

BRC-33

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

Basic InspectionNFS000QK

BASIC INSPECTION 1: BRAKE FLUID LEVEL, LEAK INSPECTION AND BRAKE PAD

1. Check fluid level in brake reservoir tank. If fluid level is low, refill brake fluid. Refer to BR-10, "CHECKING

BRAKE FLUID LEVEL" .

2. Check for leakage in brake tubes or hoses and around ABS actuator and electric unit (control unit). If

there is leaking or seeping fluid, check the following items.

If the brake tube connections at ABS actuator and electric unit (control unit) are loose, tighten flare nuts

to the specified torque. Then inspect again and confirm that there is no leakage.

If flare nuts or screws of ABS actuator and electric unit (control unit) are damaged and loose, replace

damaged parts. Then inspect again and confirm that there is no leakage.

If there is leakage at any location other than ABS actuator and electric unit (control unit) connections,

wipe away leakage with clean cloth. Then inspect again and confirm that there is no leakage.

If there is leakage from ABS actuator and electric unit (control unit), wipe away leakage with clean cloth.

Then inspect again. If there is still leakage, replace ABS actuator and electric unit (control unit).

CAUTION:

ABS actuator and electric unit (control unit) cannot be disassembled.

3. Check brake disc rotor and pads. Refer to BR-28, "

DISC ROTOR INSPECTION" (front disc rotor), BR-23,

"PAD WEAR INSPECTION" (front brake pad), BR-34, "DISC ROTOR INSPECTION" (rear disc rotor), BR-

29, "PAD WEAR INSPECTION" (rear brake pad).

BASIC INSPECTION 2: LOOSENESS OF POWER SYSTEM TERMINALS AND BATTERY

Check battery for looseness on battery positive/negative terminals and ground connection. Also make sure

battery voltage does not drop and alternator is normal.

BASIC INSPECTION 3: ABS WARNING LAMP, BRAKE WARNING LAMP, VDC OFF INDICATOR

LAMP AND SLIP INDICATOR LAMP

ON and OFF Timing for Warning Lamp and Indicator Lamp

: ON –: OFF

Note1: Brake warning lamp will turn on in case of parking brake operation (when switch is ON) or of brake fluid level switch operation

(when brake fluid is insufficient).

Note2: After starting engine, brake warning lamp is turned off.

Check the following items when unsuitable for an above condition.

ABS warning lamp: BRC-51, "Inspection 16: CAN Communication Circuit"

Brake warning lamp: BRC-51, "Inspection 16: CAN Communication Circuit" , BRC-48, "Inspection 12:

Brake Fluid Level Switch Circuit" , BRC-52, "Inspection 18: Parking Brake Switch Circuit"

VDC OFF indicator lamp:BRC-51, "Inspection 16: CAN Communication Circuit" , BRC-51, "Inspection 17:

VDC OFF Switch Circuit"

SLIP indicator lamp: BRC-51, "Inspection 16: CAN Communication Circuit"

If malfunction is not found, refer to BRC-53, "Inspection 19: Warning Lamp and Indicator Lamp Circuit" .

Condition ABS warning lampVDC OFF

indicator lampSLIP indicator lampBrake warning lamp

[Note1]

Ignition SW OFF – – – –

For 1 second after turning ON igni-

tion switch

[Note 2]

1 second later after turning ON

ignition switch–––

[Note 2]

VDC OFF switch turned ON. (VDC

function is OFF.)–

––

VDC/TCS function is malfunction-

ing.–

–

ABS function is malfunctioning.

–

EBD function is malfunctioning.

Page 1348 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-37

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

Inspection 4: ABS Actuator and Electric Unit (Control Unit) Power Supply and

Ground Circuit

NFS000 INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-37

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

Inspection 4: ABS Actuator and Electric Unit (Control Unit) Power Supply and

Ground Circuit

NFS000](/img/42/57023/w960_57023-1347.png)

TROUBLE DIAGNOSIS

BRC-37

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

Inspection 4: ABS Actuator and Electric Unit (Control Unit) Power Supply and

Ground Circuit

NFS000QO

INSPECTION PROCEDURE

1. CHECK SELF-DIAGNOSIS RESULTS

Check self-diagnosis results.

Is above displayed on the self-diagnosis display?

YES >> GO TO 2.

NO >> INSPECTION END

2. CHECK CONNECTOR

1. Turn ignition switch OFF and disconnect ABS actuator and electric unit (control unit) connector E30,

check terminal for deformation, disconnection, looseness, and so on. If any malfunction is found, repair or

replace terminal.

2. Reconnect connector and perform self-diagnosis.

OK or NG

OK >> INSPECTION END

NG >> GO TO 3.

3. CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) POWER SUPPLY CIRCUIT AND

GROUND CIRCUIT

1. Turn ignition switch OFF and disconnect ABS actuator and electric unit (control unit) connector E30.

2. Turn ignition switch ON or OFF and check voltage between ABS

actuator and electric unit (control unit) harness connector E30

terminal 28 and ground.

Self-diagnosis results

BATTERY VOLTAGE [ABNORMAL]

SFIA3032E

ABS actuator and electric unit (control unit) Ground Condition Voltage

28 —Ignition switch ONBattery voltage

(Approx. 12 V)

Ignition switch OFF Approx. 0 V

Page 1349 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-38

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

3. Turn ignition switch OFF and check continuity between ABS

actuator and electric unit (control unit) harness connector E30

t INFINITI M35 2006 Factory Service Manual BRC-38

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

3. Turn ignition switch OFF and check continuity between ABS

actuator and electric unit (control unit) harness connector E30

t](/img/42/57023/w960_57023-1348.png)

BRC-38

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

3. Turn ignition switch OFF and check continuity between ABS

actuator and electric unit (control unit) harness connector E30

terminal 1, 4 and ground.

OK or NG

OK >>Check battery for terminal looseness, low voltage, etc. If any malfunction is found, repair mal-

functioning parts.

Perform the self-diagnosis, and make sure that the result shows NO DTC IS DETECTED.

NG >>

Repair or replace malfunctioning components.

Perform the self-diagnosis, and make sure that the result shows NO DTC IS DETECTED.

Inspection 5: ABS Motor and Motor Relay CircuitNFS000QP

INSPECTION PROCEDURE

1. CHECK SELF-DIAGNOSIS RESULTS

Check self-diagnosis results.

Is above displayed on the self-diagnosis display?

YES >> GO TO 2.

NO >> INSPECTION END

2. CHECK CONNECTOR

1. Turn ignition switch OFF and disconnect ABS actuator and electric unit (control unit) connector E30,

check terminal for deformation, disconnection, looseness, and so on. If any malfunction is found, repair or

replace terminal.

2. Reconnect connector and perform self-diagnosis.

OK or NG

OK >> INSPECTION END

NG >> GO TO 3.

SFIA3033E

ABS actuator and electric unit (control unit) Ground Continuity

1, 4 — Yes

Self-diagnosis results

PUMP MOTOR