ECU INFINITI Q70 HYBRID 2015 Roadside Assistance Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2015, Model line: Q70 HYBRID, Model: INFINITI Q70 HYBRID 2015Pages: 35, PDF Size: 3.86 MB

Page 26 of 35

4-3.3 Use of Vehicle Equipped Hooks for Recovery Operations

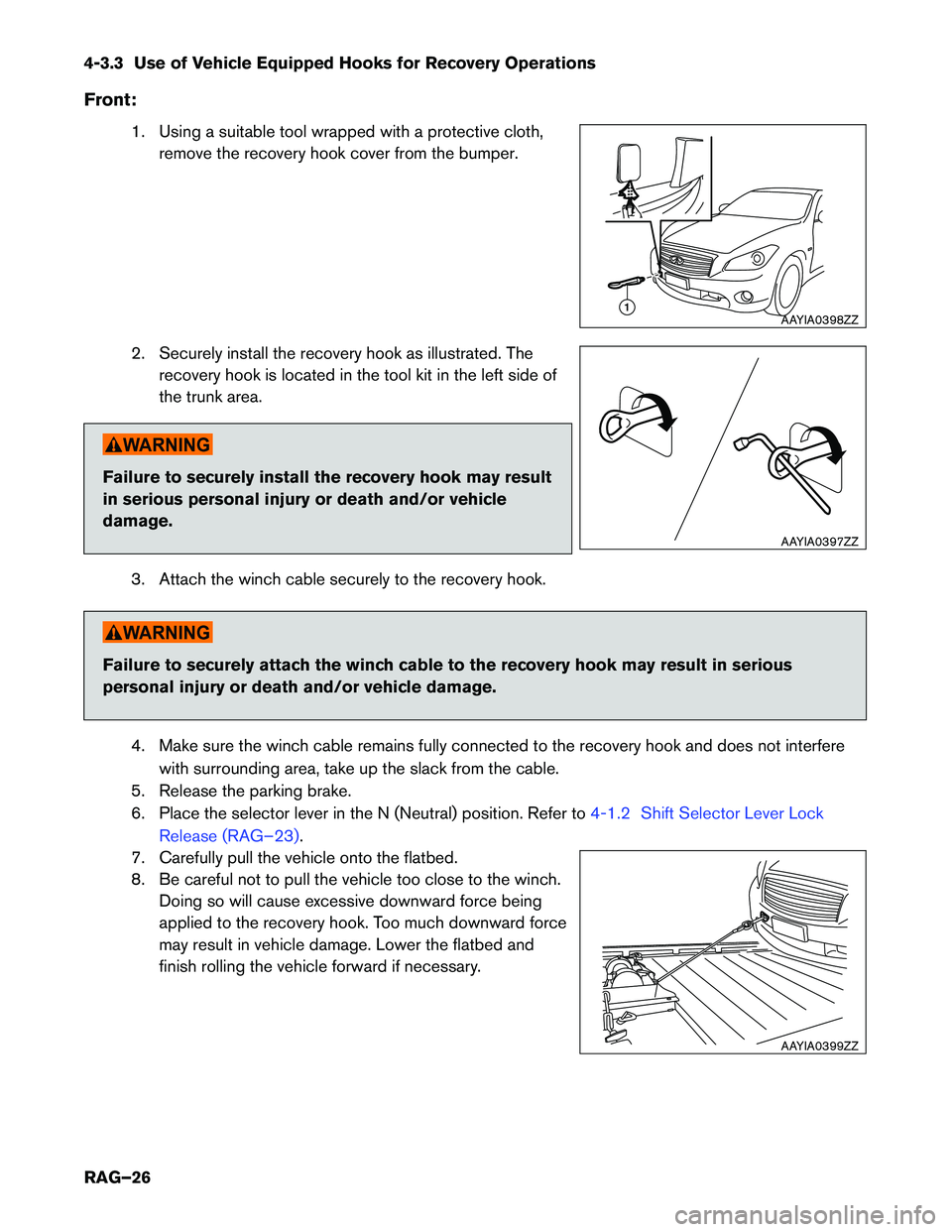

Front:1. Using a suitable tool wrapped with a protective cloth,remove the recovery hook cover from the bumper.

2. Securely install the recovery hook as illustrated. The recovery hook is located in the tool kit in the left side of

the trunk area.

Failure to securely install the recovery hook may result

in serious personal injury or death and/or vehicledamage.

3. Attach the winch cable securely to the recovery hook.

Failure to securely attach the winch cable to the recovery hook may result in serious

personal injury or death and/or vehicle damage.

4. Make sure the winch cable remains fully connected to the recovery hook and does not interferewith surrounding area, take up the slack from the cable.

5. Release the parking brake.

6. Place the selector lever in the N (Neutral) position. Refer to

4-1.2 Shift Selector Lever Lock

Release (RAG–23)

.

7. Carefully pull the vehicle onto the flatbed.

8. Be careful not to pull the vehicle too close to the winch. Doing so will cause excessive downward force being

applied to the recovery hook. Too much downward force

may result in vehicle damage. Lower the flatbed and

finish rolling the vehicle forward if necessary.

1AAYIA0398ZZ

AAYIA0397ZZ

AAYIA0399ZZ

RAG–26

Page 27 of 35

9. Secure the vehicle to the flatbed by using wheel basketsat all 4 wheel positions.

10. Make sure that the vehicle recovery hook is properly secured in its original position after use and the recovery

hook cover has been reinstalled properly.

NOTE:

To help prevent squeaks and rattles, check that

the tools are reinstalled and properly secured

in the stored place after use.

Rear Tie Down Hook: • Do not use the rear tie down hook for towing or vehiclerecovery.

• The rear tie down hook is designed for use as illustrated.

AAYIA0396ZZ

AAYIA0400ZZ

AAYIA0357ZZ

RAG–27

Page 28 of 35

4-4 Jacking Up the Vehicle and Changing a Tire

Always follow these instructions when jacking up the vehicle and changing a tire:

• Never change a tire when the vehicle is on a slope, ice or slippery areas. Jack must be onlevel ground.

• Make sure the parking brake is securely applied and shift selector is in P (Park) position.

• Never get under the vehicle while it is supported only by the jack. If it is necessary to work under the vehicle, support it with safety stands.

• Use the correct jack-up points. Never use any other part of the vehicle for jack support.

• Never jack up the vehicle more than necessary.

• Never use blocks on or under the jack.

• Do not start or run the engine while vehicle is on the jack. It may cause the vehicle to move. This is especially true for vehicles with limited slip differentials.

• Do not allow passengers to stay in the vehicle while it is on the jack.

• Never run the engine with a wheel(s) off the ground. It may cause the vehicle to move.

• Be sure to block the wheel diagonally opposite the wheel being removed as the vehicle may move and result in personal injury.

Failure to follow these instructions can result in serious personal injury or death and/or

vehicle damage.

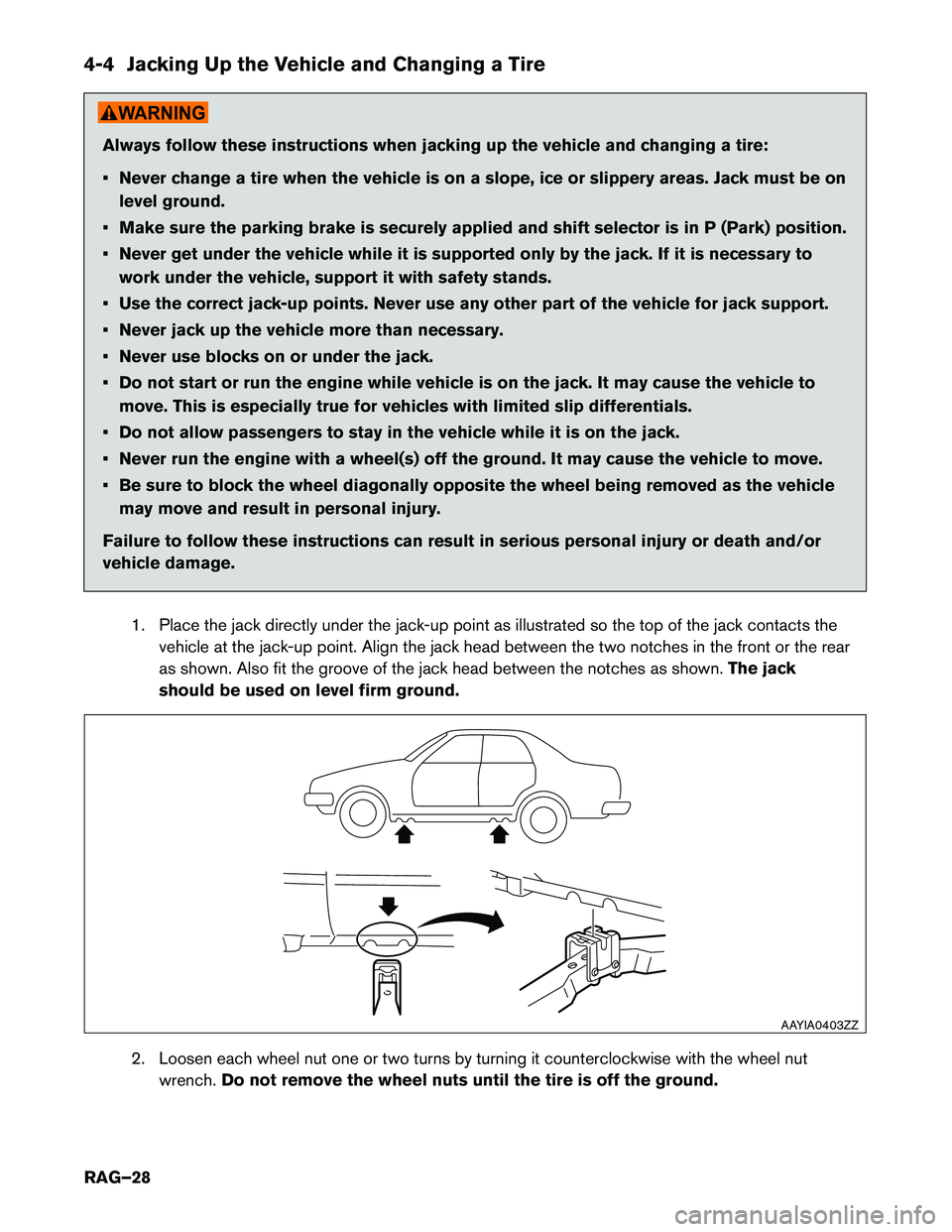

1. Place the jack directly under the jack-up point as illustrated so the top of the jack contacts thevehicle at the jack-up point. Align the jack head between the two notches in the front or the rear

as shown. Also fit the groove of the jack head between the notches as shown. The jack

should be used on level firm ground.

2. Loosen each wheel nut one or two turns by turning it counterclockwise with the wheel nut wrench. Do not remove the wheel nuts until the tire is off the ground.

AAYIA0403ZZ

RAG–28

Page 29 of 35

3. To lift the vehicle, securely hold the jack lever and rod with both hands as shown. Carefully raisethe vehicle until the tire clears the ground. Remove the wheel nuts, and then remove the tire.

4. Install new or repaired tire and hand-tighten the wheel nuts with the wheel nut wrench in an alternating pattern.

Always follow these instructions when changing a tire:

• Incorrect wheel nuts or improperly tightened wheel

nuts can cause the wheel to become loose or come

off. This could cause an accident.

• Do not use oil or grease on the wheel studs or nuts. This could cause the nuts to become loose.

Failure to follow these instructions can result in serious

personal injury or death and/or vehicle damage.

5. Securely torque the wheel nuts in an alternating patternto 80 ft-lb (108 Nm) .

6. Lower the vehicle and remove the jack and securely store the flat tire, tools and jacking equipment in thevehicle.

Always follow these instructions when using the jacking equipment or after changing a tire:

• Always make sure that the spare tire and jacking equipment are properly secured after

use. Such items can become dangerous projectiles in an accident or sudden stop.

Failure to follow these instructions can result in serious personal injury or death and/or

vehicle damage.

NOTE:

To help prevent squeaks and rattles, check that the tools are reinstalled and properly secured

in the stored place after use.

AAYIA0136ZZ

BE

CD

A

AAYIA0137ZZ

RAG–29

Page 32 of 35

5-2 Remove Service Plug

DANGER

•Do not remove the service plug without always wearing appropriate Personal

Protective Equipment (PPE) to help protect the responder from serious injury or death

by electrical shock.

•

Immediately cover the service plug socket with insulated tape. The high voltage

battery retains high voltage power even when the service plug is removed. To avoid

electric shock, NEVER touch the terminals inside the socket.

To avoid unintended reinstallation and risk of electrical shock and severe personal injury

or death, the service plug should be securely stored away from the vehicle while the vehicle

is in storage.

NOTE: Before disconnecting the 12-volt battery terminal, if necessary, lower the windows, adjust

the steering column, adjust the seats, unlock the doors, etc. Once 12-volt battery is

disconnected, power controls will not operate.

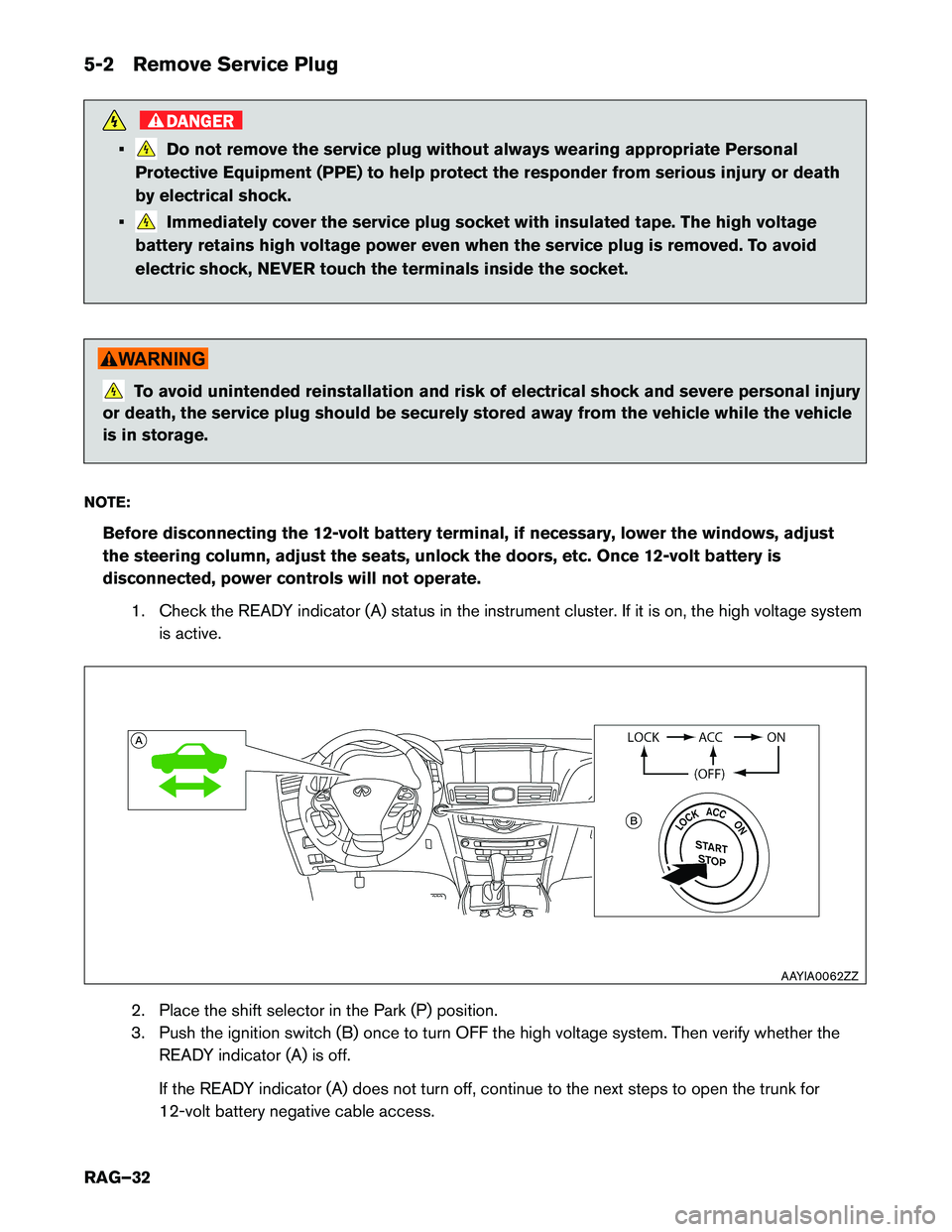

1. Check the READY indicator (A) status in the instrument cluster. If it is on, the high voltage systemis active.

2. Place the shift selector in the Park (P) position.

3. Push the ignition switch (B) once to turn OFF the high voltage system. Then verify whether the READY indicator (A) is off.

If the READY indicator (A) does not turn off, continue to the next steps to open the trunk for

12-volt battery negative cable access.

AAYIA0062ZZ

RAG–32