dimensions INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 435 of 5621

AT-356

ASSEMBLY

Revision: 2006 January2006 M35/M45

45. Adjust brake band.

a. Loosen lock nut.

b. Tighten band servo anchor end pin to specified torque.

c. Back of band servo anchor end pin three turns.

d. Holding band servo anchor end pin, tighten lock nut to the spec-

ified torque. Refer to AT- 2 7 8 , "

Components" .

AdjustmentNCS001RB

TOTAL END PLAY

Measure clearance between front sun gear and bearing race for

oil pump cover.

Select proper thickness of bearing race so that end play is within

specifications.

1. Measure dimensions “K” and “L” and then calculate dimension

“J”.

a. Measure dimension “K”.: 5.0 Nꞏm (0.51 kg-m, 44 in-lb)

SCIA5498E

SCIA2810E

SCIA7073E

SCIA7074E

Page 436 of 5621

ASSEMBLY

AT-357

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

b. Measure dimension “L”.

c. Calculate dimension “J”.

2. Measure dimensions “M

1 ” and “M2 ” and then calculate dimen-

sion “M”.

a. Place bearing race and needle bearing on oil pump assembly.

b. Measure dimension “M

1 ”.

c. Measure dimension “M

2 ”. “J”: Distance between oil pump fitting surface of

transmission case and needle bearing mating

surface of front sun gear.

J = K – L

SCIA5352E

SCIA3125E

SCIA3124E

SCIA3126E

SCIA3127E

Page 631 of 5621

![INFINITI M35 2006 Factory Service Manual AV-10

[WITHOUT MOBILE ENTERTAINMENT SYSTEM]

SYSTEM DESCRIPTION

Revision: 2006 January2006 M35/M45

Map-matching does not function correctly when a road on which

the vehicle is driving is new and not INFINITI M35 2006 Factory Service Manual AV-10

[WITHOUT MOBILE ENTERTAINMENT SYSTEM]

SYSTEM DESCRIPTION

Revision: 2006 January2006 M35/M45

Map-matching does not function correctly when a road on which

the vehicle is driving is new and not](/img/42/57023/w960_57023-630.png)

AV-10

[WITHOUT MOBILE ENTERTAINMENT SYSTEM]

SYSTEM DESCRIPTION

Revision: 2006 January2006 M35/M45

Map-matching does not function correctly when a road on which

the vehicle is driving is new and not recorded in the map DVD-

ROM, or when road pattern stored in the map data and the

actual road pattern are different due to repair.

When driving on a road not present in the map, the map-match-

ing function may find another road and position the vehicle mark

on it. Then, when the correct road is detected, the vehicle mark

may change to it.

Effective range for comparing the vehicle position and travel

direction calculated by the distance and direction with the road

data read from the map DVD-ROM is limited. Therefore, when

there is an excessive gap between current vehicle position and

the position on the map, correction by map-matching is not possible.

GPS (Global Positioning System)

GPS (Global Positioning System) was developed for and is con-

trolled by the US Department of Defense. The system utilizes GPS

satellites (NAVSTAR), sending out radio waves while flying on an

orbit around the earth at an altitude of approximately 21,000 km

(13,100miles).

The GPS receiver calculates the vehicle's position in three dimen-

sions (latitude/longitude/altitude) according to the time lag of the

radio waves received from four or more GPS satellites (three-dimen-

sional positioning). If radio waves were received only from three

GPS satellites, the GPS receiver calculates the vehicle's position in

two dimensions (latitude/longitude), utilizing the altitude data calcu-

lated previously with radio waves from four or more GPS satellites

(two-dimensional positioning).

Position correction by GPS is not available while the vehicle is stopped.

Accuracy of GPS will deteriorate under the following conditions:

In two-dimensional positioning, GPS accuracy will deteriorate when altitude of the vehicle position

changes.

The accuracy can be even lower depending on the arrangement of the GPS satellites utilized for the posi-

tioning.

Position detection is not possible when vehicle is in an area where radio waves from the GPS satellite do

not reach, such as in a tunnel, parking lot in a building, and under an elevated highway. Radio waves from

the GPS satellites may not be received when some object is located over the GPS antenna.

NOTE:

Even a high-precision three dimensional positioning, the detection result has an error about 10 m (30 ft).

Because the signals of GPS satellite is controlled by the Tracking and Control Center in the United States,

the accuracy may be degraded lower intentionally or the radio waves may stop.

HANDS-FREE PHONE

AV (NAVI) control unit has Bluetooth module. It can perform wireless hands-free telephone calls using a

cellular phone in vehicle compartment.

5 or more portable phones can be registered into the AV (NAVI) control unit.

REAR VIEW MONITOR

The small CCD camera is equipped into the rear end of the vehicle. The rear view monitor that displays

the area behind the vehicle while backing up is equipped.

Guiding lines indicating side and rear clearances are provided in the rear view monitor image, which

allows the driver to more easily judge distances between the vehicle and objects in the display. The possi-

ble route lines that indicate the possible route according to the steering angle are provided to help backing

up when parking.

Image quality of the rear view image and of the navigation screen can be adjusted separately.

SKIA0613E

SEL526V

Page 769 of 5621

![INFINITI M35 2006 Factory Service Manual AV-148

[WITH MOBILE ENTERTAINMENT SYSTEM]

SYSTEM DESCRIPTION

Revision: 2006 January2006 M35/M45

GPS (Global Positioning System)

GPS (Global Positioning System) was developed for and is con-

t INFINITI M35 2006 Factory Service Manual AV-148

[WITH MOBILE ENTERTAINMENT SYSTEM]

SYSTEM DESCRIPTION

Revision: 2006 January2006 M35/M45

GPS (Global Positioning System)

GPS (Global Positioning System) was developed for and is con-

t](/img/42/57023/w960_57023-768.png)

AV-148

[WITH MOBILE ENTERTAINMENT SYSTEM]

SYSTEM DESCRIPTION

Revision: 2006 January2006 M35/M45

GPS (Global Positioning System)

GPS (Global Positioning System) was developed for and is con-

trolled by the US Department of Defense. The system utilizes GPS

satellites (NAVSTAR), sending out radio waves while flying on an

orbit around the earth at an altitude of approximately 21,000 km

(13,100miles).

The GPS receiver calculates the vehicle's position in three dimen-

sions (latitude/longitude/altitude) according to the time lag of the

radio waves received from four or more GPS satellites (three-dimen-

sional positioning). If radio waves were received only from three

GPS satellites, the GPS receiver calculates the vehicle's position in

two dimensions (latitude/longitude), utilizing the altitude data calcu-

lated previously with radio waves from four or more GPS satellites

(two-dimensional positioning).

Position correction by GPS is not available while the vehicle is stopped.

Accuracy of GPS will deteriorate under the following conditions:

In two-dimensional positioning, GPS accuracy will deteriorate when altitude of the vehicle position

changes.

The accuracy can be even lower depending on the arrangement of the GPS satellites utilized for the posi-

tioning.

Position detection is not possible when vehicle is in an area where radio waves from the GPS satellite do

not reach, such as in a tunnel, parking lot in a building, and under an elevated highway. Radio waves from

the GPS satellites may not be received when some object is located over the GPS antenna.

NOTE:

Even a high-precision three dimensional positioning, the detection result has an error about 10 m (30ft).

Because the signals of GPS satellite is controlled by the Tracking and Control Center in the United States,

the accuracy may be degraded lower intentionally or the radio waves may stop.

MOBILE ENTERTAINMENT SYSTEM

The wireless headphone has been adopted to the rear seat. It is possible to listen to a separate sound in

front seat and rear seat and to see a separate image in front display and rear display.

When headphone mode is turned ON at radio/CD changer mode, AUX or DVD mode is turned ON only for

rear seat. The image that is different from front seat is displayed and a separate sound is output from

speaker and headphone.

HANDS-FREE PHONE

AV (NAVI) control unit has a Bluetooth module. It can perform wireless hands-free telephone calls using

the portable phone in a pocket.

5 or more portable phones can be registered into the AV (NAVI) control unit.

REAR VIEW MONITOR

The small CCD camera is equipped into the rear end of the vehicle. The rear view monitor that displays

the area behind the vehicle while backing up is equipped.

Guiding lines indicating side and rear clearances are provided in the rear view monitor image, which

allows the driver to more easily judge distances between the vehicle and objects in the display. The possi-

ble route lines that indicate the possible route according to the steering angle are provided to help backing

up when parking.

Image quality of the rear view image and of the navigation screen can be adjusted separately.

SEL526V

Page 1236 of 5621

BODY REPAIR

BL-297

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

DESCRIPTION

All dimensions indicated in the figures are actual.

When using a tracking gauge, adjust both pointers to equal length. Then check the pointers and gauge

itself to make sure there is no free play.

When a measuring tape is used, check to be sure there is no elongation, twisting or bending.

Measurements should be taken at the center of the mounting holes.

An asterisk (*) following the value at the measuring point indicates that the measuring point on the other

side is symmetrically the same value.

The coordinates of the measurement points are the distances measured from the standard line of X, Y

and Z.

PIIA0104E

Page 1379 of 5621

![INFINITI M35 2006 Factory Service Manual CO-4

[VQ35DE]

PRECAUTIONS

Revision: 2006 January2006 M35/M45

3. Attach liquid gasket tube to the tube presser [SST: WS39930000

(—)].

Use Genuine RTV Silicone Sealant or equivalent. Refer to

INFINITI M35 2006 Factory Service Manual CO-4

[VQ35DE]

PRECAUTIONS

Revision: 2006 January2006 M35/M45

3. Attach liquid gasket tube to the tube presser [SST: WS39930000

(—)].

Use Genuine RTV Silicone Sealant or equivalent. Refer to](/img/42/57023/w960_57023-1378.png)

CO-4

[VQ35DE]

PRECAUTIONS

Revision: 2006 January2006 M35/M45

3. Attach liquid gasket tube to the tube presser [SST: WS39930000

(—)].

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-48, "

RECOMMENDED CHEMICAL PRODUCTS AND

SEALANTS" .

4. Apply liquid gasket without breaks to the specified location with

the specified dimensions.

If there is a groove for the liquid gasket application, apply liq-

uid gasket to the groove.

As for the bolt holes, normally apply liquid gasket inside the

holes. Occasionally, it should be applied outside the holes.

Make sure to read the text of service manual.

Within five minutes of liquid gasket application, install the mat-

ing component.

If liquid gasket protrudes, wipe it off immediately.

Do not retighten after mounting bolts and nuts the installation.

After 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

EMA0622D

SEM159F

Page 3065 of 5621

EM-2Revision: 2006 January2006 M35/M45 IGNITION COIL ......................................................... 42

Components ........................................................... 42

Removal and Installation ........................................ 42

REMOVAL ........................................................

... 42

INSTALLATION .................................................... 42

SPARK PLUG (PLATINUM-TIPPED TYPE) ............. 43

Components ........................................................... 43

Removal and Installation ........................................ 43

REMOVAL ........................................................

... 43

INSPECTION AFTER REMOVAL ........................ 43

INSTALLATION .................................................... 44

FUEL INJECTOR AND FUEL TUBE ........................ 45

Components ........................................................... 45

Removal and Installation ........................................ 45

REMOVAL ........................................................

... 45

INSTALLATION .................................................... 47

INSPECTION AFTER INSTALLATION ................ 50

ROCKER COVER ..................................................... 51

Components ........................................................... 51

Removal and Installation ........................................ 51

REMOVAL ........................................................

... 51

INSTALLATION .................................................... 52

FRONT TIMING CHAIN CASE ................................. 54

Removal and Installation ........................................ 54

REMOVAL ........................................................

... 54

INSTALLATION .................................................... 58

INSPECTION AFTER INSTALLATION ................ 63

TIMING CHAIN .......................................................... 64

Components ........................................................... 64

Removal and Installation ........................................ 65

REMOVAL ........................................................

... 65

INSPECTION AFTER REMOVAL ........................ 72

INSTALLATION .................................................... 72

INSPECTION AFTER INSTALLATION ................ 82

CAMSHAFT ............................................................... 84

Components ........................................................... 84

Removal and Installation ........................................ 85

REMOVAL ........................................................

... 85

INSPECTION AFTER REMOVAL ........................ 86

INSTALLATION .................................................... 89

INSPECTION AFTER INSTALLATION ................ 92

Valve Clearance ...................................................... 93

INSPECTION ....................................................... 93

ADJUSTMENT .................................................... 96

OIL SEAL ......................................................

............ 98

Removal and Installation of Valve Oil Seal ............. 98

REMOVAL ........................................................

... 98

INSTALLATION .................................................... 98

Removal and Installation of Front Oil Seal ............. 99

REMOVAL ........................................................

... 99

INSTALLATION .................................................... 99

Removal and Installation of Rear Oil Seal .............. 99

REMOVAL ........................................................

... 99

INSTALLATION ..................................................100

CYLINDER HEAD .................................................. .101

On-Vehicle Service ...............................................101

CHECKING COMPRESSION PRESSURE .......101

Components .........................................................102Removal and Installation .......................................102

REMOVAL ..........................................................102

INSPECTION AFTER REMOVAL ......................103

INSTALLATION ..................................................104

INSPECTION AFTER INSTALLATION ..............105

Disassembly and Assembly ..................................106

COMPONENTS .................................................106

DISASSEMBLY ..................................................106

ASSEMBLY ........................................................107

Inspection after Disassembly ................................108

VALVE DIMENSIONS ........................................108

VALVE GUIDE CLEARANCE ............................108

VALVE GUIDE REPLACEMENT .......................109

VALVE SEAT CONTACT ....................................110

VALVE SEAT REPLACEMENT ..........................110

VALVE SPRING SQUARENESS ....................... 111

VALVE SPRING DIMENSIONS AND VALVE

SPRING PRESSURE LOAD ..............................112

ENGINE ASSEMBLY ...............................................113

Components (2WD Models) ..................................113

Removal and Installation (2WD Models) ...............113

REMOVAL ..........................................................114

INSTALLATION ..................................................116

INSPECTION AFTER INSTALLATION ..............117

Components (AWD Models) .................................118

Removal and Installation (AWD Models) ..............118

REMOVAL ..........................................................119

INSTALLATION ..................................................121

INSPECTION AFTER INSTALLATION ..............122

CYLINDER BLOCK .................................................123

Components ..........................................................123

Disassembly and Assembly ..................................124

DISASSEMBLY ..................................................124

ASSEMBLY ......................................................

..128

How to Select Piston and Bearing ........................135

DESCRIPTION ..................................................135

HOW TO SELECT PISTON ...............................135

HOW TO SELECT CONNECTING ROD BEAR-

ING .....................................................................136

HOW TO SELECT MAIN BEARING ..................137

Inspection after Disassembly ................................140

CRANKSHAFT END PLAY ................................140

CONNECTING ROD SIDE CLEARANCE .........140

PISTON TO PISTON PIN OIL CLEARANCE .....140

PISTON RING SIDE CLEARANCE ...................141

PISTON RING END GAP ..................................141

CONNECTING ROD BEND AND TORSION .....142

CONNECTING ROD BIG END DIAMETER ......142

CONNECTING ROD BUSHING OIL CLEAR-

ANCE .................................................................142

CYLINDER BLOCK DISTORTION ....................143

MAIN BEARING HOUSING INNER DIAMETER .144

PISTON TO CYLINDER BORE CLEARANCE ..144

CRANKSHAFT MAIN JOURNAL DIAMETER ...145

CRANKSHAFT PIN JOURNAL DIAMETER ......146

CRANKSHAFT OUT-OF-ROUND AND TAPER .146

CRANKSHAFT RUNOUT ..................................146

CONNECTING ROD BEARING OIL CLEAR-

Page 3067 of 5621

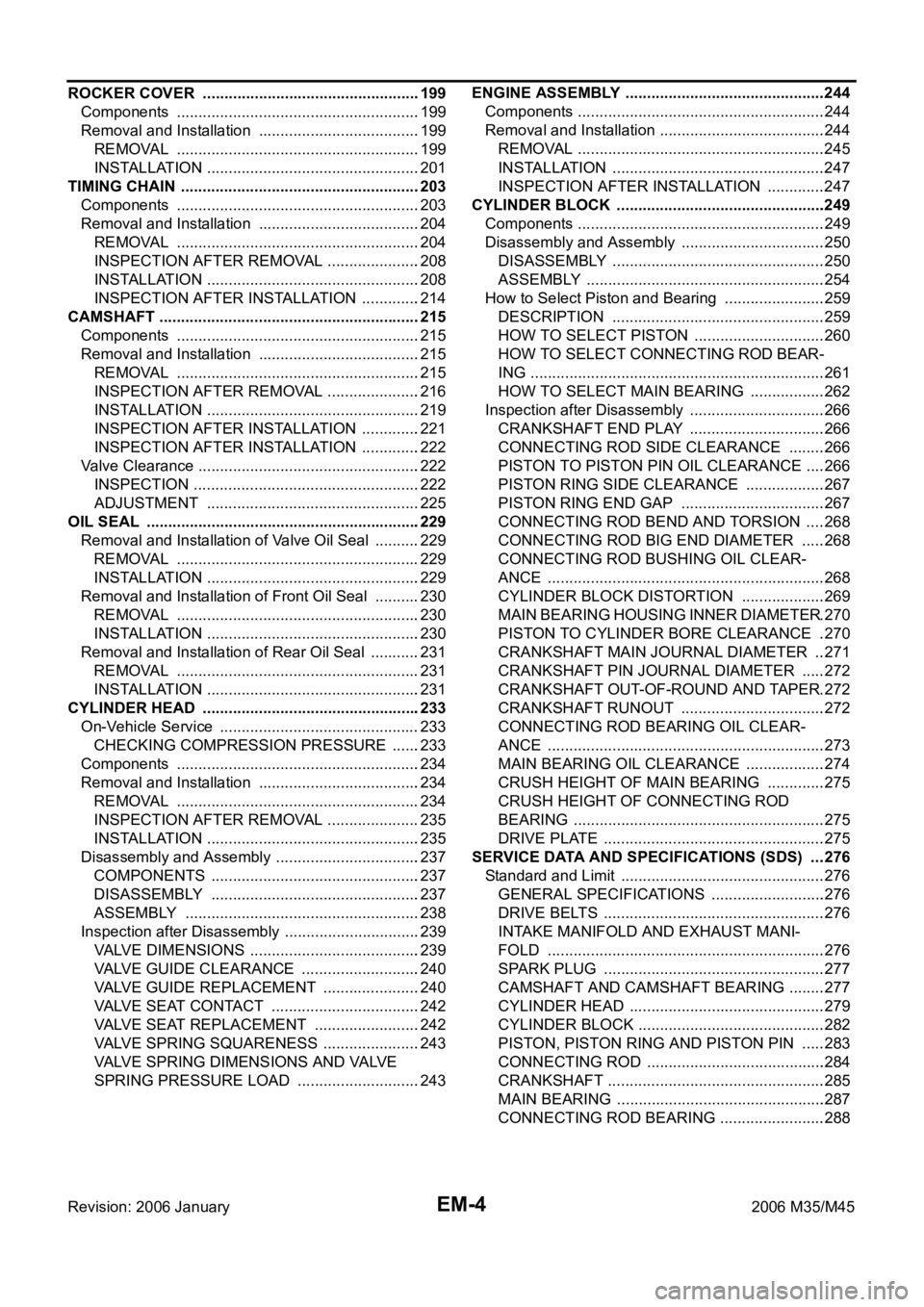

EM-4Revision: 2006 January2006 M35/M45 ROCKER COVER ...................................................199

Components .........................................................199

Removal and Installation ......................................199

REMOVAL ........................................................

.199

INSTALLATION ..................................................201

TIMING CHAIN ........................................................203

Components .........................................................203

Removal and Installation ......................................204

REMOVAL ........................................................

.204

INSPECTION AFTER REMOVAL ......................208

INSTALLATION ..................................................208

INSPECTION AFTER INSTALLATION ..............214

CAMSHAFT .............................................................215

Components .........................................................215

Removal and Installation ......................................215

REMOVAL ........................................................

.215

INSPECTION AFTER REMOVAL ......................216

INSTALLATION ..................................................219

INSPECTION AFTER INSTALLATION ..............221

INSPECTION AFTER INSTALLATION ..............222

Valve Clearance ....................................................222

INSPECTION .....................................................222

ADJUSTMENT ..................................................225

OIL SEAL ................................................................229

Removal and Installation of Valve Oil Seal ...........229

REMOVAL ........................................................

.229

INSTALLATION ..................................................229

Removal and Installation of Front Oil Seal ...........230

REMOVAL ........................................................

.230

INSTALLATION ..................................................230

Removal and Installation of Rear Oil Seal ............231

REMOVAL ........................................................

.231

INSTALLATION ..................................................231

CYLINDER HEAD .................................................. .233

On-Vehicle Service ...............................................233

CHECKING COMPRESSION PRESSURE .......233

Components .........................................................234

Removal and Installation ......................................234

REMOVAL ........................................................

.234

INSPECTION AFTER REMOVAL ......................235

INSTALLATION ..................................................235

Disassembly and Assembly ..................................237

COMPONENTS .................................................237

DISASSEMBLY .................................................237

ASSEMBLY ......................................................

.238

Inspection after Disassembly ................................239

VALVE DIMENSIONS ........................................239

VALVE GUIDE CLEARANCE ............................240

VALVE GUIDE REPLACEMENT .......................240

VALVE SEAT CONTACT ...................................242

VALVE SEAT REPLACEMENT .........................242

VALVE SPRING SQUARENESS .......................243

VALVE SPRING DIMENSIONS AND VALVE

SPRING PRESSURE LOAD .............................243ENGINE ASSEMBLY ...............................................244

Components ..........................................................244

Removal and Installation .......................................244

REMOVAL ..........................................................245

INSTALLATION ..................................................247

INSPECTION AFTER INSTALLATION ..............247

CYLINDER BLOCK .................................................249

Components ..........................................................249

Disassembly and Assembly ..................................250

DISASSEMBLY ..................................................250

ASSEMBLY ........................................................254

How to Select Piston and Bearing ........................259

DESCRIPTION ..................................................259

HOW TO SELECT PISTON ...............................260

HOW TO SELECT CONNECTING ROD BEAR-

ING .....................................................................261

HOW TO SELECT MAIN BEARING ..................262

Inspection after Disassembly ................................266

CRANKSHAFT END PLAY ................................266

CONNECTING ROD SIDE CLEARANCE .........266

PISTON TO PISTON PIN OIL CLEARANCE .....266

PISTON RING SIDE CLEARANCE ...................267

PISTON RING END GAP ..................................267

CONNECTING ROD BEND AND TORSION .....268

CONNECTING ROD BIG END DIAMETER ......268

CONNECTING ROD BUSHING OIL CLEAR-

ANCE .................................................................268

CYLINDER BLOCK DISTORTION ....................269

MAIN BEARING HOUSING INNER DIAMETER .270

PISTON TO CYLINDER BORE CLEARANCE ..270

CRANKSHAFT MAIN JOURNAL DIAMETER ...271

CRANKSHAFT PIN JOURNAL DIAMETER ......272

CRANKSHAFT OUT-OF-ROUND AND TAPER .272

CRANKSHAFT RUNOUT ..................................272

CONNECTING ROD BEARING OIL CLEAR-

ANCE .................................................................273

MAIN BEARING OIL CLEARANCE ...................274

CRUSH HEIGHT OF MAIN BEARING ..............275

CRUSH HEIGHT OF CONNECTING ROD

BEARING ...........................................................275

DRIVE PLATE ....................................................275

SERVICE DATA AND SPECIFICATIONS (SDS) ....276

Standard and Limit ................................................276

GENERAL SPECIFICATIONS ...........................276

DRIVE BELTS ....................................................276

INTAKE MANIFOLD AND EXHAUST MANI-

FOLD .................................................................276

SPARK PLUG ....................................................277

CAMSHAFT AND CAMSHAFT BEARING .........277

CYLINDER HEAD ..............................................279

CYLINDER BLOCK ............................................282

PISTON, PISTON RING AND PISTON PIN ......283

CONNECTING ROD ..........................................284

CRANKSHAFT ...................................................285

MAIN BEARING .................................................287

CONNECTING ROD BEARING .........................288

Page 3070 of 5621

![INFINITI M35 2006 Factory Service Manual PRECAUTIONS

EM-7

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove old liquid gasket adhering to the liquid

gask INFINITI M35 2006 Factory Service Manual PRECAUTIONS

EM-7

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove old liquid gasket adhering to the liquid

gask](/img/42/57023/w960_57023-3069.png)

PRECAUTIONS

EM-7

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove old liquid gasket adhering to the liquid

gasket application surface and the mating surface.

Remove liquid gasket completely from the groove of the liquid

gasket application surface, mounting bolts, and bolt holes.

2. Wipe the liquid gasket application surface and the mating sur-

face with white gasoline (lighting and heating use) to remove

adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to the tube presser [SST: WS39930000

(—)].

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-48, "

RECOMMENDED CHEMICAL PRODUCTS AND

SEALANTS" .

4. Apply liquid gasket without breaks to the specified location with

the specified dimensions.

If there is a groove for liquid gasket application, apply liquid

gasket to the groove.

As for bolt holes, normally apply liquid gasket inside the

holes. Occasionally, it should be applied outside the holes.

Make sure to read the text of this manual.

Within five minutes of liquid gasket application, install the mat-

ing component.

If liquid gasket protrudes, wipe it off immediately.

Do not retighten mounting bolts or nuts after the installation.

After 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe

them.

PBIC0003E

EMA0622D

SEM159F

Page 3074 of 5621

![INFINITI M35 2006 Factory Service Manual PREPARATION

EM-11

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

(—)

Valve seat cutter setFinishing valve seat dimensions

(—)

Piston ring expanderRemoving and installing pis INFINITI M35 2006 Factory Service Manual PREPARATION

EM-11

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

(—)

Valve seat cutter setFinishing valve seat dimensions

(—)

Piston ring expanderRemoving and installing pis](/img/42/57023/w960_57023-3073.png)

PREPARATION

EM-11

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

(—)

Valve seat cutter setFinishing valve seat dimensions

(—)

Piston ring expanderRemoving and installing piston ring

(—)

Valve guide driftRemoving and installing valve guide

Intake and Exhaust:

a: 9.5 mm (0.374 in) dia.

b: 5.5 mm (0.217 in) dia.

(—)

Valve guide reamer(1): Reaming valve guide inner hole

(2): Reaming hole for oversize valve guide

Intake and Exhaust:

d

1 : 6.0 mm (0.236 in) dia.

d

2 : 10.2 mm (0.402 in) dia.

(J-43897-18)

(J-43897-12)

Oxygen sensor thread cleanerReconditioning the exhaust system threads

before installing a new air fuel ratio sensor

and heated oxygen sensor (Use with anti-

seize lubricant shown below.)

a: J-43897-18 [18 mm (0.71 in) dia.] for

z ir c on i a h e a t e d o x y g e n s e ns o r a n d a i r f u e l

ratio sensor

b: J-43897-12 [12 mm (0.47 in) dia.] for

titania heated oxygen sensor and air fuel

ratio sensor

(—)

Anti-seize lubricant (Permatex 133AR

or equivalent meeting MIL

specification MIL-A-907)Lubricating oxygen sensor thread cleaning

tool when reconditioning exhaust system

threads (Kent-Moore No.)

To o l n a m eDescription

NT048

NT030

NT015

NT016

AEM488

AEM489