battery INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3643 of 5621

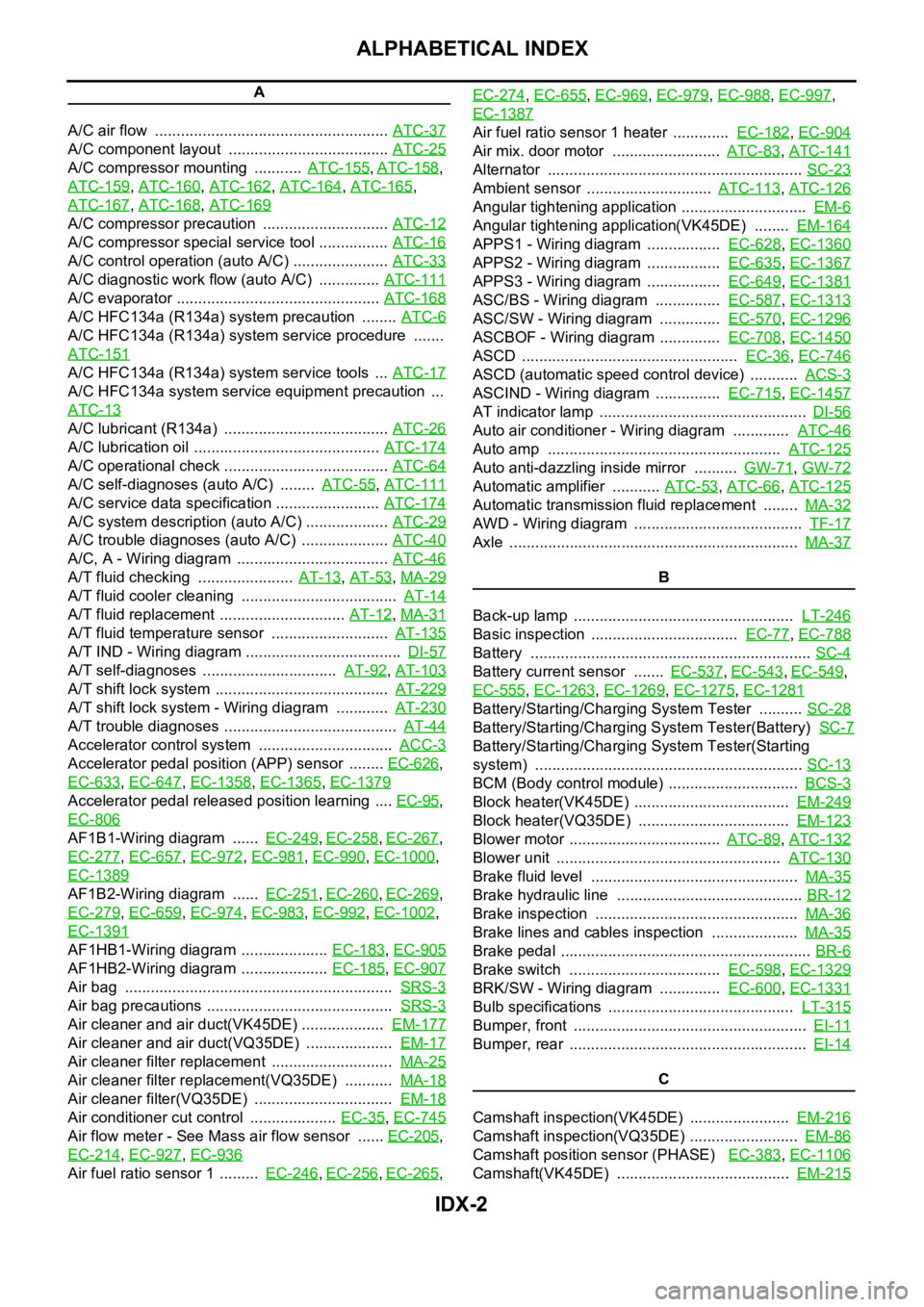

IDX-2

ALPHABETICAL INDEX

A

A/C air flow ...................................................... ATC-37

A/C component layout ..................................... ATC-25

A/C compressor mounting ........... ATC-155, ATC-158,

ATC-159

, ATC-160, ATC-162, ATC-164, ATC-165,

ATC-167

, ATC-168, ATC-169

A/C compressor precaution ............................. ATC-12

A/C compressor special service tool ................ ATC-16

A/C control operation (auto A/C) ...................... ATC-33

A/C diagnostic work flow (auto A/C) .............. ATC-111

A/C evaporator ............................................... ATC-168

A/C HFC134a (R134a) system precaution ........ ATC-6

A/C HFC134a (R134a) system service procedure .......

ATC-151

A/C HFC134a (R134a) system service tools ... ATC-17

A/C HFC134a system service equipment precaution ...

ATC-13

A/C lubricant (R134a) ...................................... ATC-26

A/C lubrication oil ........................................... ATC-174

A/C operational check ...................................... ATC-64

A/C self-diagnoses (auto A/C) ........ ATC-55, ATC-111

A/C service data specification ........................ ATC-174

A/C system description (auto A/C) ................... ATC-29

A/C trouble diagnoses (auto A/C) .................... ATC-40

A/C, A - Wiring diagram ................................... ATC-46

A/T fluid checking ...................... AT-13, AT-53, MA-29

A/T fluid cooler cleaning .................................... AT-14

A/T fluid replacement ............................. AT-12, MA-31

A/T fluid temperature sensor ........................... AT-135

A/T IND - Wiring diagram .................................... DI-57

A/T self-diagnoses ............................... AT-92, AT-103

A/T shift lock system ........................................ AT-229

A/T shift lock system - Wiring diagram ............ AT-230

A/T trouble diagnoses ........................................ AT-44

Accelerator control system ............................... ACC-3

Accelerator pedal position (APP) sensor ........ EC-626,

EC-633

, EC-647, EC-1358, EC-1365, EC-1379

Accelerator pedal released position learning .... EC-95,

EC-806

AF1B1-Wiring diagram ...... EC-249, EC-258, EC-267,

EC-277

, EC-657, EC-972, EC-981, EC-990, EC-1000,

EC-1389

AF1B2-Wiring diagram ...... EC-251, EC-260, EC-269,

EC-279

, EC-659, EC-974, EC-983, EC-992, EC-1002,

EC-1391

AF1HB1-Wiring diagram .................... EC-183, EC-905

AF1HB2-Wiring diagram .................... EC-185, EC-907

Air bag .............................................................. SRS-3

Air bag precautions ........................................... SRS-3

Air cleaner and air duct(VK45DE) ................... EM-177

Air cleaner and air duct(VQ35DE) .................... EM-17

Air cleaner filter replacement ............................ MA-25

Air cleaner filter replacement(VQ35DE) ........... MA-18

Air cleaner filter(VQ35DE) ................................ EM-18

Air conditioner cut control .................... EC-35, EC-745

Air flow meter - See Mass air flow sensor ...... EC-205,

EC-214

, EC-927, EC-936

Air fuel ratio sensor 1 ......... EC-246, EC-256, EC-265, EC-274

, EC-655, EC-969, EC-979, EC-988, EC-997,

EC-1387

Air fuel ratio sensor 1 heater ............. EC-182, EC-904

Air mix. door motor ......................... ATC-83, ATC-141

Alternator ........................................................... SC-23

Ambient sensor ............................. ATC-113, ATC-126

Angular tightening application ............................. EM-6

Angular tightening application(VK45DE) ........ EM-164

APPS1 - Wiring diagram ................. EC-628, EC-1360

APPS2 - Wiring diagram ................. EC-635, EC-1367

APPS3 - Wiring diagram ................. EC-649, EC-1381

ASC/BS - Wiring diagram ............... EC-587, EC-1313

ASC/SW - Wiring diagram .............. EC-570, EC-1296

ASCBOF - Wiring diagram .............. EC-708, EC-1450

ASCD .................................................. EC-36, EC-746

ASCD (automatic speed control device) ........... ACS-3

ASCIND - Wiring diagram ............... EC-715, EC-1457

AT indicator lamp ................................................ DI-56

Auto air conditioner - Wiring diagram ............. ATC-46

Auto amp ...................................................... ATC-125

Auto anti-dazzling inside mirror .......... GW-71, GW-72

Automatic amplifier ........... ATC-53, ATC-66, ATC-125

Automatic transmission fluid replacement ........ MA-32

AWD - Wiring diagram ....................................... TF-17

Axle ................................................................... MA-37

B

Back-up lamp ................................................... LT-246

Basic inspection .................................. EC-77, EC-788

Battery ................................................................. SC-4

Battery current sensor ....... EC-537, EC-543, EC-549,

EC-555

, EC-1263, EC-1269, EC-1275, EC-1281

Battery/Starting/Charging System Tester .......... SC-28

Battery/Starting/Charging System Tester(Battery) SC-7

Battery/Starting/Charging System Tester(Starting

system) .............................................................. SC-13

BCM (Body control module) .............................. BCS-3

Block heater(VK45DE) .................................... EM-249

Block heater(VQ35DE) ................................... EM-123

Blower motor ................................... ATC-89, ATC-132

Blower unit .................................................... ATC-130

Brake fluid level ................................................ MA-35

Brake hydraulic line ........................................... BR-12

Brake inspection ............................................... MA-36

Brake lines and cables inspection .................... MA-35

Brake pedal .......................................................... BR-6

Brake switch ................................... EC-598, EC-1329

BRK/SW - Wiring diagram .............. EC-600, EC-1331

Bulb specifications ........................................... LT-315

Bumper, front ...................................................... EI-11

Bumper, rear ....................................................... EI-14

C

Camshaft inspection(VK45DE) ....................... EM-216

Camshaft inspection(VQ35DE) ......................... EM-86

Camshaft position sensor (PHASE) EC-383, EC-1106

Camshaft(VK45DE) ........................................ EM-215

Page 3651 of 5621

IP-2

PRECAUTIONS

Revision: 2006 January2006 M35/M45

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

NIS00255

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WAR NING :

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions NIS00256

Disconnect both battery cables in advance.

Disconnect air bag system line in advance.

Never tamper with or force air bag lid open, as this may adversely affect air bag performance.

Be careful not to scratch pad and other parts.

When removing or disassembling any part, be careful not to damage or deform it. Protect parts, which

may get in the way with cloth.

When removing parts with a screwdriver or other tool, protect parts by wrapping them with vinyl or tape.

Keep removed parts protected with cloth.

If a clip is deformed or damaged, replace it.

If an unreusable part is removed, replace it with a new one.

Tighten bolts and nuts firmly to the specified torque.

After re-assembly has been completed, make sure each part functions correctly.

Remove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tightly. After wiping the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain

with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely.

Then wipe the area with a soft dry cloth.

Do not use any organic solvent, such as thinner or benzine.

Page 3676 of 5621

![INFINITI M35 2006 Factory Service Manual PRECAUTIONS

LAN-7

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

[CAN]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE- INFINITI M35 2006 Factory Service Manual PRECAUTIONS

LAN-7

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

[CAN]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-](/img/42/57023/w960_57023-3675.png)

PRECAUTIONS

LAN-7

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

[CAN]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

NKS003XO

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WAR NING :

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions When Using CONSULT-IINKS003XP

When connecting CONSULT-II to data link connector, connect them through CONSULT-II CONVERTER.

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

CHECK POINTS FOR USING CONSULT-II

1. Has CONSULT-II been used without connecting CONSULT-II CONVERTER on this vehicle?

–If YES, GO TO 2.

–If NO, GO TO 5.

2. Is there any indication other than indications relating to CAN communication system in the self-diagnosis

results?

–If YES, GO TO 3.

–If NO, GO TO 4.

3. Based on self-diagnosis results unrelated to CAN communication, carry out the inspection.

4. Malfunctions may be detected in self-diagnosis depending on control units carrying out CAN communica-

tion. Therefore, erase the self-diagnosis results.

5. Diagnose CAN communication system. Refer to LAN-9, "

TROUBLE DIAGNOSES WORK FLOW" .

Precautions For Trouble DiagnosisNKS003XQ

CAN SYSTEM

Do not apply voltage of 7.0 V or higher to the measurement terminals.

Use the tester with its open terminal voltage being 7.0 V or less.

Be sure to turn ignition switch OFF and disconnect the battery cable from the negative terminal before

checking the circuit.

Page 3678 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-9

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSES WORK FLOWPFP:00004

When Displaying CAN Communication System ErrorsNKS003XS

WHEN INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-9

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSES WORK FLOWPFP:00004

When Displaying CAN Communication System ErrorsNKS003XS

WHEN](/img/42/57023/w960_57023-3677.png)

TROUBLE DIAGNOSES WORK FLOW

LAN-9

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSES WORK FLOWPFP:00004

When Displaying CAN Communication System ErrorsNKS003XS

WHEN A MALFUNCTION IS DETECTED BY CAN COMMUNICATION SYSTEM

CAN communication line is open. (CAN H, CAN L, or both)

CAN communication line is shorted. (Ground, between CAN lines, or other harnesses)

The areas related to CAN communication of unit is malfunctioning.

WHEN A MALFUNCTION IS DETECTED EXCEPT CAN COMMUNICATION SYSTEM

Removal and installation of parts: When the units that perform CAN communication or the sensors related

to CAN communication are removed and installed, malfunction may be detected (or DTC other than CAN

communication may be detected).

Fuse blown out (removed): CAN communication of the unit may be stopped at such time.

Low voltage: If the voltage decreases because of battery discharge when IGN is ON, malfunction may be

detected by self-diagnosis according to the units.

Page 3709 of 5621

![INFINITI M35 2006 Factory Service Manual LAN-40

[CAN]

CAN COMMUNICATION

Revision: 2006 January2006 M35/M45

INPUT/OUTPUT SIGNAL CHART

2WD models

T: Transmit R: Receive

Signals

ECM

TCM

AFS control unit*1

BCM

LDW camera unit*2

Low tire pressu INFINITI M35 2006 Factory Service Manual LAN-40

[CAN]

CAN COMMUNICATION

Revision: 2006 January2006 M35/M45

INPUT/OUTPUT SIGNAL CHART

2WD models

T: Transmit R: Receive

Signals

ECM

TCM

AFS control unit*1

BCM

LDW camera unit*2

Low tire pressu](/img/42/57023/w960_57023-3708.png)

LAN-40

[CAN]

CAN COMMUNICATION

Revision: 2006 January2006 M35/M45

INPUT/OUTPUT SIGNAL CHART

2WD models

T: Transmit R: Receive

Signals

ECM

TCM

AFS control unit*1

BCM

LDW camera unit*2

Low tire pressure warning control unit

Steering angle sensor

Intelligent Key unit

Unified meter and A/C amp.

AV (NAVI) control unit

RAS control unit*3

Pre-crash seat belt control unit*4

Driver seat control unit

ABS actuator and electric unit (control unit)

ICC sensor integrated unit*5

IPDM E/R

A/C compressor request signal TR

Accelerator pedal position signal T R R R

ASCD CRUISE lamp signal T R

ASCD OD cancel request signal T R

ASCD operation signal T R

ASCD SET lamp signal T R

Battery voltage signal T R

Closed throttle position signal T R R

Cooling fan speed request signal TR

Engine coolant temperature signal T R

Engine speed signal T R R R R R R

Engine status signal T R R R

Fuel consumption monitor signal T R R

ICC brake switch signal T R

ICC prohibition signal T R

ICC steering switch signal T R

Malfunctioning indicator lamp signal T R

Power generation command value signal TR

Wide open throttle position signal T R

A/T CHECK indicator lamp signal T R

A/T position indicator signal T R R R R

A/T self-diagnosis signal R T

Current gear position signal T R R

Manual mode indicator signal T R R

N range signal T R R

Output shaft revolution signal R T R R

P range signal T R R R R

R range signal T R R R

Turbine revolution signal R T R

AFS OFF indicator signal T R

A/C switch signal R T

ACC signal T R R

Page 3713 of 5621

![INFINITI M35 2006 Factory Service Manual LAN-44

[CAN]

CAN COMMUNICATION

Revision: 2006 January2006 M35/M45

AW D m o del s

T: Transmit R: Receive

Signals

ECM

TCM

AWD control unit

AFS control unit*1

BCM

LDW camera unit*2

Low tire pressure w INFINITI M35 2006 Factory Service Manual LAN-44

[CAN]

CAN COMMUNICATION

Revision: 2006 January2006 M35/M45

AW D m o del s

T: Transmit R: Receive

Signals

ECM

TCM

AWD control unit

AFS control unit*1

BCM

LDW camera unit*2

Low tire pressure w](/img/42/57023/w960_57023-3712.png)

LAN-44

[CAN]

CAN COMMUNICATION

Revision: 2006 January2006 M35/M45

AW D m o del s

T: Transmit R: Receive

Signals

ECM

TCM

AWD control unit

AFS control unit*1

BCM

LDW camera unit*2

Low tire pressure warning control unit

Steering angle sensor

Intelligent Key unit

Unified meter and A/C amp.

AV (NAVI) control unit

Pre-crash seat belt control unit*3

Driver seat control unit

ABS actuator and electric unit (control unit)

ICC sensor integrated unit*4

IPDM E/R

A/C compressor request signal TR

Accelerator pedal position signal T R R R R

ASCD CRUISE lamp signal T R

ASCD OD cancel request signal T R

ASCD operation signal T R

ASCD SET lamp signal T R

Battery voltage signal T R

Closed throttle position signal T R R

Cooling fan speed request signal TR

Engine coolant temperature signal T R

Engine speed signal T R R R R R R

Engine status signal T R R R

Fuel consumption monitor signal T R R

ICC brake switch signal T R

ICC prohibition signal T R

ICC steering switch signal T R

Malfunctioning indicator lamp signal T R

Power generation command value signal TR

Wide open throttle position signal T R

A/T CHECK indicator lamp signal T R

A/T position indicator signal T R R R R

A/T self-diagnosis signal R T

Current gear position signal T R R

Manual mode indicator signal T R R

N range signal T R R

Output shaft revolution signal R T R R

P range signal T R R R R

R range signal T R R R

Turbine revolution signal R T R

AWD signal T R

AWD warning lamp signal T R

AFS OFF indicator signal T R

A/C switch signal R T

Page 3741 of 5621

![INFINITI M35 2006 Factory Service Manual LAN-72

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

Case 18

Check IPDM E/R ignition relay circuit continuously sticks “ON”. Refer to LAN-88, "IPDM E/R Ignition Relay Cir-

cuit INFINITI M35 2006 Factory Service Manual LAN-72

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

Case 18

Check IPDM E/R ignition relay circuit continuously sticks “ON”. Refer to LAN-88, "IPDM E/R Ignition Relay Cir-

cuit](/img/42/57023/w960_57023-3740.png)

LAN-72

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

Case 18

Check IPDM E/R ignition relay circuit continuously sticks “ON”. Refer to LAN-88, "IPDM E/R Ignition Relay Cir-

cuit Inspection" .

Inspection Between TCM and Data Link Connector CircuitNKS003Y1

1. CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check following terminals and connectors for damage, bend and loose connection (connector side and

harness side).

–Harness connector M61

–Harness connector M62

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.

2. CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect harness connector M72 and harness connector M61.

2. Check continuity between harness connector (A) and harness

connector (B).

OK or NG

OK >> GO TO 3.

NG >> Repair harness.

PKIB8398E

AB

Continuity

Connector Terminal Connector Terminal

M7243H

M61 1 Yes

42H 2 Yes

PKIC0279E

Page 3742 of 5621

![INFINITI M35 2006 Factory Service Manual CAN SYSTEM (TYPE 1)

LAN-73

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

3. CHECK HARNESS FOR OPEN CIRCUIT

Check continuity between harness connector (A) and data link con INFINITI M35 2006 Factory Service Manual CAN SYSTEM (TYPE 1)

LAN-73

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

3. CHECK HARNESS FOR OPEN CIRCUIT

Check continuity between harness connector (A) and data link con](/img/42/57023/w960_57023-3741.png)

CAN SYSTEM (TYPE 1)

LAN-73

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

3. CHECK HARNESS FOR OPEN CIRCUIT

Check continuity between harness connector (A) and data link con-

nector (B).

OK or NG

OK >> Connect all the connectors and diagnose again. Refer to

LAN-9, "

TROUBLE DIAGNOSES WORK FLOW" .

NG >> Repair harness.

Inspection Between Data Link Connector and Driver Seat Control Unit CircuitNKS003Y2

1. CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check following terminals and connectors for damage, bend and loose connection (connector side and

harness side).

–Harness connector M13

–Harness connector B2

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.

2. CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect harness connector M13.

2. Check continuity between data link connector (A) and harness

connector (B).

OK or NG

OK >> GO TO 3.

NG >> Repair harness.

AB

Continuity

Connector Terminal Connector Terminal

M621

M606 Yes

214Yes

PKIC0280E

AB

Continuity

Connector Terminal Connector Terminal

M606

M1320M Yes

14 21M Yes

PKIC0281E

Page 3743 of 5621

![INFINITI M35 2006 Factory Service Manual LAN-74

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

3. CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect harness connector B15.

2. Check continuity between harness connector (A) and INFINITI M35 2006 Factory Service Manual LAN-74

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

3. CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect harness connector B15.

2. Check continuity between harness connector (A) and](/img/42/57023/w960_57023-3742.png)

LAN-74

[CAN]

CAN SYSTEM (TYPE 1)

Revision: 2006 January2006 M35/M45

3. CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect harness connector B15.

2. Check continuity between harness connector (A) and harness

connector (B).

OK or NG

OK >> Connect all the connectors and diagnose again. Refer to

LAN-9, "

TROUBLE DIAGNOSES WORK FLOW" .

NG >> Repair harness.

Inspection Between Driver Seat Control Unit and ABS Actuator and Electric Unit

(Control Unit) Circuit

NKS003Y3

1. CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check following terminals and connectors for damage, bend and loose connection (connector side and

harness side).

–Harness connector B3

–Harness connector E105

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.

2. CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect harness connector B15 and harness connector B3.

2. Check continuity between harness connector (A) and harness

connector (B).

OK or NG

OK >> GO TO 3.

NG >> Repair harness.

AB

Continuity

Connector Terminal Connector Terminal

B220M

B153 Yes

21M 19 Yes

PKIC0282E

AB

Continuity

Connector Terminal Connector Terminal

B153

B3 9Yes

19 8 Yes

PKIC0283E

Page 3744 of 5621

![INFINITI M35 2006 Factory Service Manual CAN SYSTEM (TYPE 1)

LAN-75

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

3. CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connector.

INFINITI M35 2006 Factory Service Manual CAN SYSTEM (TYPE 1)

LAN-75

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

3. CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connector.](/img/42/57023/w960_57023-3743.png)

CAN SYSTEM (TYPE 1)

LAN-75

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

3. CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connector.

2. Check continuity between harness connector (A) and ABS actu-

ator and electric unit (control unit) harness connector (B).

OK or NG

OK >> Connect all the connectors and diagnose again. Refer to

LAN-9, "

TROUBLE DIAGNOSES WORK FLOW" .

NG >> Repair harness.

ECM Circuit InspectionNKS003Y4

1. CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check terminals and connector of ECM for damage, bend and loose connection (control module side and

harness side).

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.

2. CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect ECM connector.

2. Check resistance between ECM harness connector terminals.

OK or NG

OK >> Replace ECM.

NG >> Repair harness between ECM and A/T assembly.

TCM Circuit InspectionNKS003Y5

1. CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check following terminals and connectors for damage, bend and loose connection (control module side

and harness side).

–A/T assembly connector

–Harness connector F102

–Harness connector M72

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.

AB

Continuity

Connector Terminal Connector Terminal

E1059

E30 35 Yes

814Yes

PKIC0284E

ECM connector TerminalResistance

(Approx.)

M71 94 86 108 – 132

PKIA9860E