tire pressure INFINITI M35 2006 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3182 of 5621

![INFINITI M35 2006 Factory Owners Manual ENGINE ASSEMBLY

EM-119

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

If items or work required are not covered by the engine section, refer to the applicable sections.

Always u INFINITI M35 2006 Factory Owners Manual ENGINE ASSEMBLY

EM-119

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

If items or work required are not covered by the engine section, refer to the applicable sections.

Always u](/img/42/57023/w960_57023-3181.png)

ENGINE ASSEMBLY

EM-119

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

If items or work required are not covered by the engine section, refer to the applicable sections.

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for

unavoidable reasons, support at rear axle jacking point with transmission jack or similar tool

before starting work, in preparation for the backward shift of center of gravity.

For supporting points for lifting and jacking point at rear axle, refer to GI-42, "Garage Jack and

Safety Stand and 2-Pole Lift" .

REMOVAL

Outline

At first, remove the engine, the transmission assembly, the transfer assembly and the front final drive assem-

bly with front suspension member from vehicle downward. Then separate the engine, the transmission assem-

bly, the transfer and the front final drive assembly.

Preparation

1. Release fuel pressure. Refer to EC-98, "FUEL PRESSURE RELEASE" .

2. Drain engine coolant from radiator. Refer to CO-11, "

Changing Engine Coolant" .

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belts.

3. Disconnect both battery terminals. Refer to SC-4, "

BATTERY" .

4. Remove the following parts:

Engine room cover (RH and LH); Refer to EM-14, "ENGINE ROOM COVER" .

Engine cover; Refer to EM-19, "INTAKE MANIFOLD COLLECTOR" .

Front road wheel and tires (power tool)

Front and rear engine undercover (power tool)

Front cross bar; Refer to FSU-23, "FRONT SUSPENSION ASSEMBLY" .

Cowl top cover (RH); Refer to EI-18, "COWL TOP" .

Air duct and air cleaner case assembly; EM-17, "AIR CLEANER AND AIR DUCT" .

5. Discharge refrigerant from A/C circuit. Refer to ATC-151, "

REFRIGERANT LINES" .

6. Remove radiator hoses (upper and lower). Refer to CO-14, "

RADIATOR" .

Engine Room LH

1. Disconnect heater hose from vehicle-side, and fit a plug onto hose end to prevent engine coolant leak.

2. Disconnect wire bonding (between vehicle to left bank cylinder head).

3. Disconnect A/C piping from A/C compressor, and temporarily fasten it on vehicle with a rope. Refer to

AT C - 1 5 1 , "

REFRIGERANT LINES" .

4. Disconnect brake booster vacuum hose.

Engine Room RH

1. Disconnect battery positive cable vehicle side and temporarily fasten it on engine.

2. Disconnect grounding cables.

3. Disconnect fuel feed hose (with damper) and EVAP hose. Refer to EM-45, "

FUEL INJECTOR AND FUEL

TUBE" .

CAUTION:

Fit plugs onto disconnected hoses to prevent fuel leak.

4. Remove reservoir tank of power steering oil pump and piping from vehicle, and temporarily secure them

on engine. Refer to PS-29, "

POWER STEERING OIL PUMP" .

CAUTION:

When temporarily securing, keep the reservoir tank upright to avoid a fluid leak.

Vehicle inSide

Follow procedure below to disconnect engine room harness connectors at passenger room side, and tempo-

rarily secure them on engine.

Page 3308 of 5621

![INFINITI M35 2006 Factory Owners Manual ENGINE ASSEMBLY

EM-245

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type li INFINITI M35 2006 Factory Owners Manual ENGINE ASSEMBLY

EM-245

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type li](/img/42/57023/w960_57023-3307.png)

ENGINE ASSEMBLY

EM-245

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for

unavoidable reasons, support at the rear axle jacking point with transmission jack or similar tool

before starting work, in preparation for the backward shift of center of gravity.

For supporting points for lifting and jacking point at rear axle, refer to GI-42, "Garage Jack and

Safety Stand and 2-Pole Lift" .

REMOVAL

Outline

At first, remove engine, transmission assembly with front suspension member from vehicle downward. Then

separate engine from transmission.

Preparation

1. Release fuel pressure. Refer to EC-809, "FUEL PRESSURE RELEASE" .

2. Drain engine coolant from radiator. Refer to CO-40, "

Changing Engine Coolant" .

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belts.

3. Disconnect both battery cables. Refer to SC-4, "

BATTERY" .

4. Remove crankshaft position sensor (POS) from transmission.

CAUTION:

Handle carefully to avoid dropping and shocks.

Do not disassemble.

Do not allow metal powder to adhere to magnetic part at sensor tip.

Do not place sensors in a location where they are exposed to magnetism.

5. Remove the following parts:

Front and rear engine undercover (power tool)

Air duct (inlet), air duct and air cleaner case assembly; Refer to EM-177, "AIR CLEANER AND AIR

DUCT" .

Front road wheels and tires (power tool)

Engine Room LH

1. Disconnect heater hoses, and install plugs to avoid leakage of engine coolant.

2. Disconnect wire bonding from exhaust manifold cover to vehicle.

3. Disconnect vacuum hose between vehicle and engine and set it aside.

4. Discharge refrigerant from A/C circuit. Refer to ATC-151, "

REFRIGERANT LINES" .

5. Remove A/C piping from A/C compressor, and temporarily fasten it on vehicle with a rope. Refer to AT C -

151, "REFRIGERANT LINES" .

Engine Room RH

1. Disconnect fuel feed hose and EVAP hose. Refer to EM-193, "FUEL INJECTOR AND FUEL TUBE" .

CAUTION:

Fit plugs onto disconnected hose to prevent fuel leak.

2. Disconnect ground cable (between vehicle and right bank cylinder head).

3. Disconnect vacuum hose between vehicle and engine and set it aside.

4. Disconnect reservoir tank of power steering oil pump from engine, and move it aside for easier work.

CAUTION:

When temporarily securing, keep reservoir tank upright to avoid a fluid leak.

Ve h i c le i n s i d e

Follow procedure below to disconnect engine room harness connectors at passenger room side, and tempo-

rarily secure them on engine.

1. Remove passenger-side kicking plate, dash side finisher, and glove box. Refer to EI-37, "

BODY SIDE

TRIM" and IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Disconnect engine room harness connectors at unit sides TCM, ECM and other.

Page 3433 of 5621

![INFINITI M35 2006 Factory Owners Manual FSU-6

[2WD]

FRONT SUSPENSION ASSEMBLY

Revision: 2006 January2006 M35/M45

FRONT SUSPENSION ASSEMBLYPFP:54010

On-Vehicle Inspection and ServiceNES000IA

Make sure the mounting conditions (looseness, INFINITI M35 2006 Factory Owners Manual FSU-6

[2WD]

FRONT SUSPENSION ASSEMBLY

Revision: 2006 January2006 M35/M45

FRONT SUSPENSION ASSEMBLYPFP:54010

On-Vehicle Inspection and ServiceNES000IA

Make sure the mounting conditions (looseness,](/img/42/57023/w960_57023-3432.png)

FSU-6

[2WD]

FRONT SUSPENSION ASSEMBLY

Revision: 2006 January2006 M35/M45

FRONT SUSPENSION ASSEMBLYPFP:54010

On-Vehicle Inspection and ServiceNES000IA

Make sure the mounting conditions (looseness, back lash) of each component and component conditions

(wear, damage) are normal.

INSPECTION OF LOWER BALL JOINT END PLAY

1. Set front wheels in a straight-ahead position. Do not depress brake pedal.

2. Place an iron bar or similar tool between transverse link and steering knuckle.

3. Measure axial end play by prying it up and down.

CAUTION:

Be careful not to damage ball joint boot. Do not damage the installation position by applying

excessive force.

SHOCK ABSORBER INSPECTION

Check for oil leakage, damage and breakage of installation positions.

Wheel Alignment InspectionNES000IB

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY CHECK

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-6, "

ROAD WHEEL" .

3. Wheel bearing axial end play. Refer to FAX-5, "

WHEEL BEARING INSPECTION" .

4. Transverse link ball joint axial end play. Refer to FSU-14, "

INSPECTION AFTER REMOVAL" .

5. Shock absorber operation.

6. Each mounting part of axle and suspension for looseness and deformation.

7. Each of suspension member, shock absorber, upper link and transverse link for cracks, deformation and

other damage.

8. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

A four-wheel thrust alignment should be performed.

–This type of alignment is recommended for any NISSAN/INFINITI vehicle.

–The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel is

centered.

–The alignment rack itself should be capable of accepting any NISSAN/INFINITI vehicle.

–The rack should be checked to ensure that it is level.

Make sure the machine is properly calibrated.

–Your alignment equipment should be regularly calibrated in order to give correct information.

–Check with the manufacturer of your specific equipment for their recommended Service/Calibration

Schedule.Axial end play : 0 mm (0 in)

Page 3450 of 5621

![INFINITI M35 2006 Factory Owners Manual FRONT SUSPENSION ASSEMBLY

FSU-23

[AWD]

C

D

F

G

H

I

J

K

L

MA

B

FSU

Revision: 2006 January2006 M35/M45

FRONT SUSPENSION ASSEMBLYPFP:54010

On-Vehicle Inspection and ServiceNES000IQ

Make sure the mount INFINITI M35 2006 Factory Owners Manual FRONT SUSPENSION ASSEMBLY

FSU-23

[AWD]

C

D

F

G

H

I

J

K

L

MA

B

FSU

Revision: 2006 January2006 M35/M45

FRONT SUSPENSION ASSEMBLYPFP:54010

On-Vehicle Inspection and ServiceNES000IQ

Make sure the mount](/img/42/57023/w960_57023-3449.png)

FRONT SUSPENSION ASSEMBLY

FSU-23

[AWD]

C

D

F

G

H

I

J

K

L

MA

B

FSU

Revision: 2006 January2006 M35/M45

FRONT SUSPENSION ASSEMBLYPFP:54010

On-Vehicle Inspection and ServiceNES000IQ

Make sure the mounting conditions (looseness, back lash) of each component and component conditions

(wear, damage) are normal.

INSPECTION OF LOWER BALL JOINT END PLAY

1. Set front wheels in a straight-ahead position. Do not depress brake pedal.

2. Place an iron bar or similar tool between transverse link and steering knuckle.

3. Measure axial end play by prying it up and down.

CAUTION:

Be careful not to damage ball joint boot. Do not damage the installation position by applying

excessive force.

SHOCK ABSORBER INSPECTION

Check for oil leakage, damage and breakage of installation positions.

Wheel Alignment InspectionNES000IR

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY CHECK

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-6, "

ROAD WHEEL" .

3. Wheel bearing axial end play. Refer to FAX-5, "

WHEEL BEARING INSPECTION" .

4. Transverse link ball joint axial end play. Refer to FSU-31, "

INSPECTION AFTER REMOVAL" .

5. Shock absorber operation.

6. Each mounting part of axle and suspension for looseness and deformation.

7. Each of suspension member, shock absorber, upper link and transverse link for cracks, deformation and

other damage.

8. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

A four-wheel thrust alignment should be performed.

–This type of alignment is recommended for any NISSAN/INFINITI vehicle.

–The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel is

centered.

–The alignment rack itself should be capable of accepting any NISSAN/INFINITI vehicle.

–The rack should be checked to ensure that it is level.

Make sure the machine is properly calibrated.

–Your alignment equipment should be regularly calibrated in order to give correct information.

–Check with the manufacturer of your specific equipment for their recommended Service/Calibration

Schedule.Axial end play : 0 mm (0 in)

Page 3646 of 5621

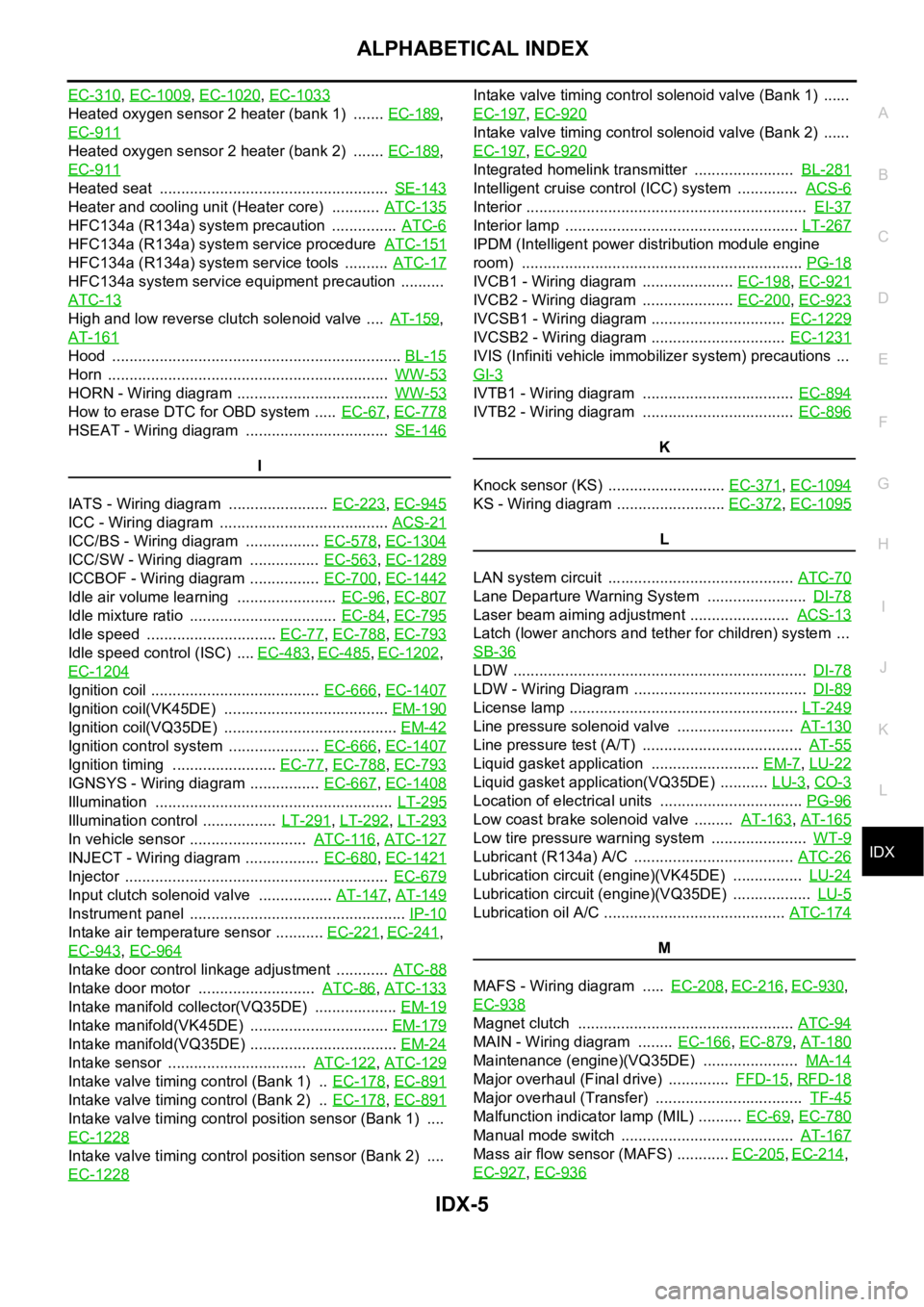

IDX-5

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

EC-310, EC-1009, EC-1020, EC-1033

Heated oxygen sensor 2 heater (bank 1) ....... EC-189,

EC-911

Heated oxygen sensor 2 heater (bank 2) ....... EC-189,

EC-911

Heated seat ..................................................... SE-143

Heater and cooling unit (Heater core) ........... ATC-135

HFC134a (R134a) system precaution ............... ATC-6

HFC134a (R134a) system service procedure ATC-151

HFC134a (R134a) system service tools .......... ATC-17

HFC134a system service equipment precaution ..........

ATC-13

High and low reverse clutch solenoid valve .... AT-159,

AT-161

Hood ................................................................... BL-15

Horn ................................................................. WW-53

HORN - Wiring diagram ................................... WW-53

How to erase DTC for OBD system ..... EC-67, EC-778

HSEAT - Wiring diagram ................................. SE-146

I

IATS - Wiring diagram ....................... EC-223

, EC-945

ICC - Wiring diagram ....................................... ACS-21

ICC/BS - Wiring diagram ................. EC-578, EC-1304

ICC/SW - Wiring diagram ................ EC-563, EC-1289

ICCBOF - Wiring diagram ................ EC-700, EC-1442

Idle air volume learning ....................... EC-96, EC-807

Idle mixture ratio .................................. EC-84, EC-795

Idle speed .............................. EC-77, EC-788, EC-793

Idle speed control (ISC) .... EC-483, EC-485, EC-1202,

EC-1204

Ignition coil ....................................... EC-666, EC-1407

Ignition coil(VK45DE) ...................................... EM-190

Ignition coil(VQ35DE) ........................................ EM-42

Ignition control system ..................... EC-666, EC-1407

Ignition timing ........................ EC-77, EC-788, EC-793

IGNSYS - Wiring diagram ................ EC-667, EC-1408

Illumination ....................................................... LT-295

Illumination control ................. LT-291, LT-292, LT-293

In vehicle sensor ........................... ATC-116, ATC-127

INJECT - Wiring diagram ................. EC-680, EC-1421

Injector ............................................................. EC-679

Input clutch solenoid valve ................. AT-147, AT-149

Instrument panel .................................................. IP-10

Intake air temperature sensor ........... EC-221, EC-241,

EC-943

, EC-964

Intake door control linkage adjustment ............ ATC-88

Intake door motor ........................... ATC-86, ATC-133

Intake manifold collector(VQ35DE) ................... EM-19

Intake manifold(VK45DE) ................................ EM-179

Intake manifold(VQ35DE) .................................. EM-24

Intake sensor ................................ ATC-122, ATC-129

Intake valve timing control (Bank 1) .. EC-178, EC-891

Intake valve timing control (Bank 2) .. EC-178, EC-891

Intake valve timing control position sensor (Bank 1) ....

EC-1228

Intake valve timing control position sensor (Bank 2) ....

EC-1228

Intake valve timing control solenoid valve (Bank 1) ......

EC-197

, EC-920

Intake valve timing control solenoid valve (Bank 2) ......

EC-197

, EC-920

Integrated homelink transmitter ....................... BL-281

Intelligent cruise control (ICC) system .............. ACS-6

Interior ................................................................. EI-37

Interior lamp ...................................................... LT-267

IPDM (Intelligent power distribution module engine

room) ................................................................. PG-18

IVCB1 - Wiring diagram ..................... EC-198, EC-921

IVCB2 - Wiring diagram ..................... EC-200, EC-923

IVCSB1 - Wiring diagram ............................... EC-1229

IVCSB2 - Wiring diagram ............................... EC-1231

IVIS (Infiniti vehicle immobilizer system) precautions ...

GI-3

IVTB1 - Wiring diagram ................................... EC-894

IVTB2 - Wiring diagram ................................... EC-896

K

Knock sensor (KS) ........................... EC-371

, EC-1094

KS - Wiring diagram ......................... EC-372, EC-1095

L

LAN system circuit ........................................... ATC-70

Lane Departure Warning System ....................... DI-78

Laser beam aiming adjustment ....................... ACS-13

Latch (lower anchors and tether for children) system ...

SB-36

LDW .................................................................... DI-78

LDW - Wiring Diagram ........................................ DI-89

License lamp ..................................................... LT-249

Line pressure solenoid valve ........................... AT-130

Line pressure test (A/T) ..................................... AT-55

Liquid gasket application ......................... EM-7, LU-22

Liquid gasket application(VQ35DE) ........... LU-3, CO-3

Location of electrical units ................................. PG-96

Low coast brake solenoid valve ......... AT-163, AT-165

Low tire pressure warning system ...................... WT-9

Lubricant (R134a) A/C ..................................... ATC-26

Lubrication circuit (engine)(VK45DE) ................ LU-24

Lubrication circuit (engine)(VQ35DE) .................. LU-5

Lubrication oil A/C .......................................... ATC-174

M

MAFS - Wiring diagram ..... EC-208

, EC-216, EC-930,

EC-938

Magnet clutch .................................................. ATC-94

MAIN - Wiring diagram ........ EC-166, EC-879, AT-180

Maintenance (engine)(VQ35DE) ...................... MA-14

Major overhaul (Final drive) .............. FFD-15, RFD-18

Major overhaul (Transfer) .................................. TF-45

Malfunction indicator lamp (MIL) .......... EC-69, EC-780

Manual mode switch ........................................ AT-167

Mass air flow sensor (MAFS) ............ EC-205, EC-214,

EC-927

, EC-936

Page 3648 of 5621

IDX-7

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

LT-266

Rear disc brake ................................................. BR-29

Rear door ............................................ BL-190, GW-67

Rear parcel shelf finisher ..................................... EI-42

Rear seat ......................................................... SE-172

Rear seat belt .................................................... SB-32

Rear suspension ............................................... RSU-5

Rear window ..................................................... GW-61

Rear window defogger ...................................... GW-73

Refrigerant connection precaution ..................... ATC-7

Refrigerant discharging evacuating charging ATC-151

Refrigerant general precaution .......................... ATC-7

Refrigerant lines ............................................ ATC-151

Refrigerant pressure sensor ........... EC-692, EC-1434,

ATC-98

, ATC-167

Refrigeration cycle ........................................... ATC-20

Removal and installation (A/T) ........... AT-271, AT-275

Removal and installation (Transfer) .................... TF-44

Reverse interlock door mirror ........................... GW-96

Revolution sensor (A/T) ...................... AT-119, AT-261

Rocker cover(VK45DE) ................................... EM-199

Rocker cover(VQ35DE) ..................................... EM-51

Room lamp - See Interior lamp ......................... LT-267

ROOM/L - Wiring diagram ................................ LT-274

RP/SEN - Wiring diagram ................ EC-693, EC-1435

S

SAE J1979 - Service $01 - 09 ............. EC-54

, EC-764

SEAT - Wiring diagram ...................................... SE-98

Seat belt inspection ........................................... SB-33

Seat belt, front ................................................... SB-30

Seat belt, rear .................................................... SB-32

Seat, rear ......................................................... SE-172

Self-diagnosis (Transfer) .................................... TF-22

SEN/PW - Wiring diagram ............... EC-500, EC-1219

SHIFT - Wiring diagram ................................... AT-230

Shift lock system .............................................. AT-229

Shock absorber (rear) ..................................... RSU-10

Side air bag (satellite) sensor .......................... SRS-46

Side curtain air bag .......................................... SRS-43

Side trim .............................................................. EI-37

SMJ (super multiple junction) .......................... PG-106

Spark plug replacement ..................................... MA-27

Spark plug replacement(VQ35DE) .................... MA-20

Spark plug(VK45DE) ....................................... EM-191

Spark plug(VQ35DE) ......................................... EM-43

Specification value ............................. EC-155, EC-868

Speedometer ........................................................ DI-5

Spiral cable ...................................................... SRS-40

SROOF - Wiring diagram .................................. RF-13

SRS - See Supplemental Restraint System ...... SRS-5

SRS - Wiring diagram ...................................... SRS-12

SRS Trouble diagnoses ..................................... SRS-8

Stabilizer bar (rear) ......................................... RSU-17

Stall test (A/T) .................................................... AT-53

Standardized relay ........................................... PG-109

START - Wiring diagram ................................... SC-11

Starter ................................................................ SC-10

Starting system .................................................. SC-10

Steering gear and linkage inspection ................ MA-36

Steering linkage ................................................. PS-18

Steering wheel and column ................... PS-10, PS-13

Steering wheel turning force .............................. PS-10

Stop lamp .......................................................... LT-243

Stop lamp switch .............................. EC-598, EC-1329

STSIG - Wiring diagram ................................... AT-109

Sun roof, electric ................................................ RF-10

Sunload sensor ............................. ATC-119, ATC-128

Sunroof .................................................. RF-25, RF-28

Sunshade ............................................................ EI-44

Supplemental Restraint System ....................... SRS-5

Supplemental restraint system - Wiring diagram ..........

SRS-12

Suspension ....................................................... MA-37

Symbols and abbreviations ...................... GI-11, GI-24

System readiness test (SRT) code ...... EC-60, EC-770

T

Tachometer ........................................................... DI-5

Tail lamp ........................................................... LT-249

TCM circuit diagram ........................................... AT-52

TCM inspection table ......................................... AT-89

Thermostat(VK45DE) ....................................... CO-55

Thermostat(VQ35DE) ....................................... CO-29

Three way catalyst function (Bank 1) EC-392, EC-1113

Three way catalyst function (Bank 2) EC-392, EC-1113

Three way catalyst precautions ............................ GI-6

Three way catalyst(VK45DE) .......................... EM-183

Throttle control motor ....................... EC-619, EC-1351

Throttle control motor relay .............. EC-607, EC-1338

Throttle position sensor (TPS) .......... EC-231, EC-354,

EC-533

, EC-535, EC-640, EC-954, EC-1077, EC-1259,

EC-1261

, EC-1372

Throttle valve closed position learning . EC-95, EC-806

Tie-rod ............................................................... PS-18

Timing chain(VK45DE) ................................... EM-203

Timing chain(VQ35DE) ..................................... EM-64

Tire rotation ....................................................... MA-35

TLID - Wiring diagram ...................................... BL-211

Top tether strap child restraint ........................... SB-37

Torque converter installation ............. AT-274, AT-277

Torque convertor clutch solenoid valve AT-126, AT-128

TPS1 - Wiring diagram .................... EC-356, EC-1079

TPS2 - Wiring diagram ...................... EC-233, EC-956

TPS3 - Wiring diagram .................... EC-642, EC-1374

Transfer control unit inspection table ................. TF-20

TRNSCV - Wiring diagram ............................... BL-281

Trouble diagnoses .............................................. GI-12

Trunk lid ........................................................... BL-203

Trunk lid opener - See Trunk lid ...................... BL-209

TURN - Wiring diagram .................................... LT-215

Turn signal lamp ............................................... LT-211

Two trip detection logic ........................ EC-54, EC-764

Tyre pressure monitoring system - trouble diagnoses ..

WT-13

Page 3670 of 5621

LAN-1

LAN SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION LAN

A

B

LAN

Revision: 2006 January2006 M35/M45

LAN SYSTEM

CAN

PRECAUTIONS .......................................................... 7

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 7

Precautions When Using CONSULT-II ..................... 7

CHECK POINTS FOR USING CONSULT-II ......... 7

Precautions For Trouble Diagnosis .......................... 7

CAN SYSTEM ....................................................... 7

Precautions For Harness Repair .............................. 8

CAN SYSTEM ....................................................... 8

TROUBLE DIAGNOSES WORK FLOW .................... 9

When Displaying CAN Communication System

Errors ....................................................................... 9

WHEN A MALFUNCTION IS DETECTED BY

CAN COMMUNICATION SYSTEM ....................... 9

WHEN A MALFUNCTION IS DETECTED

EXCEPT CAN COMMUNICATION SYSTEM ........ 9

TROUBLE DIAGNOSIS FLOW CHART ............. 10

Diagnosis Procedure ............................................... 11

SELECTING CAN SYSTEM TYPE (HOW TO

USE SPECIFICATION TABLE) ............................ 11

ACQUISITION OF DATA BY CONSULT-II .......... 12

HOW TO USE CHECK SHEET TABLE .............. 14

CAN Diagnostic Support Monitor ........................... 20

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR ECM ............................... 20

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR TCM ............................... 21

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR AWD CONTROL UNIT ... 21

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR AFS CONTROL UNIT .... 22

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR BCM ............................... 23

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR LDW CAMERA UNIT ..... 24

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR LOW TIRE PRESSURE WARNING CONTROL UNIT ............................... 25

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR INTELLIGENT KEY UNIT ... 26

DESCRIPTION OF “CAN DIAG SUPPORT

M N T R ” S C R E E N F O R U N I F I E D M E T E R A N D A /

C AMP. ................................................................. 27

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR AV(NAVI) CONTROL

UNIT .................................................................... 28

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR RAS CONTROL UNIT .... 29

DESCRIPTION OF “CAN DIAG SUPPORT

M N T R ” S C R E E N F O R P R E - C R A S H S E A T B E L T

CONTROL UNIT ................................................. 30

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR DRIVER SEAT CON-

TROL UNIT ...................................................... ... 31

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR ABS ACTUATOR AND

ELECTRIC UNIT (CONTROL UNIT) ................... 31

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR ICC SENSOR INTE-

GRATED UNIT .................................................... 32

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR IPDM E/R ....................... 33

CAN COMMUNICATION ........................................... 34

System Description ................................................. 34

CAN Communication Unit ....................................... 34

SYSTEM DIAGRAM ............................................ 34

INPUT/OUTPUT SIGNAL CHART ...................... 40

CAN SYSTEM (TYPE 1) ........................................... 48

Component Parts and Harness Connector Location ... 48

Schematic ............................................................... 49

Wiring Diagram — CAN — ..................................... 50

Check Sheet ........................................................... 53

CHECK SHEET RESULTS (EXAMPLE) ............. 56

Inspection Between TCM and Data Link Connector

Circuit ..................................................................

... 72

Inspection Between Data Link Connector and Driver

Seat Control Unit Circuit ......................................

... 73

Page 3671 of 5621

LAN-2Revision: 2006 January2006 M35/M45 Inspection Between Driver Seat Control Unit and

ABS Actuator and Electric Unit (Control Unit) Circuit ... 74

ECM Circuit Inspection ........................................... 75

TCM Circuit Inspection ........................................... 75

BCM Circuit Inspection ........................................... 76

Low Tire Pressure Warning Control Unit Circuit

Inspection ............................................................... 76

Steering Angle Sensor Circuit Inspection ............... 77

Intelligent Key Unit Circuit Inspection ..................... 77

Unified Meter and A/C Amp. Circuit Inspection ...... 78

AV Control Unit Circuit Inspection ........................... 78

Data Link Connector Circuit Inspection .................. 79

Driver Seat Control Unit Circuit Inspection ............. 79

ABS Actuator and Electric Unit (Control Unit) Circuit

Inspection ............................................................... 80

IPDM E/R Circuit Inspection ................................... 80

CAN Communication Circuit Inspection .................. 81

IPDM E/R Ignition Relay Circuit Inspection ............ 88

CAN SYSTEM (TYPE 2) ........................................... 89

Component Parts and Harness Connector Location ... 89

Schematic ............................................................... 90

Wiring Diagram — CAN — ..................................... 91

Check Sheet ........................................................... 94

CHECK SHEET RESULTS (EXAMPLE) ............. 97

Inspection Between TCM and Data Link Connector

Circuit ...................................................................113

Inspection Between Data Link Connector and Driver

Seat Control Unit Circuit ......................................

.114

Inspection Between Driver Seat Control Unit and

ABS Actuator and Electric Unit (Control Unit) Circuit .115

ECM Circuit Inspection .........................................116

TCM Circuit Inspection .........................................116

BCM Circuit Inspection .........................................117

Low Tire Pressure Warning Control Unit Circuit

Inspection .............................................................117

Steering Angle Sensor Circuit Inspection .............118

Intelligent Key Unit Circuit Inspection ...................118

Unified Meter and A/C Amp. Circuit Inspection ....119

NAVI Control Unit Circuit Inspection .....................119

Data Link Connector Circuit Inspection ................120

Driver Seat Control Unit Circuit Inspection ...........120

ABS Actuator and Electric Unit (Control Unit) Circuit

Inspection .............................................................121

IPDM E/R Circuit Inspection .................................121

CAN Communication Circuit Inspection ................122

IPDM E/R Ignition Relay Circuit Inspection ..........129

CAN SYSTEM (TYPE 3) .........................................130

Component Parts and Harness Connector Location .130

Schematic .............................................................131

Wiring Diagram — CAN — ...................................132

Check Sheet .........................................................136

CHECK SHEET RESULTS (EXAMPLE) ...........139

Inspection Between TCM and Data Link Connector

Circuit ...................................................................158

Inspection Between Data Link Connector and Pre-

Crash Seat Belt Control Unit Circuit .....................159

Inspection Between Pre-Crash Seat Belt Control

Unit and Driver Seat Control Unit Circuit ..............160

Inspection Between Driver Seat Control Unit and ABS Actuator and Electric Unit (Control Unit) Circuit .160

ECM Circuit Inspection .........................................161

TCM Circuit Inspection ......................................... .162

AFS Control Unit Circuit Inspection ......................162

BCM Circuit Inspection .........................................163

Low Tire Pressure Warning Control Unit Circuit

Inspection ..............................................................163

Steering Angle Sensor Circuit Inspection ..............164

Intelligent Key Unit Circuit Inspection ...................164

Unified Meter and A/C Amp. Circuit Inspection .....165

AV Control Unit Circuit Inspection .........................165

Data Link Connector Circuit Inspection .................166

Pre-Crash Seat Belt Control Unit Circuit Inspection .166

Driver Seat Control Unit Circuit Inspection ...........167

ABS Actuator and Electric Unit (Control Unit) Circuit

Inspection ..............................................................167

IPDM E/R Circuit Inspection .................................168

CAN Communication Circuit Inspection ................169

IPDM E/R Ignition Relay Circuit Inspection ...........176

CAN SYSTEM (TYPE 4) ..........................................177

Component Parts and Harness Connector Location .177

Schematic .............................................................178

Wiring Diagram — CAN — ...................................179

Check Sheet .........................................................183

CHECK SHEET RESULTS (EXAMPLE) ............186

Inspection Between TCM and Data Link Connector

Circuit ....................................................................205

Inspection Between Data Link Connector and Pre-

Crash Seat Belt Control Unit Circuit ......................206

Inspection Between Pre-Crash Seat Belt Control

Unit and Driver Seat Control Unit Circuit ..............207

Inspection Between Driver Seat Control Unit and

ABS Actuator and Electric Unit (Control Unit) Circuit .207

ECM Circuit Inspection .........................................208

TCM Circuit Inspection ......................................... .209

AFS Control Unit Circuit Inspection ......................209

BCM Circuit Inspection .........................................210

Low Tire Pressure Warning Control Unit Circuit

Inspection ..............................................................210

Steering Angle Sensor Circuit Inspection ..............211

Intelligent Key Unit Circuit Inspection ...................211

Unified Meter and A/C Amp. Circuit Inspection .....212

NAVI Control Unit Circuit Inspection .....................212

Data Link Connector Circuit Inspection .................213

Pre-Crash Seat Belt Control Unit Circuit Inspection .213

Driver Seat Control Unit Circuit Inspection ...........214

ABS Actuator and Electric Unit (Control Unit) Circuit

Inspection ..............................................................214

IPDM E/R Circuit Inspection ................................

.215

CAN Communication Circuit Inspection ................216

IPDM E/R Ignition Relay Circuit Inspection ...........223

CAN SYSTEM (TYPE 5) ..........................................224

Component Parts and Harness Connector Location .224

Schematic .............................................................225

Wiring Diagram — CAN — ...................................226

Check Sheet .........................................................230

CHECK SHEET RESULTS (EXAMPLE) ............233

Inspection Between TCM and Data Link Connector

Circuit ....................................................................255

Page 3672 of 5621

LAN-3

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45 Inspection Between Data Link Connector and Pre-

Crash Seat Belt Control Unit Circuit .....................256

Inspection Between Pre-Crash Seat Belt Control

Unit and Driver Seat Control Unit Circuit ..............257

Inspection Between Driver Seat Control Unit and

ABS Actuator and Electric Unit (Control Unit) Circuit .257

Inspection Between ABS Actuator and Electric Unit

and ICC Sensor Integrated Unit Circuit ................258

ECM Circuit Inspection .........................................259

TCM Circuit Inspection .........................................259

AFS Control Unit Circuit Inspection ......................260

BCM Circuit Inspection .........................................260

LDW Camera Unit Circuit Inspection ...................261

Low Tire Pressure Warning Control Unit Circuit

Inspection .............................................................261

Steering Angle Sensor Circuit Inspection .............262

Intelligent Key Unit Circuit Inspection ...................262

Unified Meter and A/C Amp. Circuit Inspection ....263

NAVI Control Unit Circuit Inspection .....................263

Data Link Connector Circuit Inspection ................264

Pre-Crash Seat Belt Control Unit Circuit Inspection .264

Driver Seat Control Unit Circuit Inspection ...........265

ABS Actuator and Electric Unit (Control Unit) Circuit

Inspection .............................................................265

ICC Sensor Integrated Unit Circuit Inspection .....266

IPDM E/R Circuit Inspection .................................266

CAN Communication Circuit Inspection ...............267

IPDM E/R Ignition Relay Circuit Inspection ..........274

CAN SYSTEM (TYPE 6) .........................................275

Component Parts and Harness Connector Location .275

Schematic ............................................................276

Wiring Diagram — CAN — ...................................277

Check Sheet .........................................................281

CHECK SHEET RESULTS (EXAMPLE) ...........284

Inspection Between TCM and Data Link Connector

Circuit ...................................................................303

Inspection Between Data Link Connector and RAS

Control Unit Circuit ...............................................304

Inspection Between RAS Control Unit and Driver

Seat Control Unit Circuit ......................................

.305

Inspection Between Driver Seat Control Unit and

ABS Actuator and Electric Unit (Control Unit) Circuit .305

ECM Circuit Inspection .........................................306

TCM Circuit Inspection .........................................306

AFS Control Unit Circuit Inspection ......................307

BCM Circuit Inspection .........................................307

Low Tire Pressure Warning Control Unit Circuit

Inspection .............................................................308

Steering Angle Sensor Circuit Inspection .............308

Intelligent Key Unit Circuit Inspection ...................309

Unified Meter and A/C Amp. Circuit Inspection ....309

AV Control Unit Circuit Inspection ........................310

Data Link Connector Circuit Inspection ................310

RAS Control Unit Circuit Inspection ...................... 311

Driver Seat Control Unit Circuit Inspection ............ 311

ABS Actuator and Electric Unit (Control Unit) Circuit

Inspection ............................................................

.312

IPDM E/R Circuit Inspection .................................312CAN Communication Circuit Inspection ...............313

IPDM E/R Ignition Relay Circuit Inspection ..........320

CAN SYSTEM (TYPE 7) .........................................321

Component Parts and Harness Connector Location .321

Schematic .............................................................322

Wiring Diagram — CAN — ...................................323

Check Sheet .........................................................327

CHECK SHEET RESULTS (EXAMPLE) ...........330

Inspection Between TCM and Data Link Connector

Circuit ...................................................................349

Inspection Between Data Link Connector and RAS

Control Unit Circuit ...............................................350

Inspection Between RAS Control Unit and Driver

Seat Control Unit Circuit ......................................

.351

Inspection Between Driver Seat Control Unit and

ABS Actuator and Electric Unit (Control Unit) Circuit .351

ECM Circuit Inspection .........................................352

TCM Circuit Inspection .........................................352

AFS Control Unit Circuit Inspection ......................353

BCM Circuit Inspection .........................................353

Low Tire Pressure Warning Control Unit Circuit

Inspection .............................................................354

Steering Angle Sensor Circuit Inspection .............354

Intelligent Key Unit Circuit Inspection ...................355

Unified Meter and A/C Amp. Circuit Inspection ....355

NAVI Control Unit Circuit Inspection .....................356

Data Link Connector Circuit Inspection ................356

RAS Control Unit Circuit Inspection ......................357

Driver Seat Control Unit Circuit Inspection ...........357

ABS Actuator and Electric Unit (Control Unit) Circuit

Inspection .............................................................358

IPDM E/R Circuit Inspection .................................358

CAN Communication Circuit Inspection ...............359

IPDM E/R Ignition Relay Circuit Inspection ..........366

CAN SYSTEM (TYPE 8) .........................................367

Component Parts and Harness Connector Location .367

Schematic .............................................................368

Wiring Diagram — CAN — ...................................369

Check Sheet .........................................................373

CHECK SHEET RESULTS (EXAMPLE) ...........376

Inspection Between TCM and Data Link Connector

Circuit ...................................................................397

Inspection Between Data Link Connector and RAS

Control Unit Circuit ...............................................398

Inspection Between RAS Control Unit and Pre-

Crash Seat Belt Control Unit Circuit .....................399

Inspection Between Pre-Crash Seat Belt Control

Unit and Driver Seat Control Unit Circuit ..............399

Inspection Between Driver Seat Control Unit and

ABS Actuator and Electric Unit (Control Unit) Circuit .400

ECM Circuit Inspection .........................................400

TCM Circuit Inspection .........................................401

AFS Control Unit Circuit Inspection ......................402

BCM Circuit Inspection .........................................402

Low Tire Pressure Warning Control Unit Circuit

Inspection ............................................................

.403

Steering Angle Sensor Circuit Inspection .............403

Intelligent Key Unit Circuit Inspection ...................404

Unified Meter and A/C Amp. Circuit Inspection ....404

Page 3673 of 5621

LAN-4Revision: 2006 January2006 M35/M45 AV Control Unit Circuit Inspection .........................405

Data Link Connector Circuit Inspection ................405

RAS Control Unit Circuit Inspection ......................406

Pre-Crash Seat Belt Control Unit Circuit Inspection .406

Driver Seat Control Unit Circuit Inspection ...........407

ABS Actuator and Electric Unit (Control Unit) Circuit

Inspection .............................................................407

IPDM E/R Circuit Inspection .................................408

CAN Communication Circuit Inspection ................409

IPDM E/R Ignition Relay Circuit Inspection ..........416

CAN SYSTEM (TYPE 9) .........................................417

Component Parts and Harness Connector Location .417

Schematic .............................................................418

Wiring Diagram — CAN — ...................................419

Check Sheet .........................................................423

CHECK SHEET RESULTS (EXAMPLE) ...........426

Inspection Between TCM and Data Link Connector

Circuit ...................................................................447

Inspection Between Data Link Connector and RAS

Control Unit Circuit ...............................................448

Inspection Between RAS Control Unit and Pre-

Crash Seat Belt Control Unit Circuit .....................449

Inspection Between Pre-Crash Seat Belt Control

Unit and Driver Seat Control Unit Circuit ..............449

Inspection Between Driver seat control unit and ABS

Actuator and Electric Unit (Control Unit) Circuit ....450

ECM Circuit Inspection .........................................450

TCM Circuit Inspection .........................................451

AFS Control Unit Circuit Inspection ......................452

BCM Circuit Inspection .........................................452

Low Tire Pressure Warning Control Unit Circuit

Inspection .............................................................453

Steering Angle Sensor Circuit Inspection .............453

Intelligent Key Unit Circuit Inspection ...................454

Unified Meter and A/C Amp. Circuit Inspection ....454

NAVI Control Unit Circuit Inspection .....................455

Data Link Connector Circuit Inspection ................455

RAS Control Unit Circuit Inspection ......................456

Pre-Crash Seat Belt Control Unit Circuit Inspection .456

Driver Seat Control Unit Circuit Inspection ...........457

ABS Actuator and Electric Unit (Control Unit) Circuit

Inspection .............................................................457

IPDM E/R Circuit Inspection .................................458

CAN Communication Circuit Inspection ................459

IPDM E/R Ignition Relay Circuit Inspection ..........466

CAN SYSTEM (TYPE 10) .......................................467

Component Parts and Harness Connector Location .467

Schematic .............................................................468

Wiring Diagram — CAN — ...................................469

Check Sheet .........................................................473

CHECK SHEET RESULTS (EXAMPLE) ...........476

Inspection Between TCM and Data Link Connector

Circuit ...................................................................500

Inspection Between Data Link Connector and RAS

Control Unit Circuit ...............................................501

Inspection Between RAS Control Unit and Pre-

Crash Seat Belt Control Unit Circuit .....................502

Inspection Between Pre-Crash Seat Belt Control

Unit and Driver Seat Control Unit Circuit ..............502Inspection Between Driver Seat Control Unit and

ABS Actuator and Electric Unit (Control Unit) Circuit .503

Inspection Between ABS Actuator and Electric Unit

and ICC Sensor Integrated Unit Circuit .................504

ECM Circuit Inspection .........................................504

TCM Circuit Inspection ......................................... .505

AFS Control Unit Circuit Inspection ......................505

BCM Circuit Inspection .........................................506

LDW Camera Unit Circuit Inspection ....................506

Low Tire Pressure Warning Control Unit Circuit

Inspection ..............................................................507

Steering Angle Sensor Circuit Inspection ..............507

Intelligent Key Unit Circuit Inspection ...................508

Unified Meter and A/C Amp. Circuit Inspection .....508

NAVI Control Unit Circuit Inspection .....................509

Data Link Connector Circuit Inspection .................509

RAS Control Unit Circuit Inspection ......................510

Pre-Crash Seat Belt Control Unit Circuit Inspection .510

Driver Seat Control Unit Circuit Inspection ...........511

ABS Actuator and Electric Unit (Control Unit) Circuit

Inspection ..............................................................511

ICC Sensor Integrated Unit Circuit Inspection ......512

IPDM E/R Circuit Inspection .................................512

CAN Communication Circuit Inspection ................513

IPDM E/R Ignition Relay Circuit Inspection ...........520

CAN SYSTEM (TYPE 11) ........................................521

Component Parts and Harness Connector Location .521

Schematic .............................................................522

Wiring Diagram — CAN — ...................................523

Check Sheet .........................................................526

CHECK SHEET RESULTS (EXAMPLE) ............529

Inspection Between TCM and Data Link Connector

Circuit ....................................................................546

Inspection Between Data Link Connector and Driver

Seat Control Unit Circuit .......................................547

Inspection Between Driver Seat Control Unit and

ABS Actuator and Electric Unit (Control Unit) Circuit .548

ECM Circuit Inspection .........................................549

TCM Circuit Inspection ......................................... .549

AWD Control Unit Circuit Inspection .....................550

BCM Circuit Inspection .........................................550

Low Tire Pressure Warning Control Unit Circuit

Inspection ..............................................................551

Steering Angle Sensor Circuit Inspection ..............551

Intelligent Key Unit Circuit Inspection ...................552

Unified Meter and A/C Amp. Circuit Inspection .....552

AV Control Unit Circuit Inspection .........................553

Data Link Connector Circuit Inspection ................

.553

Driver Seat Control Unit Circuit Inspection ...........554

ABS Actuator and Electric Unit (Control Unit) Circuit

Inspection ..............................................................554

IPDM E/R Circuit Inspection .................................555

CAN Communication Circuit Inspection ................556

IPDM E/R Ignition Relay Circuit Inspection ...........563

CAN SYSTEM (TYPE 12) ........................................564

Component Parts and Harness Connector Location .564

Schematic .............................................................565

Wiring Diagram — CAN — ...................................566

Check Sheet .........................................................569